Vehicle balance suspension with balance axles and brackets integrated into one

A technology for balancing suspensions and balance shafts, which is applied in the direction of cantilevers, suspensions, and vehicle parts installed on pivots, and can solve the problem of high strength requirements for balance shafts and balance hubs, poor lubrication of steel bimetal bushings, and no Cushion performance and other issues, to achieve the effect of light weight, light weight, and reduce the impact of the bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

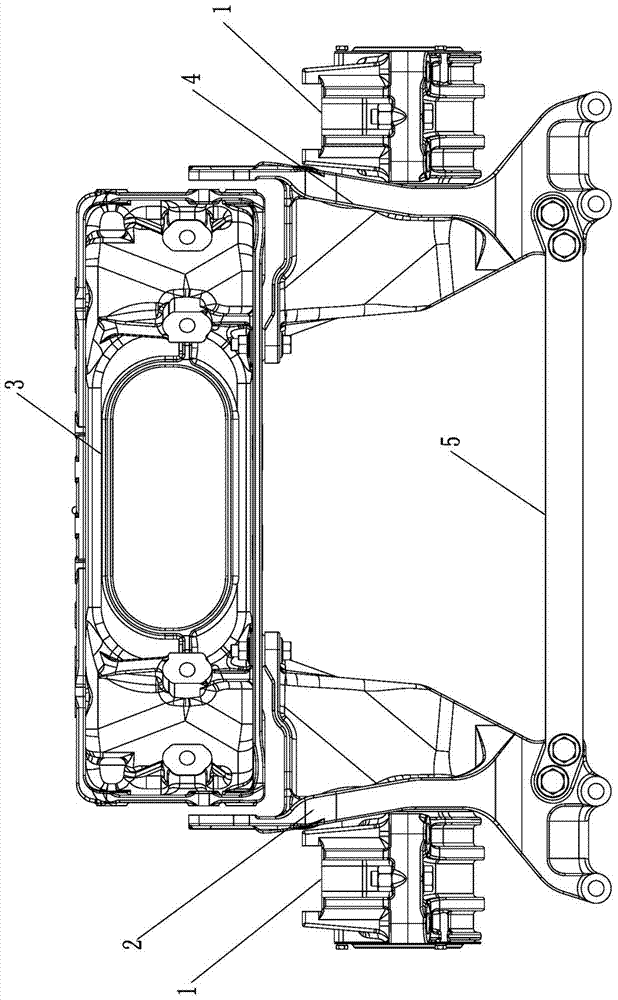

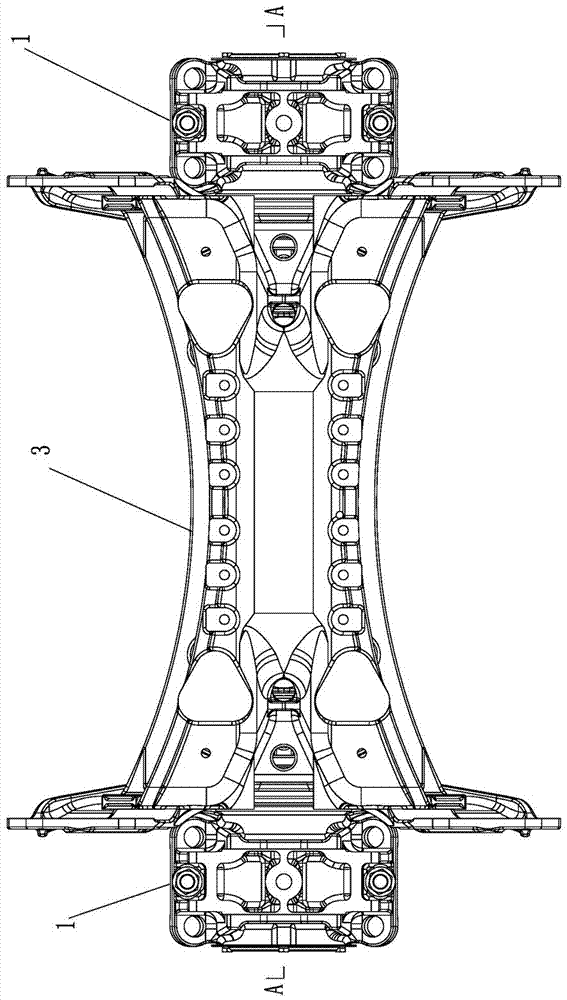

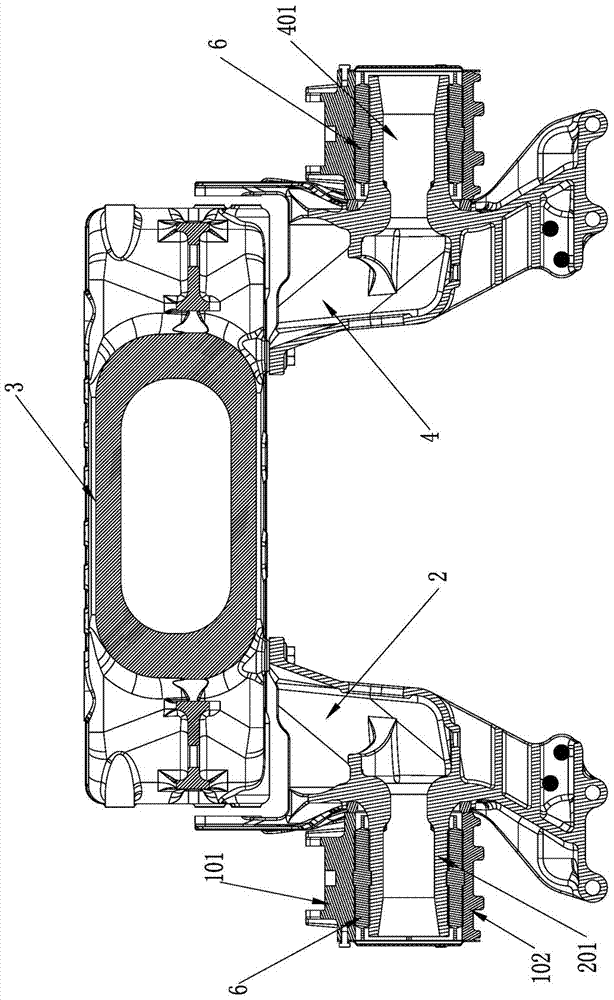

[0017] combine Figure 1-Figure 4 As shown, the technical scheme of the present invention is further described as follows: the balance shaft and support integrated automobile balance suspension, including left support 2, right support 4, crossbeam 3, two balance shaft bushings 6, two balance hubs 1, The balance wheel hub is composed of an upper tile cover 101 and a lower tile cover 102. The left bracket 2 is integrally cast with a left balance shaft function part 201, which constitutes the left bracket and shaft assembly; the right bracket 4 is integrally cast with a right balance shaft function. Part 401 constitutes a right bracket and a shaft joint;

[0018] The balance shaft bushing 6 is an integrally formed integral rubber bush, and the outer circle and the inner hole of the rubber bush are respectively provided with an outer limit annular boss 601 and an inner limit annular boss 602; There is an axial opening 603, and the integral rubber bushing is assembled through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com