Patents

Literature

64 results about "Bush rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valve bush rubber and its preparation method

InactiveCN1733831AImprove thermal stabilityExcellent resistance to sulfur reductionValve housingsPolymer scienceWater vapor

The rubber for valve bushing with well anti-abrasive, chemical-resisting, thermostable and waterproof property comprises constituents as: 60 / 40 EPT, activated zinc oxide, organic activated agent stearic acid 0, quinoline polymer, HAF, and sulfur. After milling, inject the material with rubber syringe on piston pressure (2.5-3.0)kg / cm2 and temperature of 40-50Deg into directly on the surface of the objective valve part in mould; vulcanizing and covering the rubber layer. The product can be used on pipes for steam and acid / alkali medium more than one year.

Owner:天津凯发阀门有限公司

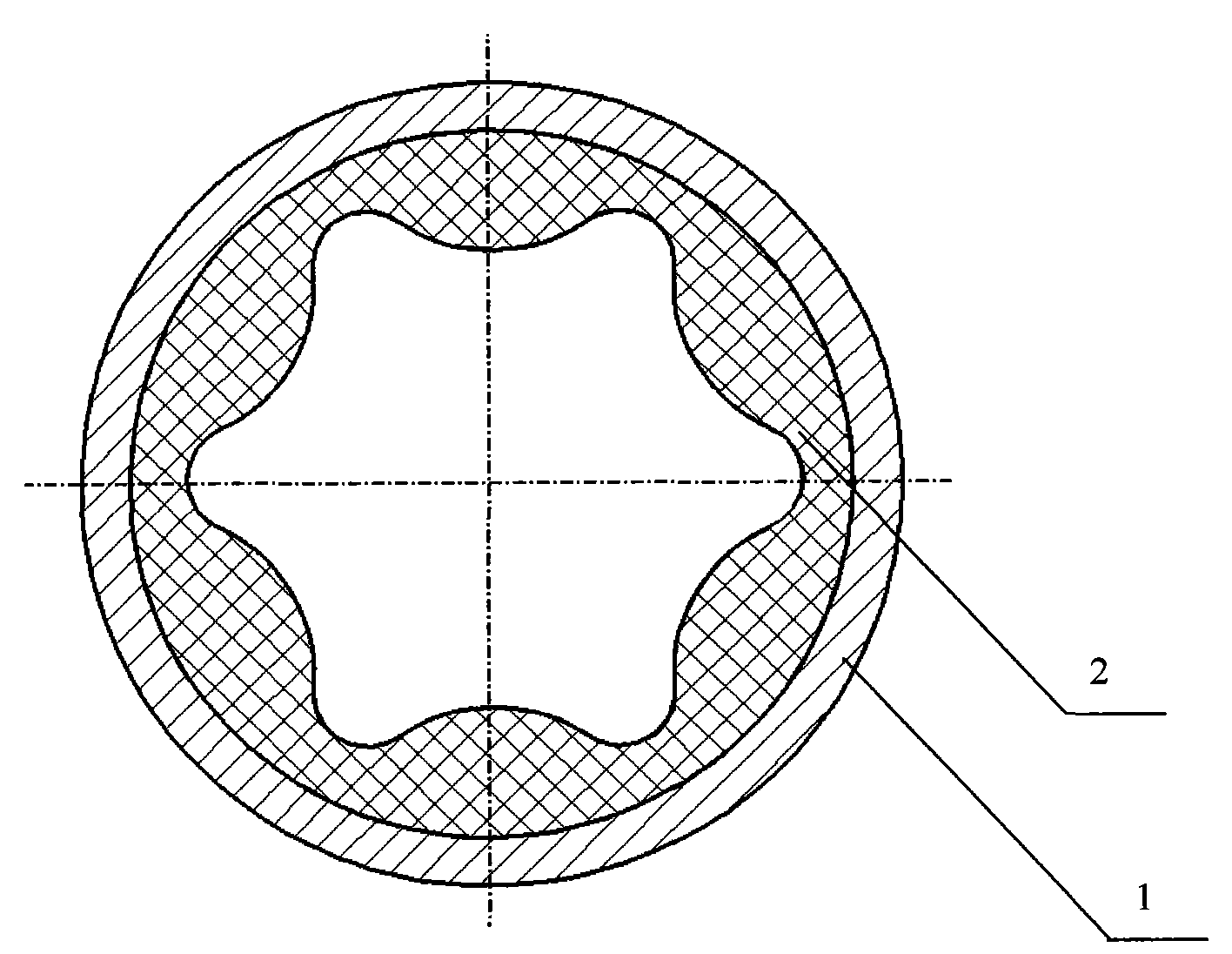

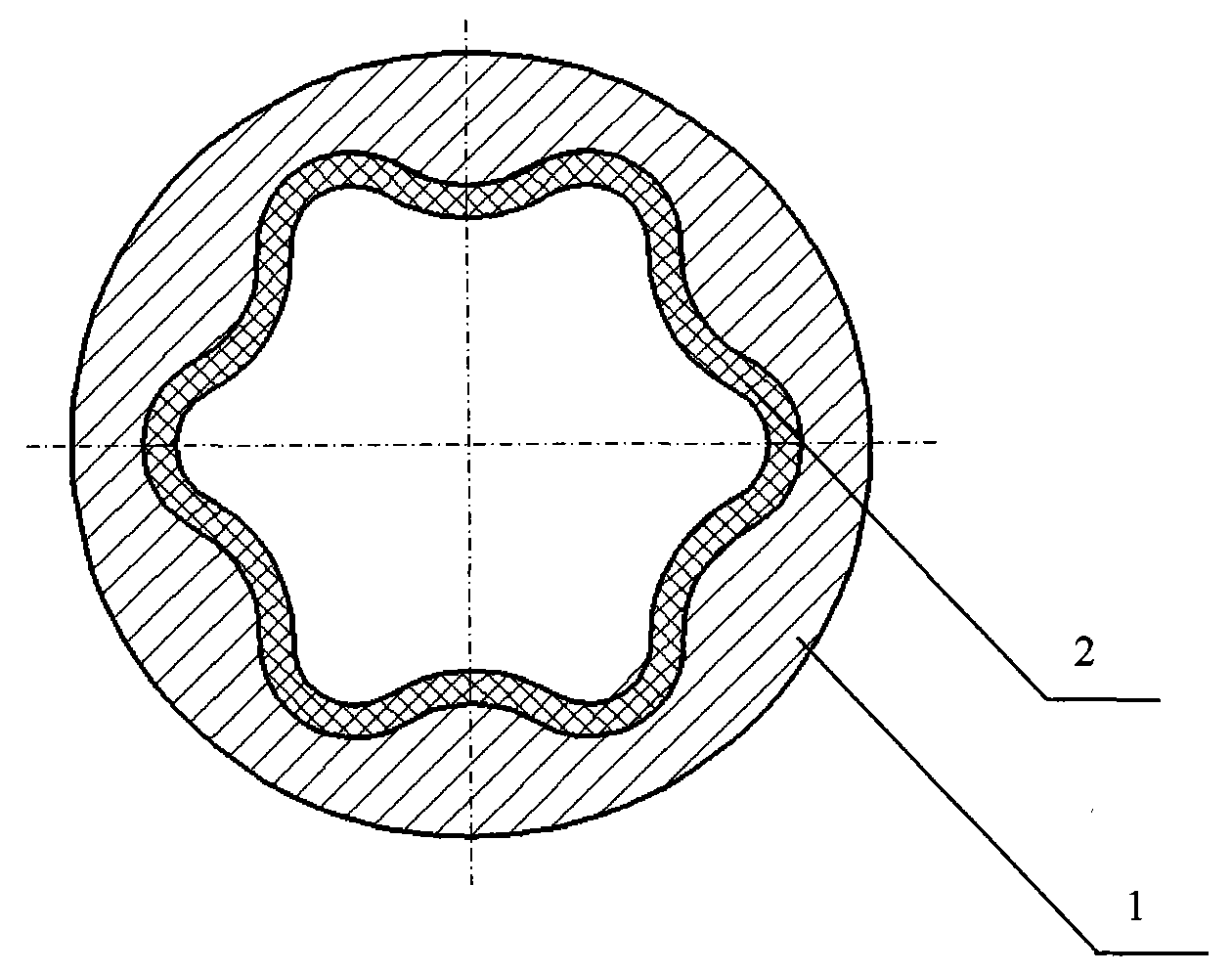

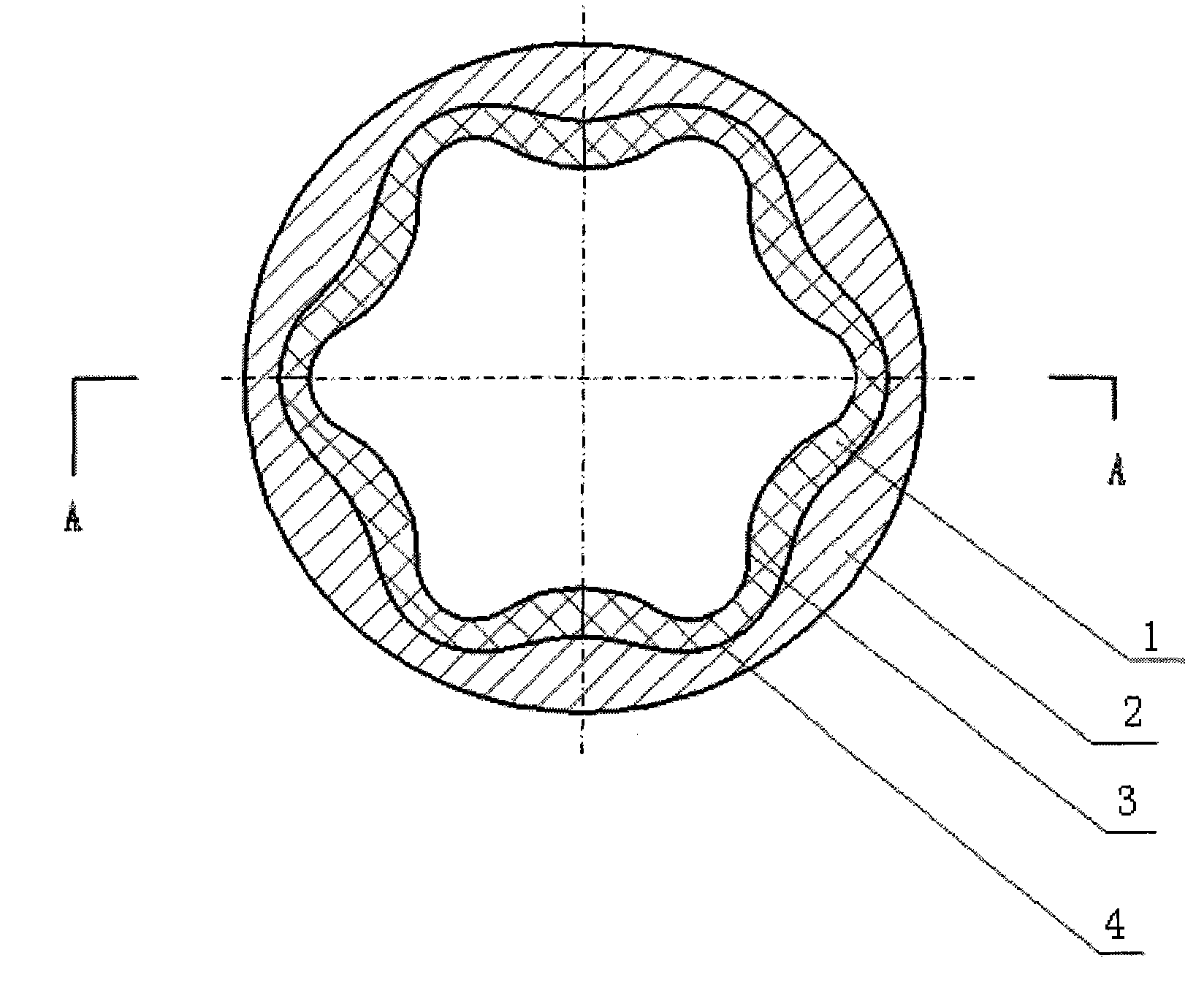

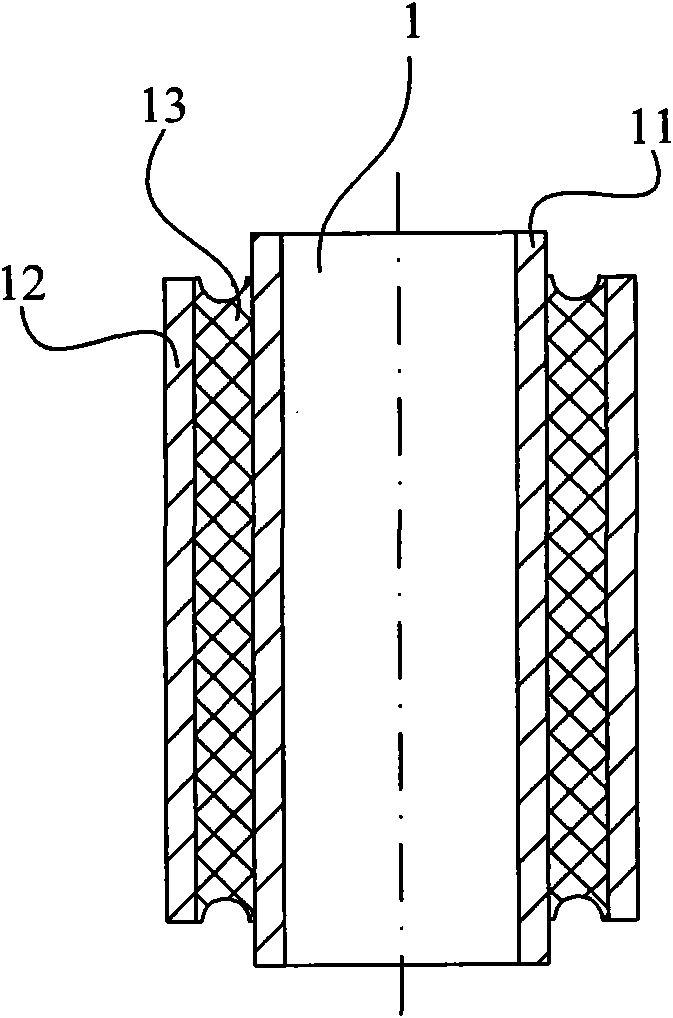

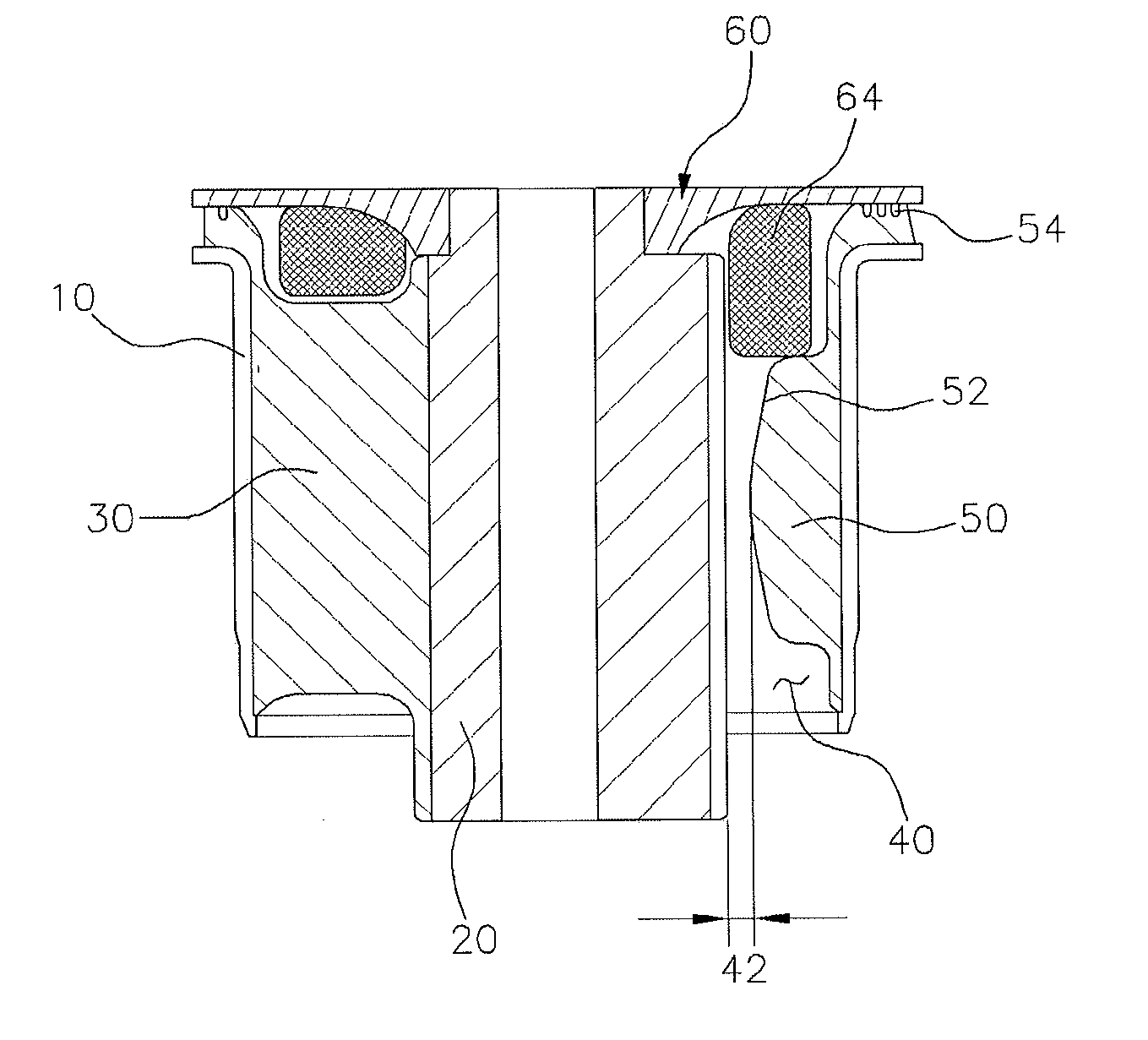

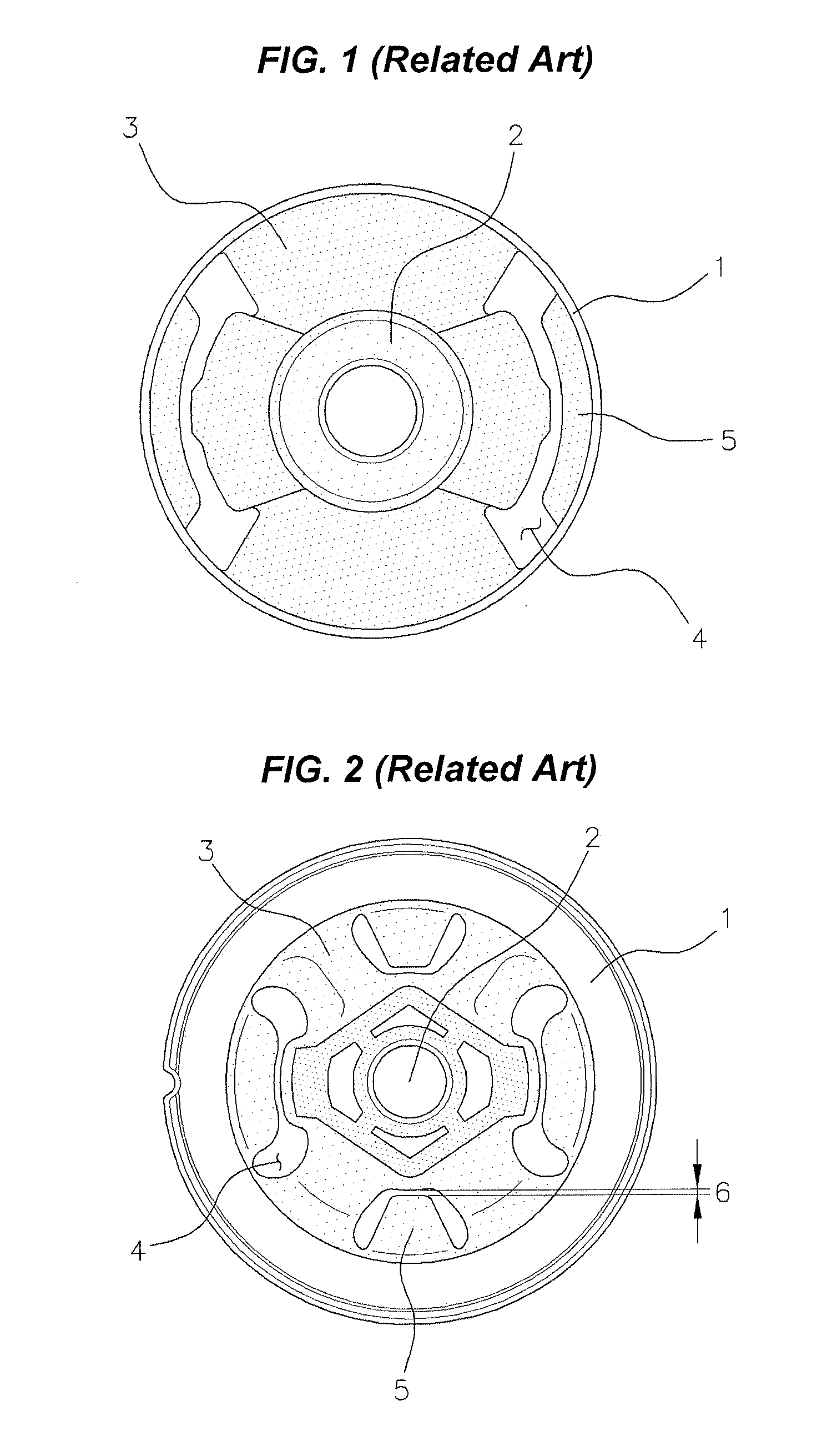

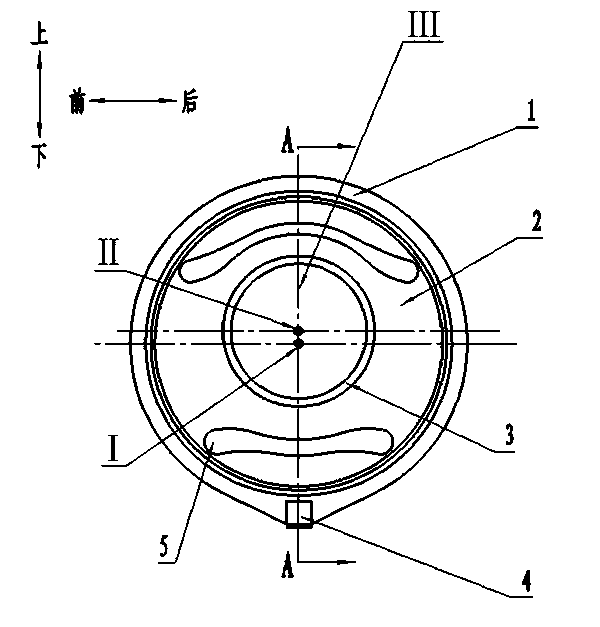

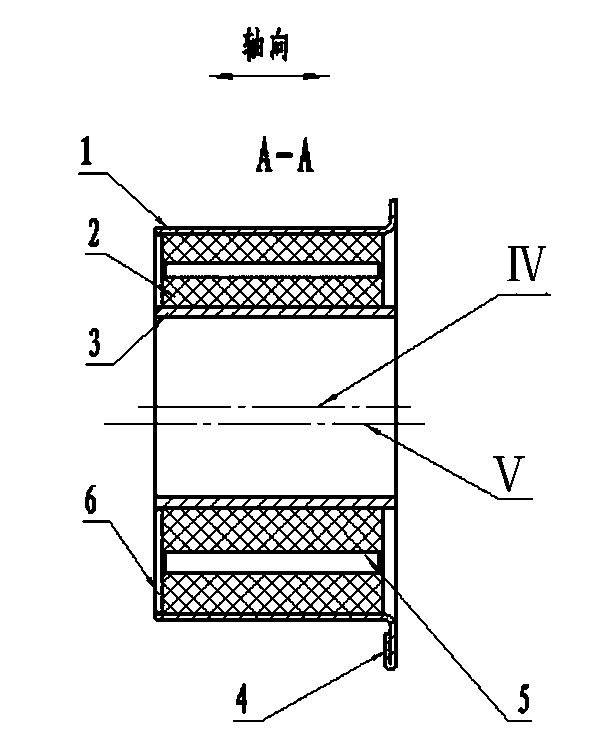

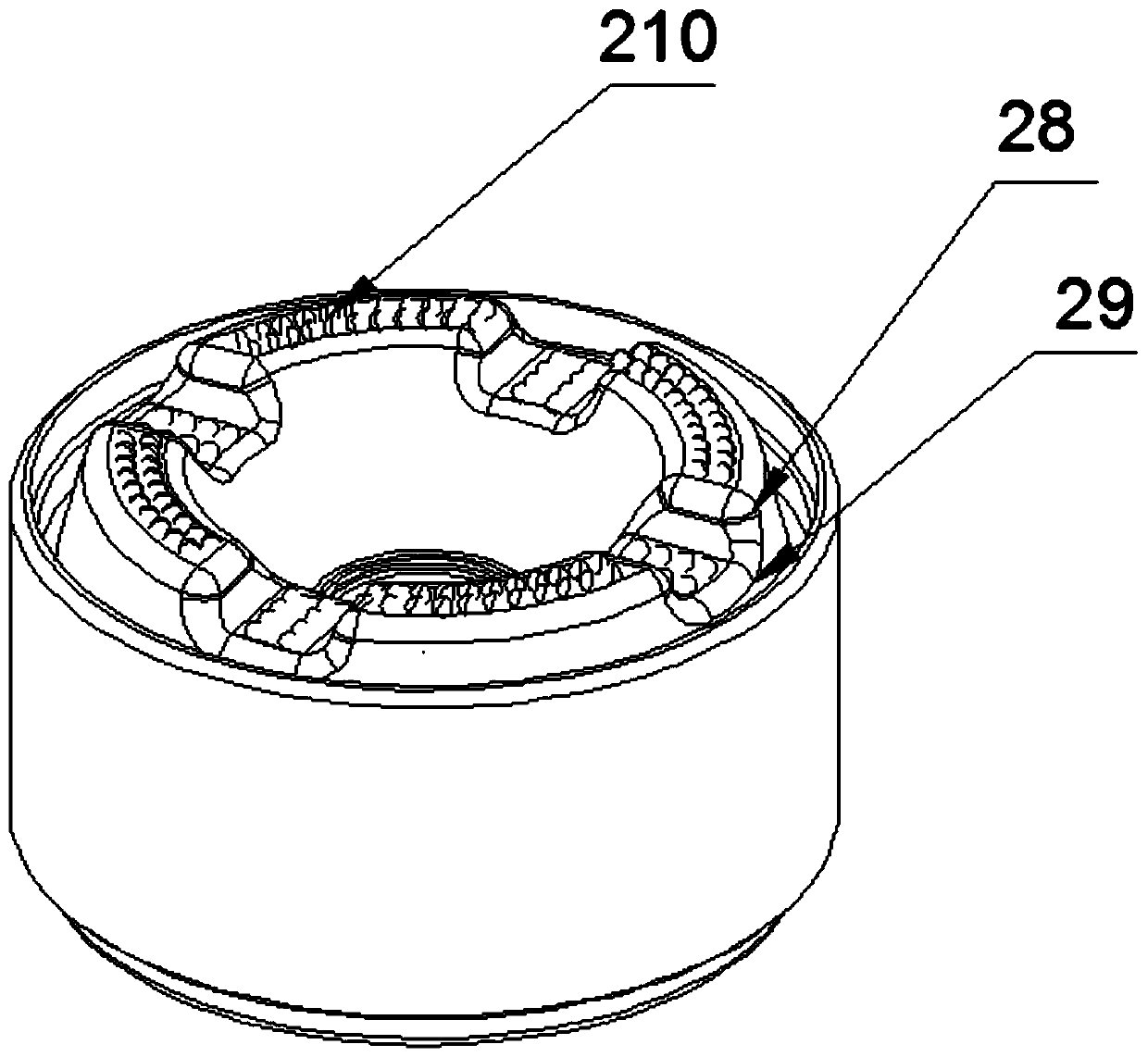

Screw drilling tool motor stator

ActiveCN101656438AReduce swellingAvoid premature failureMagnetic circuit stationary partsBorehole drivesWell drillingSlurry

The invention relates to a motor stator which is used for the petroleum and natural gas well-drilling field and is matched with the screw drilling tool. The motor stator comprises a casing and a rubber bushing. The rubber bushing is bonded with the inner opening of the casing. The inner opening of the rubber bushing is of a continuous spiral type. The radial cross section is of a circumferential uniformly-distributed petal shape. The difference is that the wall thickness of the rubber bushing at the radial cross section is not even. The wall thickness of each petal of the rubber bushing at the radial cross section from the lowest part of the dent to the highest part of the projection gradually increases. The largest thickness is 1.2-2 times of the smallest thickness. The shape of each petal on the radial cross section is same,The motor