Rear supporting structure of cab

A support structure and rear support technology, which is applied to the upper structure, the upper structure of trucks, transportation and packaging, etc., can solve the interference of ship-shaped brackets, poor low-frequency and high-frequency vibration vibration isolation, and easy to be affected by the outside of the frame. The impact of tension and other issues can solve the problem of shock absorption and noise reduction, good damping limits low-frequency large-scale vibration, and eliminates the effect of dynamic hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments thereof. However, the protection orientation of the present invention is not limited to the following examples, and should include all content in the claims.

[0033] All of the following drawings are only convenient for explaining the basic teaching of the present invention, and the number, position, relationship, and size extension of the components that constitute the preferred embodiment will be described in the accompanying drawings. After reading and understanding the teaching of the present invention The associated change implementation is within the skill of the industry. In addition, modification of precise dimensions and dimensional ratios to meet specific strength, weight, strength, and similar requirements is within the skill of the art upon reading and understanding the teachings of this invention.

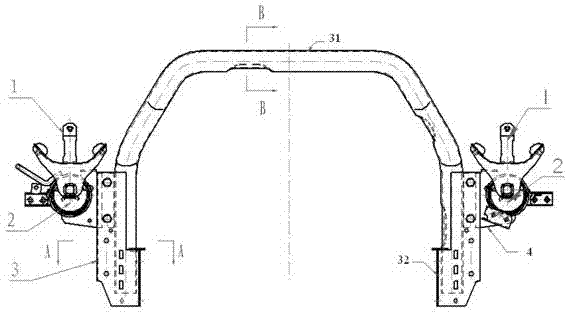

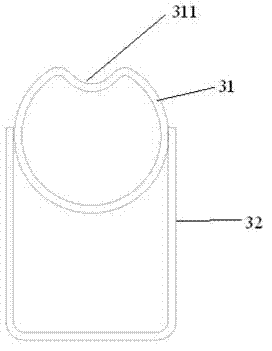

[0034] Such as figure 1 , 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com