Formula for producing polyvinyl chloride double-wall corrugated pipe

A technology of double-wall corrugated pipe and polyvinyl chloride, applied in pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as lead stabilizer pollution, achieve cost reduction, excellent weather resistance, and good light aging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

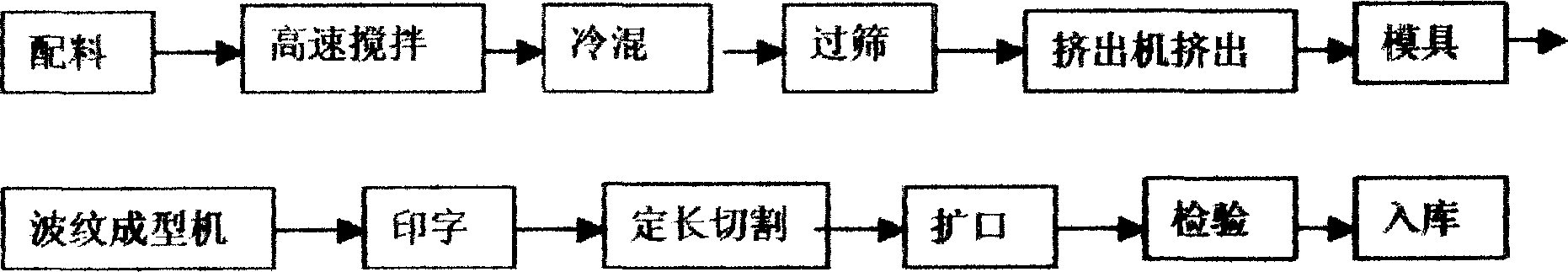

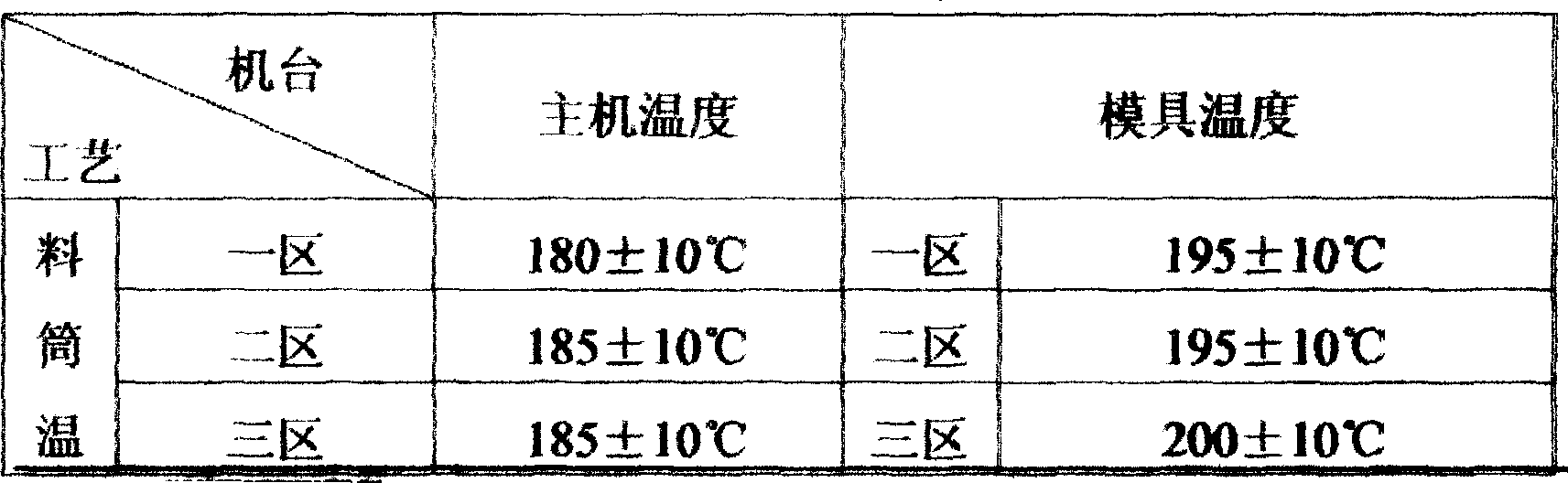

Method used

Image

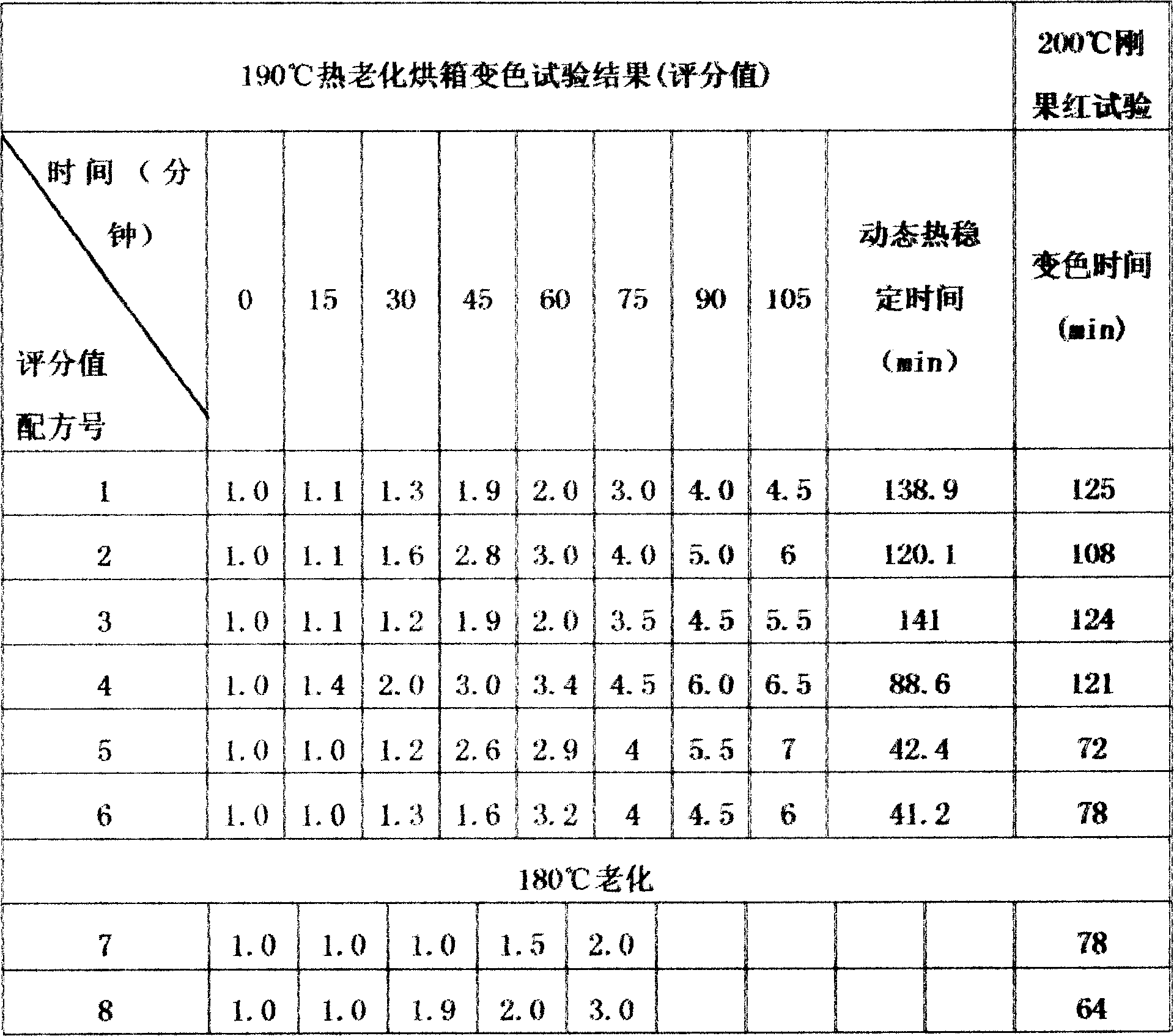

Examples

Embodiment Construction

[0015] PVC double-wall corrugated pipe is made of rigid polyvinyl chloride resin as the main raw material. According to the material characteristics of rigid polyvinyl chloride resin-poor impact toughness and the use characteristics of large-diameter buried drainage pipes, it is considered to add Toughened calcium carbonate particles not only improve the toughness of the product, but also improve the ring stiffness of the pipe.

[0016] According to the special performance requirements of the buried drainage pipeline, the ring stiffness performance of the pipe is its key technical indicator. After various comparisons and tests, choose SLK-1000 or SLP-1000 or rigid polyvinyl chloride with similar indicators Resin is used as raw material for production.

[0017]

name

SLK-1000

SLP-1000

Superior product

Superior product

Average degree of polymerization P

1030±50

1030±50

The number of impurity particles, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com