stator of the invention not only can prevent the damage of the stator rubber caused by the easy blocking of the rotor in the stator and no easy discharge of the slurry pressure when an overgreat drilling pressure generates on the stator with same wall thickness, but also prevents the problem of over-early failure caused by the large wall thickness difference of the rubber bushing and easy heat accumulation to the part with thick rubber. Therefore the advantages of greatly increasing the efficiency of the motor stator and effectively prolonging the service lifetime are obtained.

Owner:KINGDREAM PLC CO +1

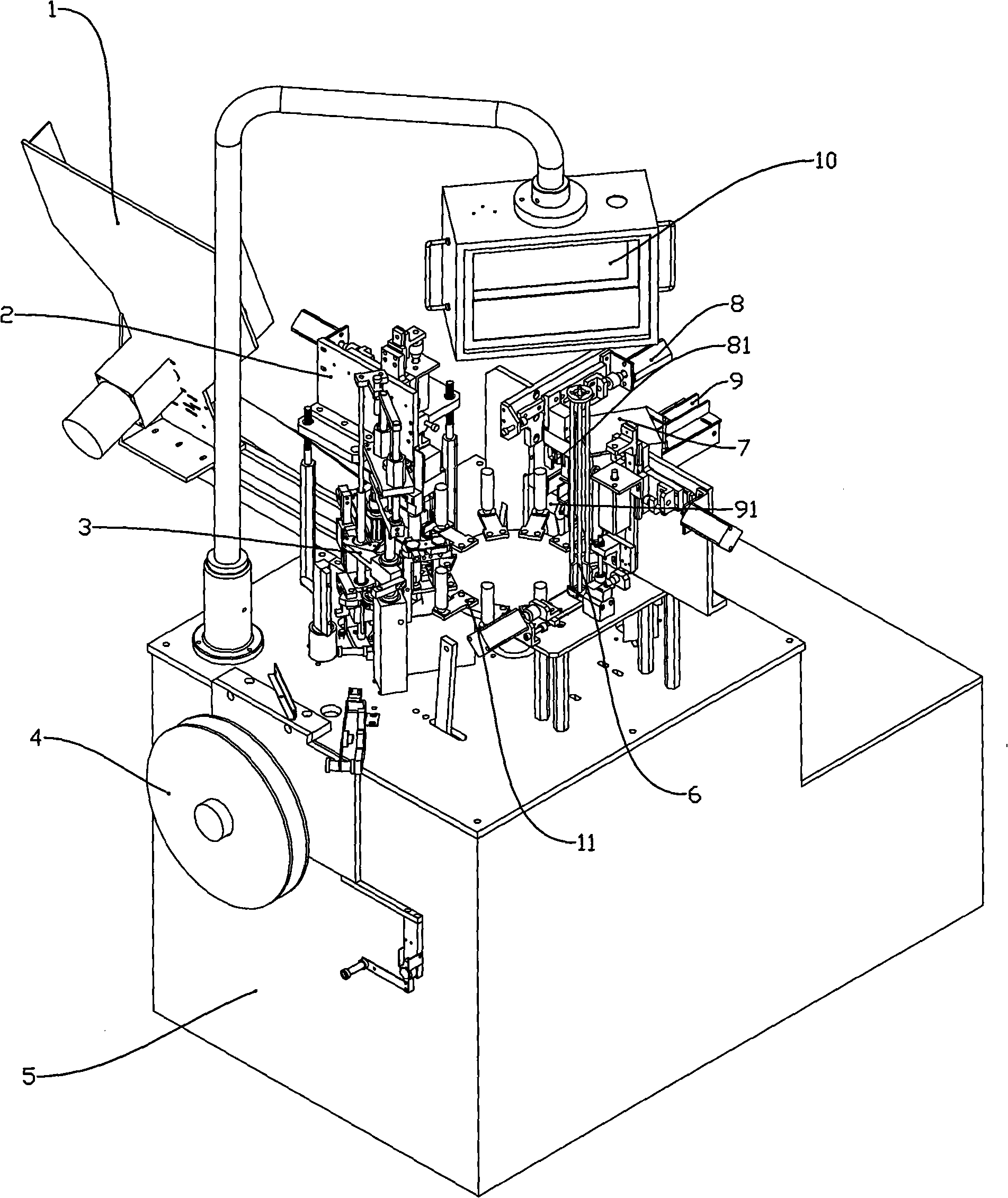

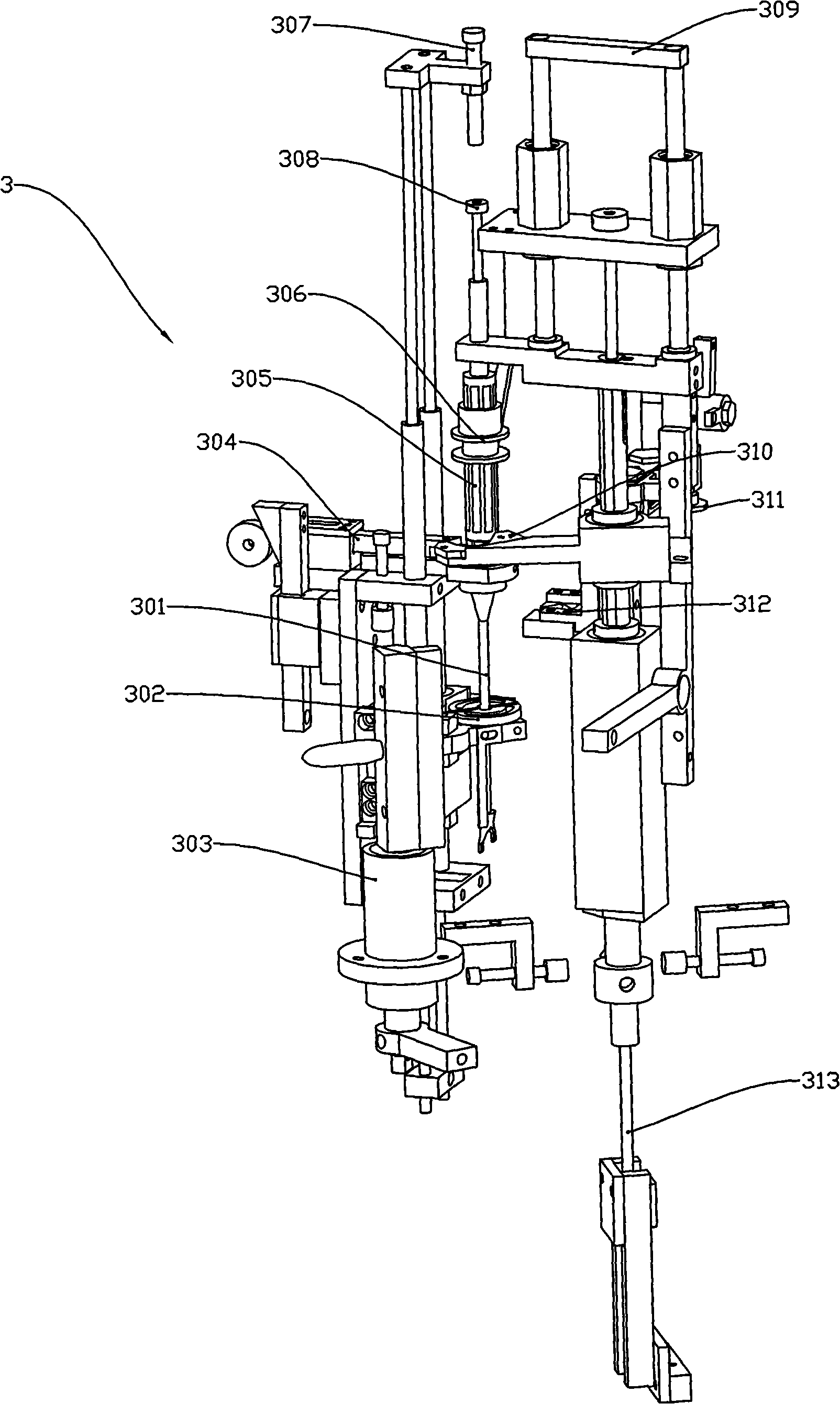

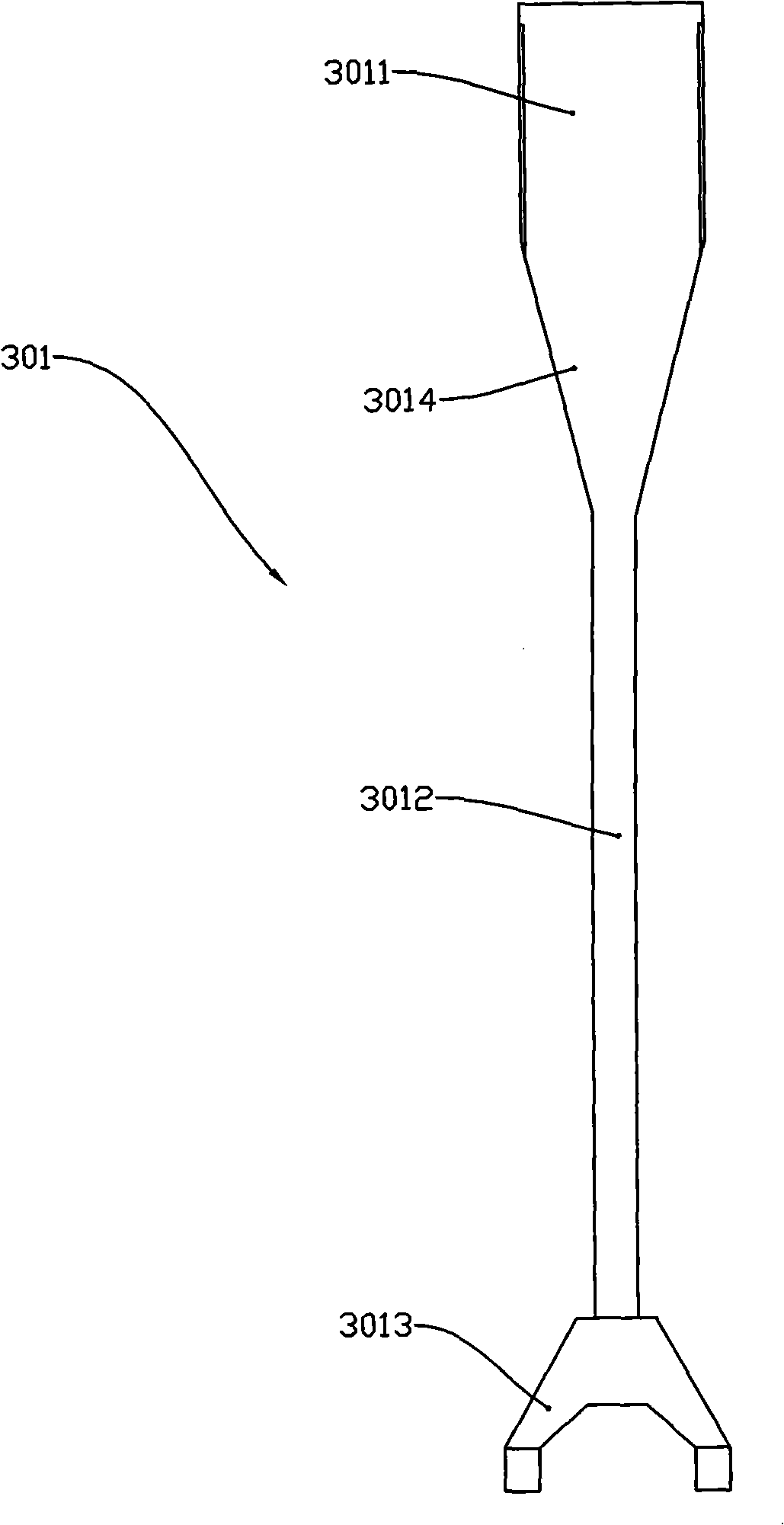

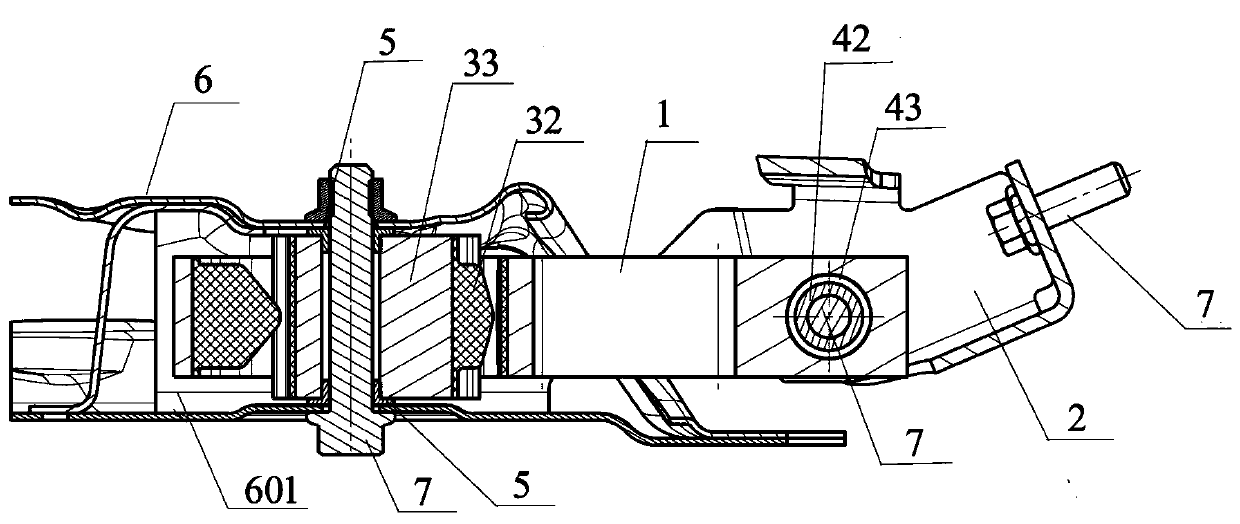

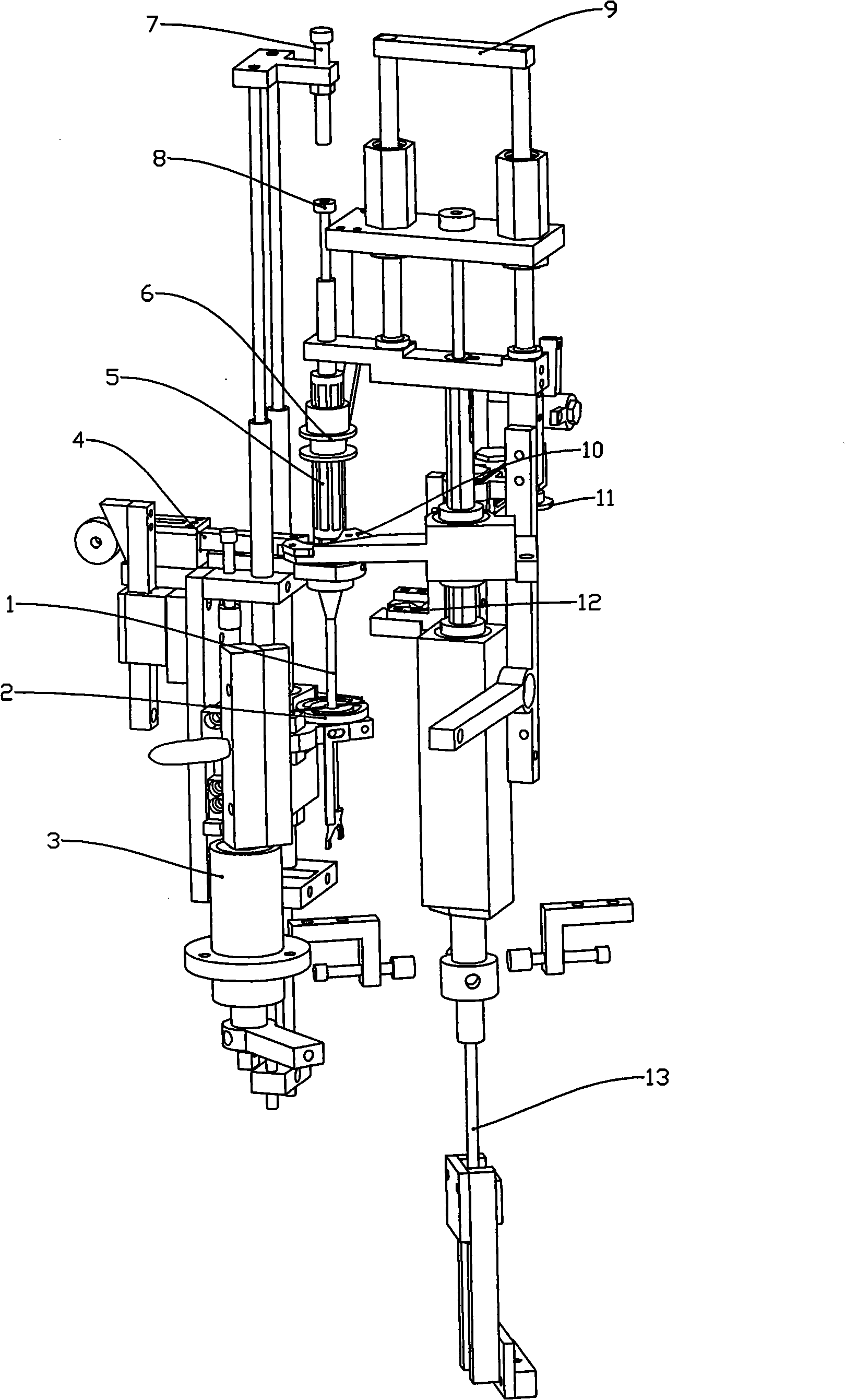

Apparatus for capping sebific duct and adding spacer automatically

The invention relates to a one-off molding equipment for automatically bushing rubber tube and adding gasket on the battery. The automatic rubber tube bushing and gasket adding equipment comprises a material carrying plate; a material feeding device connected with the material carrying plate; a rubber bushing device connected with the material feeding device; a rubber tube carrying plate; a machine station used as the base of the equipment; a gasket transfer device connected with the rubber bushing device; a heat wind device connected with the gasket transfer device; a product output device connected with the heat wind device, the product output device comprises material clamp for clamping battery; a product output channel adjacent to the product output device; a working rotary plate fixed with a plurality of fixing bases for fixing battery, the material feeding device, rubber bushing device, gasket transfer device, heat wind device and product output device are sequentially connected via the working rotary plate; a control case comprises control buttons for controlling motions of electric motors and cylinders. The rubber tube bushing and gasket adding equipment can automatically bushing the rubber tube and adding gasket on the battery in hight efficiency without labor force.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

