Double-arm robot cooperative vibration reduction method for grinding large thin-walled workpiece

A large-scale thin-walled part and robot technology, which is applied to machine tools suitable for grinding workpiece planes, grinding workpiece supports, grinding machine parts, etc., can solve the problems of reducing grinding thin-walled parts and large vibration amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

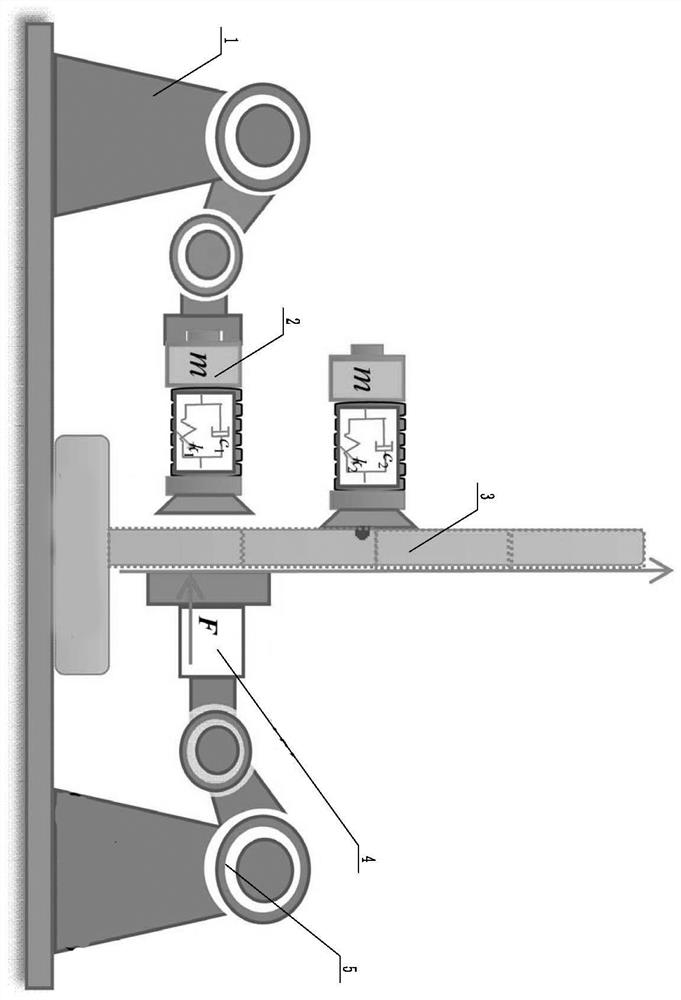

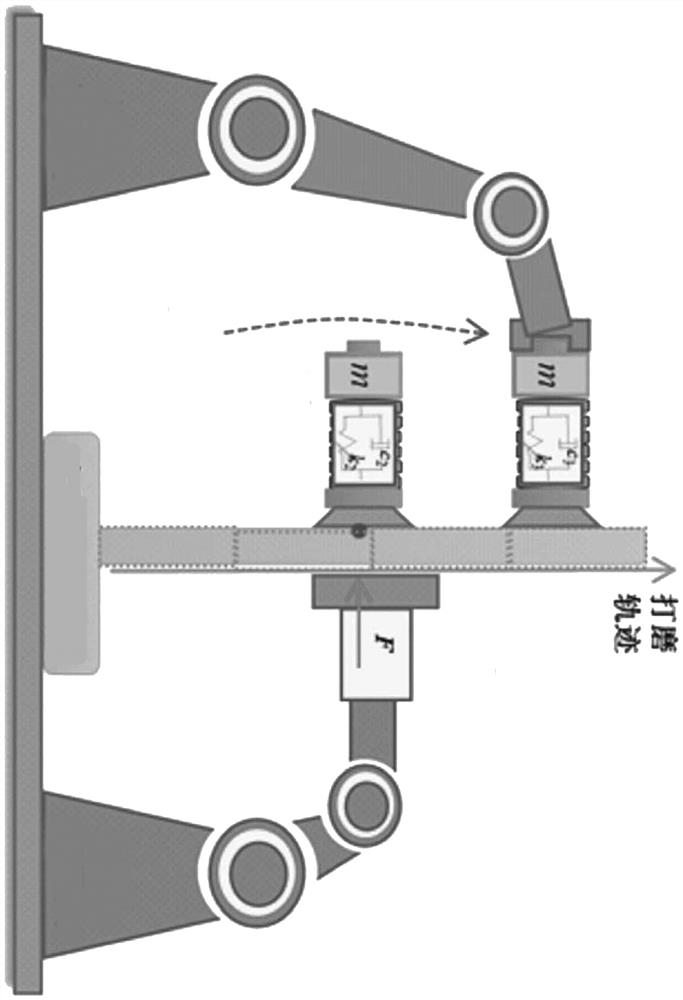

[0035] Such as Figure 1-8 Shown is a dual-arm robot cooperative vibration reduction method for grinding large thin-walled parts. The grinding and vibration reduction device used for vibration reduction includes a handling robot 1 and a grinding robot 5. The handling end of the handling robot 1 is connected with a vibration-absorbing 2, the grinding end of the grinding robot 5 is connected with a powerful control end effector 4, and the force control end effector 4 grinds one end of the thin-walled part 3 in the left-right direction, and the vibration absorber 2 acts on the other end of the thin-walled part 3 in the left-right direction. one end, including the following steps,

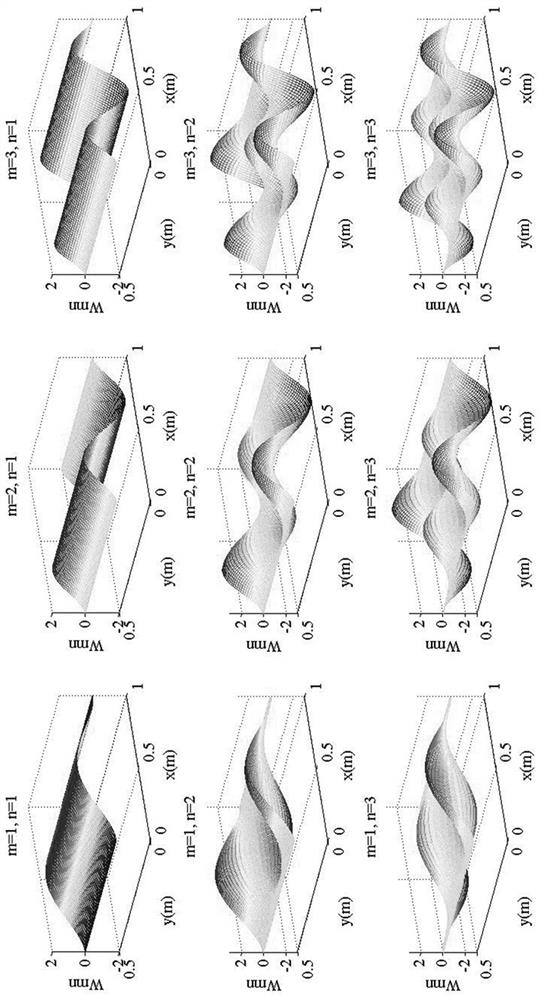

[0036] (1) Analyze and establish the steady-state response model of the forced vibration of the thin-walled part 3;

[0037] (2) Carry out a modal test on the thin-walled part 3 with two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com