Fixing structure for exhaust pipes

A fixed structure and exhaust pipe technology, which is applied in the direction of power unit gas intake, power unit, transportation and packaging, etc., can solve the problems of high risk of rust, easy cracking of solder joints, high cost, etc., to avoid resonance and vibration , Guarantee anti-rust performance, improve the effect of dynamic stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

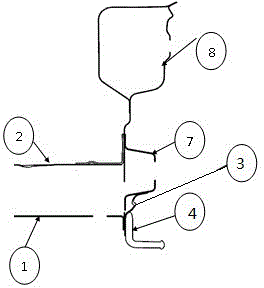

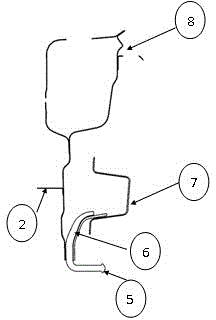

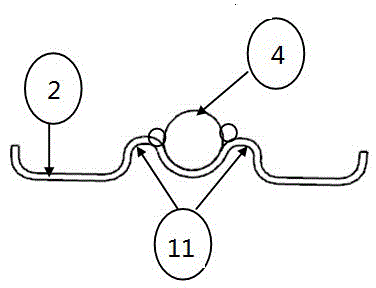

[0028] Figure 3 to Figure 12 The reference numerals in are: rear longitudinal beam 1; rear floor 2; first exhaust pipe installation bracket 3; first exhaust pipe installation hook 4; second exhaust pipe installation hook 5; second exhaust pipe Mounting bracket 6 ; rear anti-collision beam 7 ; rear end plate 8 ; second-layer plate welding spot 9 ; third-layer plate welding spot 10 ; first reinforcing rib 11 ; second reinforcing rib 12 .

[0029] Such as Figure 3 to Figure 12 As shown, an exhaust pipe fixing structure includes a rear longitudinal beam 1, a rear floor 2, a first exhaust pipe installation bracket 3, a first exhaust pipe installation hook 4, a second exhaust pipe installation hook 5, The second exhaust pipe mounting bracket 6 and the rear anti-collision beam 7, wherein the rear anti-collision beam 7 is respectively connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com