Double-H-shaped concrete rail beam of rubber-tyred tram and construction method thereof

A technology for trams and construction methods, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of low rigidity of steel guide rail beams, poor driving comfort, and poor construction convenience, and achieve high overall rigidity, small post-maintenance Comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

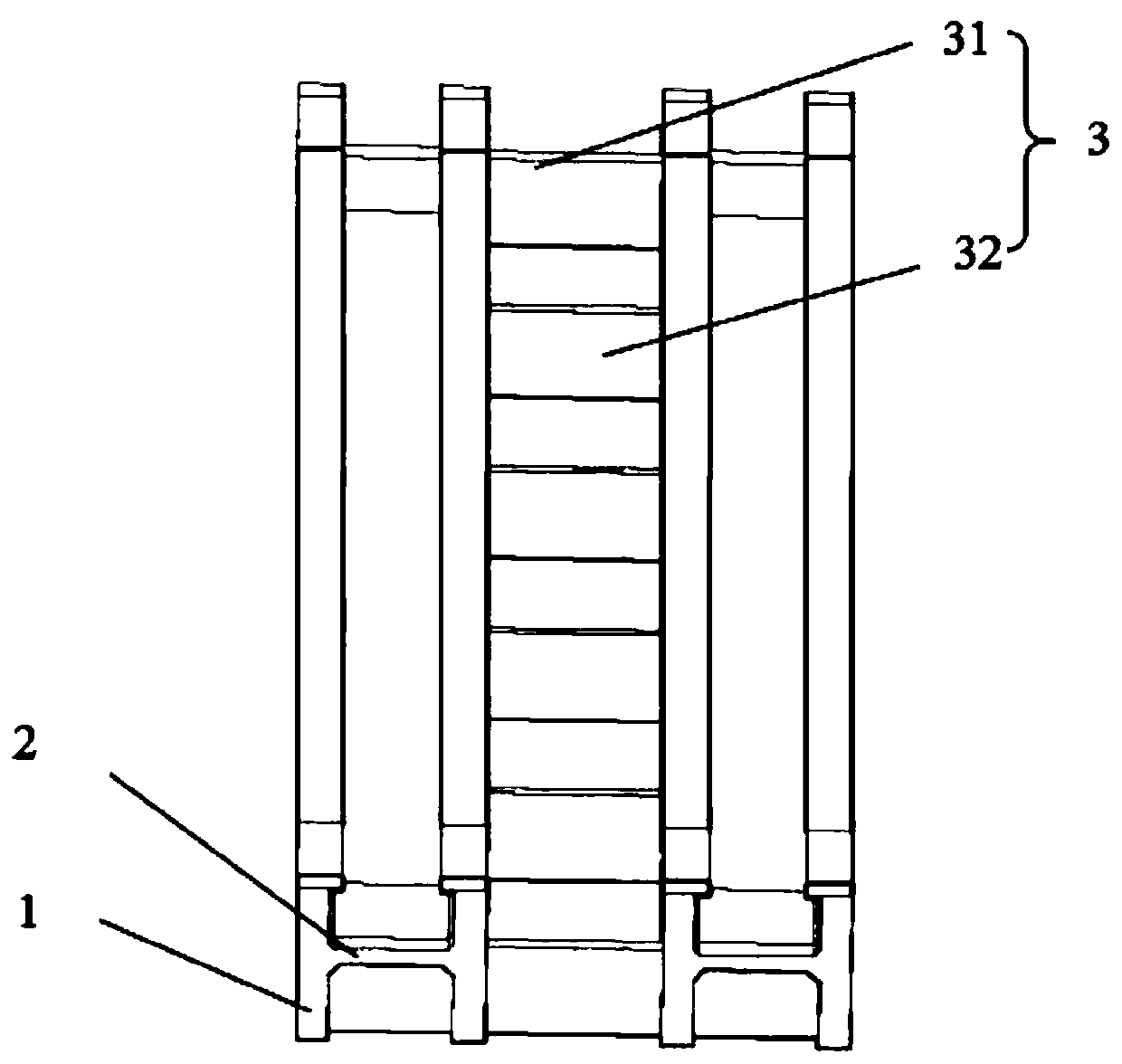

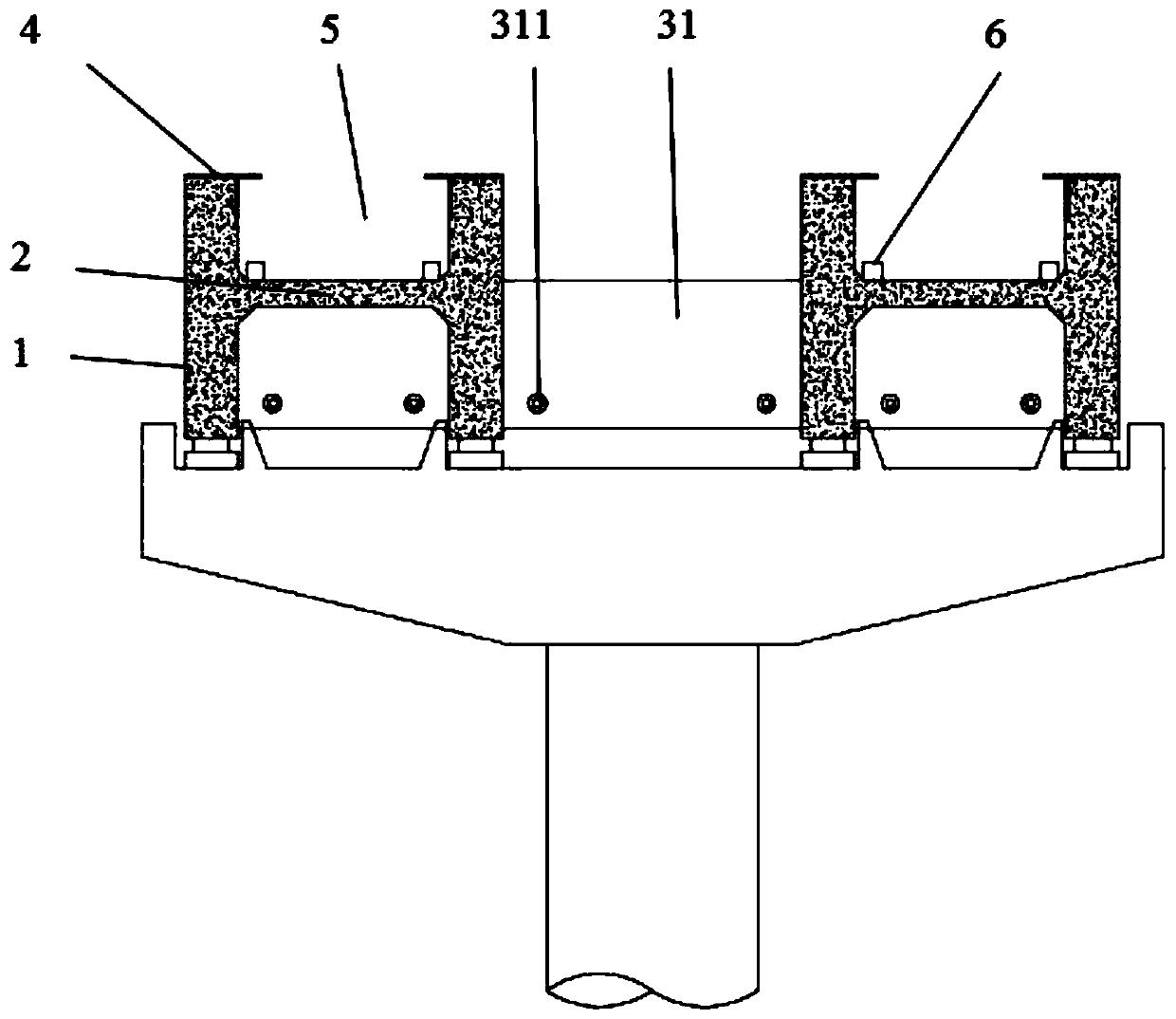

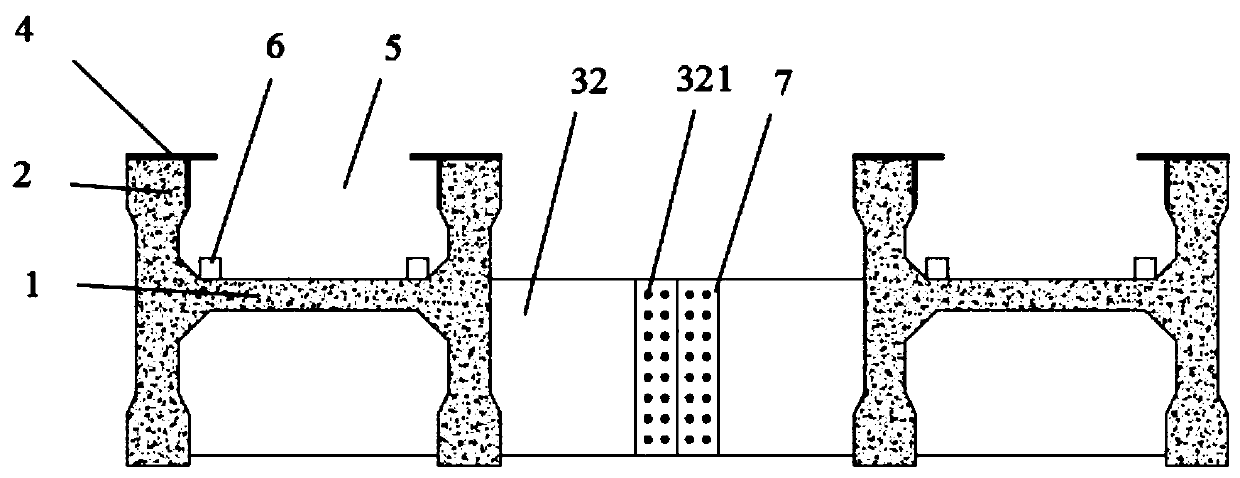

[0036] refer to figure 1 Shown is a double H-shaped concrete track beam for a rubber-tyred tram, which is set on a bridge pier and includes several guide rail beam spans, and two adjacent guide rail beam spans are linked and connected;

[0037] The guide rail beam span section includes 4 webs 1, 2 bottom plates 2 and a diaphragm 3; 4 webs 1 and 2 bottom plates 2 are combined to form a double "H" structure, and then connected by a diaphragm 3 to form a Integral structure; each web 1 is set as an "I"-shaped structure in cross section, and the top of each web and one side of the top are equipped with embedded wear-resistant steel plates 4; and the bottom plate 2 is set on its top surface The position below 60 cm from the top surface of the web 1 forms an open slot structure 5 with two adjacent webs 1 ; the bottom of both sides of the open slot structure 5 is provided with cable passages 6 .

[0038] The diaphragm 3 is located below the bottom plate 2 , and the diaphragm 3 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com