Front suspension damping mechanism for vehicle cab

A vibration damping mechanism and cab technology, which is applied to the upper structure, upper structure, and mechanical equipment of trucks, can solve the problems of misalignment of inner and outer cylinder axes, and achieve product structure optimization, vibration damping performance improvement, and bonding The effect of increased intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

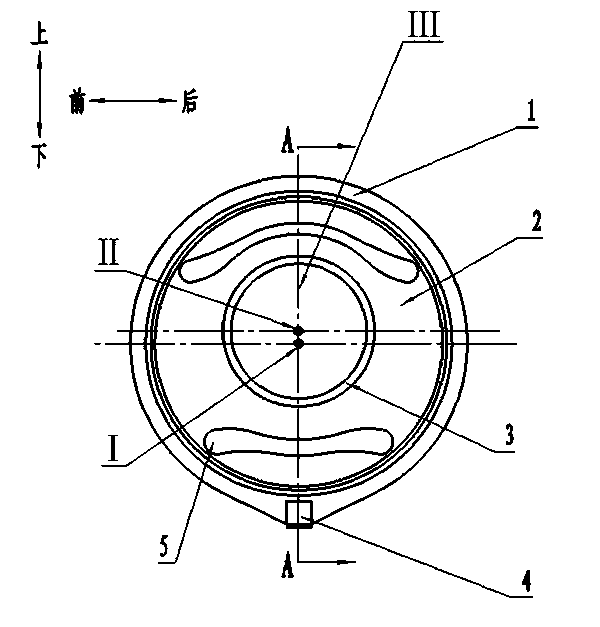

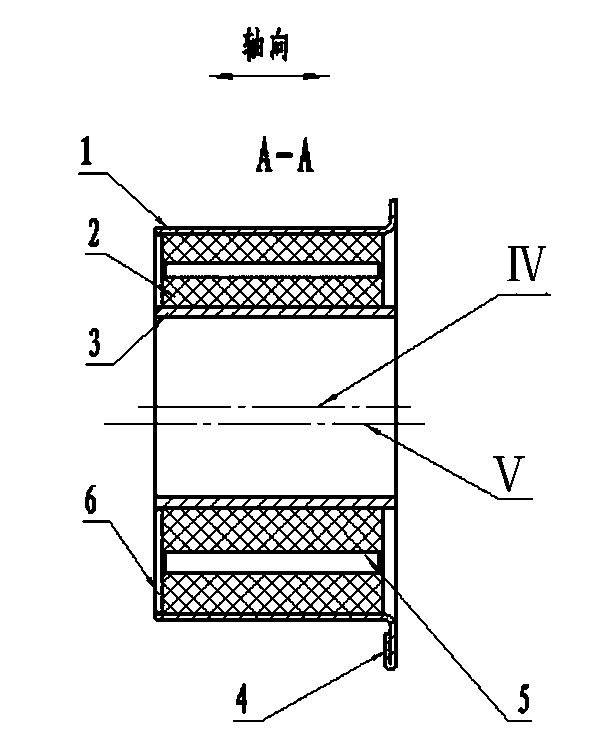

[0017] figure 1 Among them, the outer cylinder 1 and the inner cylinder 3 are used as the framework of the whole mechanism, mainly used for supporting and assembling with other parts, and the rubber layer 2 plays the role of damping and buffering. The outer cylinder 1 is used as an outer skeleton for matching with the front suspension hole, and a boss 4 is designed on it to limit the installation direction; the inner cylinder 3 is an inner skeleton for installing a composite bushing. The space between the outer cylinder 1 and the inner cylinder 3 is filled with rubber and vulcanized to form a whole. The main bearing direction (up and down direction), the thickness of the rubber filled between the inner and outer cylinders is different, that is, the axes of the inner and outer cylinders do not coincide, and there is a certain eccentric design. On the rubber layer 2, there are two opposite process holes 5, which are distributed on both sides of the axis of the outer cylinder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com