Bushing rubber prepared raw material under lightening development of high-grade cars

A technology for cars and raw materials, applied in the field of rubber, can solve the problems of small heat generation, small loss factor, low heat generation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

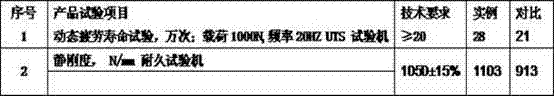

Examples

Embodiment Construction

[0009] The current examples specifically illustrate the raw materials for the preparation of bushing rubber under the development of lightweight high-end cars, and the content is in parts by mass:

[0010] example recipe

[0011] serial number components supplier Dosage / serving 1 Natural rubber TSR CV 60 China Rubber International Group Co., Ltd. 90 2 Butadiene Rubber EUROPRENE NEOCIS BR 60 POLIMERI EUROPA GMBH 10 3 Carbon black Carbon black DUREX O DEGUSSA 27 4 Carbon black Carbon black N 683 EVONIK 6 5 Naphthenic oil GRAVEX 973 SHELL 2 6 Zinc Oxide ZNO Changzhou Magnesium Zinc 3.5 7 Antiaging agent IPPD LANXESS 2 8 Antiaging agent TMQ LANXESS 1 9 Microcrystalline Wax WAX T3 TECETE CHEMIE 1 10 Microcrystalline Wax WAX 5700 TECETE CHEMIE 1 11 Activator Struktol ZEH-DL STRUKTOL 1.5 12 SULPHUR + OIL ARNSPERGER 1.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com