Torsion-resistant suspension structure of power assembly

A powertrain and torsion suspension technology, which is applied in power units, jet propulsion units, internal combustion propulsion units, etc., can solve the problems of affecting the NVH performance of the whole vehicle, large vibration and noise in the vehicle, and high acceleration noise in the third gear area. Achieve the effect of improving NVH performance, reducing vibration intensity, and smoothing the change of stiffness curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

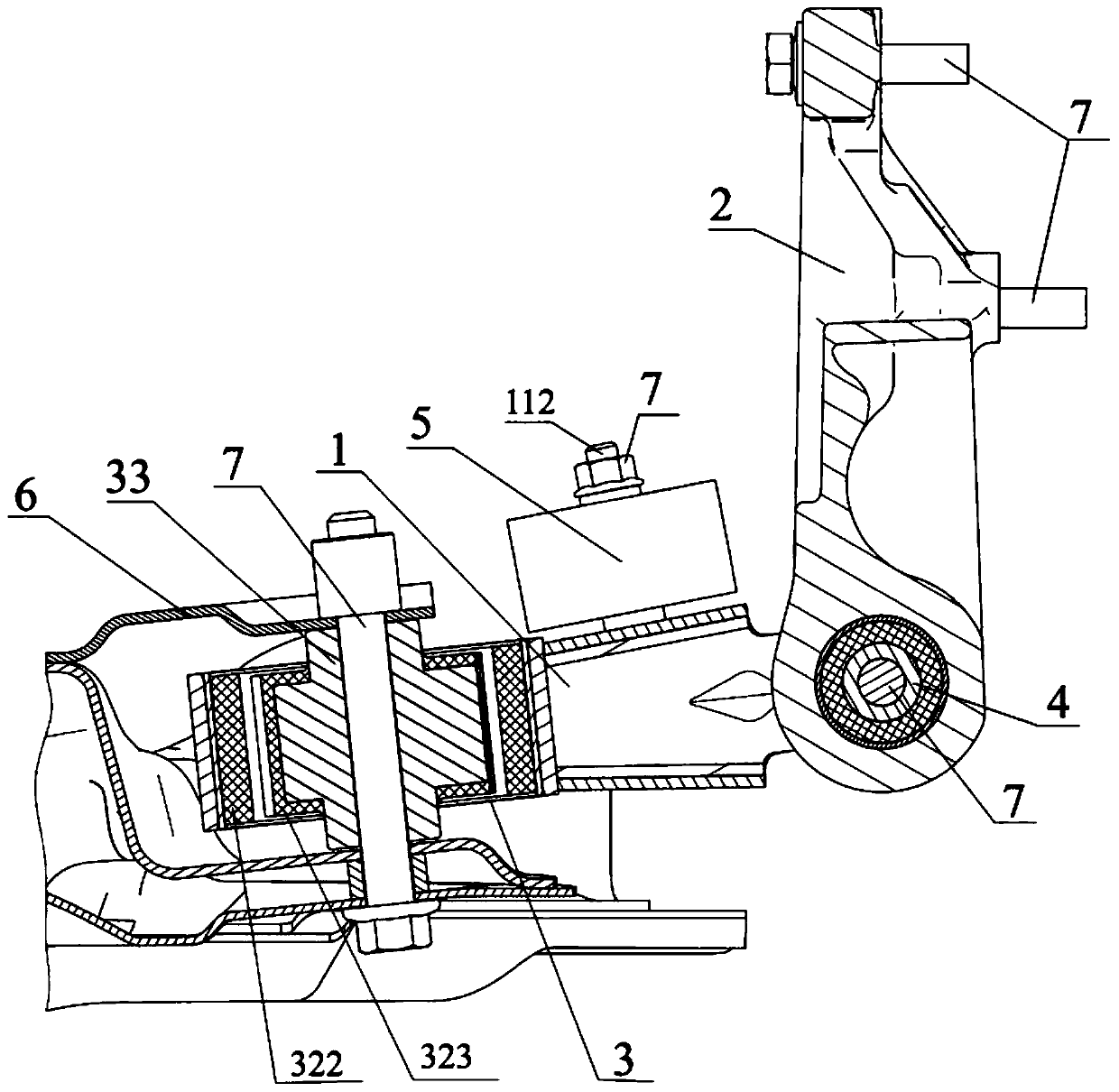

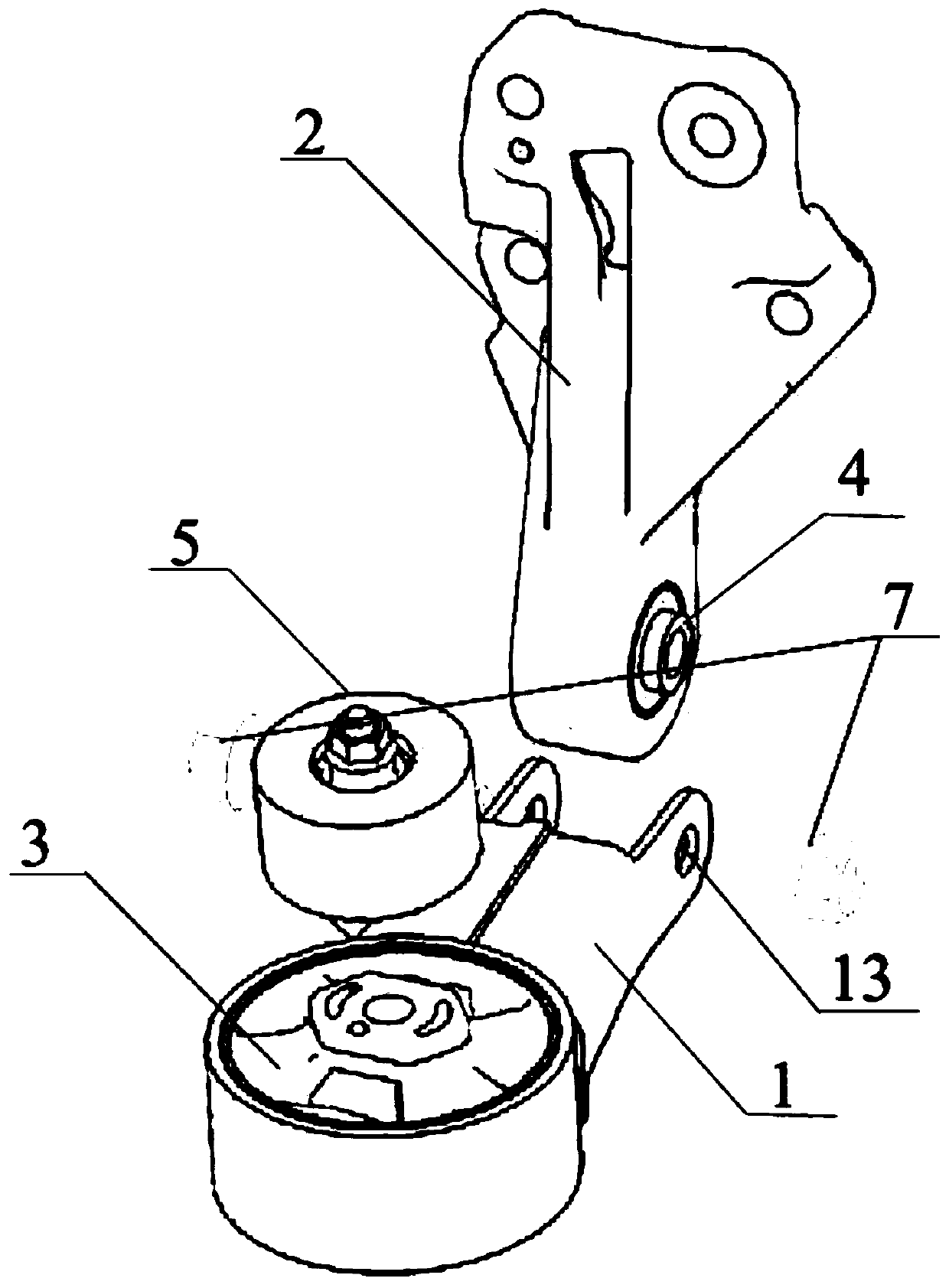

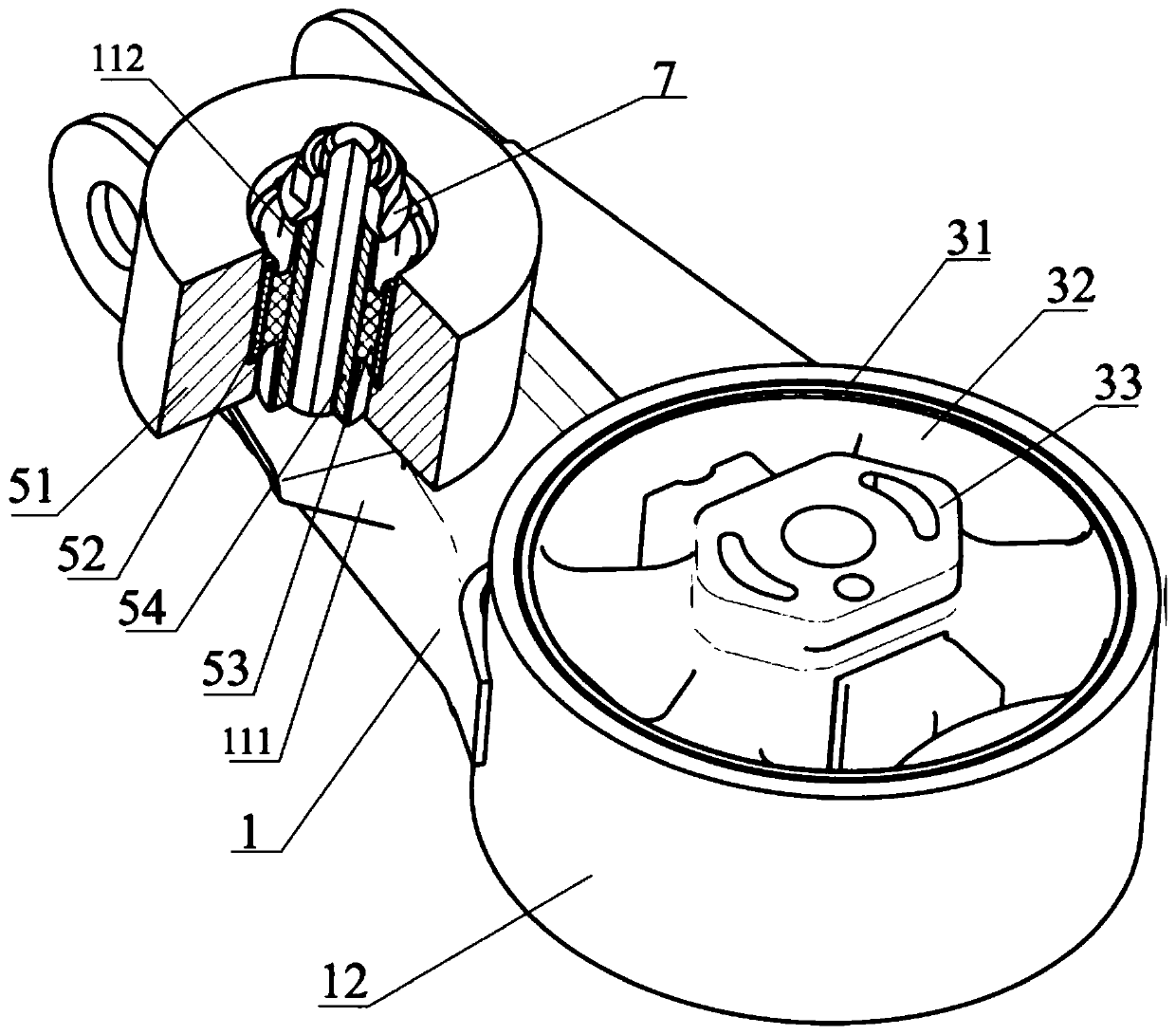

[0028] like Figure 1~6 As shown, a powertrain anti-torsion suspension structure includes a torsion-resistant tie rod and a torsion-resistant support. The torsion-resistant tie rod includes a torsion-resistant tie-rod skeleton 1, and one end of the torsion-resistant tie-rod skeleton 1 is fixedly connected to one end of the torsion-resistant brace through a small bush 4. , the other end of the anti-torsion bracket is fixedly connected with the power assembly; the other end of the anti-torsion rod frame 1 is provided with a large bush 3 fixedly connected with the front sub-frame 6, and the large bush 3 is provided with a large bush rubber ring 32 and The large bush inner core 33 also includes a shock absorber 5, which is detachably fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com