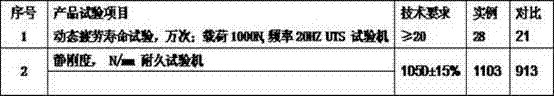

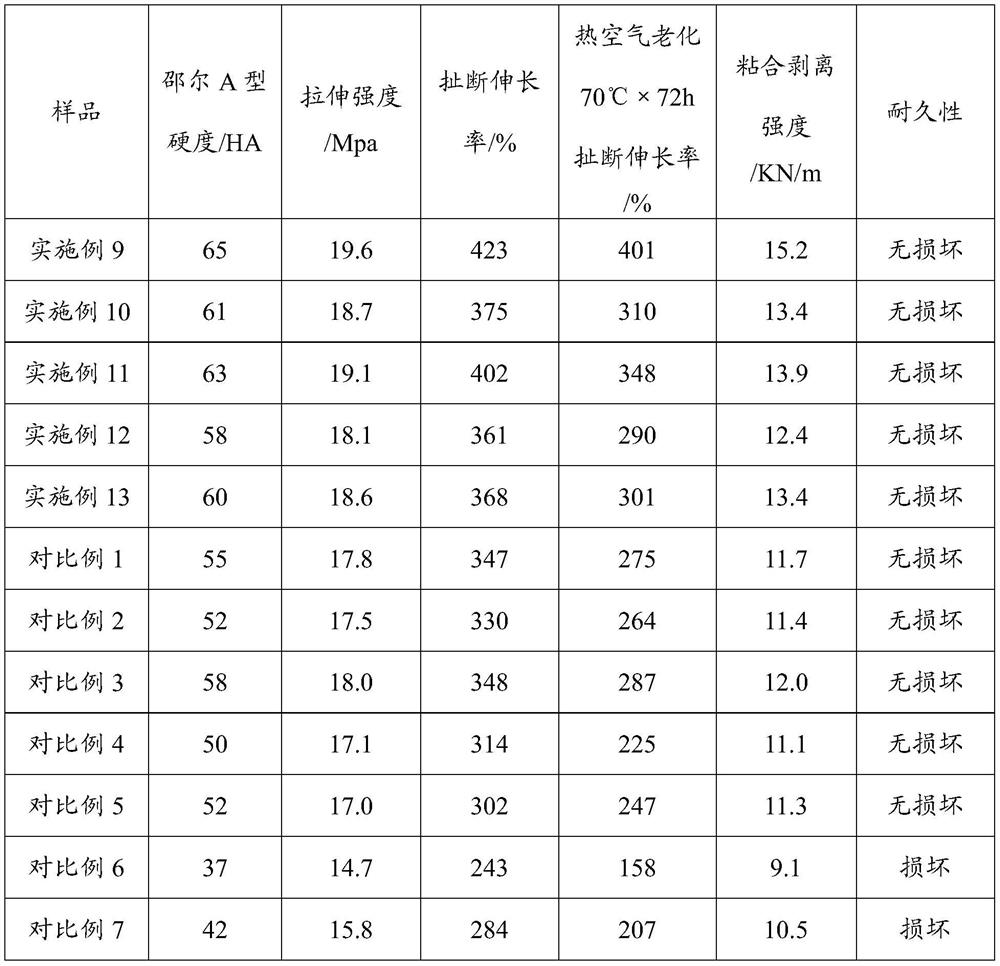

Bushing rubber prepared raw material under lightening development of high-grade cars

The invention discloses a bushing rubber prepared raw material under lightening development of high-end cars. The bushing rubber prepared raw material comprises the following components in parts by weight: 80 to 90 parts of natural rubber, 10 to 20 parts of butadiene rubber, 2 parts of naphthenic oil, 3.5 parts of zinc oxide, 2 parts of anti-aging agent IPPD (isopropyl-phenyl-paraphenylene diamine), 1 part of anti-aging agent TMQ (trimethyl dihydroquinoline), 2 to 3 parts of microcrystal wax, 6 parts of carbon black N683, 27 parts of carbon black DUREXO, 1.7 parts of sulfur, 1.5 parts of activating agent Struktol ZEH-DL and 1.82 parts of accelerating agent. With the adoption of the bushing rubber prepared raw material under lightening development of the high-end cars prepared by the prepared raw materials, the presulfiding effect and the anti-aging performance of a rubber material can be effectively improved, and the product durability is improved.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

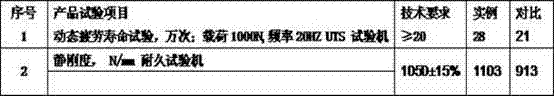

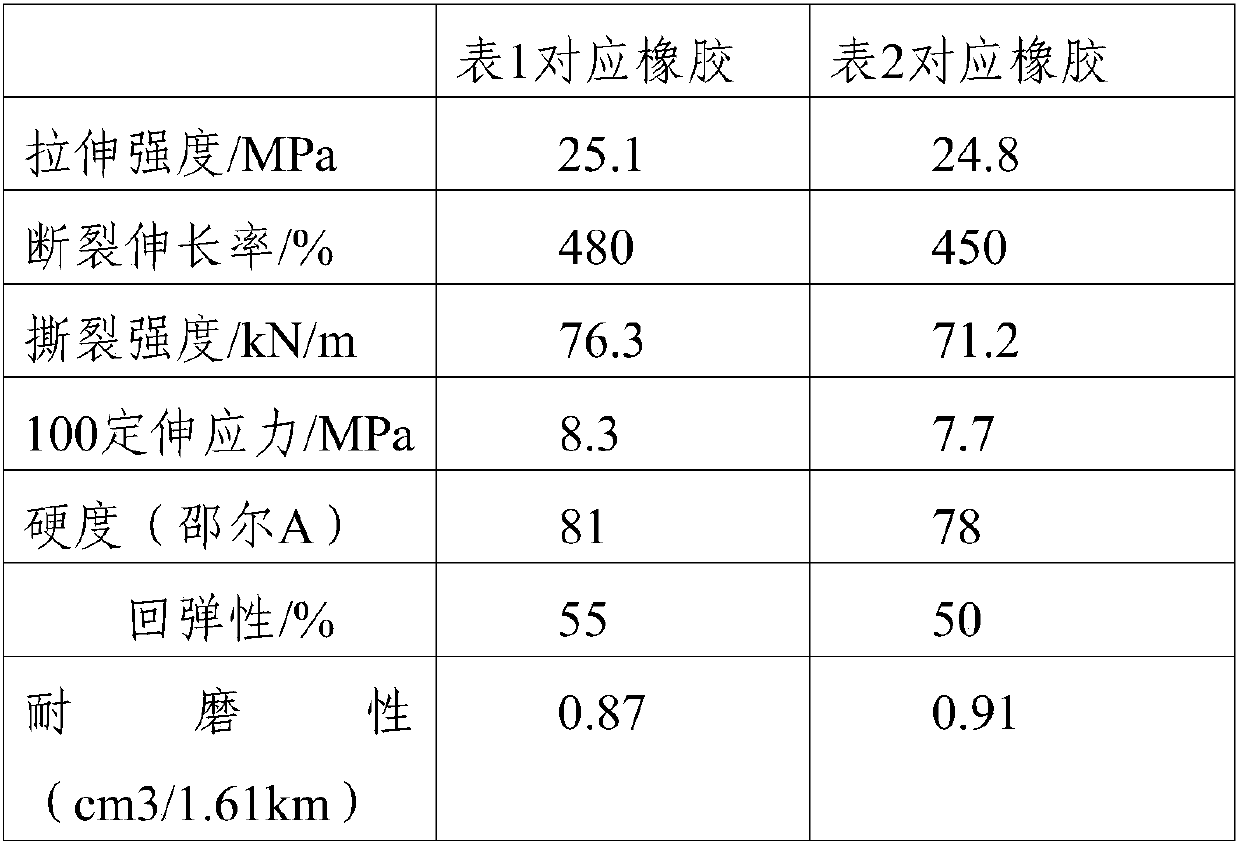

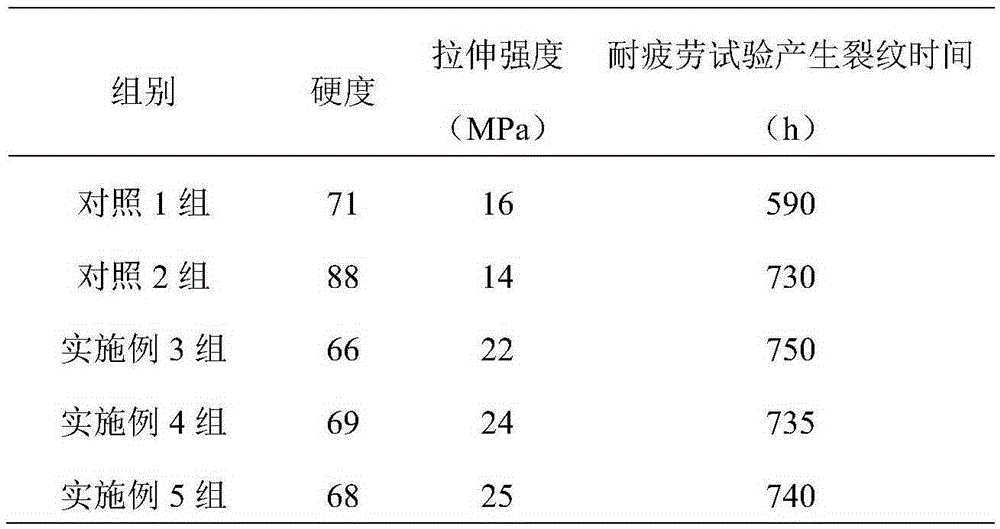

Bushing rubber for guiding device of automotive suspension system and manufacture method of rubber bushing

The invention discloses a bushing rubber for a guiding device of an automotive suspension system and a manufacture method of a rubber bushing. The bushing rubber in the guiding device for the automotive suspension system comprises the following components based on the total weight: 40 to 60% of natural rubber, 1 to 5% of zinc oxide, 1 to 5% of active auxiliary, 1 to 5% of composite vulcanizing agent, 20 to 30% of carbon black, 5 to 10% of plasticizer, and 1 to 5% of plastic age resister. According to the bushing rubber for the guiding device of the automotive suspension system, the rubber formula is improved, so that the resistance to wear, fatigue crack, aging, plastic deformation and stiffness change and the like are improved; and a test shows that the rubber made according to the formula and a bushing manufactured according to the method are characterized in that the rubber hardly falls from an inner steel pipe.

Owner:NINGBO SUOPU RUBBER & PLASTIC

Highly heat-resistant stabilizer bar bush rubber composition

InactiveUS20090099286A1Minimizing compression setImprove cross-linking efficiencyLayered productsOrganic dyesPolymer scienceHeat resistance

Owner:HYUNDAI MOTOR CO LTD

Automobile chassis bush rubber composition

The invention discloses an automobile chassis bush rubber composition, characterized by comprising the following materials according to parts by weight: 70-90 parts of natural rubber, 10-30 parts of cis-butadiene rubber, 0.5-3 parts of a diphenylamine antiaging agent, 1-3 parts of a dihydroquinoline antiaging agent, 1-3.5 parts of paraffin, 0.5-3 parts of a bridging agent, 6-10 parts of an activating agent, 35-75 parts of a reinforcing agent, 5-10 parts of a plasticizing agent, 1.5-3 parts of sulfur, 0.5-1.5 parts of a sulfur-containing compound, and 1-1.7 parts of an accelerant.The invention is simple and apparent and requires no addition of special expensive materials or special processing techniques; the whole production process is convenient to perform, all the materials are easy to purchase, the obtained rubber has excellent fatigue resistance and very low ratio of dynamic stiffness to static stiffness, is advanced in the technical field of the same industry and has a boarder market.

Owner:SHANGHAI ZHONGLI AUTO PARTS

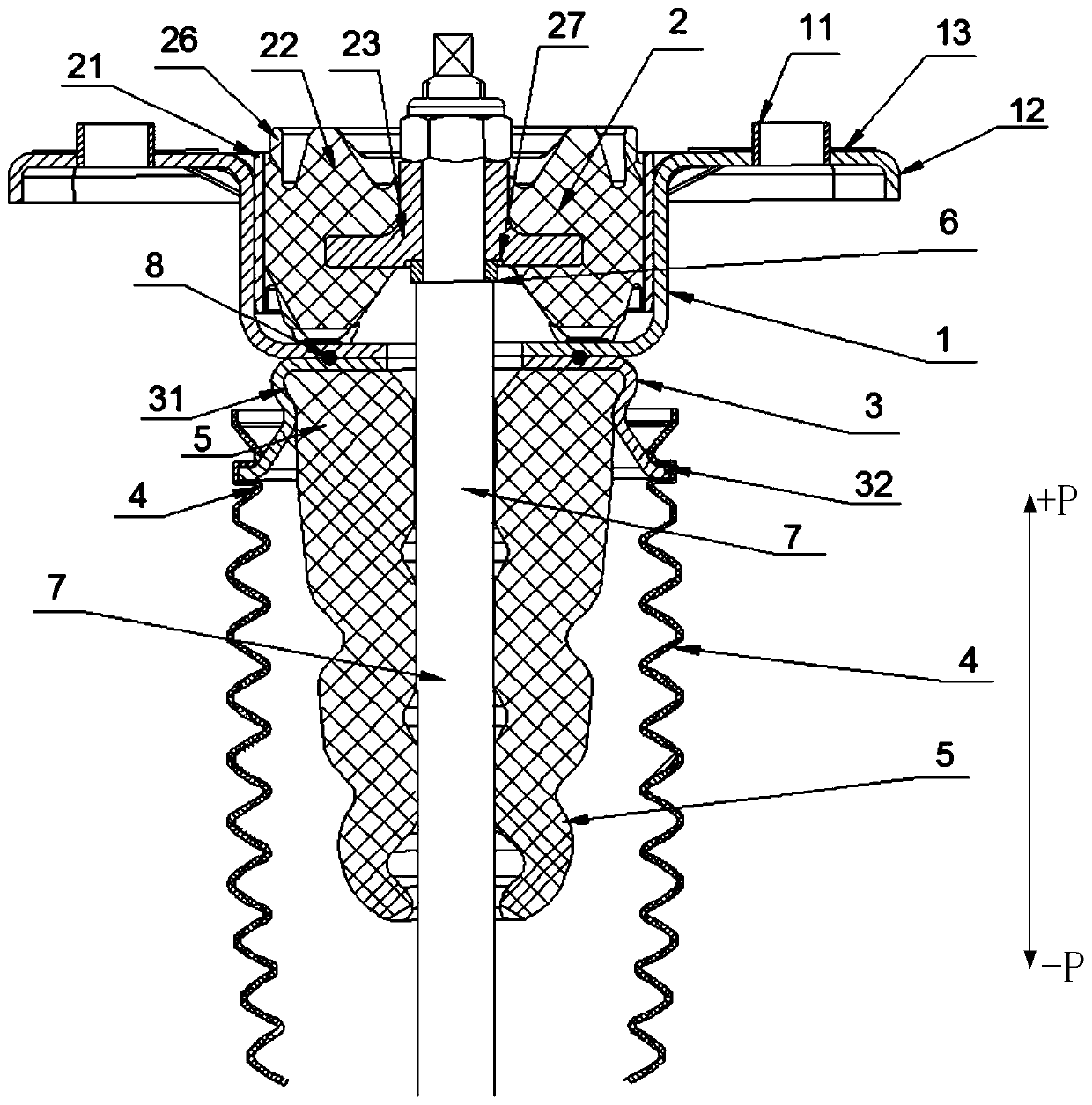

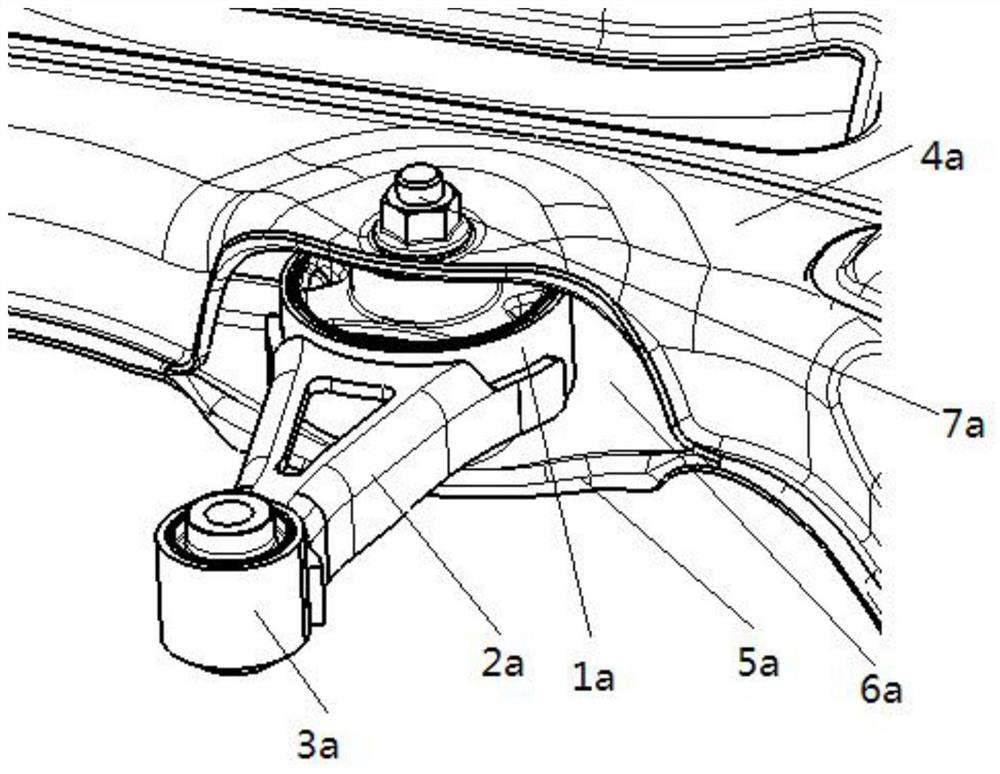

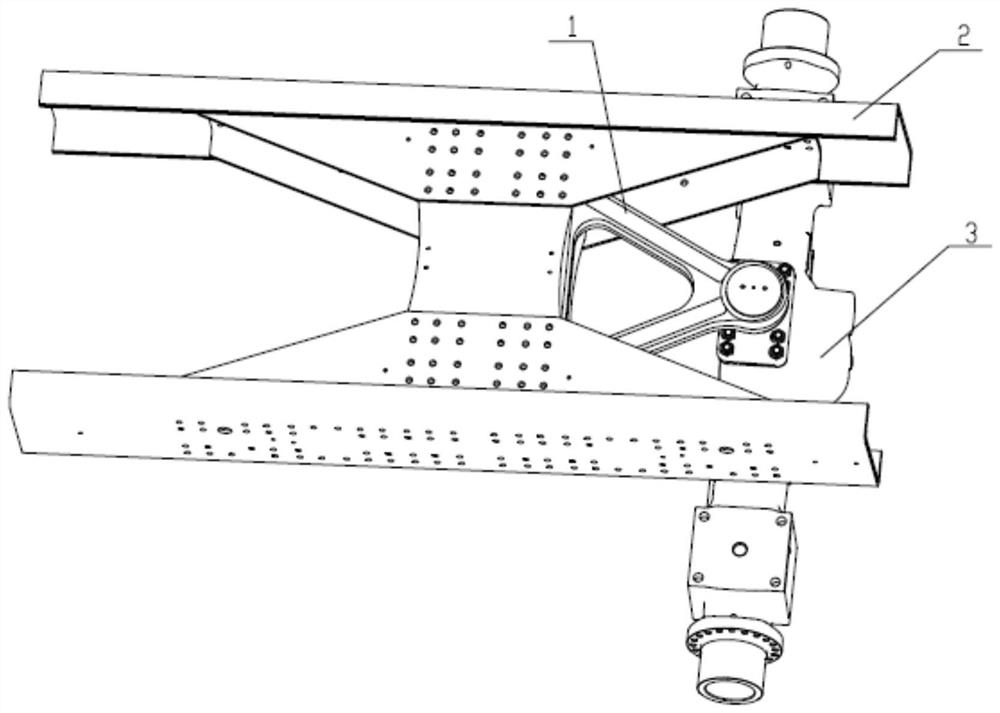

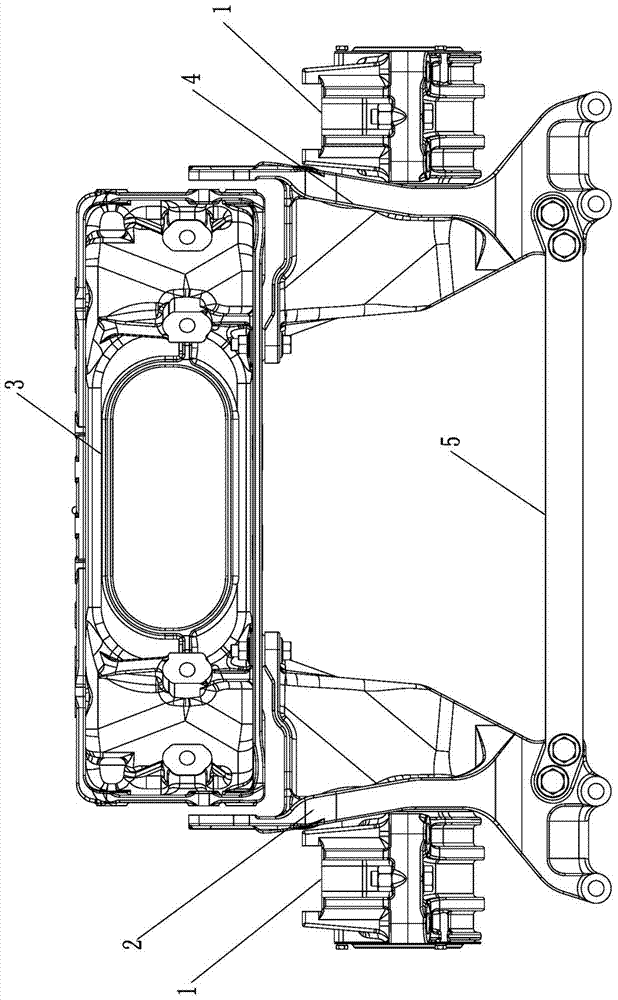

Torsion-resistant suspension structure of power assembly

ActiveCN109774448AReduce noiseImprove NVH performanceJet propulsion mountingInternal combustion mountingRubber ringResonance

The invention discloses an torsion-resistant suspension structure of a power assembly, which comprises a torsion-resistant pull rod and a torsion-resistant bracket, wherein the torsion-resistant pullrod comprises a torsion-resistant pull rod framework, one end of the torsion-resistant pull rod framework is fixedly connected with the torsion-resistant bracket through a small bushing, the other endof the torsion-resistant pull rod framework is provided with a large bushing, a large bushing rubber ring and a large bushing inner core are arranged in the large bushing, and the torsion-resistant suspension structure also comprises a vibration absorber, wherein the vibration absorber is detachably and fixedly connected with the torsion-resistant pull rod framework; the large bushing rubber ringis provided with a forward gear rubber collision block, the large bushing inner core is provided with a forward gear rubber limit block, and the forward gear rubber collision block and the forward gear rubber limit block are both in convex arc shapes and are oppositely arranged in the length direction of the torsion-resistant pull rod framework. According to the invention, the natural frequency of the torsion-resistant suspension structure is shifted to two sides of an original resonance frequency, so that the vibration intensity under the resonance frequency is reduced; meanwhile, the changeof the rigidity curve under the three-gear acceleration working condition is smooth, the vibration intensity is further integrally reduced, the noise in the vehicle caused by the resonance and the acceleration working condition is obviously reduced, and the NVH performance of the whole vehicle is improved.

Owner:DONGFENG MOTOR CORP HUBEI

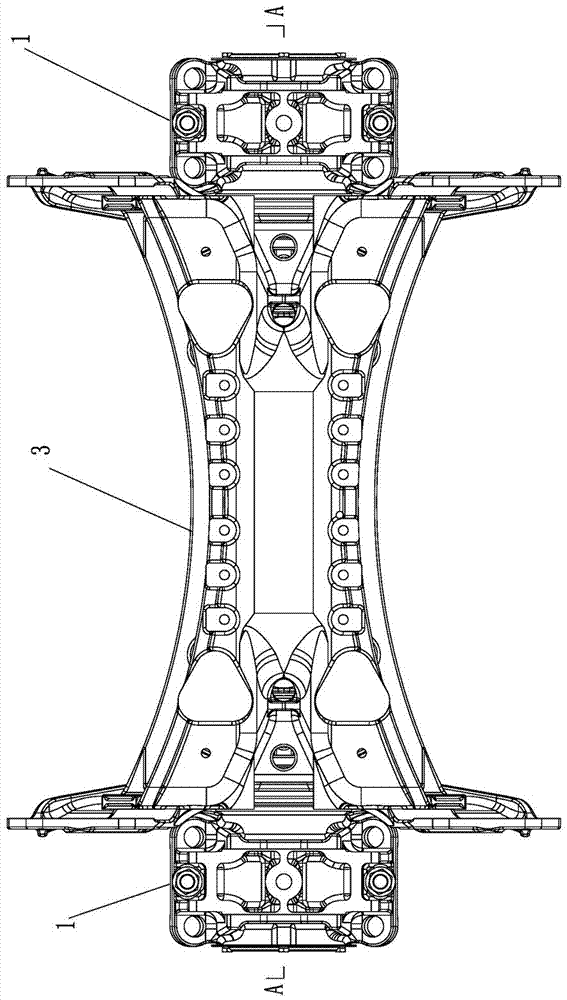

Torsion-resistant pull rod structure of power assembly

ActiveCN109760503AImprove NVH performanceReduce the stiffness of the torsional tie rodJet propulsion mountingInternal combustion mountingRubber ringEngineering

Owner:DONGFENG MOTOR CORP HUBEI

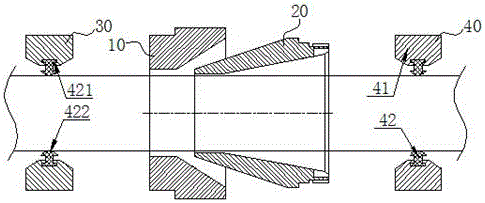

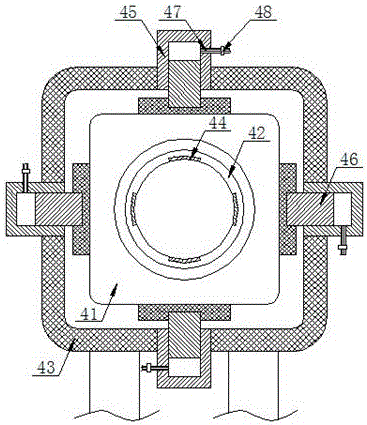

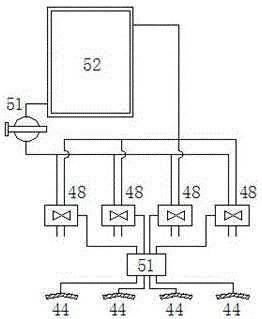

Cable insulation extrusion process capable of realizing automatic regulation of concentricity

ActiveCN106346733AHigh concentricityGuarantee the quality of eccentricityDomestic articlesCoatingsRubber ringInsulation layer

The invention discloses a cable insulation extrusion process capable of realizing automatic regulation of concentricity. Equipment for the cable insulation extrusion process includes an insulation layer extrusion mold which comprises an internal core, an outer sleeve, an upstream concentric guide bushing and a downstream concentric guide bushing; each of the upstream concentric guide bushing and the downstream concentric guide bushing comprises a hard tube of the guide bushing and a guide bushing rubber ring disposed in the hard tube of the guide bushing. The cable insulation extrusion process includes the steps of S1, regulating the direction of a to-be-extruded cable so that the to-be-extruded cable cannot rub against the inner wall of the internal core when running through the internal core; S2, regulating positions of the upstream concentric guide bushing and the downstream concentric guide bushing so that the guide bushing rubber rings of the upstream concentric guide bushing and the downstream concentric guide bushing are free of deformation; S3, regulating positions of an upstream tension pulley and a downstream tension pulley so that the guide bushing rubber rings of the of the upstream concentric guide bushing and the downstream concentric guide bushing are free of deformation. The cable insulation extrusion process can guarantee quality of eccentricity of insulation layers of products such as cables and tracing ribbons.

