Belt conveyor roller frame vertical beam drilling device and method

A belt conveyor and processing device technology, applied in positioning devices, metal processing, boring/drilling, etc., can solve the problems of poor position and size of longitudinal beam holes, belt deviation, time-consuming and labor-intensive problems, and achieve safety Reliable maintenance, easy maintenance and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

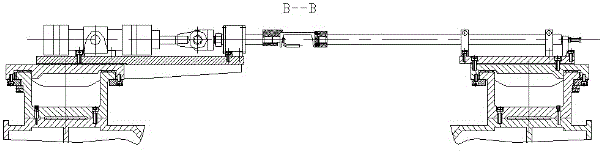

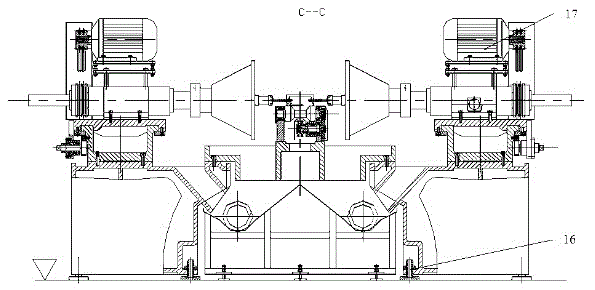

Image

Examples

Embodiment Construction

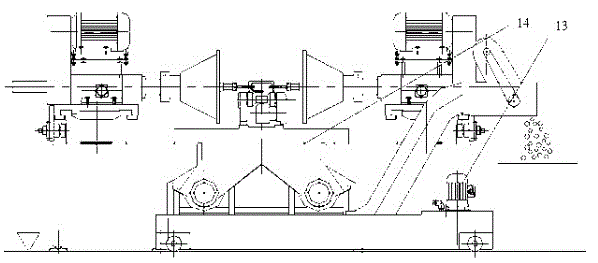

[0030] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0031] The feeding part 19 is mainly composed of a support, a raw material storage rack, a feeding conveying device and a feeding device.

[0032] bracket

[0033] The bracket is welded by steel structure, artificial aging treatment after welding, it is the basic part of the whole feeding part.

[0034] raw material storage rack

[0035] The raw material storage rack is used for the storage of the "roller rack longitudinal beam" before processing. The lower raw material is pushed away and the upper raw material automatically slides down. The storage rack forms an angle of 60° with the horizontal plane, and the designed storage quantity is 10 pieces.

[0036] Feeding conveyor

[0037] The feeding conveying device is composed of motor, chain transmission pair, feeding guide rail and so on. The chain of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com