Screw drilling tool motor stator

A technology of motor stator and screw drilling tool, which is applied in the manufacture of stator/rotor body, earthwork drilling, drilling equipment, etc., can solve the problems affecting the working efficiency and service life of the screw drilling tool motor, the damage of stator rubber, and the small amount of deformation. , to achieve the effect of small difference in expansion, extended service life and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

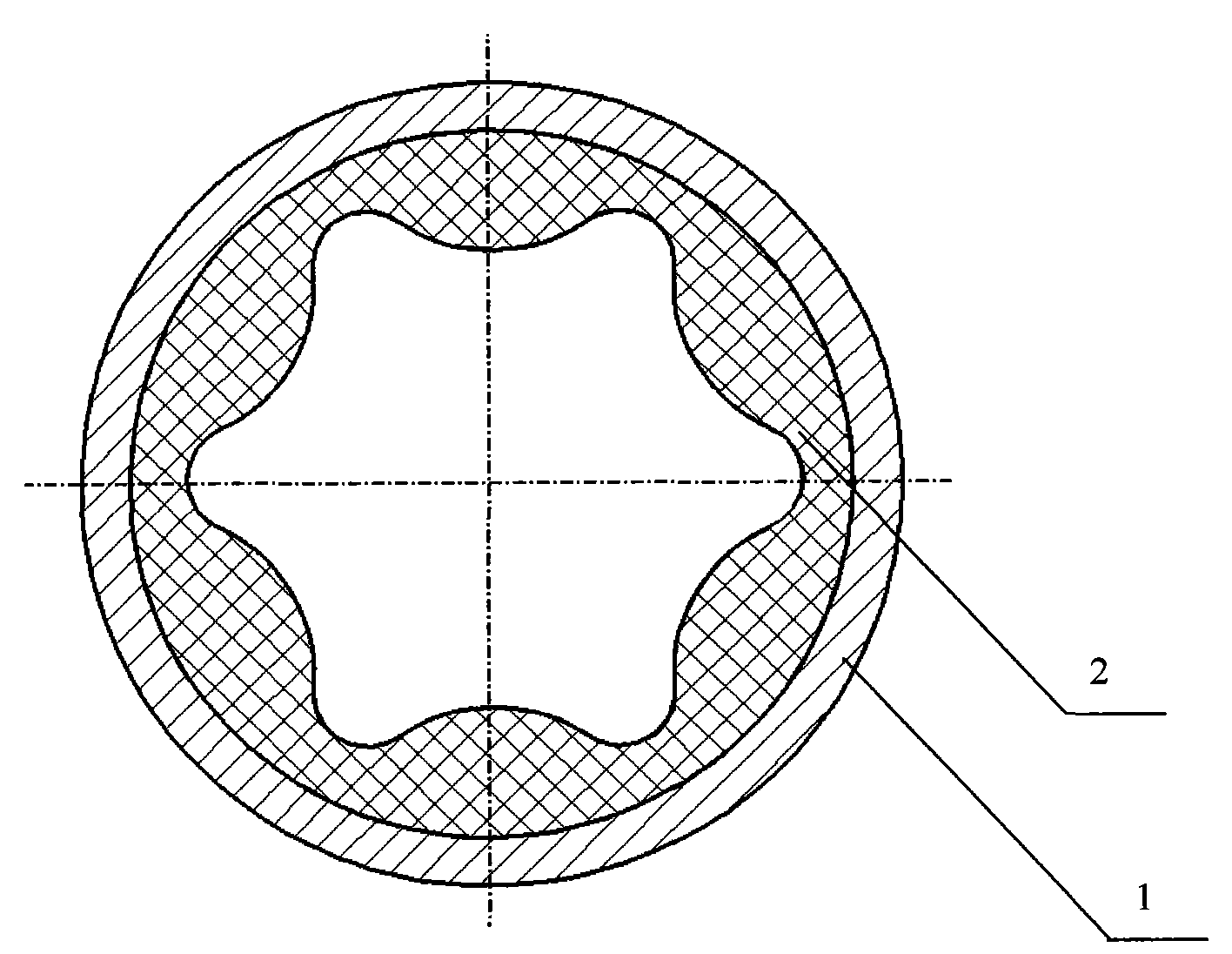