Owner:BAODING JINGYANG LIJIN CABLE MFG CO LTD

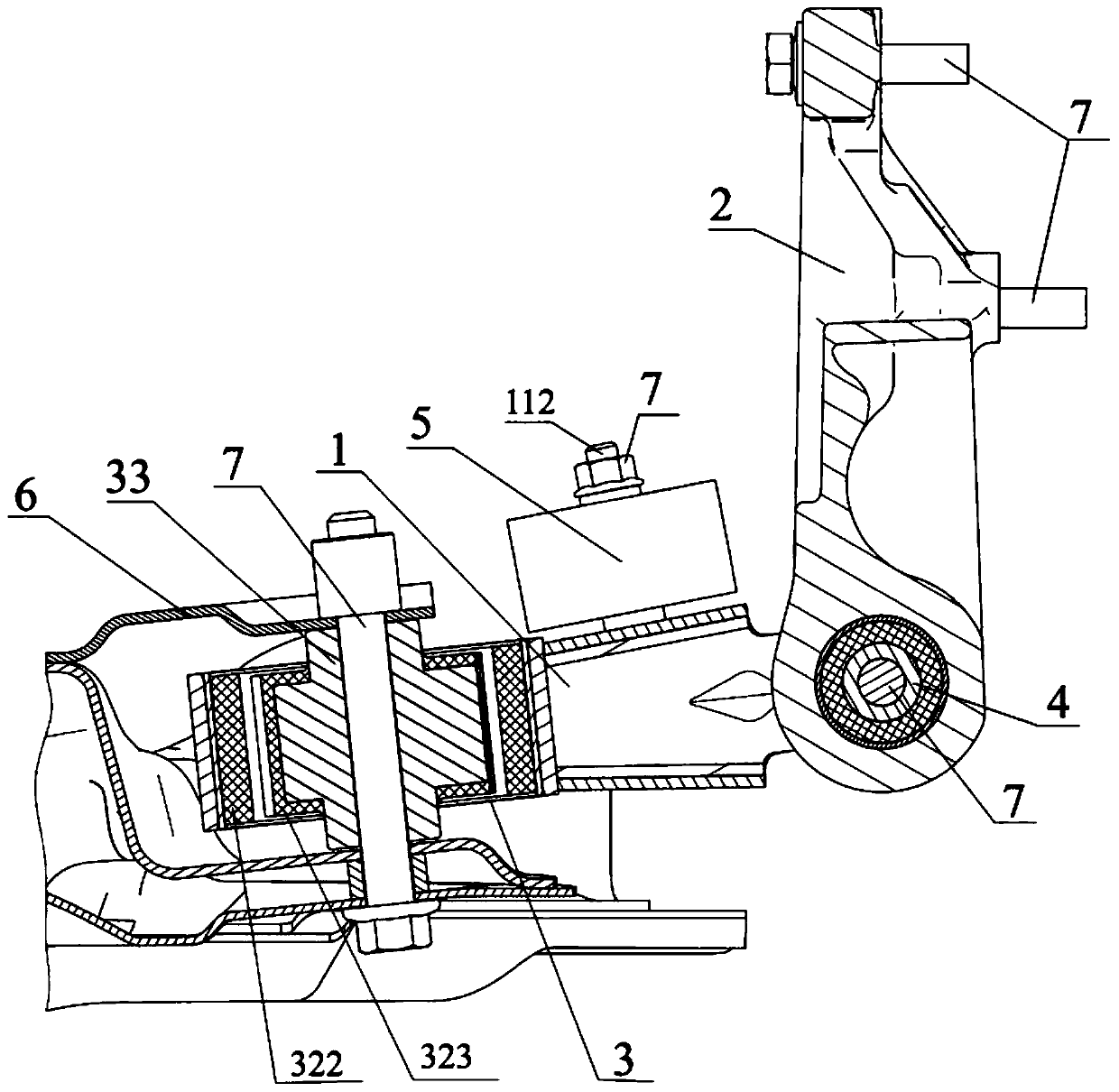

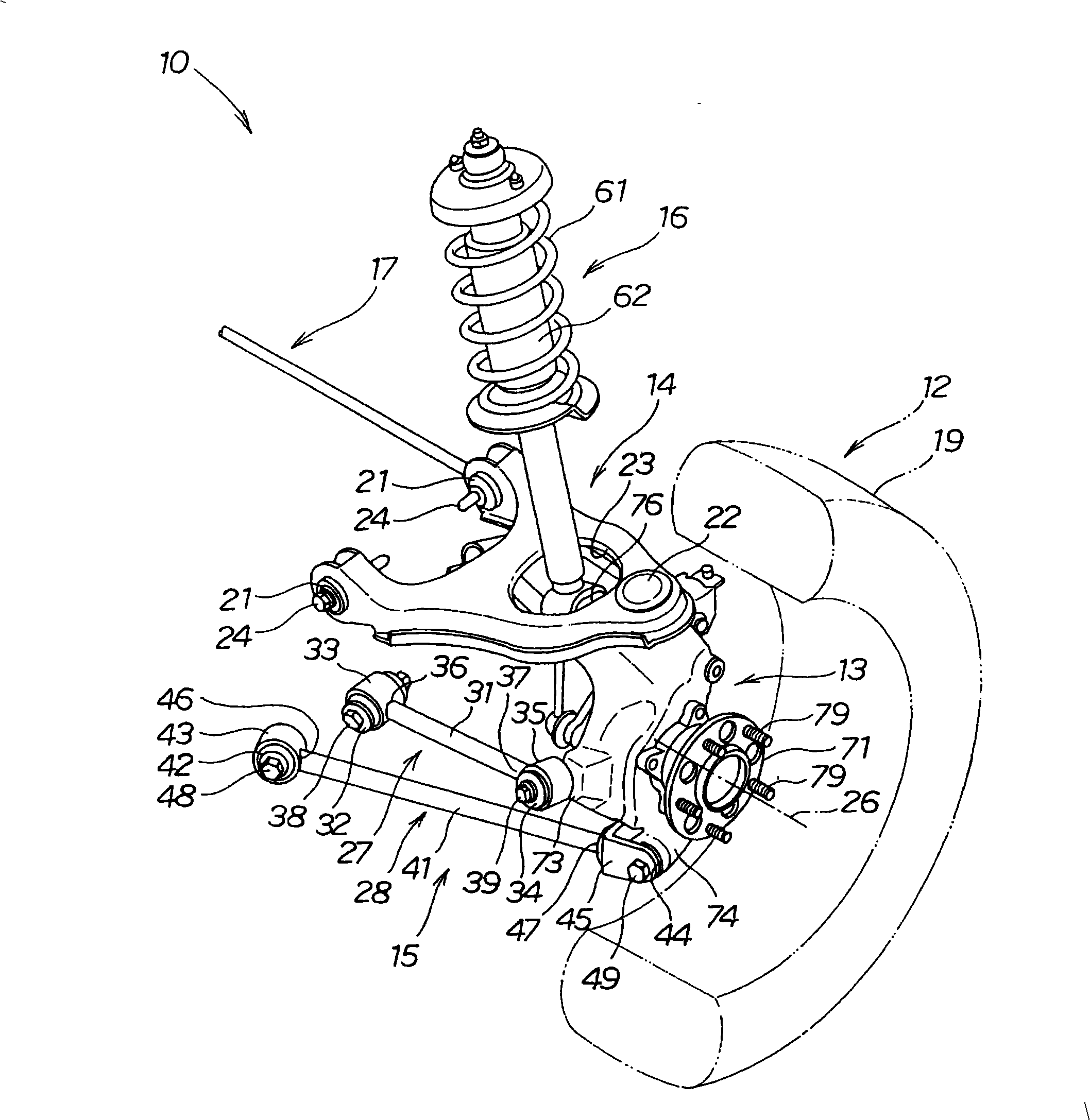

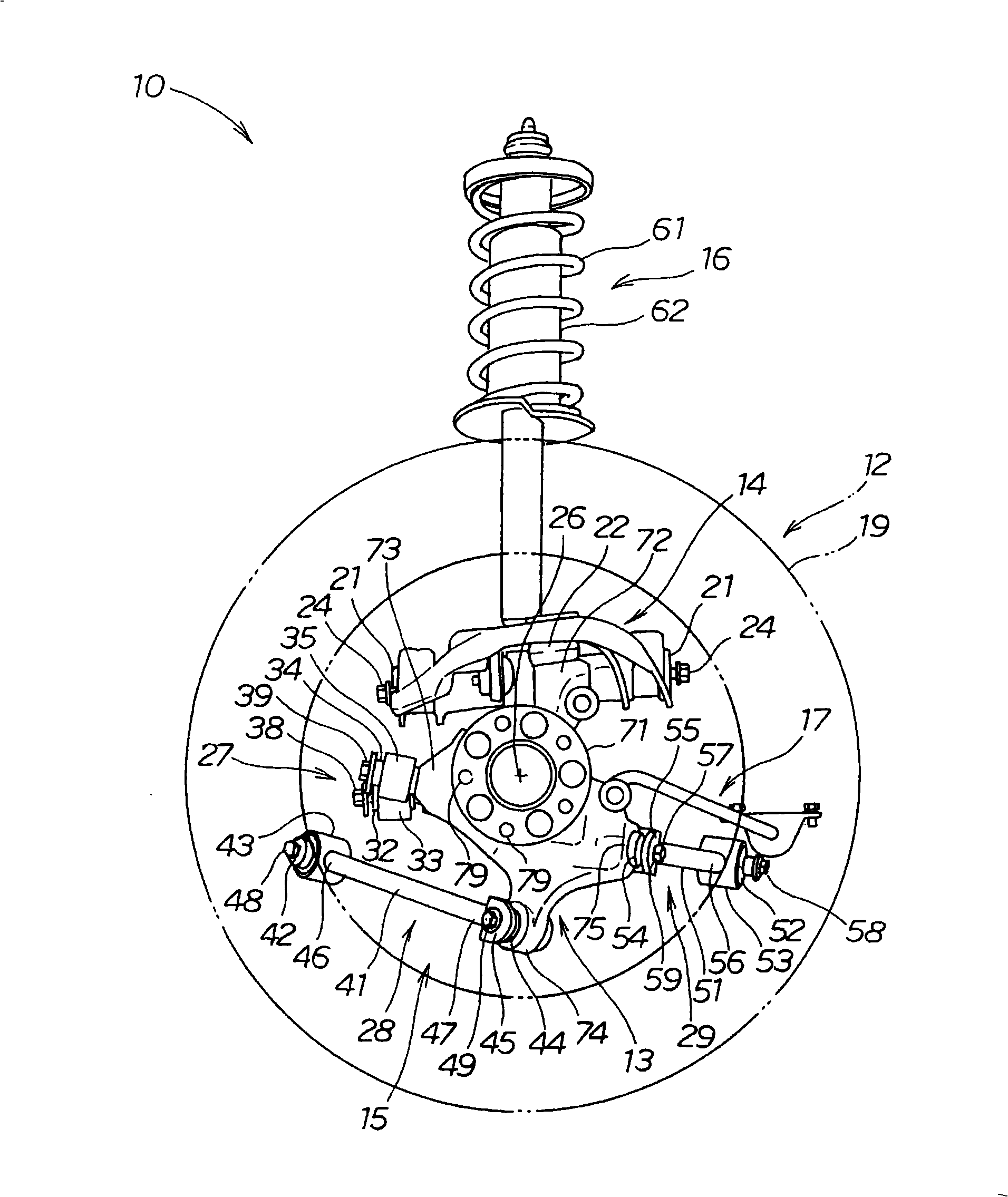

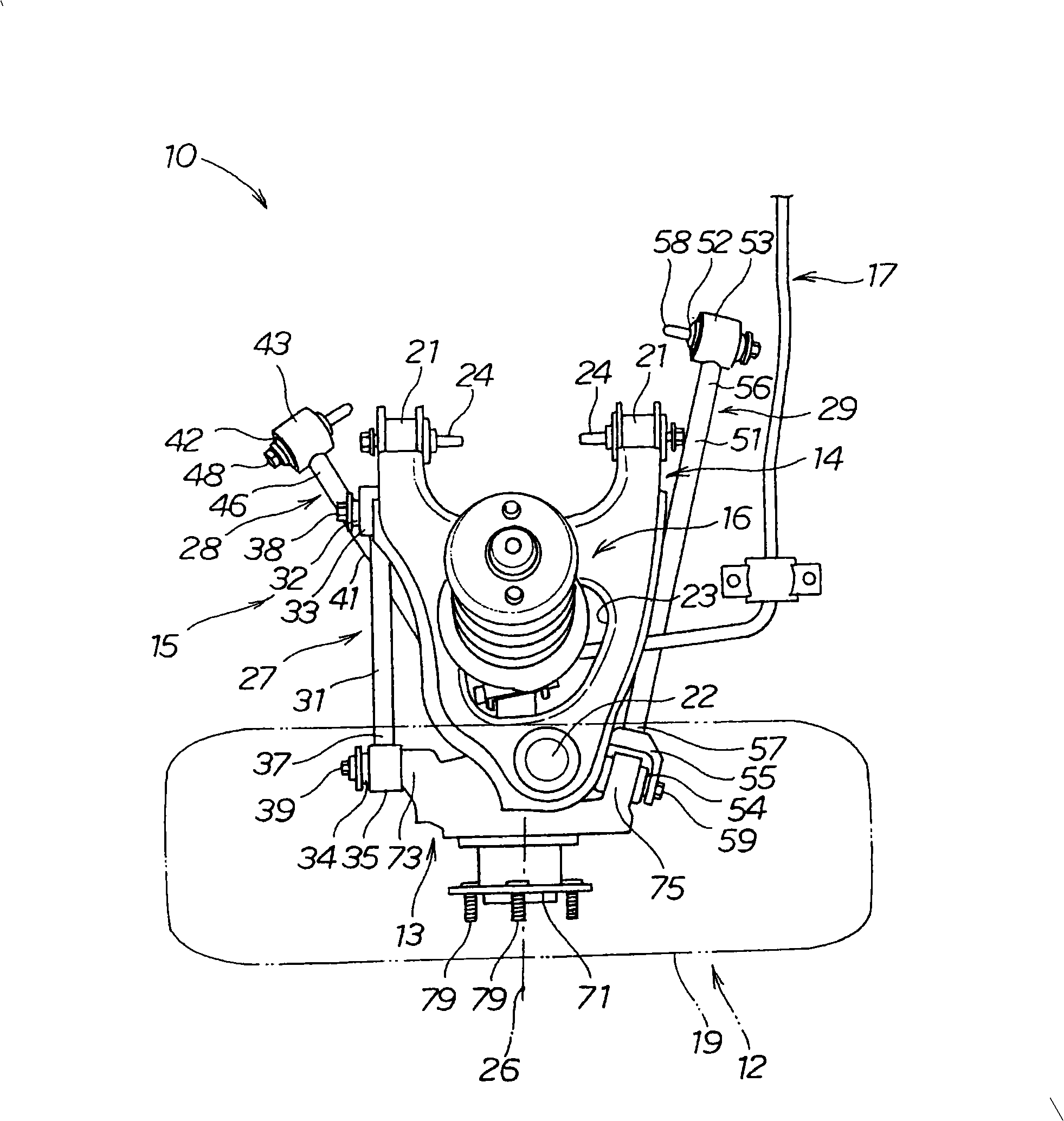

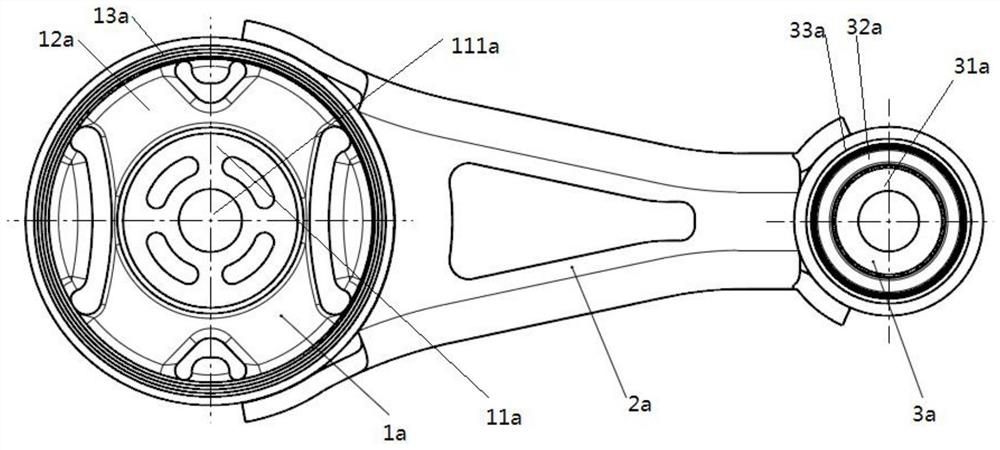

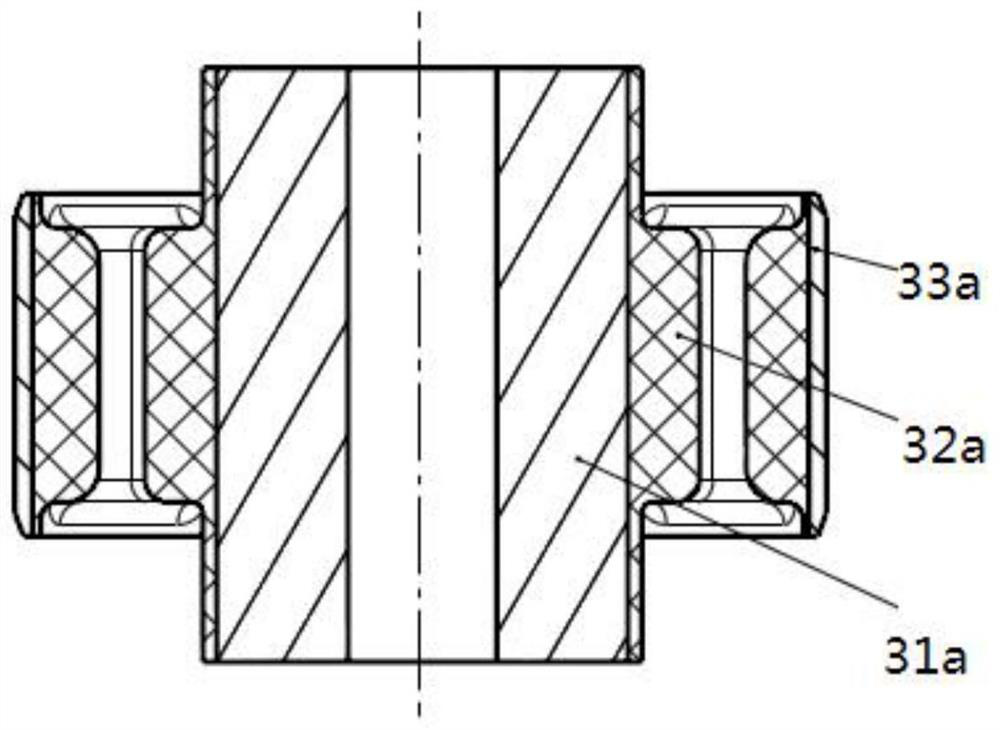

Vehicle suspension apparatus

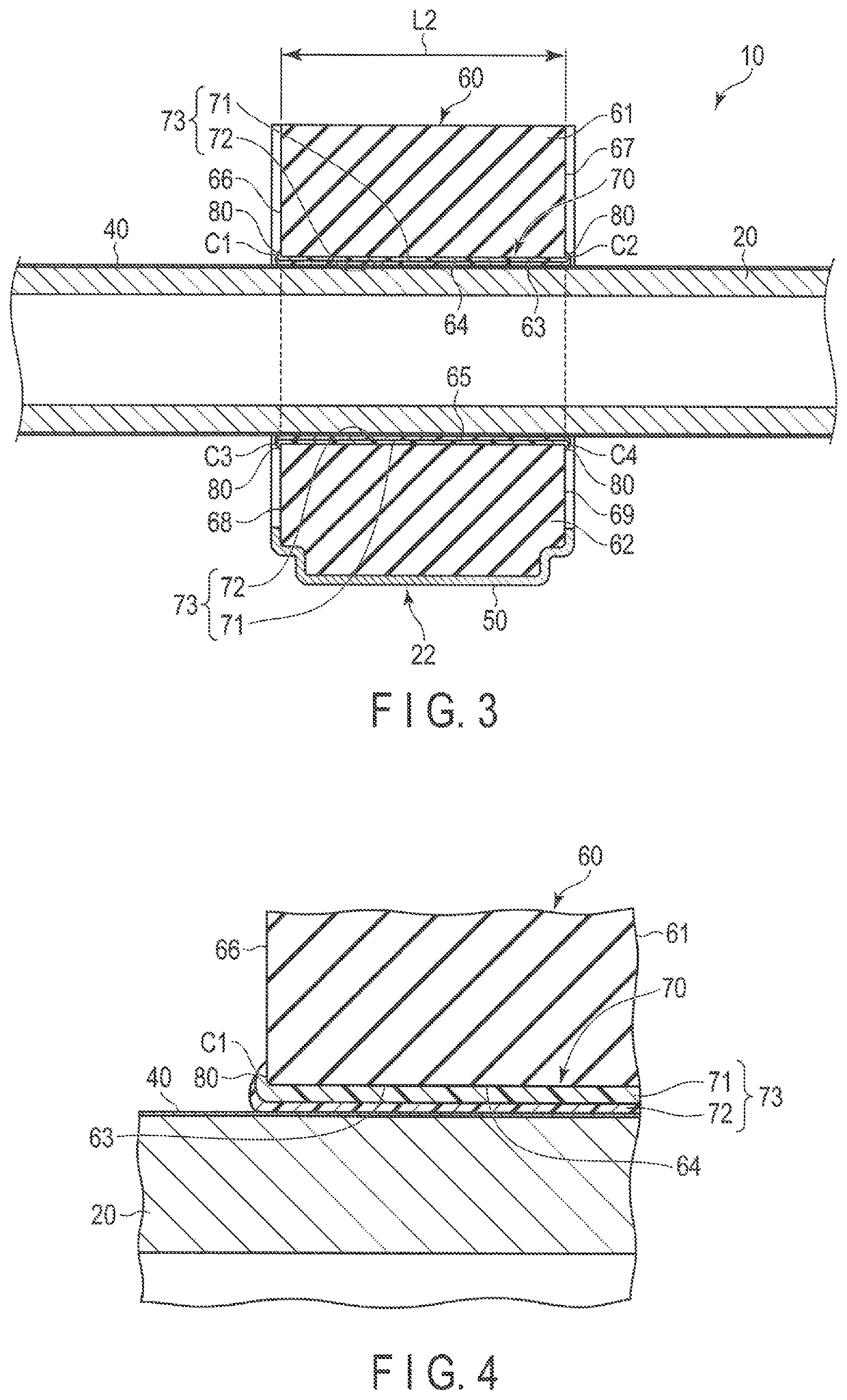

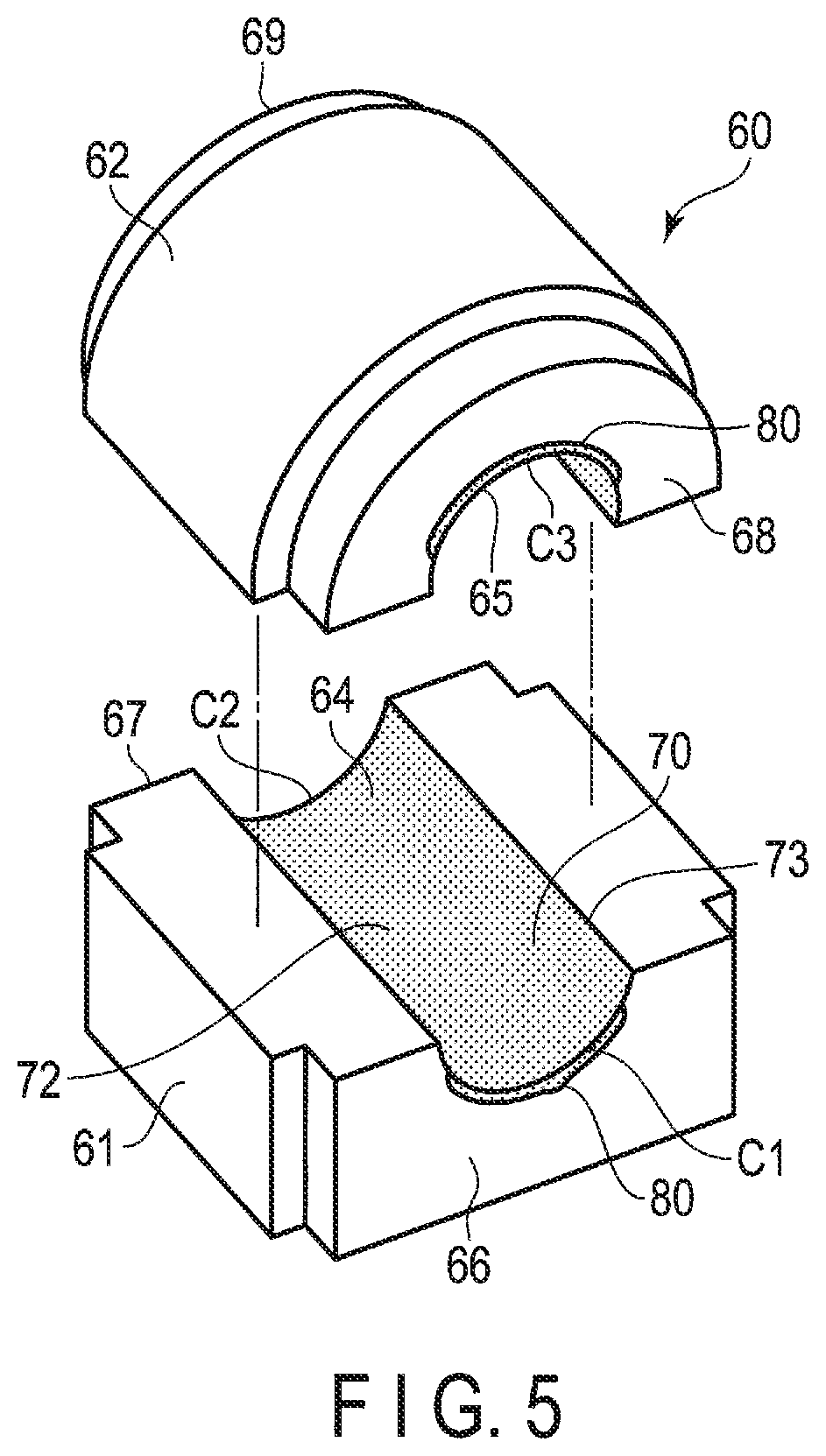

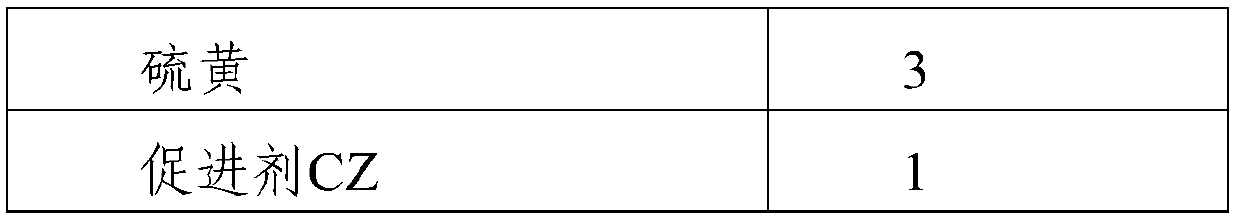

ActiveCN101353002ASwing freelyAchieve lightweightResilient suspensionsVehicle springsMechanical engineeringAngle of inclination

A vehicle suspension apparatus 10 includes a plurality of arms 14, 27 to 29 respectively extending from the side of a vehicle body, and a knuckle 13 swingably supported on the leading ends of these arms 14, 27 to 29 for swingably mounting a wheel 12 thereon. The arm 27 includes a straight arm portion 31, a first rubber bush 32 provided on one end of the arm portion 31 and a second rubber bush 34 provided on the other end of the arm portion 31. And, the center lines C1 and C2 of the first and second rubber bushes 32 and 34, when they are viewed from the axial direction of the arm portion 31, are set to have a predetermined angle of inclination between them.

Owner:HONDA MOTOR CO LTD

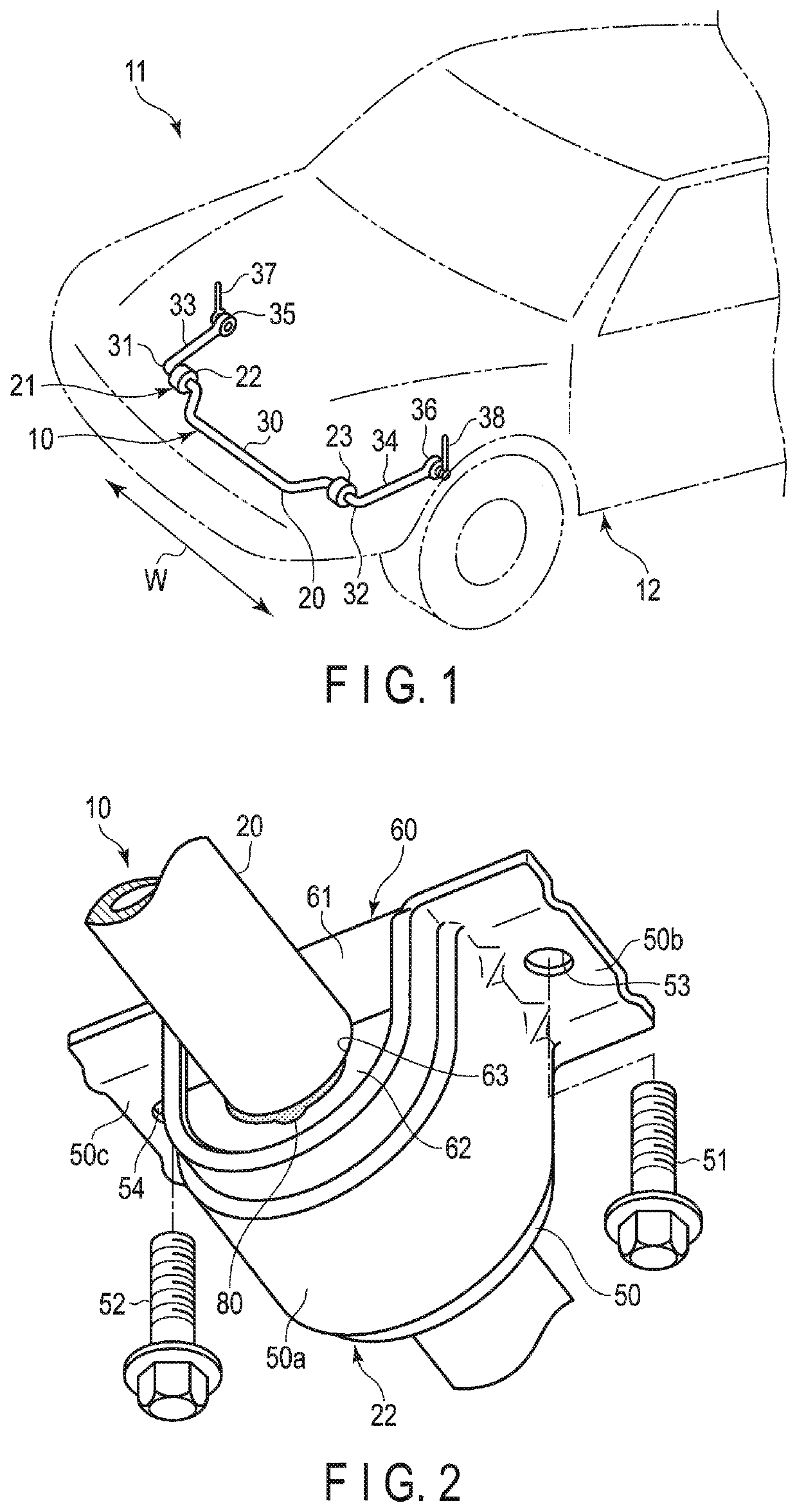

Vehicle stabilizer device

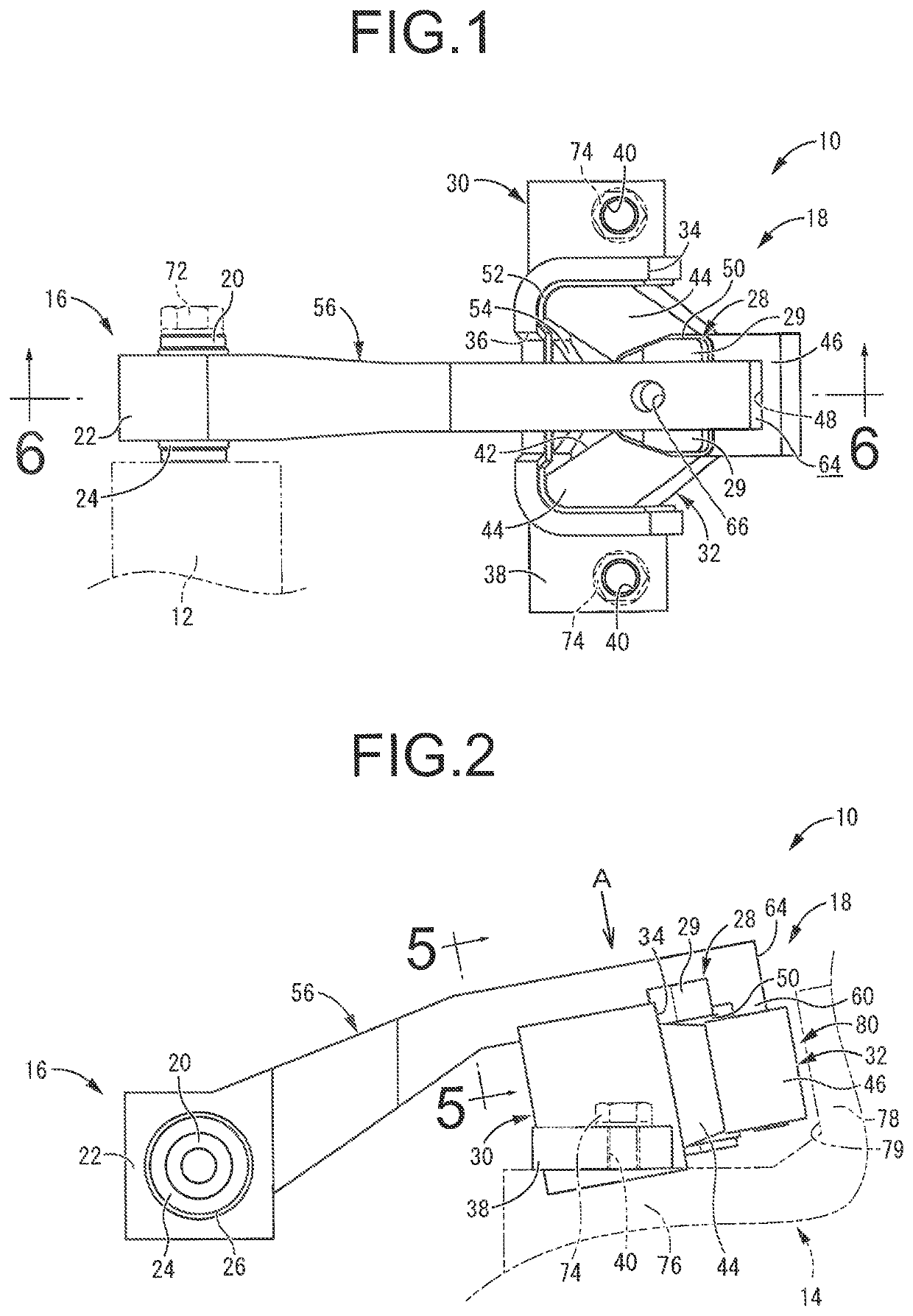

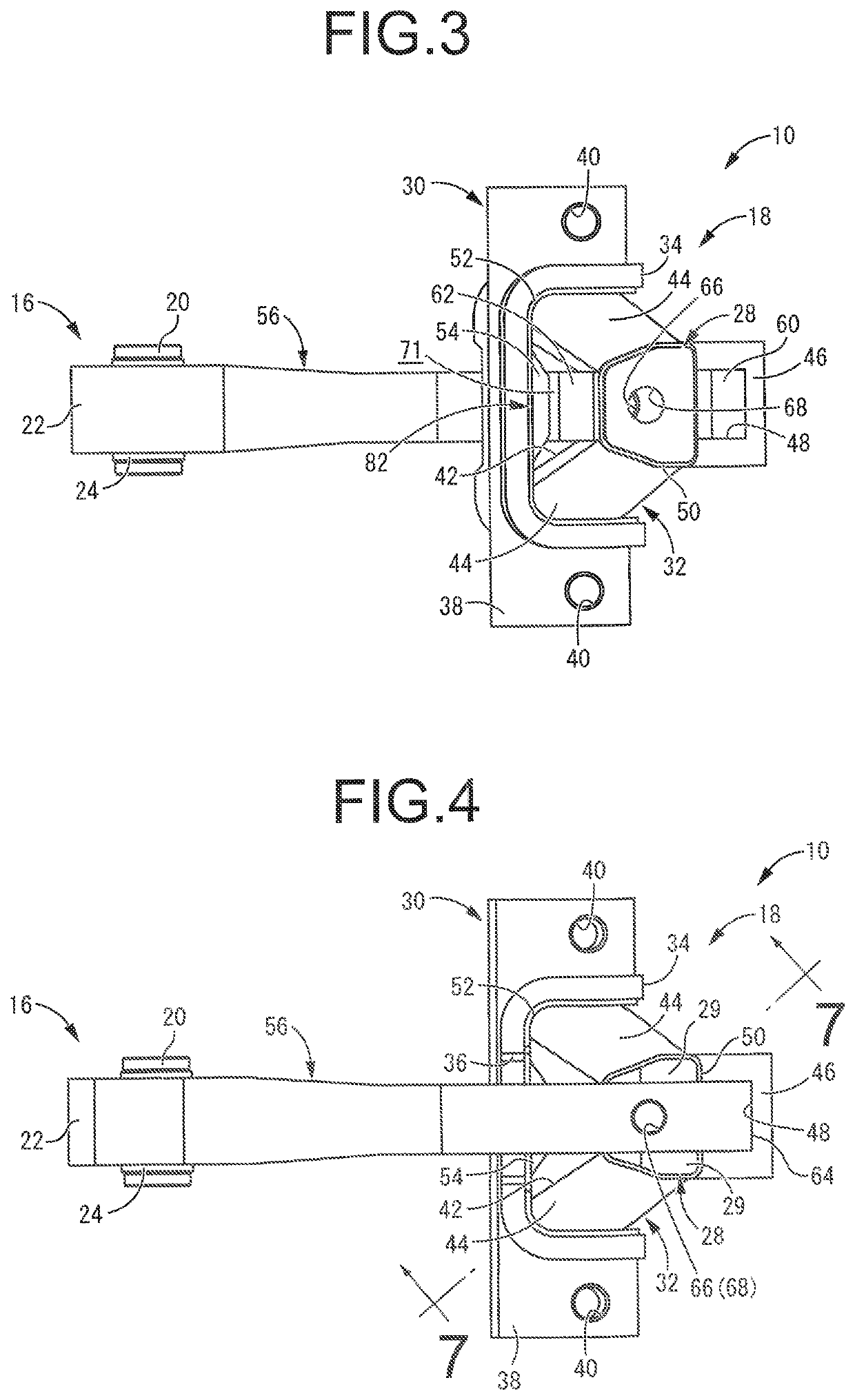

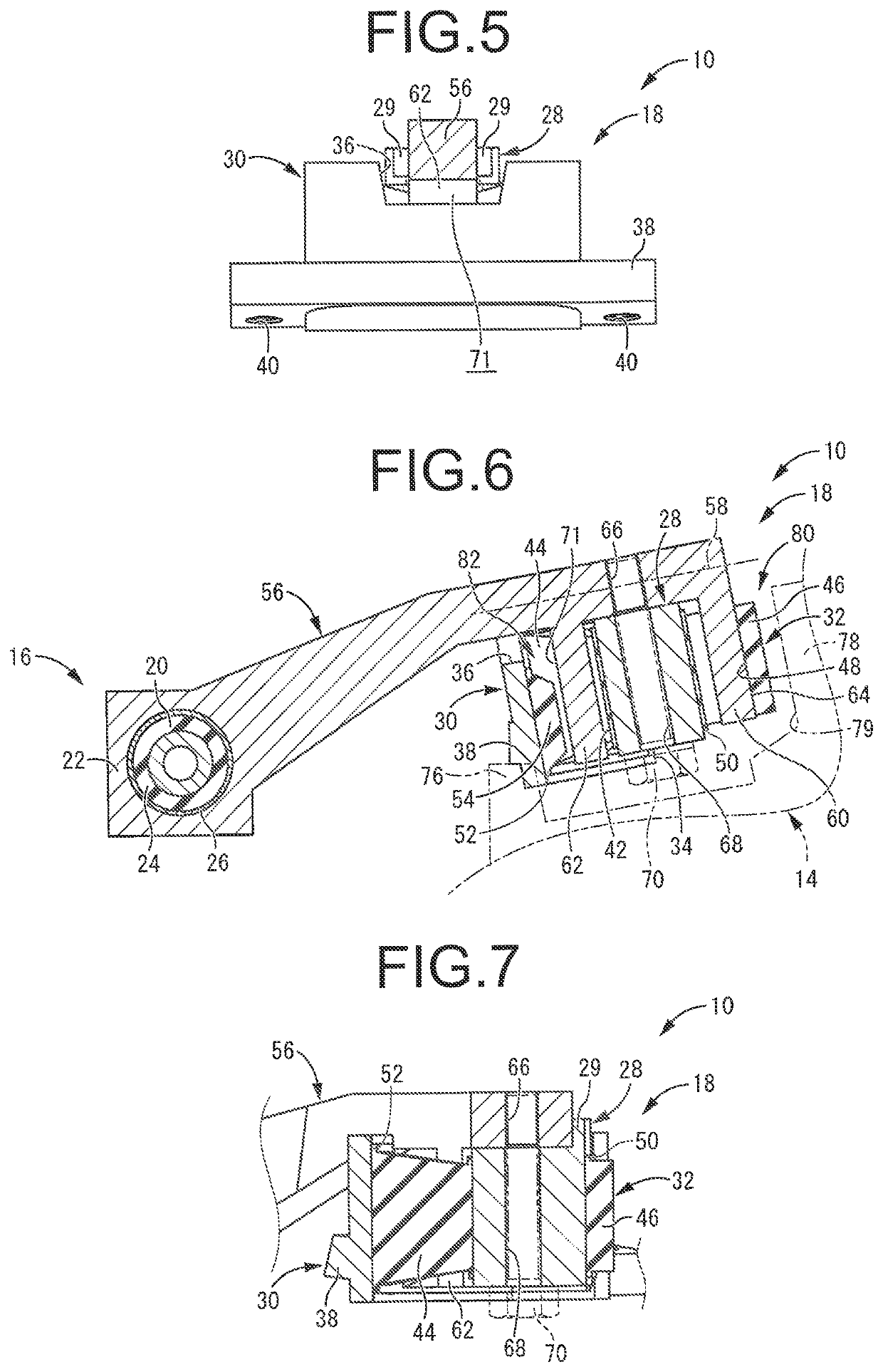

