Apparatus for capping sebific duct and adding spacer automatically

A technology for adding gaskets and rubber hoses, which is applied in the field of one-time molding equipment for automatically inserting rubber hoses and gaskets to batteries, and can solve the problems of high labor intensity, low production efficiency, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

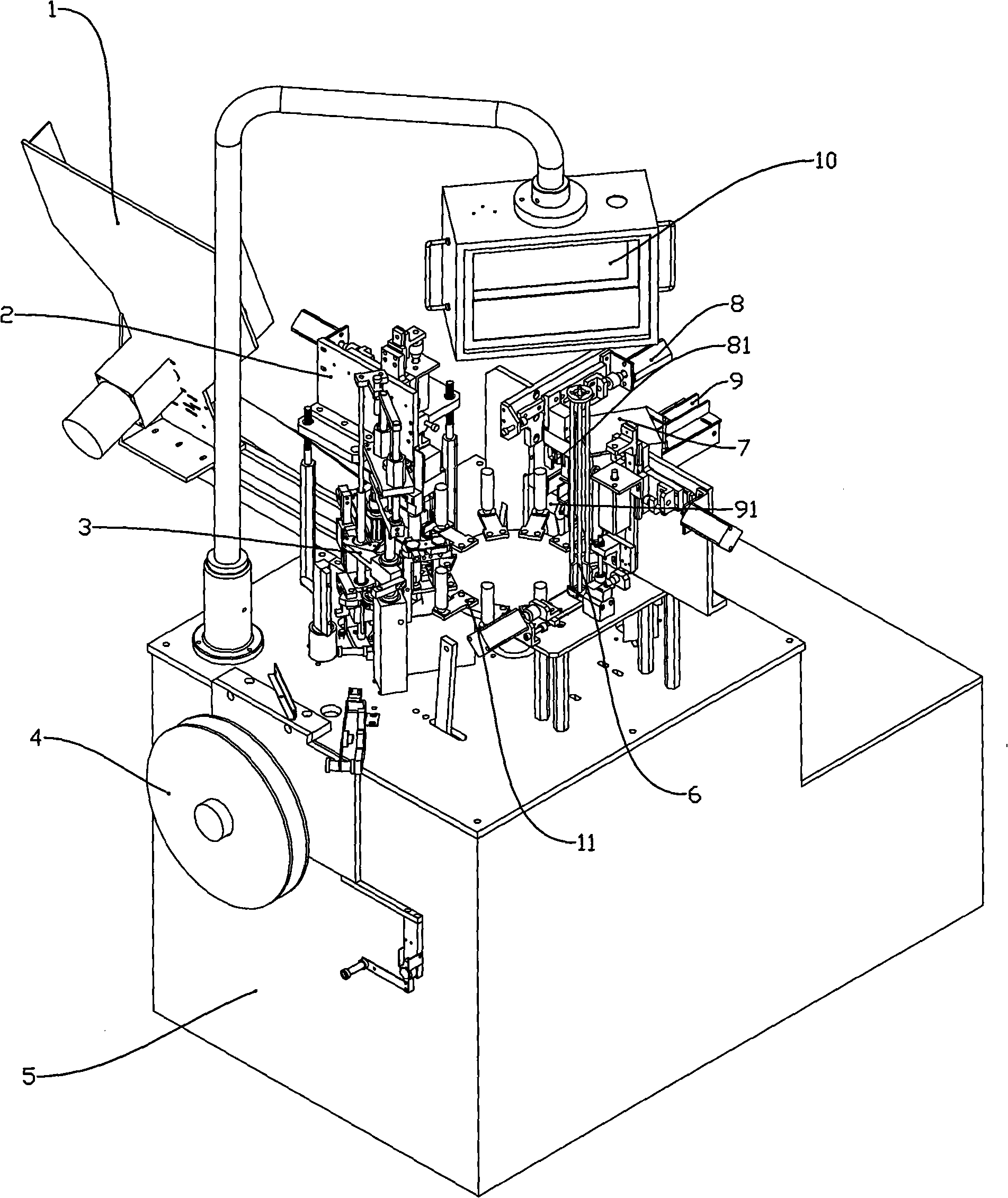

[0043] see figure 1 , The automatic rubber hose and gasketing equipment includes a discharge tray 1, in which the battery to be sleeved and gasketed is housed.

