Cable insulation extrusion process capable of realizing automatic regulation of concentricity

A cable insulation and automatic adjustment technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve the problems affecting the eccentricity and concentricity deviation of the insulating layer, and achieve the guarantee of eccentricity quality and high concentricity. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

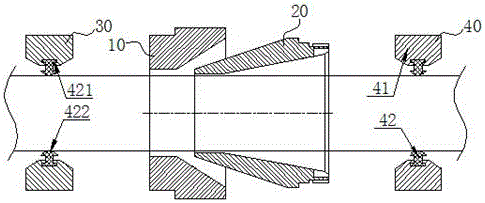

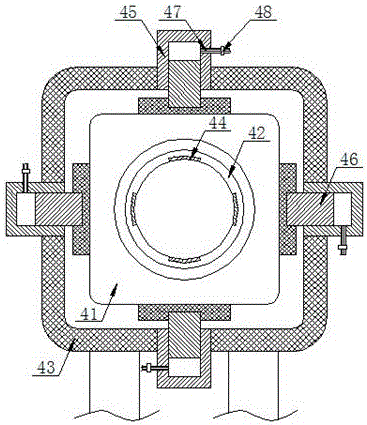

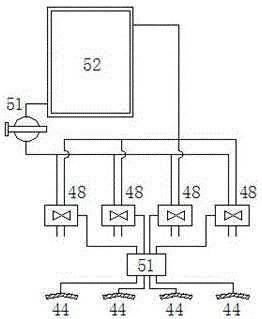

[0021] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0022] Such as Figure 1 to Figure 3 As shown, a cable insulation extrusion process that automatically adjusts concentricity includes an insulation layer extrusion die, and the insulation layer extrusion die includes an inner mold core 20 for defining the position of the cable to be extruded, and a The outer mold casing 10 that extrudes the insulating material and wraps the cable, the outer mold casing 10 is coaxially set on the outside of the inner mold core 20, and the inner mold core 20 is located on the outer mold casing 10 upstream; also includes an upstream concentric guide sleeve 40 arranged upstream of the outer mold casing 10, and a downstream concentric guide sleeve 30 arranged downstream of the inner mold core 20, the upstream concentric guide sleeve 40 and the downstream concentric The guide sleeves 30 are all ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com