ActiveUS10759250B2Increase usageReduce areaSpringsSprings/dampers design characteristicsAdhesiveMechanical engineering

A stabilizer device includes a stabilizer extending in a width direction of a vehicle, and a bush unit. The bush unit includes a bracket formed of metal, and a rubber bush. The rubber bush is formed of a plurality of bush pieces, and is fixed to the stabilizer by an adhesion layer. The adhesion layer is constituted of an adhesion member including an adhesive applied to inner surfaces of the bush pieces. A bonding display portion formed of a part of the adhesion member is provided at a corner on an end face of the bush piece.

Owner:NHK SPRING CO LTD

Bushing rubber for single-board and single-pin vehicle track pin

The invention discloses bushing rubber for a single-board and single-pin vehicle track pin. The bushing rubber is prepared from components in parts by mass as follows: 100 parts of natural rubber, 30-50 parts of carbon black, 4-10 parts of carbon fiber, 2-5 parts of an anti-aging agent, 3-6 parts of an active agent, 1-3 parts of a softener, 3-8 parts of a reinforcing agent, 1-4 parts of a vulcanizing agent and 1-4 parts of an accelerant. The torsional force borne by traditional bushing rubber and dual extrusion-torsion shear loss of a rubber bushing can be improved, optimization of an overallrunning function of a track is realized, and the mileage life of the track is prolonged.

