Automobile air conditioner assembly

A technology for automotive air conditioners and assemblies, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problem that the requirements of passenger comfort cannot be well met, the use effect of air conditioners does not meet the requirements, and the internal sealing of air conditioners It can improve the impact resistance of high and low temperature, improve the cooling efficiency, and avoid external air leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

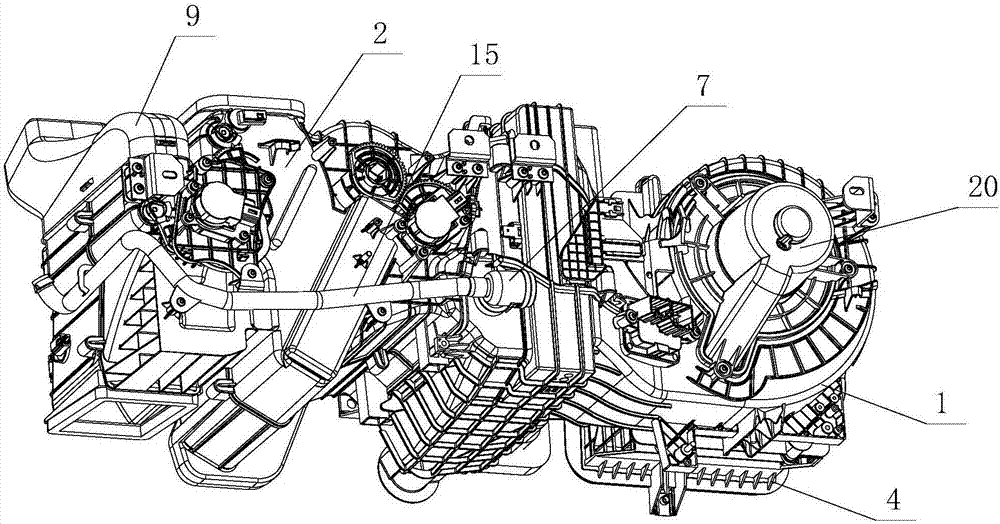

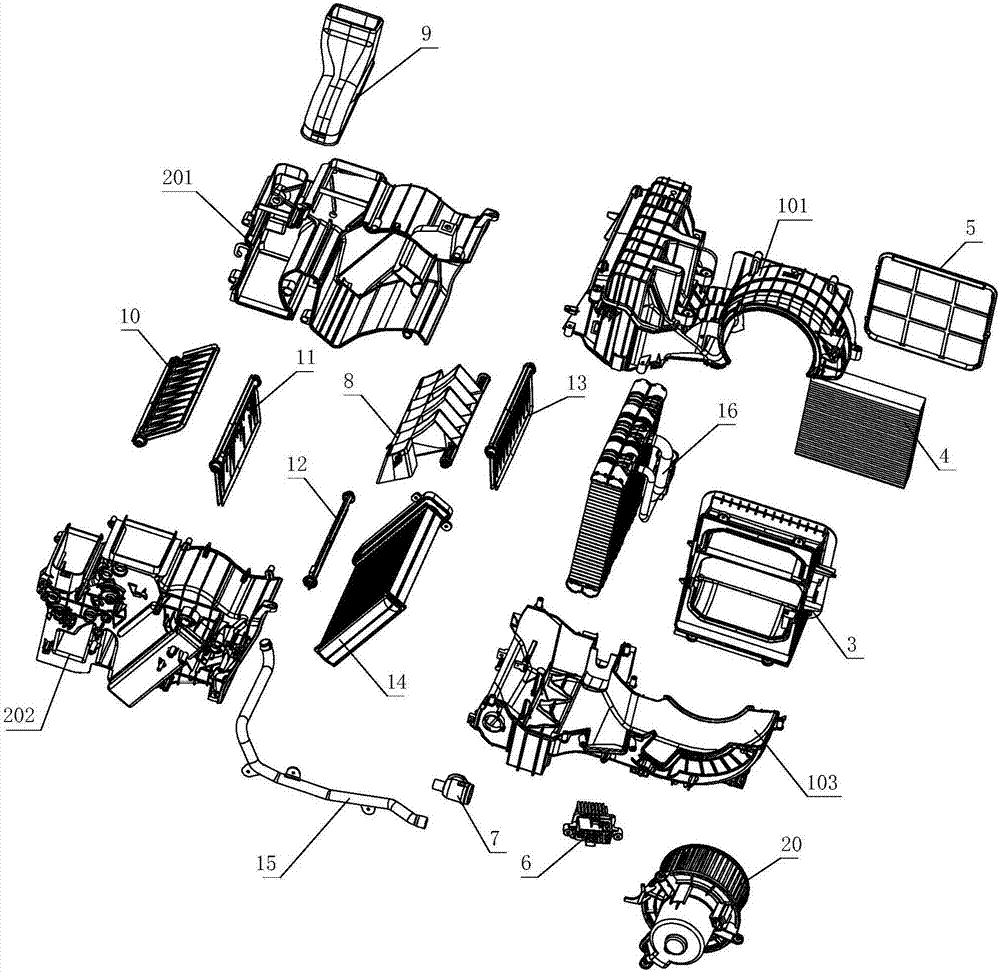

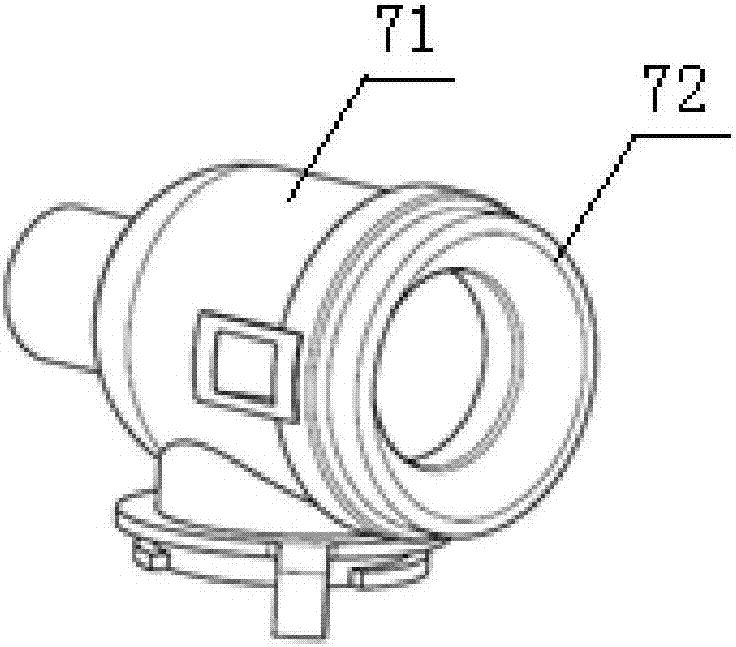

[0031] like Figure 1-2 Shown, a kind of automobile air-conditioning assembly of the present invention comprises blower assembly and component air device assembly, blower assembly and component air device assembly are fixedly connected by evaporator housing 1 and air distributor housing 2 (as figure 1 The evaporator shell 1 is composed of two half shells, that is, the evaporator upper shell 101 and the evaporator lower shell 102 are fixed together by screws to form the evaporator shell 1, The blower assembly includes a blower 20, an evaporator 16, an air intake assembly 3, a filter 4 and an air intake grid 5, the blower 20 is fixedly installed in the rear side of the evaporator shell 1, and the evaporator 16 is installed in the evaporator shell 1 Behind the blower 20 air passage, it is used to cool the air drawn in by the blower 20. The air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com