Integrated triangular thrust rod assembly

A thrust rod, triangular technology, applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problems of V-push connection bolt loosening, reduce vehicle utilization rate, increase vehicle failure rate, etc., to achieve The effect of avoiding stress concentration, simple and reliable structure, and solving lateral positioning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

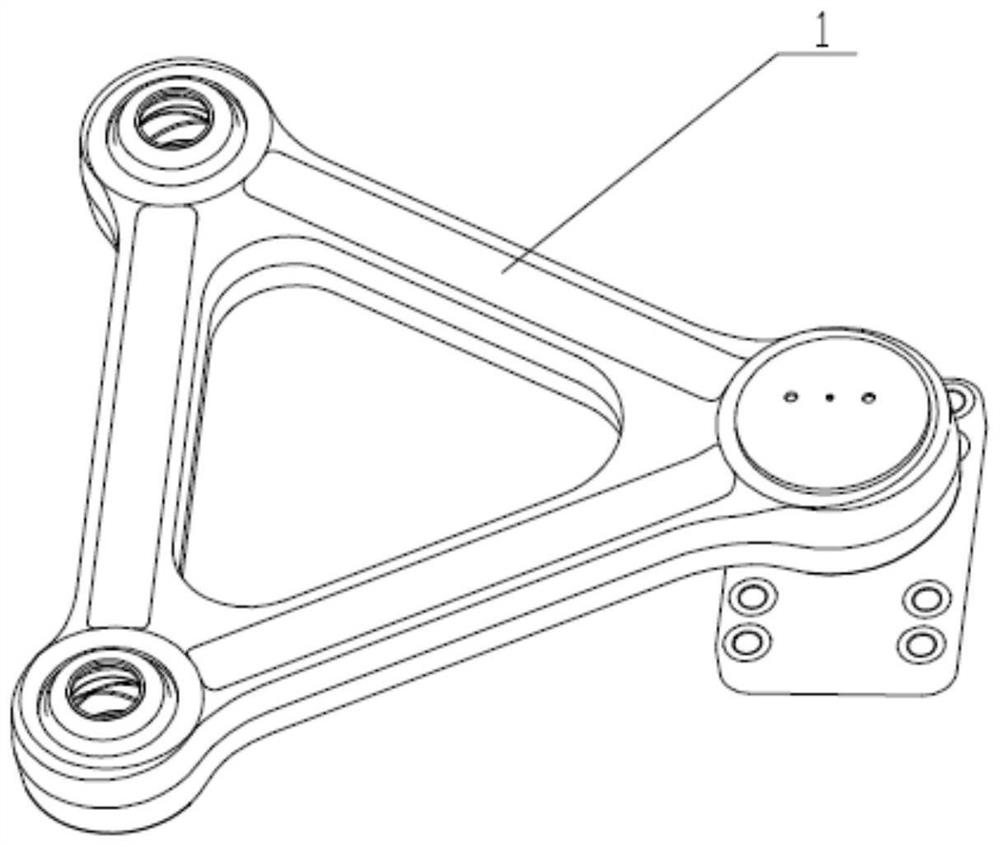

[0028] figure 1 Shown is the structural representation of the present invention.