Owner:内蒙古第一机械集团股份有限公司

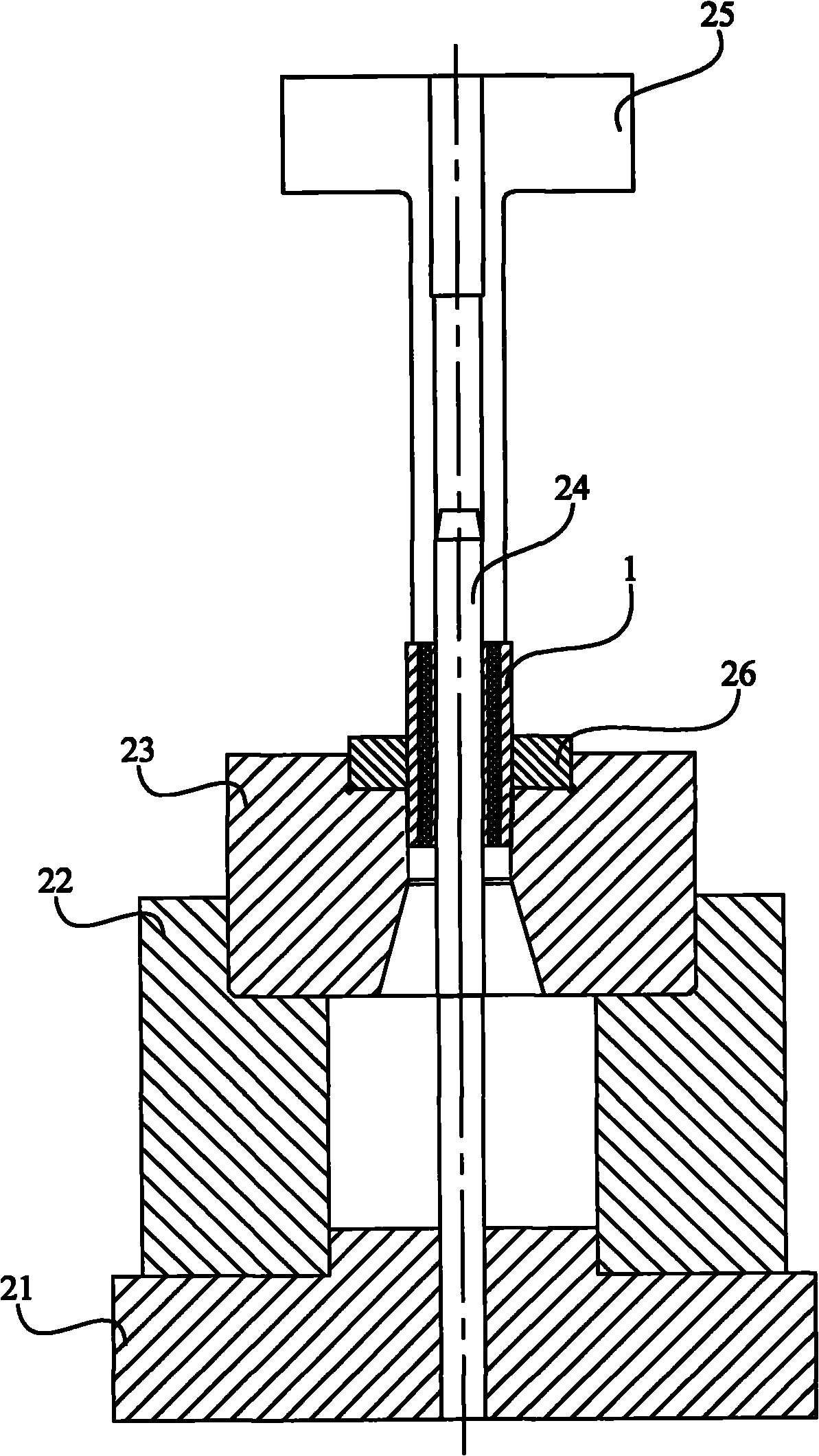

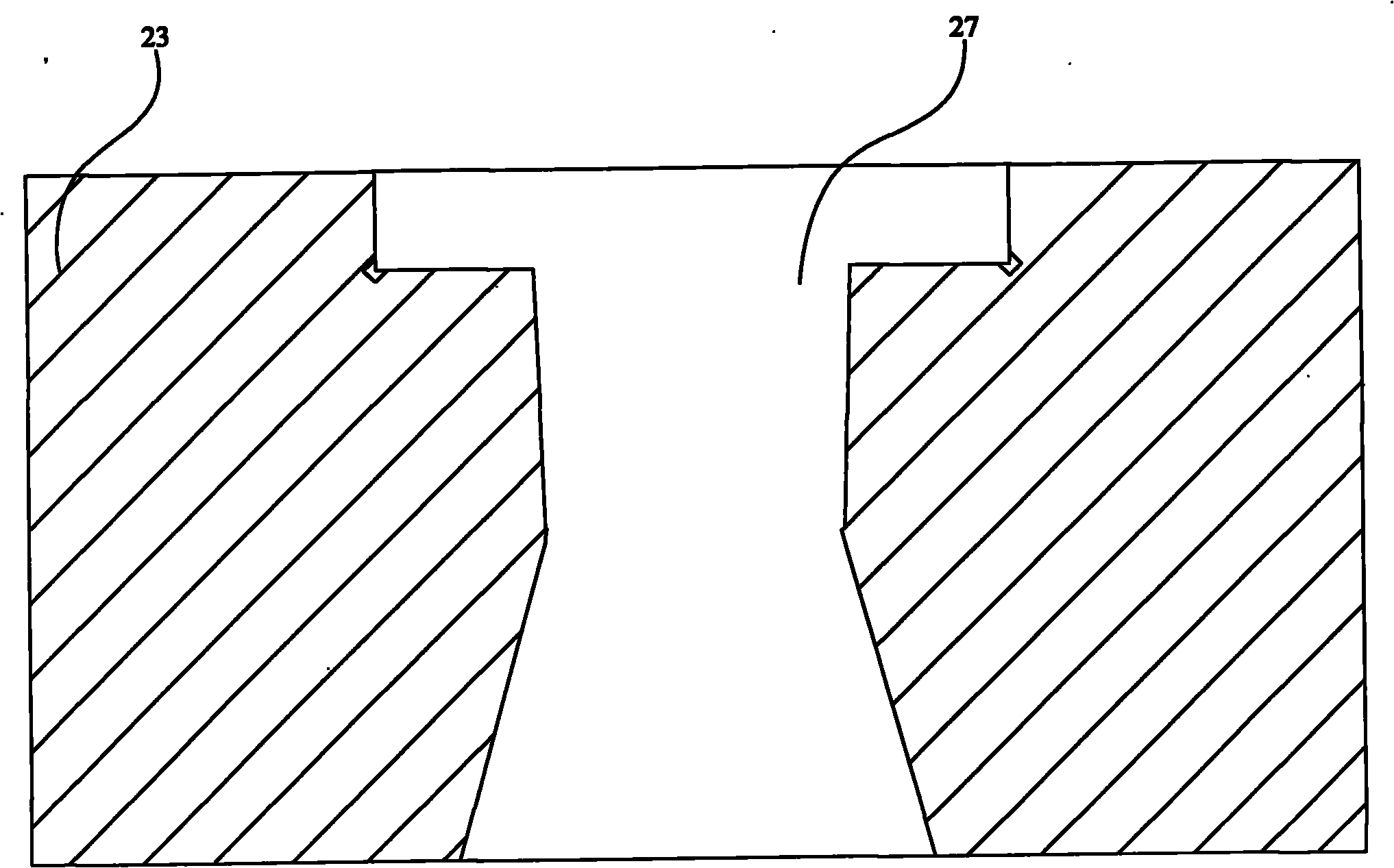

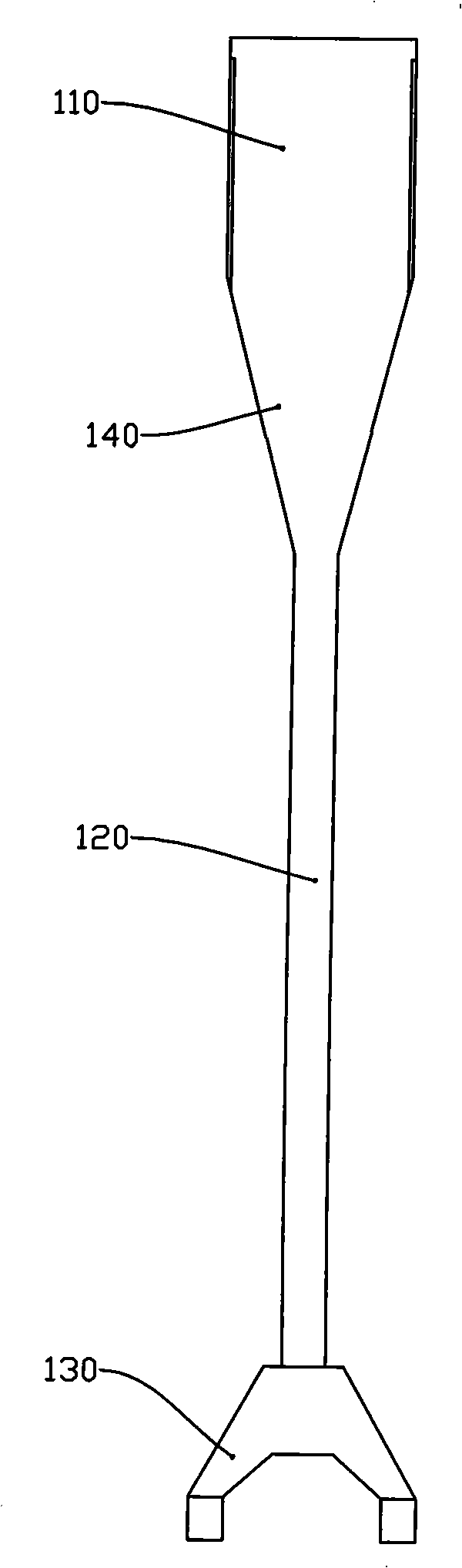

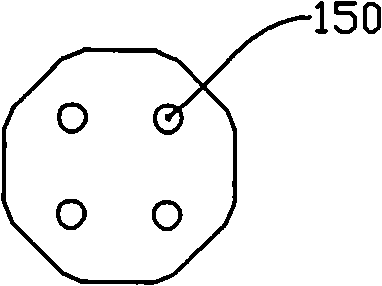

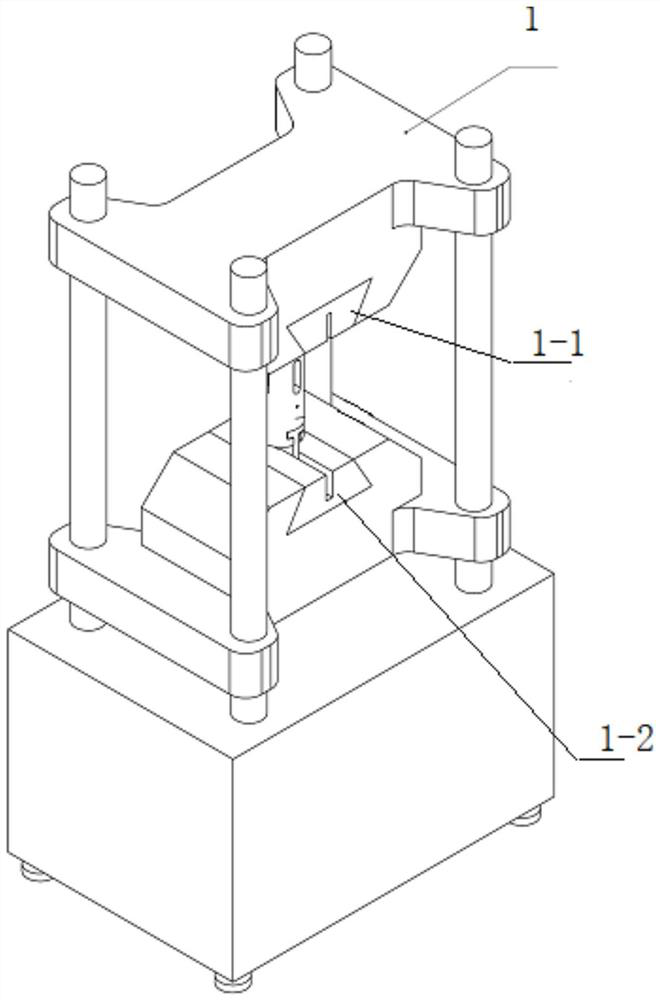

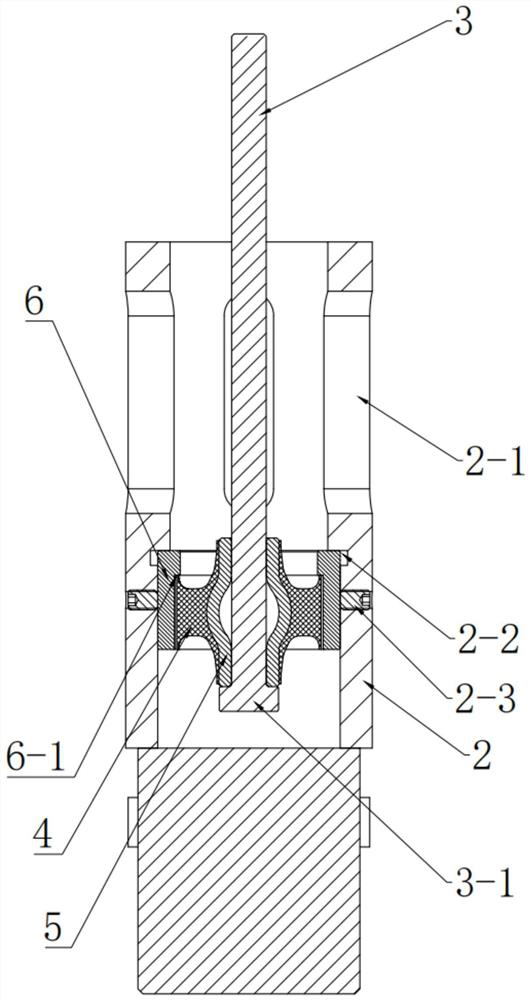

Rubber bushing compacting mould

InactiveCN101804425AExtended service lifeGood adhesionExtrusion diesExtrusion mandrelsEngineeringBush rubber

The invention discloses a rubber bushing compacting mould. The mould comprises a pressure head, a base, a support ring, a compacting block and a guide pillar, wherein the guide pillar is fixed on the base, the compacting block is provided with a through-hole, the upper part of the through-hole is tapered, the upper part of the taper of the through-hole is a 3-degree tapered bore, and the lower part of the through-hole is flared. The invention also comprises a baffle ring which is arranged on the compacting block. Therefore, by using the rubber bushing compacting mould of the invention, the external metal bushing can be compacted, the adhesive force between the internal and external metal bushings and the rubber layer can be increased, the rubber layer of the rubber bushing can be prevented from dropping and the service life of the rubber bushing can be prolonged.

Owner:AVIC HUIYANG AVIATION PROPELLER

Apparatus for capping sebific duct automatically

The invention relates to lithium battery packing and manufacturing equipment field, especially a gasket transfer device for bushing rubber tube on battery. An automatic bushing device, comprising a rubber-pulling rod inserting into the end part of the rubber tube; a material feeding clamp retractably disposed on middle of the rubber-pulling rod; a rubber-pulling clamp opener for controlling open / close of the material feeding clamp; a rubber-pulling rod pressing block pressed transversely on side of the top of the rubber-pulling rod; a column-shaped rubber bushing rod disposed right above the rubber-pulling rod, the rubber bushing rod is bushed with a pressed rubber bush, the rubber-pulling rod is fixedly connected with a rubber bushing rod shaft; a lifting upper rubber pressing shaft disposed right above the rubber bushing rod shaft; a rubber bushing swing rod fixedly connected with the rubber bushing rod shaft; a pressed rubber bush peak shaft fixedly connected with the rubber bushing swing rod; a rubber cutter disposed between the rubber bushing rod and the rubber pulling rod; a force conducting mechanism; a driving electric motor for driving the pressed rubber bush to rotate, the upper rubber pressing shaft to lift, and the rubber-pulling clamp opener to open and close. The device can realize automatically transferring rubber tube and bushing the rubber tube on the battery.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

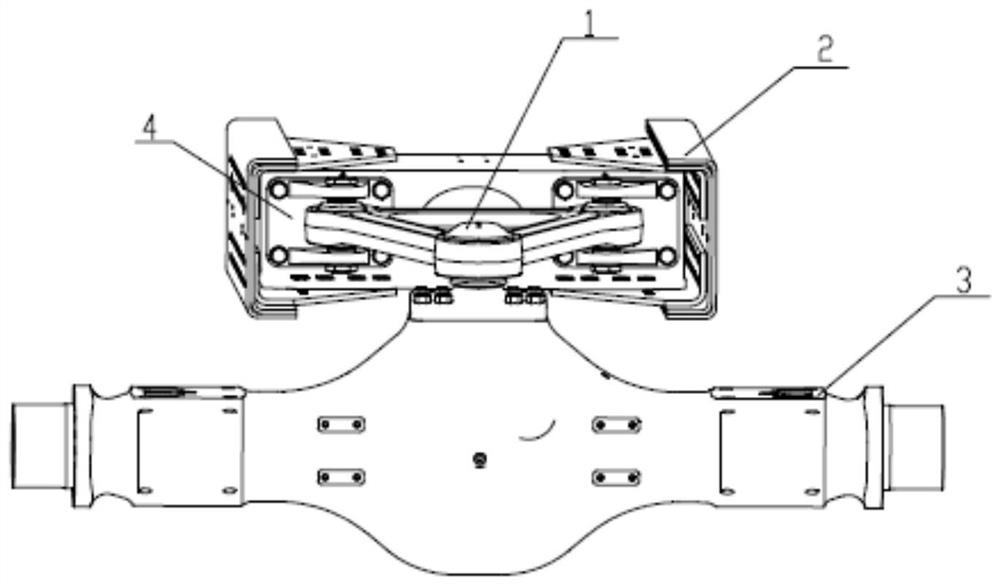

Trailing arm bush for coupled torsion beam axle

ActiveUS20150183290A1Easy to handleReduce exceptionInterconnection systemsResilient suspensionsEngineeringMechanical engineering

A trailing arm bush may include a cylindrical outer pipe, an inner pipe inserted to a central portion of the outer pipe at an interval, a first bush rubber unit, a second bush rubber unit and a third bush rubber unit that connect between an inner peripheral surface of the outer pipe and an outer peripheral surface of the inner pipe, respectively, a hollow void part formed between the inner peripheral surface of the outer pipe and the outer peripheral surface of the inner pipe, and a stopper attached to the inner peripheral surface of the outer pipe and disposed among the first bush rubber unit, the second bush rubber unit and the third bush rubber unit.

Owner:HYUNDAI MOTOR CO LTD +1

Front suspension damping mechanism for vehicle cab

InactiveCN103387013AIncrease in sizeIncrease contact areaRubber-like material springsLoading-carrying vehicle superstructuresVulcanizationMechanical engineering

A front suspension damping mechanism for a vehicle cab comprises an outer drum, rubber and an inner drum; the rubber is filled between the inner and outer drums, and is integrated with the inner and outer drums by vulcanization and pasting; the axes of the inner and outer drums are not coincided; the outer drum is used for matching with a front suspension hole; the inner drum is used for assembling a composite bush; the rubber plays the functions of damping and buffering; two oppositely arranged process holes parallel with the axes of the inner and outer drums are formed in the rubber layer, and are positioned in a section vertical to the axes of the inner and outer drums; and the profiles of the process holes are in arc transition so as to improve the stress dispersing capacity of a product and eliminate the local stress concentration phenomenon after bearing. The shape of the profiles of the process holes is set according to the rigidity value in the main bearing direction (the vertical direction), so the damping and buffering properties of the mechanism are improved, and the service life is prolonged. The front suspension damping mechanism for the vehicle cab has excellent damping, sound isolating and buffering properties.

Owner:襄阳群龙汽车部件股份有限公司

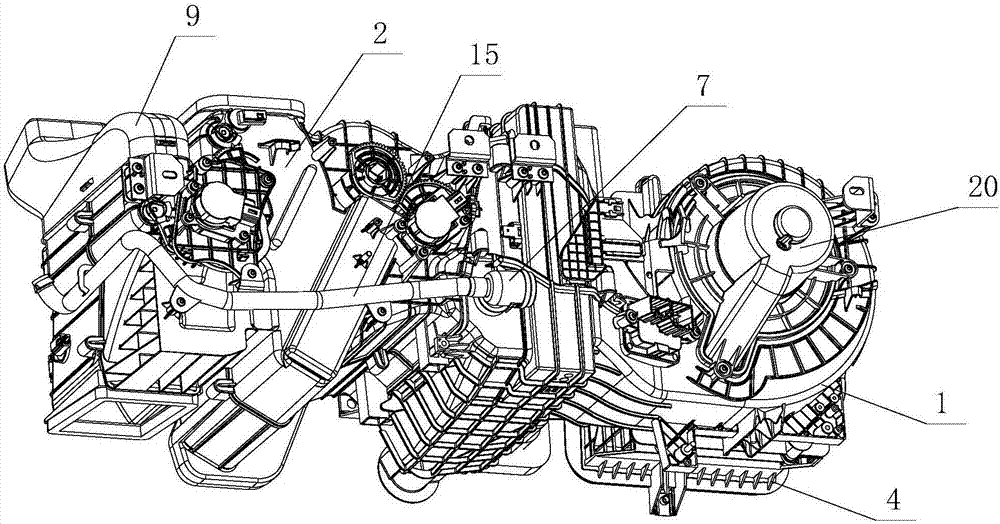

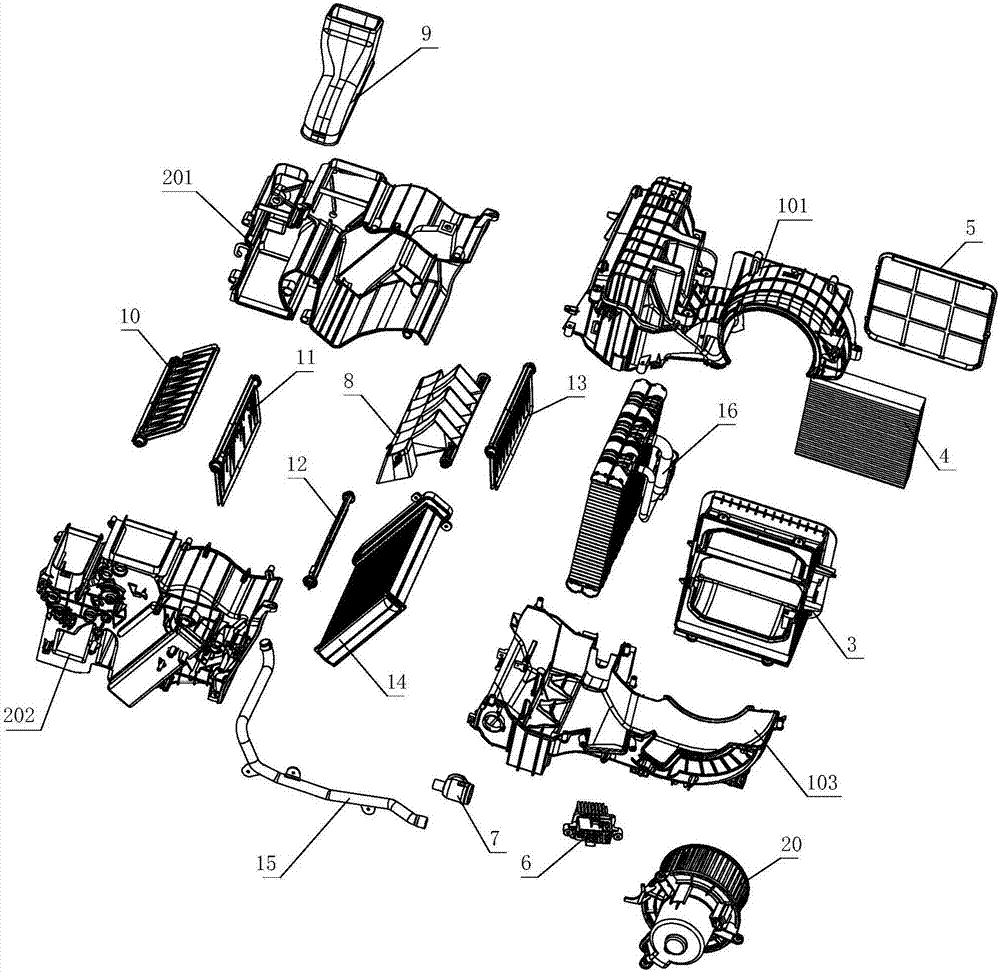

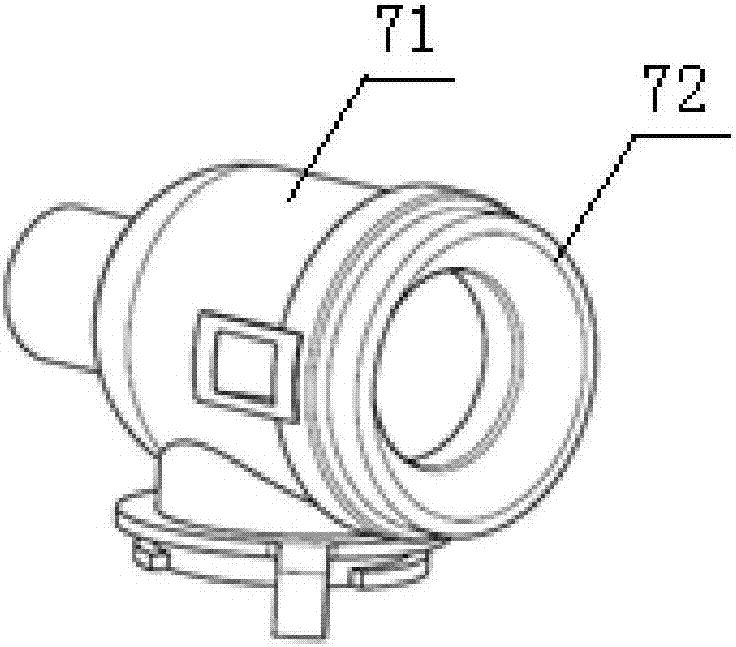

Automobile air conditioner assembly

ActiveCN107323211APrevent air leakageImprove air tightnessAir-treating devicesVehicle heating/cooling devicesInterference fitComing out

The invention relates to an automobile air conditioner technology, in particular to an automobile air conditioner assembly. The Automobile air conditioner assembly comprises an air blower assembly and an air distributing device assembly. An air door is matched with an air distributing device shell through bearing bush rubber edges to avoid air leakage of the two ends of the air door and improve the air tightness of the air door; through interference fit design of a boss and a groove which are designed on / in the matching surface of the shell, external air leakage is avoided, and the air tightness of an overall structure is further improved; the technical scheme for improving the reliability of an air conditioner is divided into improvement of the shock-resisting property and improvement of the high-and-low-temperature-resisting property; a specific air blocking mechanism is arranged at the bottom of an evaporator to ensure that air entering through an air inlet grid can pass through the evaporator, and refrigerating efficiency of the evaporator is improved, and the situation that condensate water does not splash in the discharging process is guaranteed; and a hot air channel and a cold air channel are each formed into a cylinder shape with the two open ends, cold air coming out of the evaporator is guided to a hot air area, and hot air coming out of an air heating core is guided to a cold air area, so that the cold air and the hot air are effectively mixed in a mixing area.

