Apparatus for capping sebific duct automatically

A glue-covering and automatic technology, applied in packaging, wrapping paper, shrinkage of wrapping paper, etc., can solve the problems of low production efficiency, high labor intensity, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

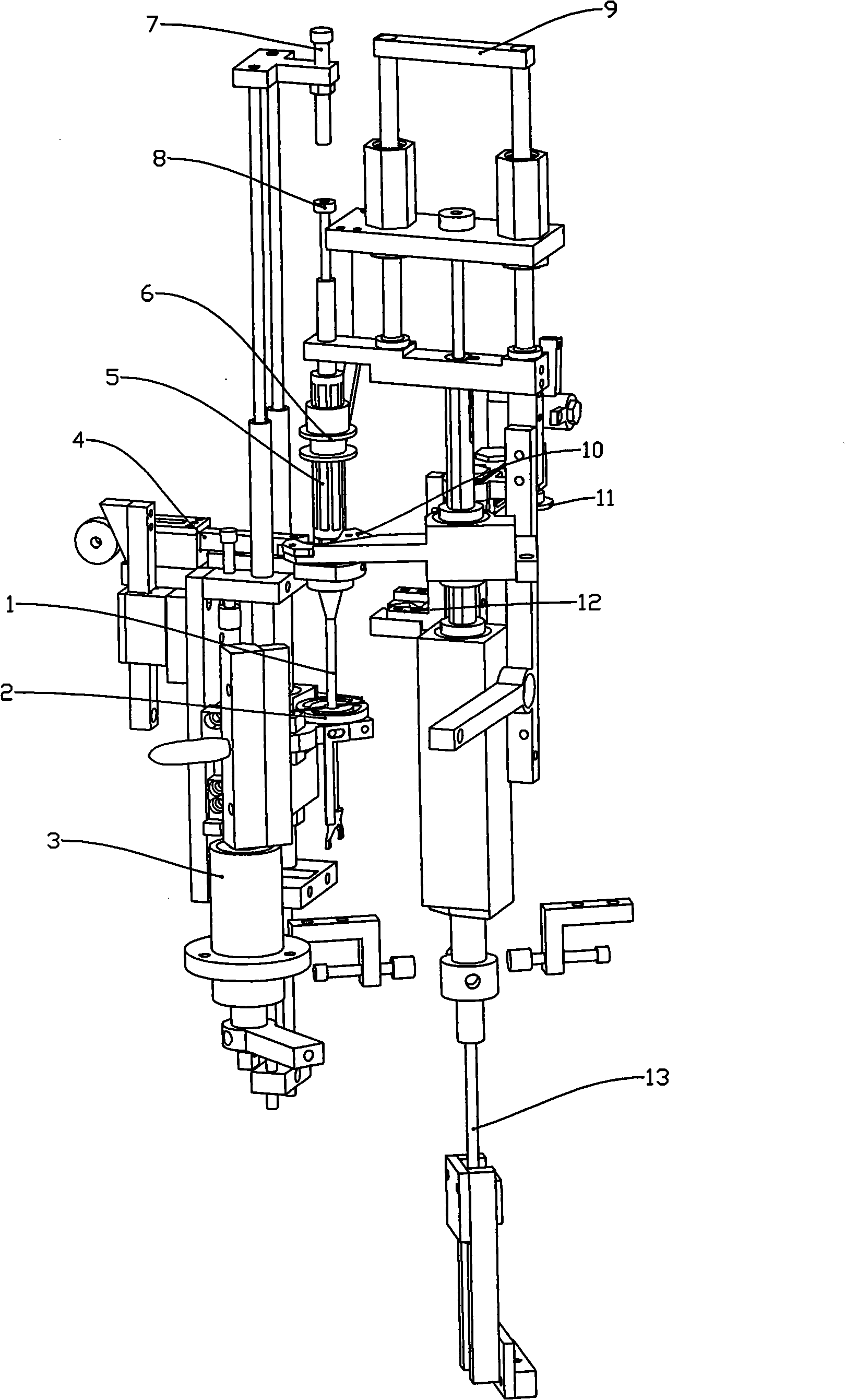

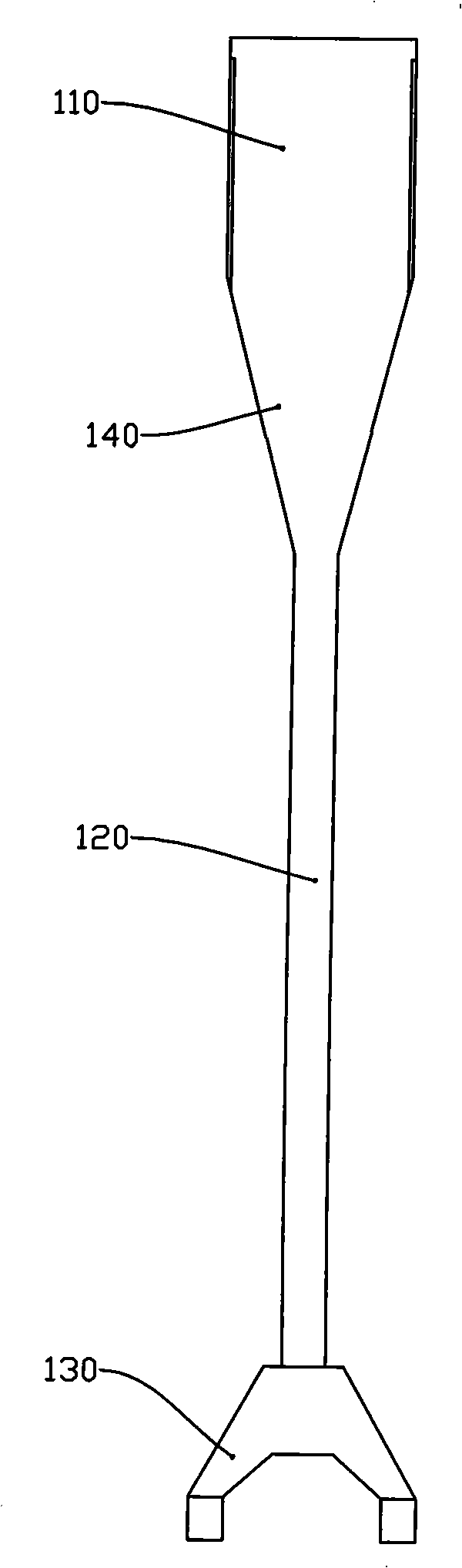

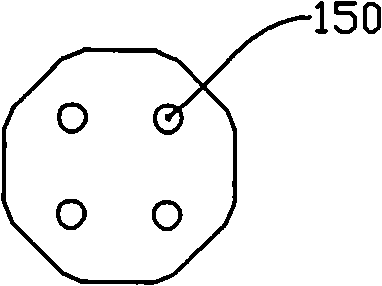

[0023] see figure 1 , the automatic sleeve rubber hose device includes a glue stick 1, and the glue stick 1 extends into the end of the rubber hose. For the specific structure of glue stick 1, see figure 2 and image 3 , the upper end of the glue stick 1 is a thick columnar part 110 , the middle part is a thin columnar part 120 thinner than the upper end, and the lower part is a fishtail part 130 . The thick columnar part 110 and the thin columnar part 120 are connected by a transition cone, which makes it easier for the rubber hose to fit into the thick columnar part 110 . from image 3 It can be seen that the outer surface of the thick columnar portion 110 in this embodiment is similar to a cylindrical surface, and in order to facilitate the insertion of the rubber hose, the outer surface of the thick columnar portion 110 is a smooth curved surface. Of course, the outer surface of the thick columnar portion 110 may also be a cylindrical surface. The main function of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com