[0044] The feeding device 2 is connected to the discharging tray 1, and the feeding device 2 has a clip for transporting the battery to the working turntable 11.

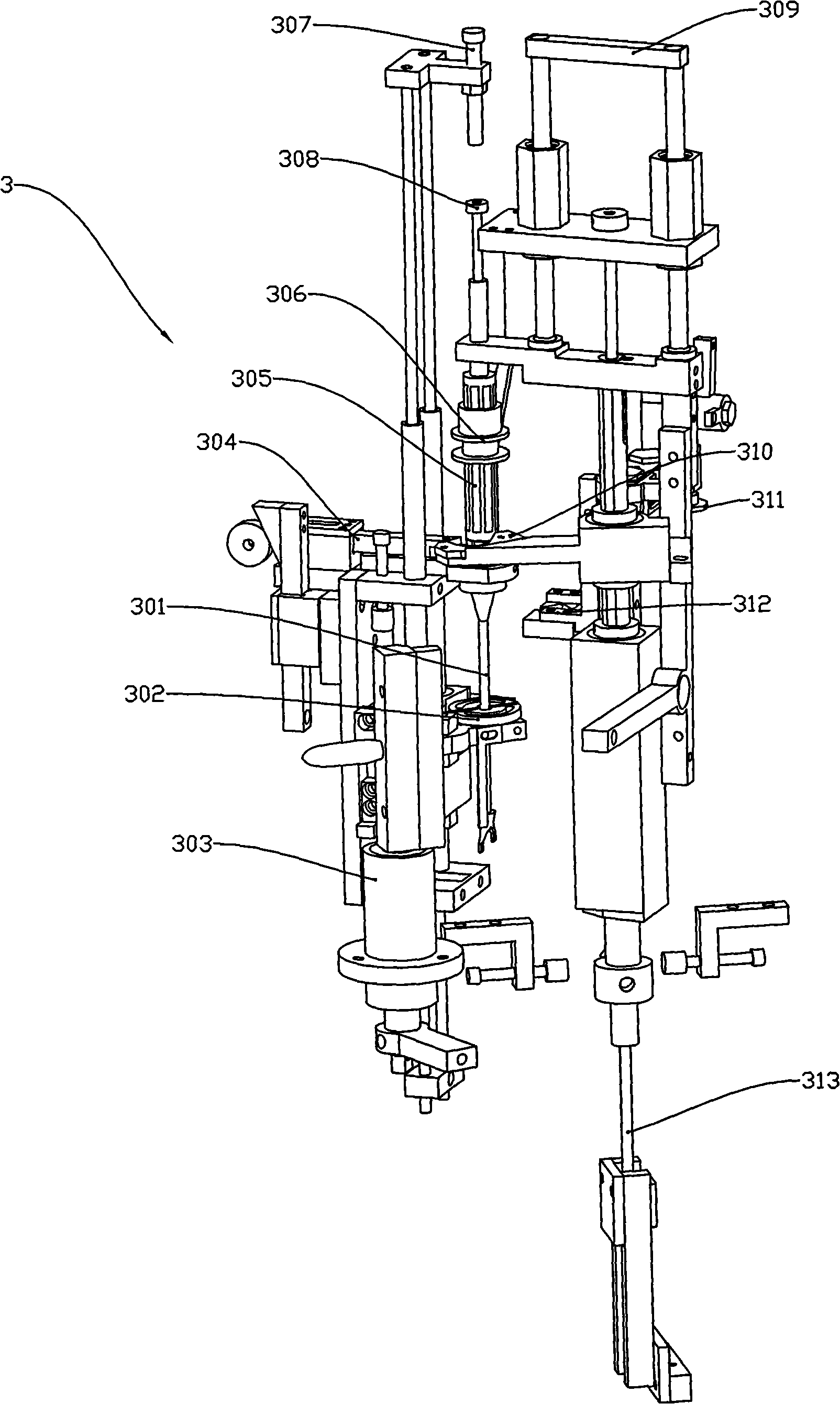

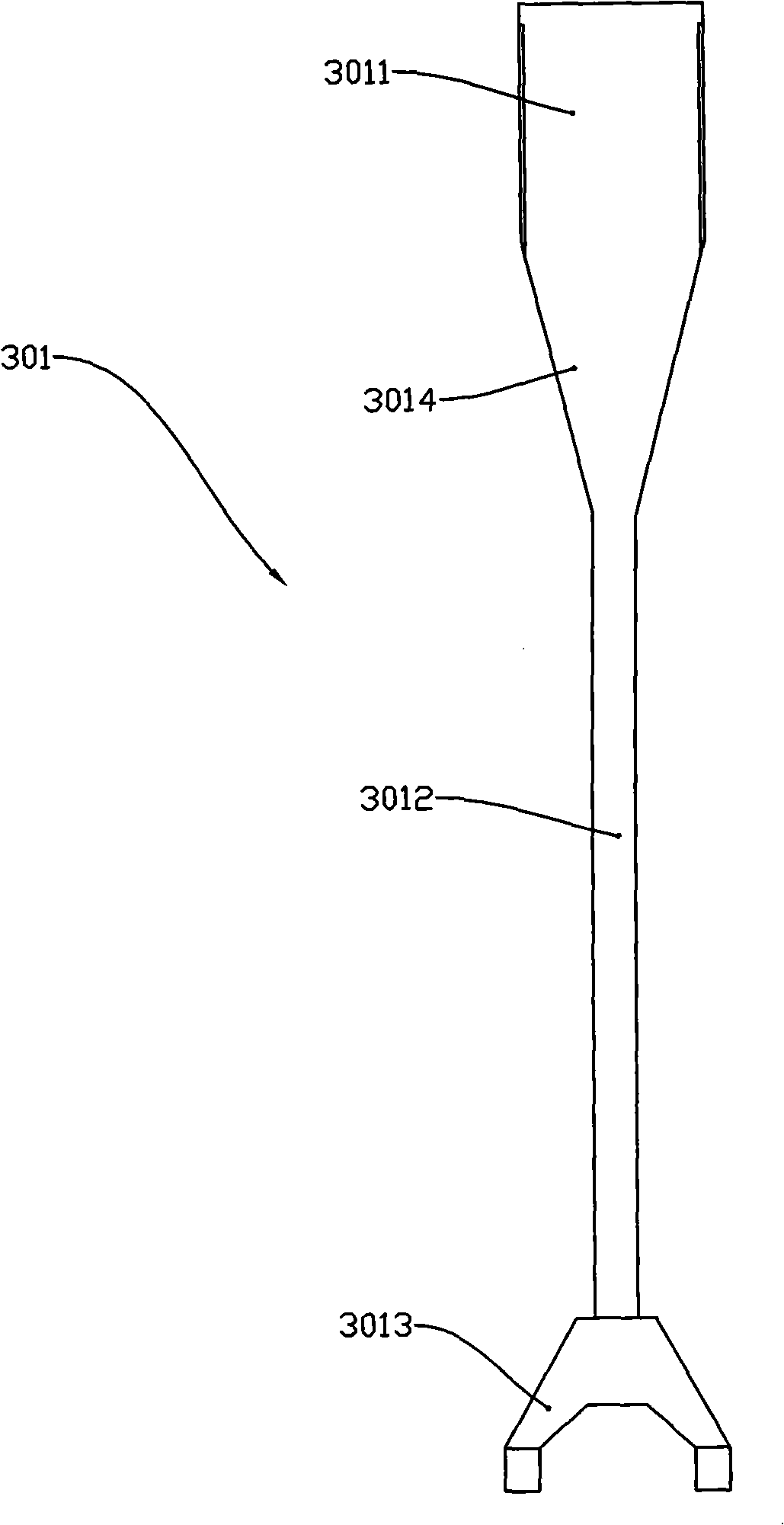

[0045] The gluing device 3 is connected to the feeding device 2, and the specific structure of the gluing device 3 can be found in figure 2 , The gluing device 3 includes a glue stick 301, and the glue stick 301 extends into the end of the rubber hose. For the specific structure of glue stick 301, see image 3 and Figure 4 , the upper end of the glue stick 301 is a thick columnar part 3011 , the middle part is a thin columnar part 3012 thinner than the upper end, and the lower part is a fishtail part 3013 . The thick columnar part 3011 and the thin columnar part 3012 are connected by a transition cone part 3014 , which makes it easier for the rubber h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com