Owner:DONGFENG BEHR THERMAL SYST

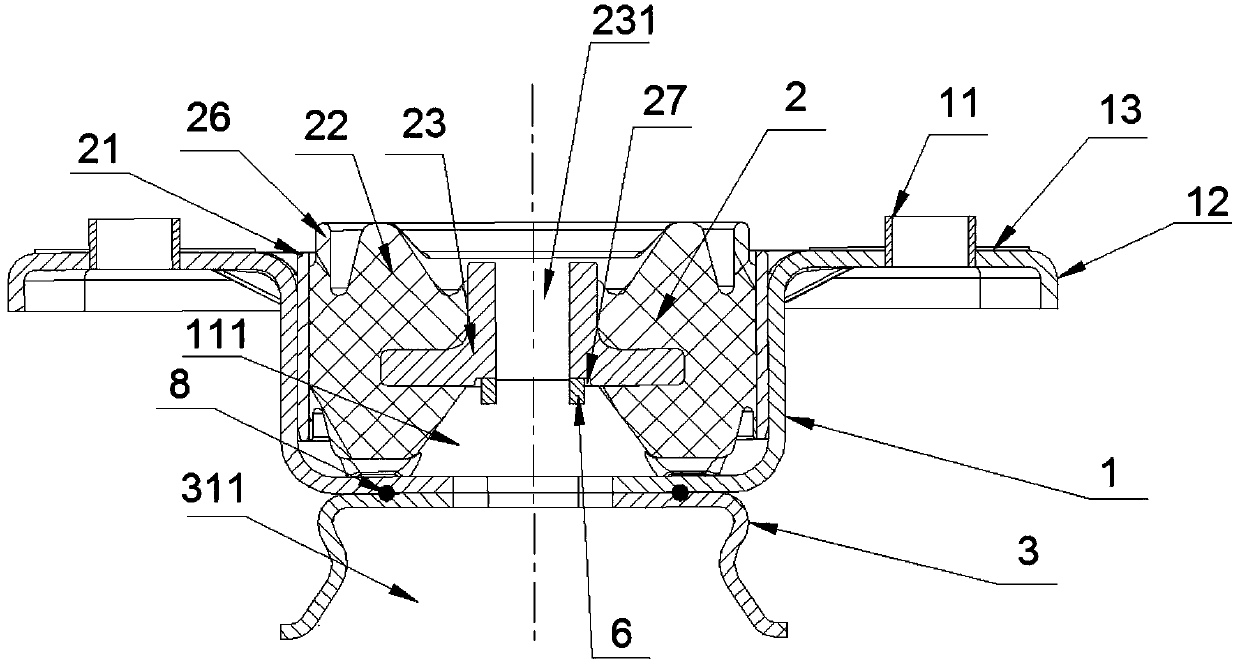

Connecting device of rear shock absorber and automobile

The invention relates to a connecting device of a rear shock absorber and an automobile so as to solve the problem that an upper mounting seat type rear shock absorber connecting device in the prior art cannot be matched dynamic force of a shock absorber in different forms, and consequently the whole vehicle comfort is poor. The connecting device of the rear shock absorber comprises a mounting framework connected with a vehicle body and a rubber bushing arranged in a first mounting groove, and the end face, facing the vehicle body, of the mounting framework is provided with the first mountinggroove; the rubber bushing is partially exposed to the first mounting groove so as to be in contact with the vehicle body; and the rubber bushing comprises an inner frame, an outer frame and a rubberlayer which form a whole through vulcanization, the rubber layer is divided by the inner frame in the deformation direction of the rubber layer into a first part and a second part which are in asymmetrical arrangement, and therefore the static rigidity of the first part in the deformation direction is different from the static rigidity of the second part in the deformation direction.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

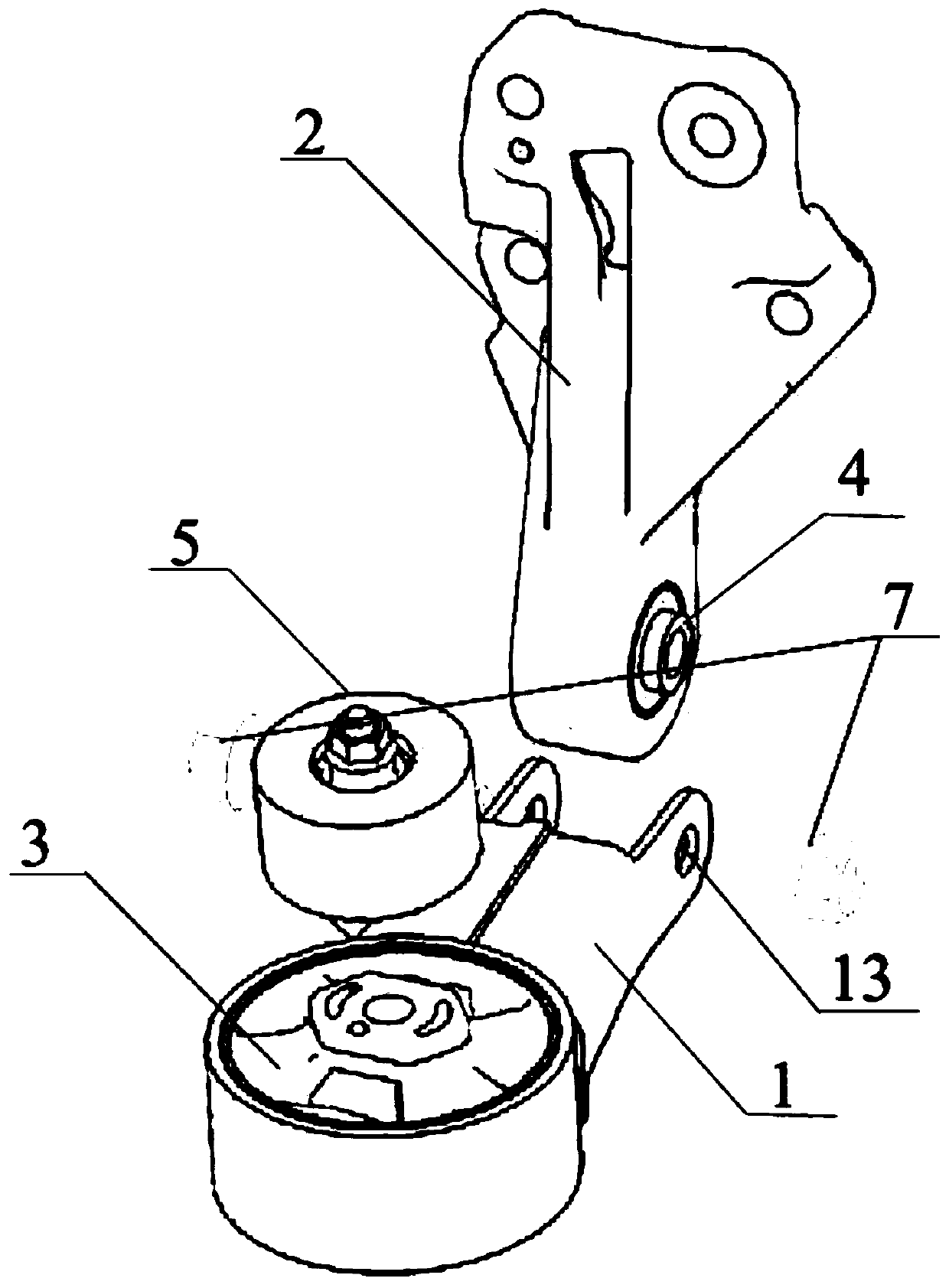

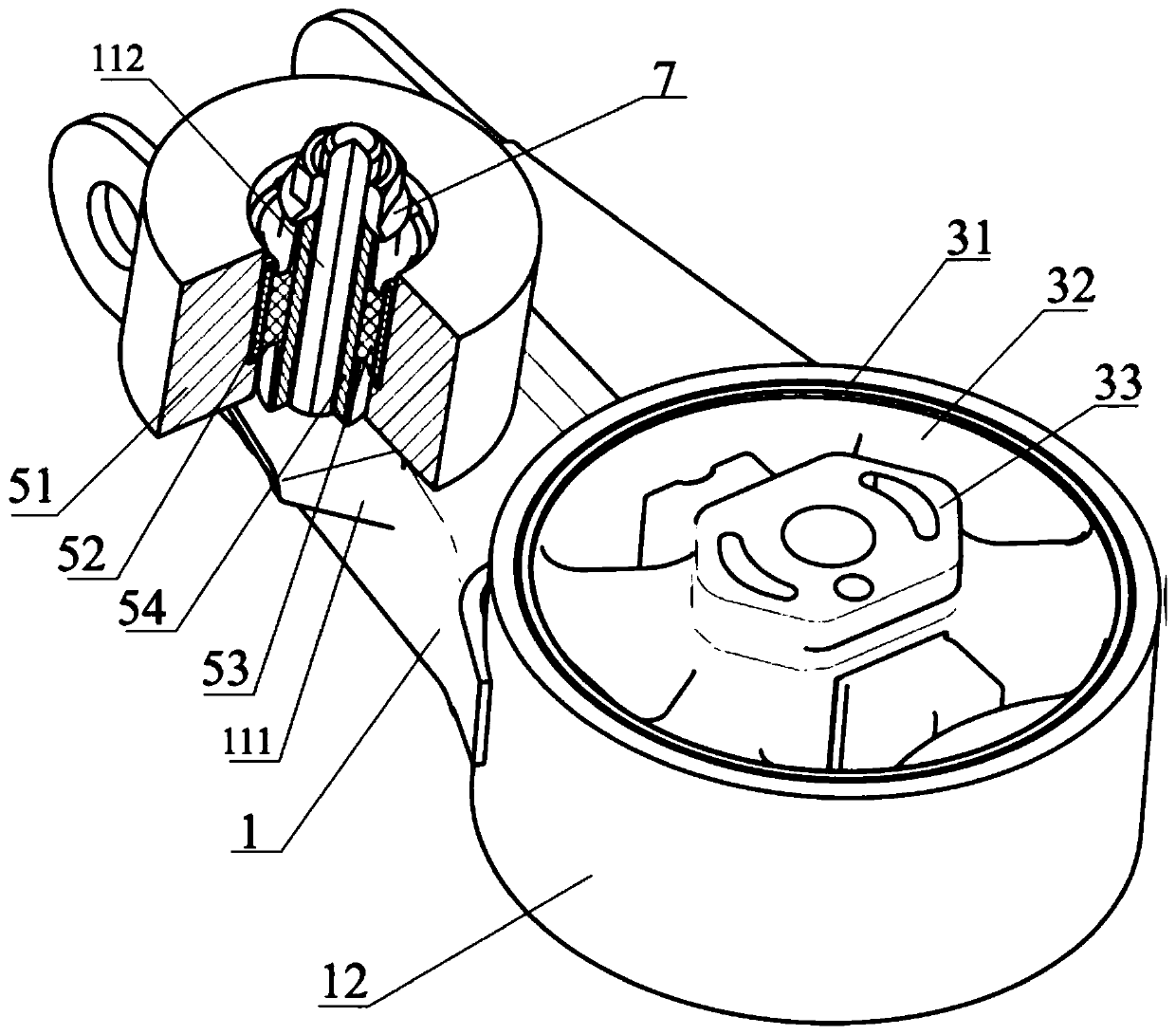

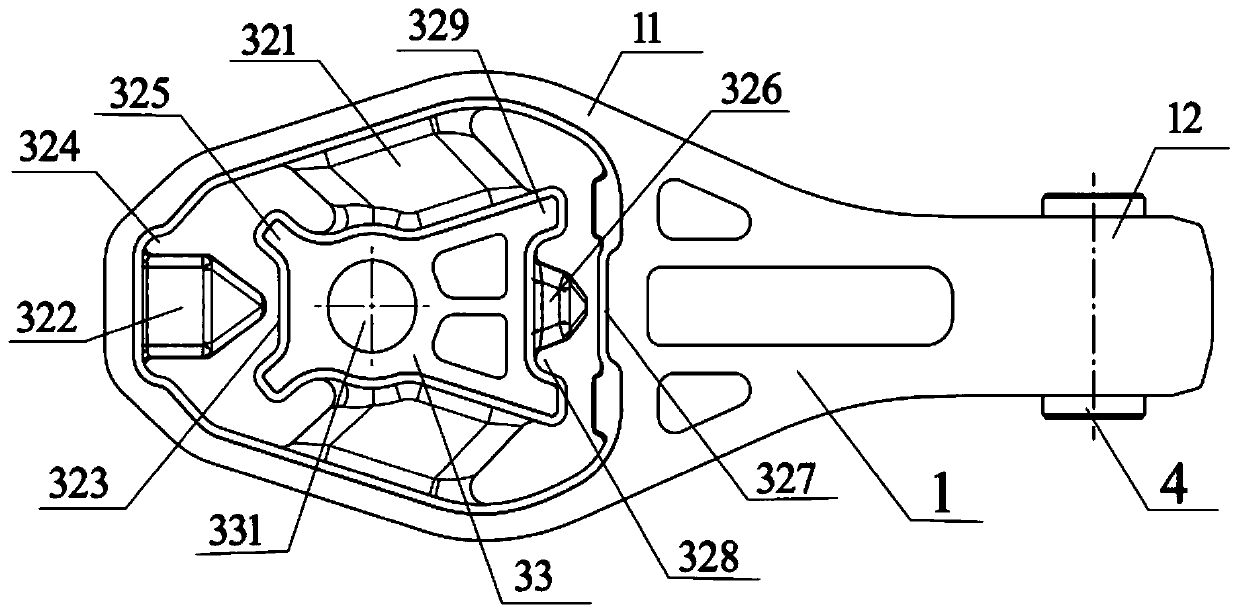

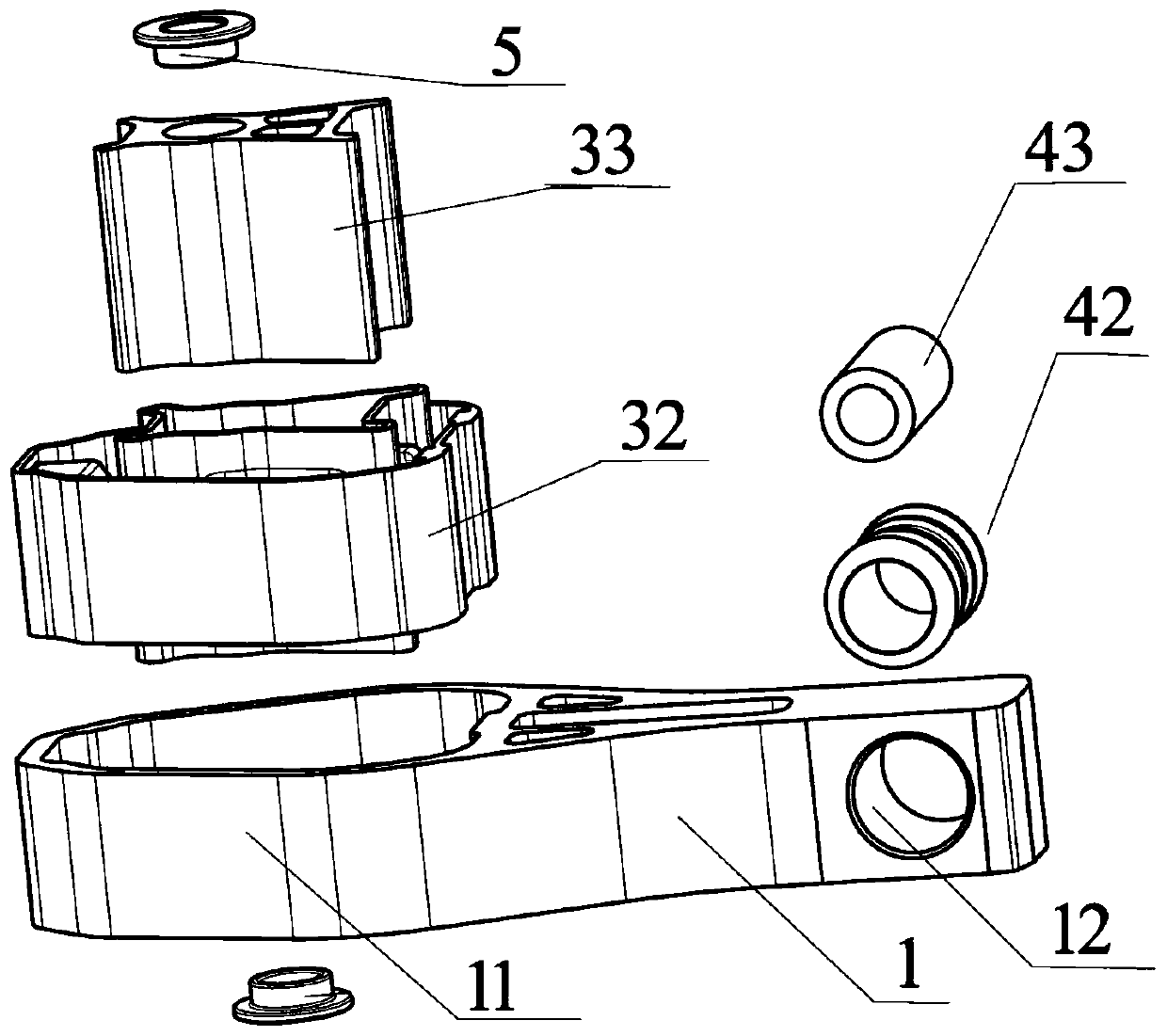

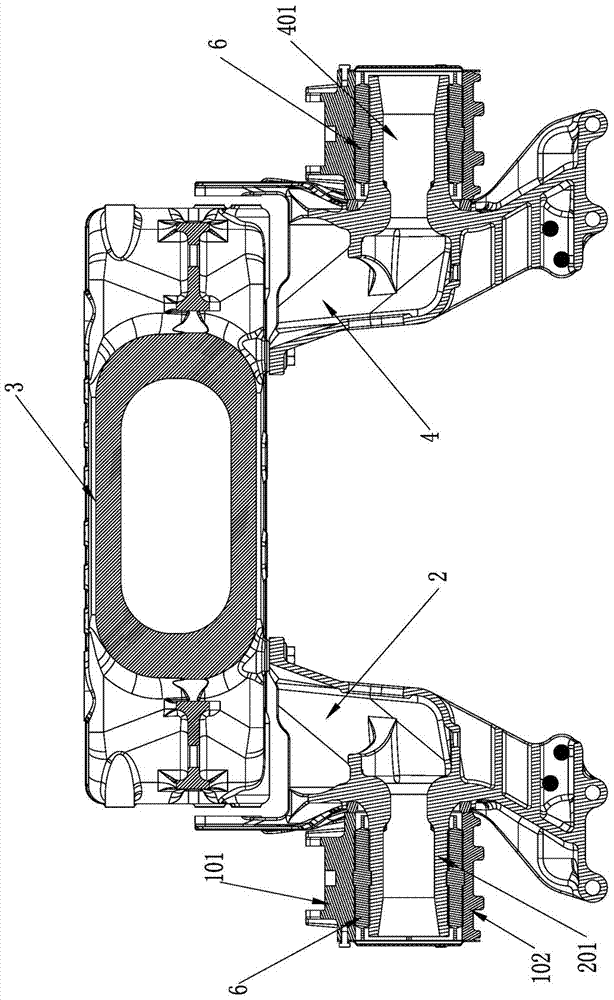

Anti-torque pull rod and mounting structure thereof

PendingCN111845313AStable supportImprove scalabilityJet propulsion mountingInternal combustion mountingVehicle frameBush rubber

The invention provides an anti-torque pull rod, which comprises a large-end bushing, a small-end bushing and a pull rod bracket, wherein the large-end bushing comprises a large-end bushing inner pipe,a large-end bushing rubber body and a large-end bushing outer pipe; the large-end bushing outer pipe is provided with a notch, one end of the pull rod bracket penetrates through the notch to be connected with the large-end bushing inner pipe, the other end of the pull rod bracket is connected with the small-end bushing, the large-end bushing outer pipe is provided with a first fixing hole, and the first fixing hole is used for allowing a fixing piece to penetrate through and fixing the large-end bushing outer pipe to an auxiliary frame. The invention further discloses an anti-torque pull rodmounting structure. The anti-torque pull rod of the anti-torque pull rod mounting structure is the anti-torque pull rod; the anti-torsion pull rod mountingstructure further comprises an auxiliary frame, the auxiliary frame comprises an upper layer plate and a lower layer plate, the upper layer plate and the lower layer plate form a mounting opening, second fixing holes are formed in the upper layer plate and the lower layer plate, the large-end bushing is arranged in the mountingopening, and the fixing piece penetrates through the first fixing hole and the second fixing hole to fix the large-end bushing outer pipe to the auxiliary frame.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

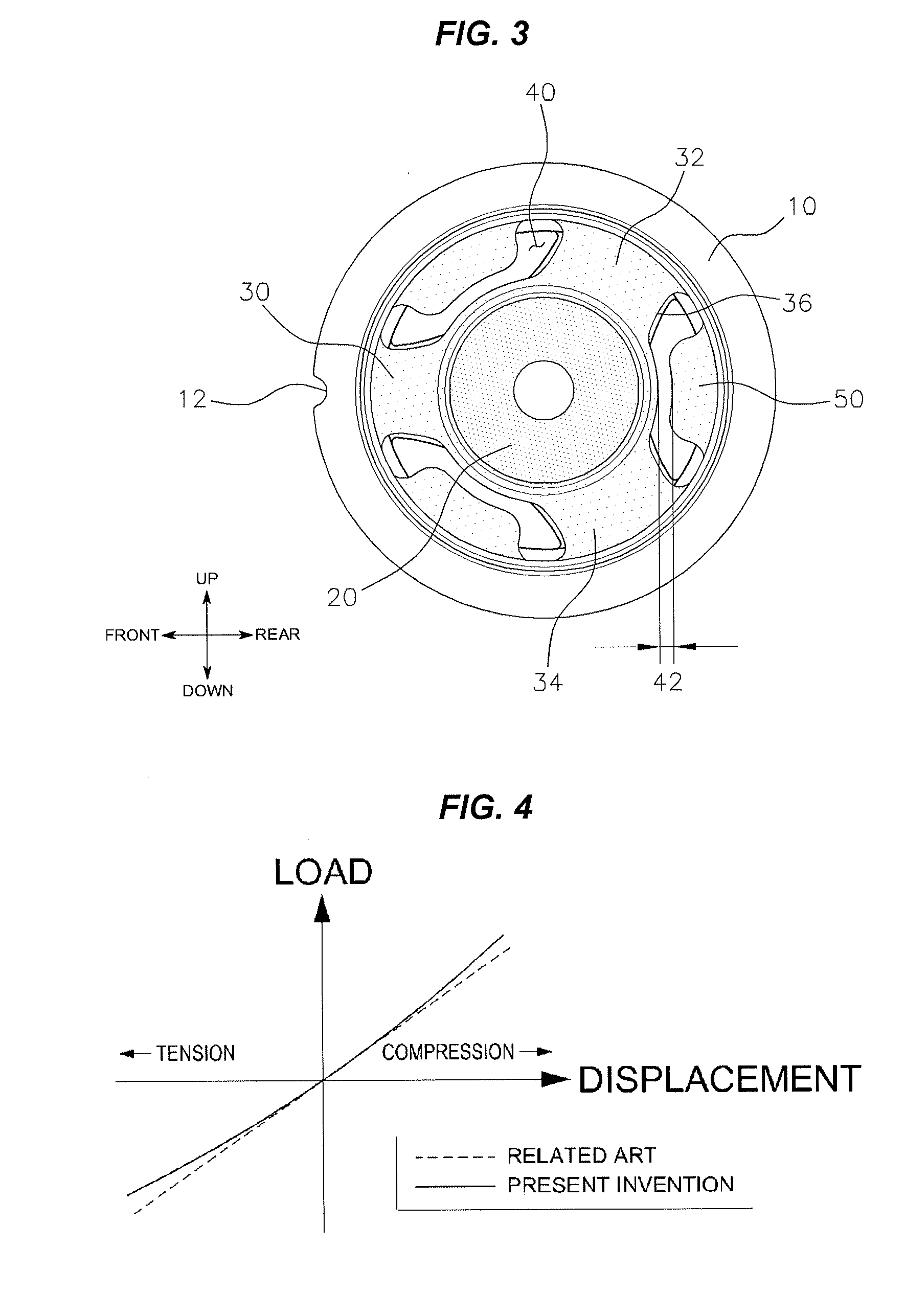

Torque rod

ActiveUS10981441B2Save spaceImprove rendering capabilitiesNon-rotating vibration suppressionJet propulsion mountingElastomerRubber elasticity

A torque rod for straddling connection target members including a rod member and a rubber bushing provided to a lengthwise end of the rod member. The rubber bushing includes an inside shaft member, an outer peripheral member to be attached to one of the connection target members, and a rubber elastic body connecting the inside shaft member and the outer peripheral member. The rubber bushing is a part separate from the rod member and the end of the rod member is fixed to the inside shaft member. The rod member includes an abutting face to abut against the one of the connection target members without interposing the outer peripheral member of the rubber bushing. A stopper to limit an amount of elastic deformation of the rubber elastic body in the rubber bushing is constituted by including the abutting face of the rod member.

