Bushing rubber for single-board and single-pin vehicle track pin

A track pin and bushing technology, which is applied in the field of composite materials for armored vehicles, can solve the problems of tearing damage of the rubber layer of the bushing, extrusion damage of the rubber layer of the bushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention further relates to a method for preparing a single-plate single-pin vehicle track pin rubber bushing, comprising the following steps:

[0033] S1: First use the hydroxyl groups on the surface of graphene oxide and γ-chloropropyltriethoxysilane (CTS) to graft, and react to prepare graphene oxide grafted CTS; then the reaction product is further mixed with anti-aging agent 2-mercaptobenzene And imidazole (MB) undergoes grafting reaction to obtain graphene oxide grafted antioxidant MB;

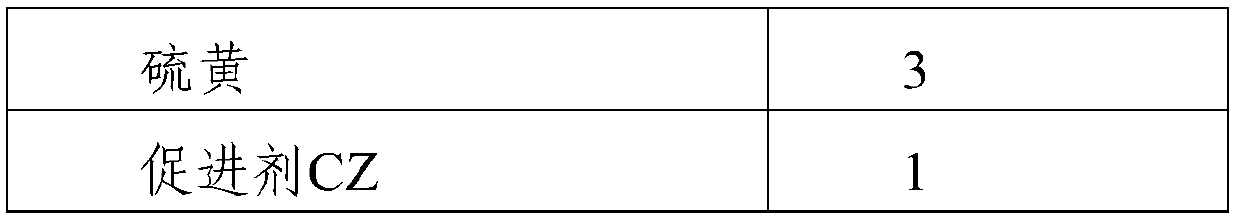

[0034] S2: masticate the natural rubber in the internal mixer for 1-3 minutes, then add the compounding agent including active agent, softener, anti-aging agent, reinforcing agent and carbon fiber, and mix on the internal mixer for 3-5 minutes, then add Mix the carbon black filler for 9-11 minutes; then add accelerator and sulfur to the open mill and mix for 4-6 minutes to obtain the mixed rubber for high modulus shock-absorbing rubber rings, and test the normal vulca...

Embodiment 1

[0040] (1) Preparation process of high modulus rubber bushing

[0041] First, 5 g of graphene oxide and 15 g of γ-chloropropyltriethoxysilane (CTS) were dispersed in 400 ml of absolute ethanol, and stirred at 50° C. for 24 hours to prepare graphene oxide grafted CTS. Then add 0.5g sodium hydroxide (NaOH) and 2g anti-aging agent 2-mercaptobenzimidazole (MB), nitrogen protection, stirring and reacting for 24h, the reaction product is filtered, washed 3 times with ethanol and deionized water, and dried to obtain Graphene oxide grafted antioxidant MB.

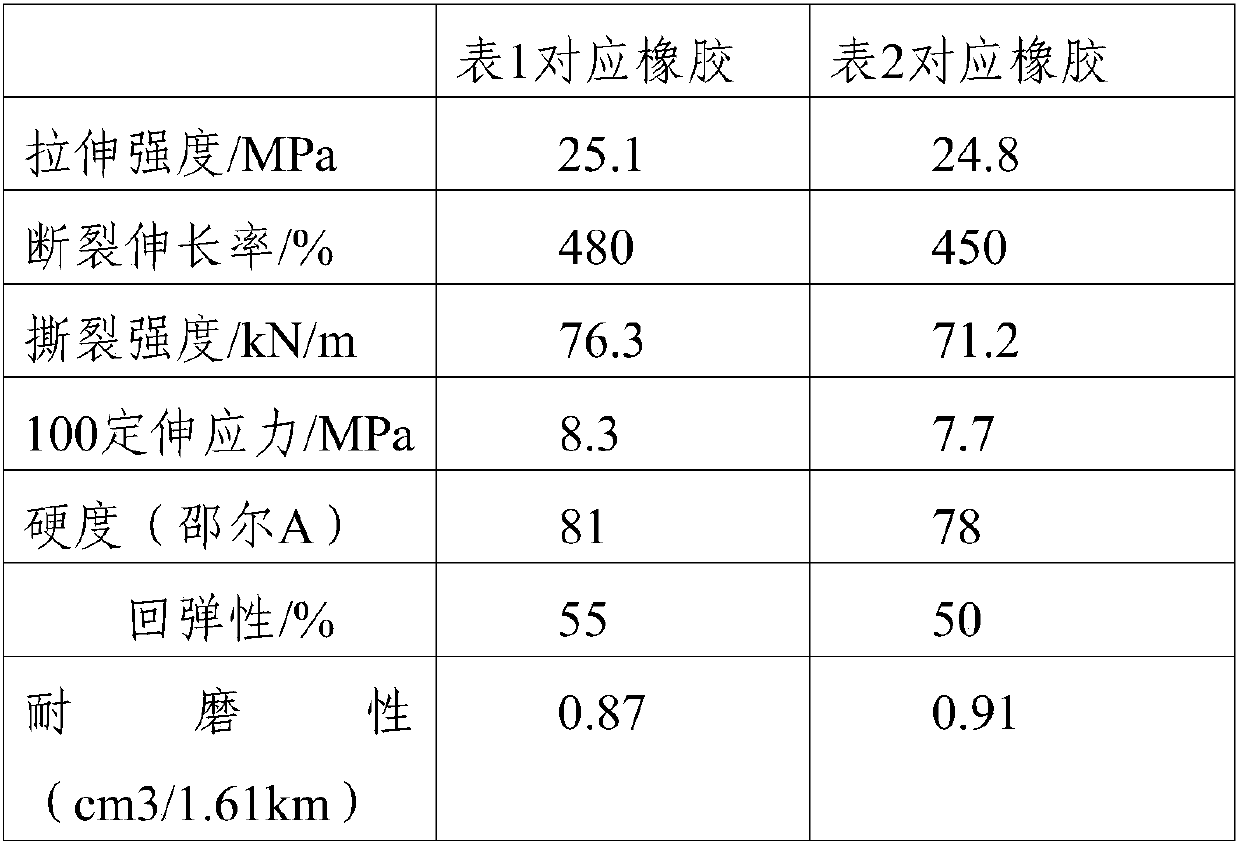

[0042] Weigh the natural rubber and various compounding agents required for high modulus formula 1, masticate the natural rubber raw rubber in an internal mixer for 2 minutes, and then add zinc oxide, stearic acid, graphene oxide grafted anti-aging agent MB, Liquid polyisoprene and carbon fiber, mixed for 4 minutes, finally added carbon black, mixed for 10 minutes, debinding. After the rubber material is cooled, continue mixing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com