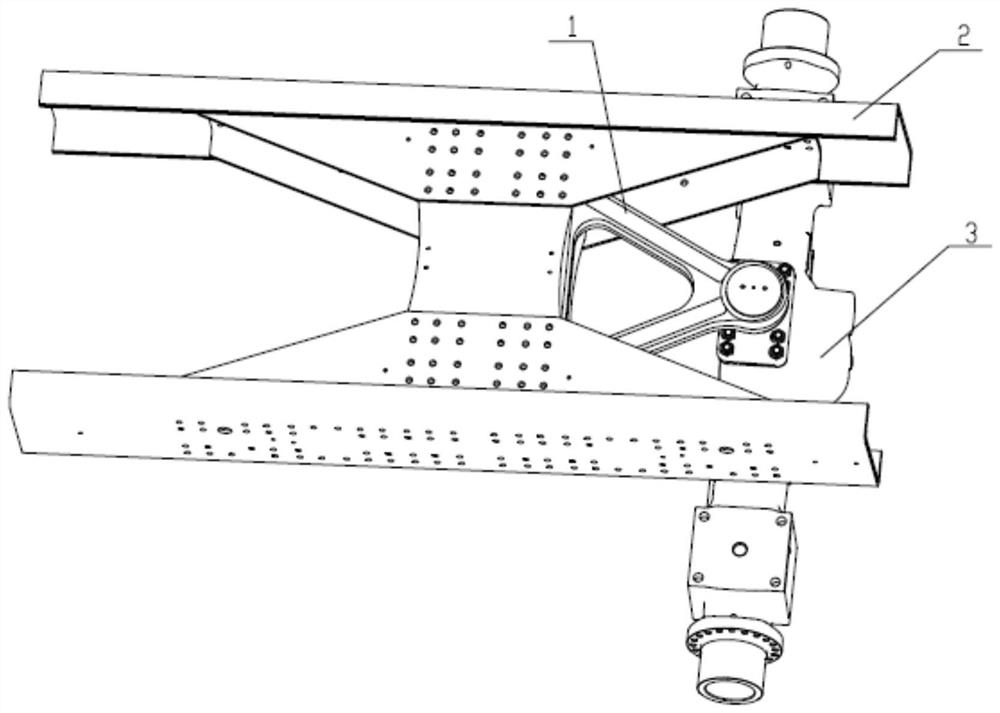

[0029] Figure 4 Shown is the explosion schematic diagram of the present invention.

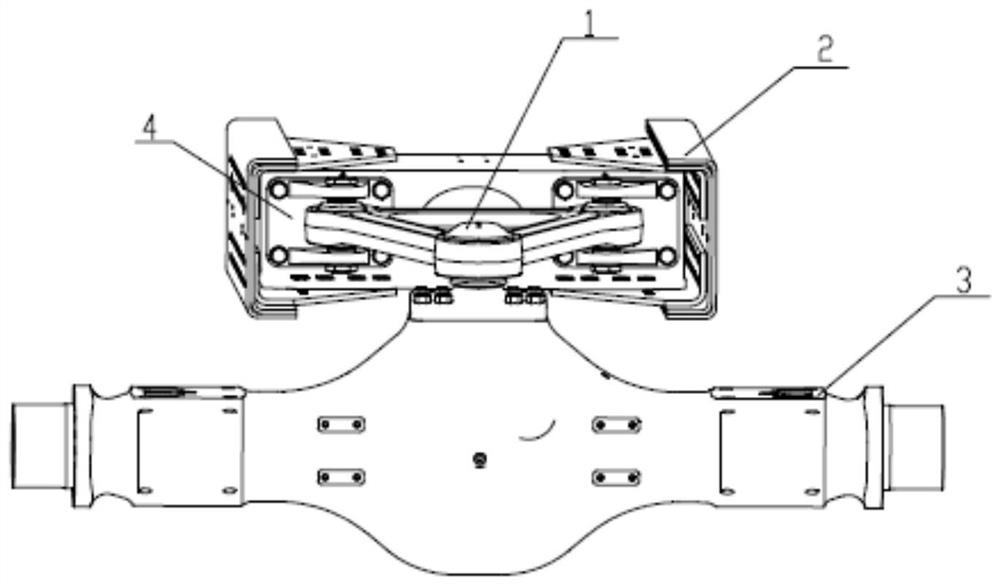

[0030] Figure 5 Shown is a schematic top view of the structure of the present invention.

[0031] Figure 5a Shown is the invention Figure 5 A-A cross-sectional schematic diagram.

[0032] Figure 5b Shown is the invention Figure 5 Schematic diagram of the B-B section

[0033] The present invention provides an integral triangular thrust rod assembly, including a triangular thrust rod 101, a spacer bush 102, a rubber sealing ring 103, a rubber vulcanized joint bearing assembly 104, an elastic retaining ring 105, a thrust rod support 106, Rubber sealing ring 2 107, metal joint bearing assembly 108, pressure plate 109, nut 2 110, sealing cover 111 and grease nipple 112. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com