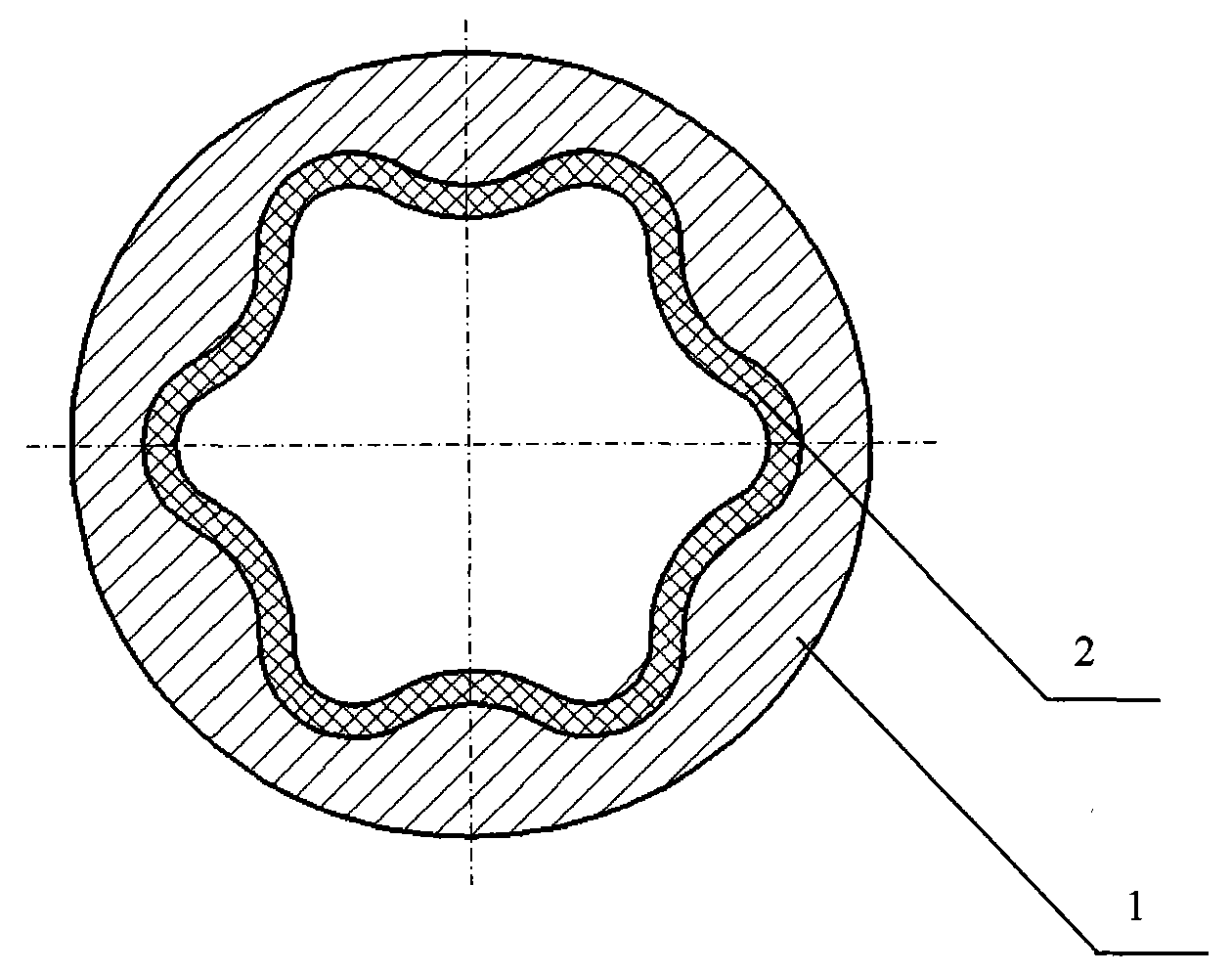

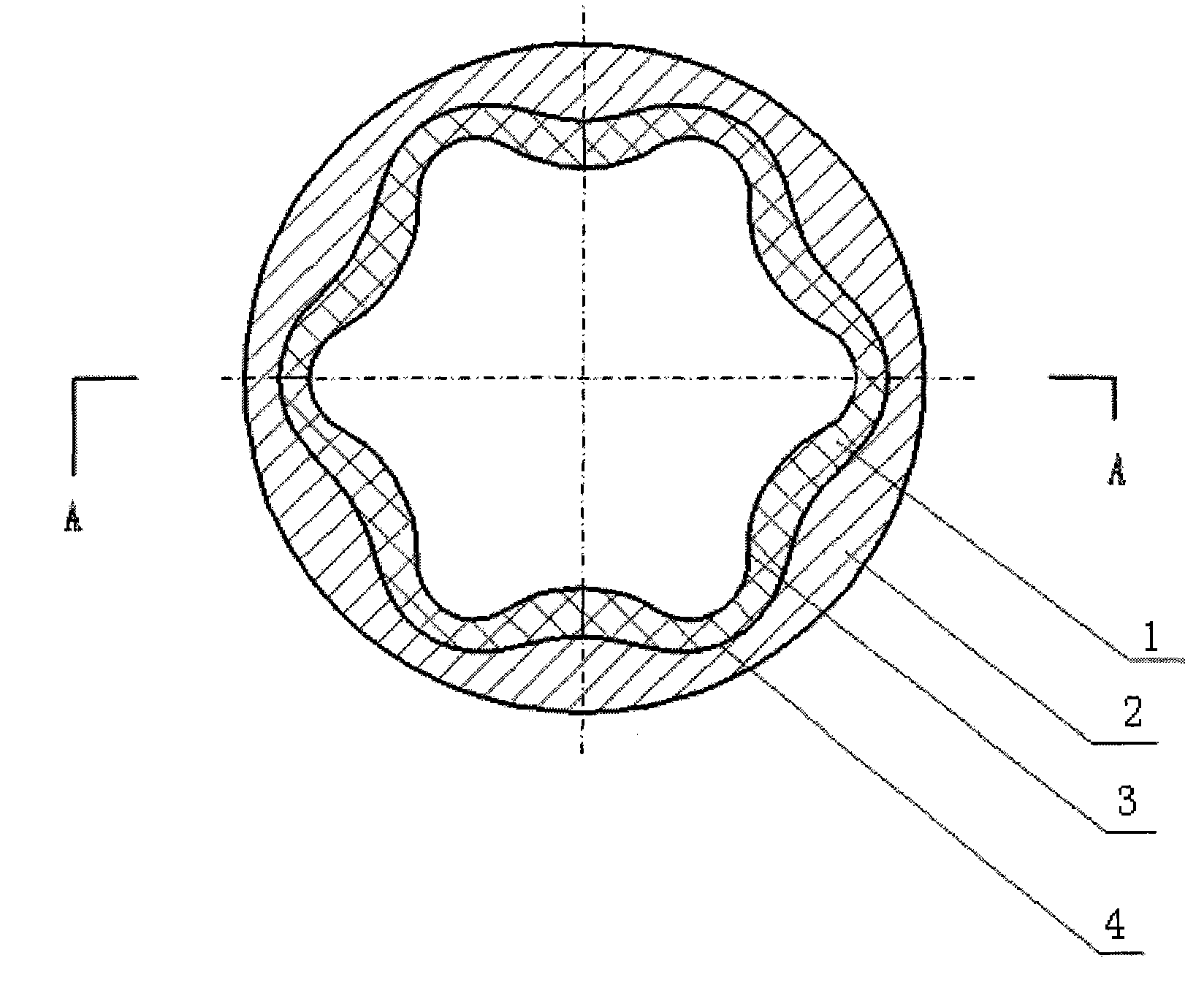

[0014] The embodiment of the present invention will be further described below in conjunction with the accompanying drawings, including a housing 1 and a rubber bushing 2, the rubber bushing is bonded to the inner hole of the housing by vulcanization of wear-resistant rubber, and the inner hole 3 of the rubber bushing is a continuous helical line , the radial cross-section is uniformly distributed petals in the circumferential direction, and the number of petals is 6. On the radial cross-section, each petal of the rubber bushing is from the lowest point of the concave (the largest radius) to the highest point of the outer convex (the smallest radius). The wall thickness is increasing, that is, the wall thickness is gradually thickened, and the maximum thickness is 1.6 times the minimum thickness. The curve formed by the outer peripheral surface 4 of each petal on the radial section of the rubber bush from the lowest concave point to the highest convex point is Short hypocycloid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com