Owner:SUMITOMO RIKO CO LTD

Integrated triangular thrust rod assembly

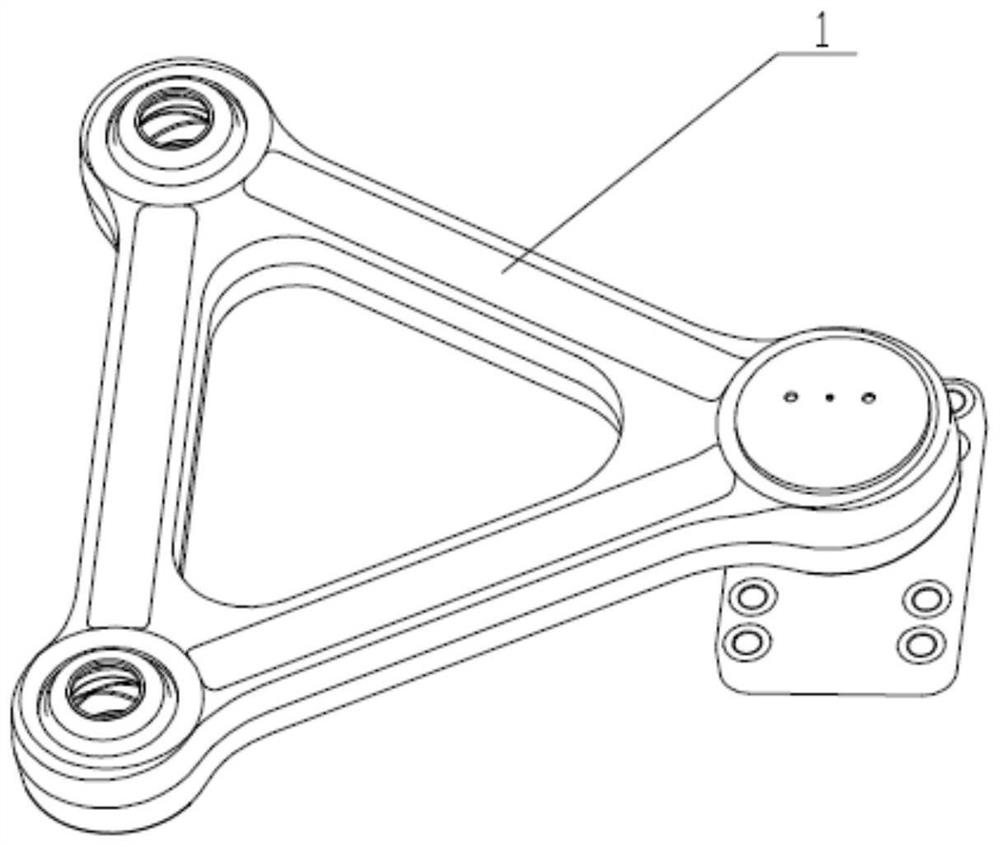

ActiveCN111619297AHigh strengthImprove fatigue resistancePivoted suspension armsVulcanizationCirclip

The invention discloses an integrated triangular thrust rod assembly. The thrust rod assembly comprises a triangular thrust rod, a spacing bush, a rubber sealing ring I, a rubber vulcanized joint bearing assembly, an elastic check ring, a thrust rod support, a rubber sealing ring II, a metal joint bearing assembly, a pressing plate, a nut II, a sealing cover and a grease nozzle. A triangular thrust rod is a flat triangular structure formed through integral forging, a middle portion of the triangular thrust rod is a triangular hollow structure, a rod body portion of the triangular thrust rodis an ''I''-shaped structure, and cylindrical cavities are arranged in three end portions of the triangular thrust rod. The thrust rod support, the rubber sealing ring II, the metal joint bearing assembly, the pressing plate, the nut II, the sealing cover and the grease nozzle are arranged in a cavity in a top end. Inner structures of two side end cavities are the same, and each side end cavity comprises the rubber vulcanization joint bearing assembly, the rubber sealing ring I, the spacing bush and the elastic check ring. The assembly is simple and reliable in structure, extremely high in safety coefficient and convenient to mount and dismount.

Owner:SINO TRUK JINAN POWER

Automobile control arm bushing rubber material and preparation method

The present invention discloses an automobile control arm bushing rubber material and a preparation method, the rubber material is mainly made from the following components by weight: 40 parts of polyethylene terephthalate, 30-50 parts of chlorosulfonated polyethylene, 40 to 60 parts of natural rubber, 1-9 parts of ethyl benzoate, 2-6 parts of glyceryl stearate citrate, 1-5 parts of zinc oxide, 2-8 parts of carbon black, 0.2 to 0.6 part of an antioxidant, 0.1 to 0.7 part of an accelerator, 0.5 to 1.5 parts of sulfur and 10 to 20 parts of paraffin oil. Compared with the prior art, the automobile control arm bushing rubber material obtained by the preparation method is simple in process and low in cost, not only has the heat and wear resistance and other properties of automobile control arm bushings of the prior art, and to be most important, the automobile control arm bushing rubber material combines hardness and fatigue resistance and excellent overall performance.

Owner:SUZHOU GOODTIME TECH DEV

Wearproof bushing rubber composite material and preparation method thereof

InactiveCN106751060AImprove wear resistanceImprove high temperature resistanceSodium stearateTriethylamine phosphate

The invention discloses a wearproof bushing rubber composite material and a preparation method thereof. The wearproof bushing rubber composite material is prepared from the following raw materials in parts by weight: 20-48 parts of chlorinated polyethylene rubber, 15-30 parts of neoprene, 10-25 parts of brominated butyl rubber, 15-30 parts of natural rubber, 3-10 parts of calcium carbonate, 2-6 parts of pentaerythritol phosphate, 3-6 parts of zinc borate, 2-6 parts of aluminum nitride, 3-9 parts of tungsten boride micropowder, 6-14 parts of silicon carbide micropowder, 2-5 parts of poly(sodium-p-styrenesulfonate), 4-9 parts of paraffin, 8-16 parts of carbon nano tubes, 1-5 parts of zinc dibutyl dithiocarbamate, 3-8 parts of nano silicon oxide, 1-3 parts of triethyl phosphate, 0.8-2.5 parts of mono lauryl phosphate potassium, 3-8 parts of graphene, 1-5 parts of sodium stearate and 1-5 parts of an anti-wear agent. The wearproof bushing rubber composite material disclosed by the invention has good wear resistance and high temperature resistance, thus decreasing damage of a bushing caused by high temperature and wear.

Owner:安徽微威环保科技有限公司

Bushing rubber prepared raw material under lightening development of high-grade cars

The invention discloses a bushing rubber prepared raw material under lightening development of high-end cars. The bushing rubber prepared raw material comprises the following components in parts by weight: 80 to 90 parts of natural rubber, 10 to 20 parts of butadiene rubber, 2 parts of naphthenic oil, 3.5 parts of zinc oxide, 2 parts of anti-aging agent IPPD (isopropyl-phenyl-paraphenylene diamine), 1 part of anti-aging agent TMQ (trimethyl dihydroquinoline), 2 to 3 parts of microcrystal wax, 6 parts of carbon black N683, 27 parts of carbon black DUREXO, 1.7 parts of sulfur, 1.5 parts of activating agent Struktol ZEH-DL and 1.82 parts of accelerating agent. With the adoption of the bushing rubber prepared raw material under lightening development of the high-end cars prepared by the prepared raw materials, the presulfiding effect and the anti-aging performance of a rubber material can be effectively improved, and the product durability is improved.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

Preparation method of rubber reinforcing agent, automobile plate spring bushing sizing material containing rubber reinforcing agent and preparation method thereof

The invention relates to the technical field of rubber, and discloses a preparation method of a rubber reinforcing agent. The preparation method comprises the following steps: carrying out acid washing and crushing on rice husk; mixing the crushed rice husks with humic acid and an ethanol aqueous solution, and adding the mixture into a reactor for reaction to obtain a first intermediate; firing the first intermediate; and after firing, crushing and grinding to obtain a finished product. The invention discloses an automobile plate spring bushing rubber material containing the rubber reinforcingagent and a preparation process thereof. The rice husk and humic acid are grafted to form the copolymer so that the adsorption performance and active groups in the copolymer can be improved, and meanwhile, the strength of the copolymer can be enhanced through carbonization treatment; when the copolymer is used as a rubber reinforcing agent, the mechanical property and the wear resistance of rubber can be improved.

Owner:SUINING SENDI AUTO PARTS MFG CO LTD

Vehicle balance suspension with balance axles and brackets integrated into one

PendingCN107415626AReduce overall weightGuaranteed connection strengthInterconnection systemsPivoted suspension armsEngineeringThrust lever

In order to reduce the weight of a vehicle balance suspension, ensure the strength and improve the load condition, the invention provides the vehicle balance suspension with balance axles and brackets integrated into one. A left balance axle functional part is integrally cast and molded at a left bracket to form a left bracket and axle integrated part. A right balance axle functional part is integrally cast and molded at a right bracket to form a right bracket and axle integrated part. Balance axle bushes are integral rubber bushes which are integrally molded and an outer limit annular boss and an inner limit annular boss are respectively arranged at the outer circumference and the inner hole of each of the rubber bushes. Each of the integral rubber bush is provided with an axial opening on the circumference, and the integral rubber bushes are unfolded through the axial openings for assembling. Lower thrust lever mounting parts of the left bracket and axle integrated part and the right bracket and axle integrated part are connected through a reinforcing connection plate. The inner limit annular bosses of the balance axle bushes are matched with fixing grooves on the left balance axle functional part and the right balance axle functional part. The outer limit annular bosses of the balance axle bushes are matched with the fixing grooves on balance hubs.

Owner:SHIYAN PRECISION MFR

Ceiling structure capable of being freely dismounted

The invention provides a ceiling structure capable of being freely dismounted. The ceiling structure comprises rubber bushings, rubber broached bushings, broached grooves, limiting baffle rings, reserved threading pipes, short welded pipes, angle iron and broached holes. A keel frame body is of a rectangular frame structure which is formed by welding four rectangular pipes, and hanging pipes are also each of a rectangular frame structure which is formed by welding four rectangular welded pipes. Two hanging pipe cross struts are welded to the inner side face of a frame of each hanging pipe, andthe pipe walls of the two short edge welded pipes of the rectangular frame structure of each hanging pipe are each provided with the corresponding outward-extending short welded pipe in a welded mode. Reinforced supporting pipes are each of a rectangular pipe structure, the left end faces and the right end faces of the reinforced supporting pipes are each provided with the corresponding reservedthreading pipe which is of a circular pipe structure in a welded mode, and inner cavities of guiding sleeves are further each provided with the corresponding rubber bushing in a gluing matched mode tobe provided with structures of the corresponding reinforced supporting pipe and the corresponding hanging pipe in an inserted mode to achieve sliding adjusting, so that more convenience is achieved when the inserted reinforced supporting pipes and hanging pipes are mounted on the keel frame body.

Owner:苏州市永盛防火材料有限公司

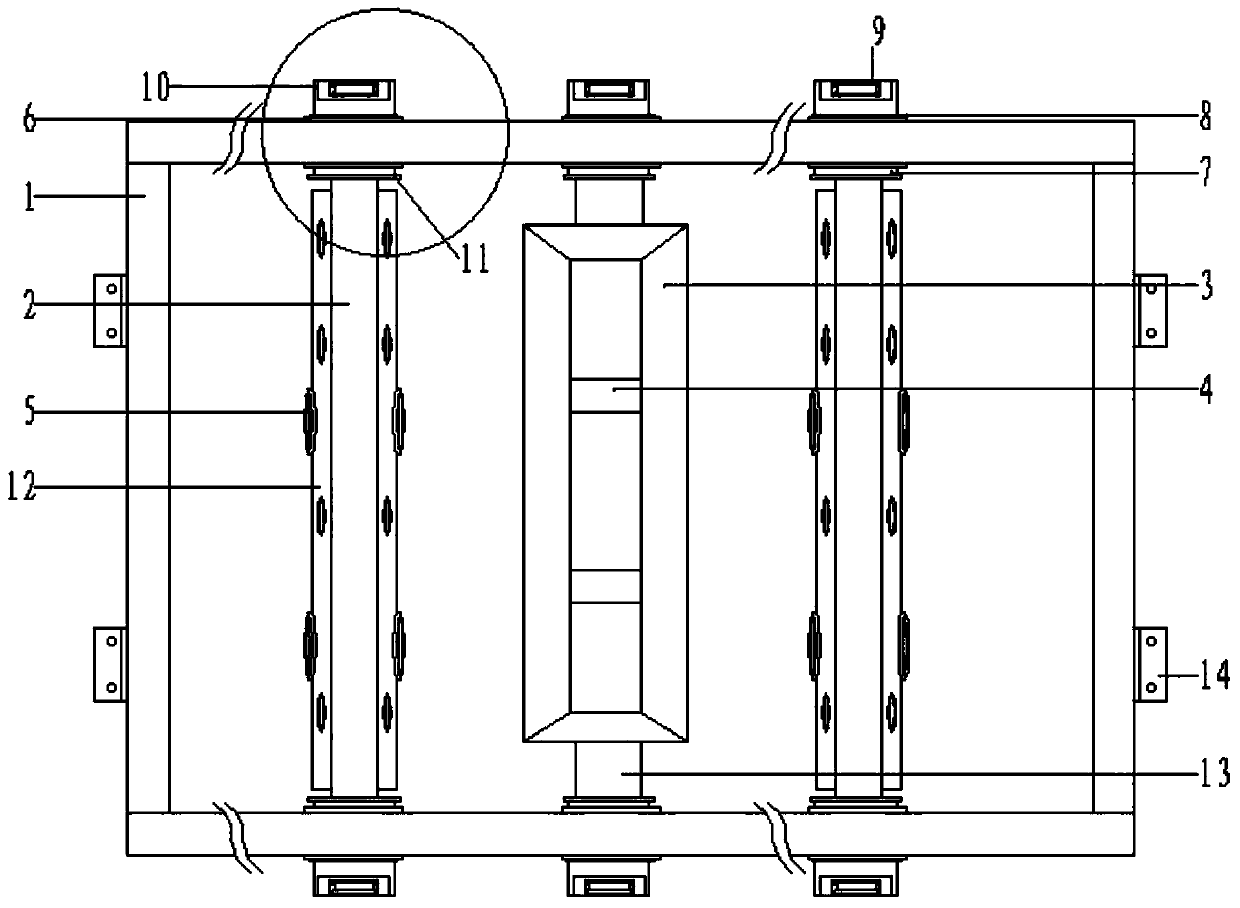

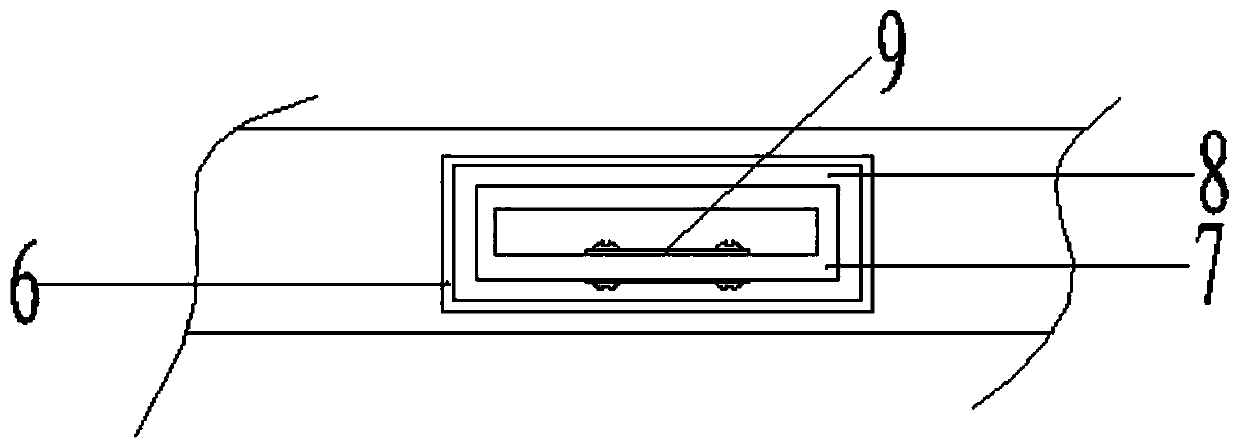

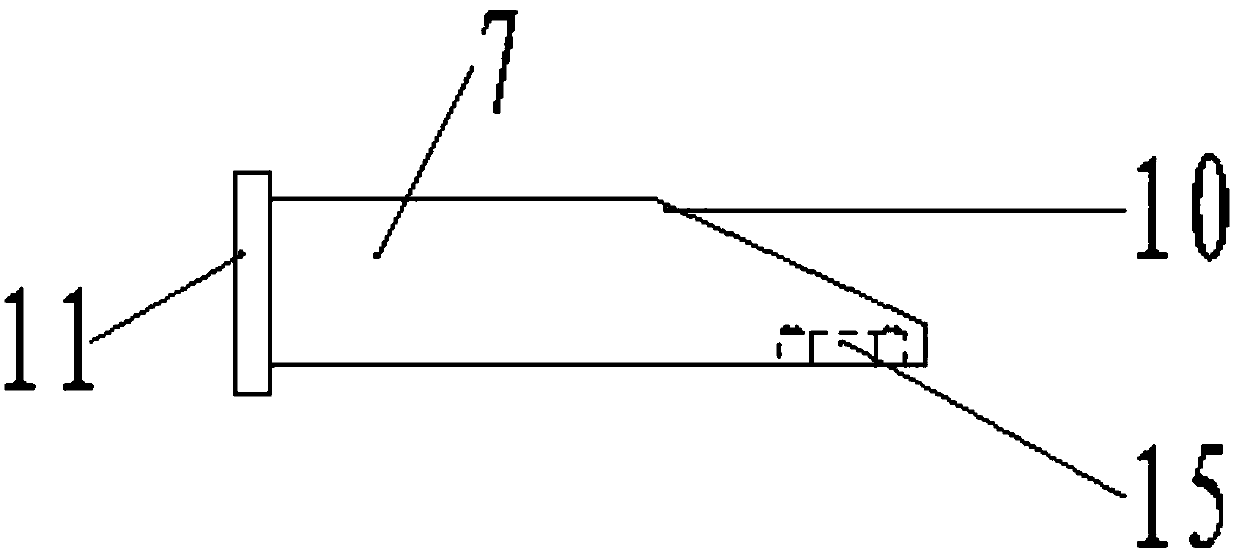

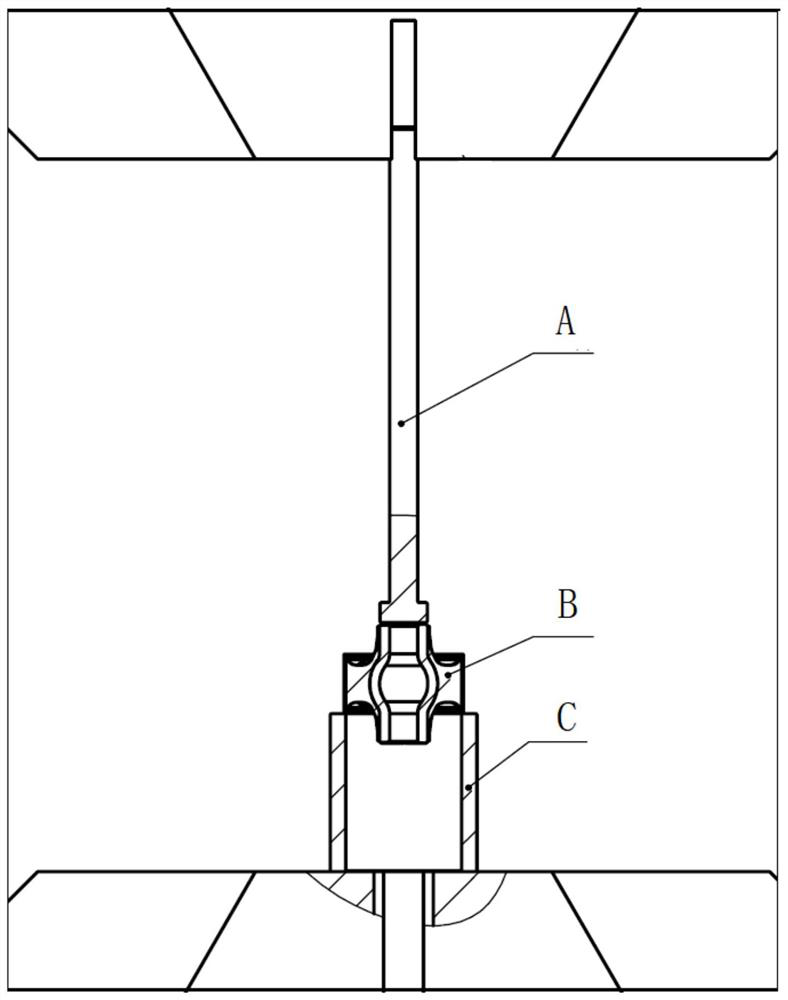

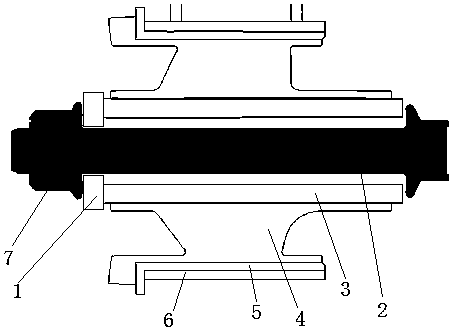

Swing arm bushing rubber and framework pull-off test tool

PendingCN113640214AImprove securityProcess stabilityUsing mechanical meansMaterial analysisControl engineeringProcess engineering

The invention relates to the field of automobile part experiment tools, in particular to a swing arm bushing rubber and framework pull-off test tool which comprises a tension testing machine, a bushing inner positioning base, a bushing outer positioning base and a pull rod, wherein the tension testing machine is provided with a lower clamping mechanism for fixing the bushing outer positioning base and an upper clamping mechanism for fixing the pull rod, an outer framework is fixed in the bushing outer positioning base, the pull rod is connected with an inner framework, and the upper clamping mechanism moves upwards to drive the pull rod to separate the inner framework from the outer framework. Due to the fact that the separation process is achieved in the bushing outer positioning base, the problem that the bushing pops up cannot occur.

Owner:ZHEJIANG WANXIANG SYST +1

Nut fixing structure for automobile subframe

The invention provides a nut fixing structure for an automobile subframe. The nut fixing structure comprises an automobile body, the automobile body is mounted and fixed through a subframe assemblingbolt, a bushing inner steel sleeve is arranged on the exterior of the subframe assembling bolt, bushing rubber is arranged on the exterior of the bushing inner steel sleeve, impact load is reduced through the bushing rubber, and a bushing outer steel sleeve is arranged on the exterior of the bushing rubber. Through the bushing rubber, fixing of a subframe is changed into flexible contact, abnormalsound of the subframe is avoided, the problem that the automobile subframe is prone to generating the abnormal sound during use is solved, as for flexible connection, the rubber bushing is pressed into the subframe, thus the impact load transmitted to the automobile body from the road surface is reduced, and thus riding comfortableness is improved.

Owner:WUHU POWER TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com