Torsion-resistant pull rod structure of power assembly

A technology of anti-torsion tie rod and powertrain, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc. It can solve the problems affecting the performance of torsion tie rod, NVH performance, and small surface friction coefficient, so as to improve NVH performance , enhance the stability of the connection, and the effect of gentle stiffness curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

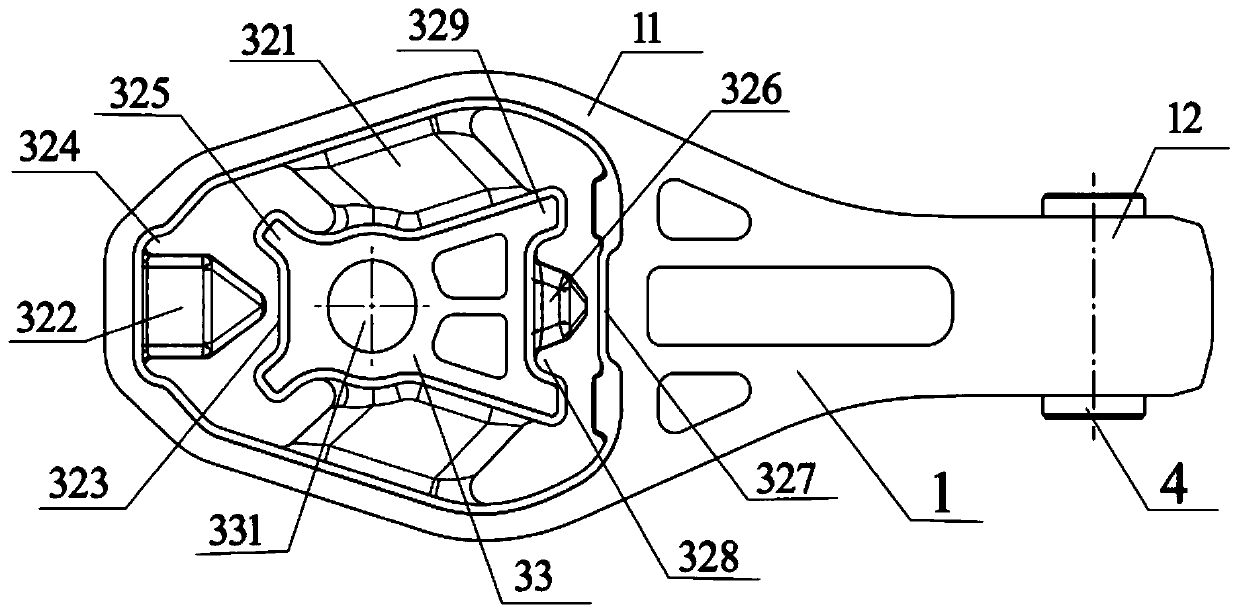

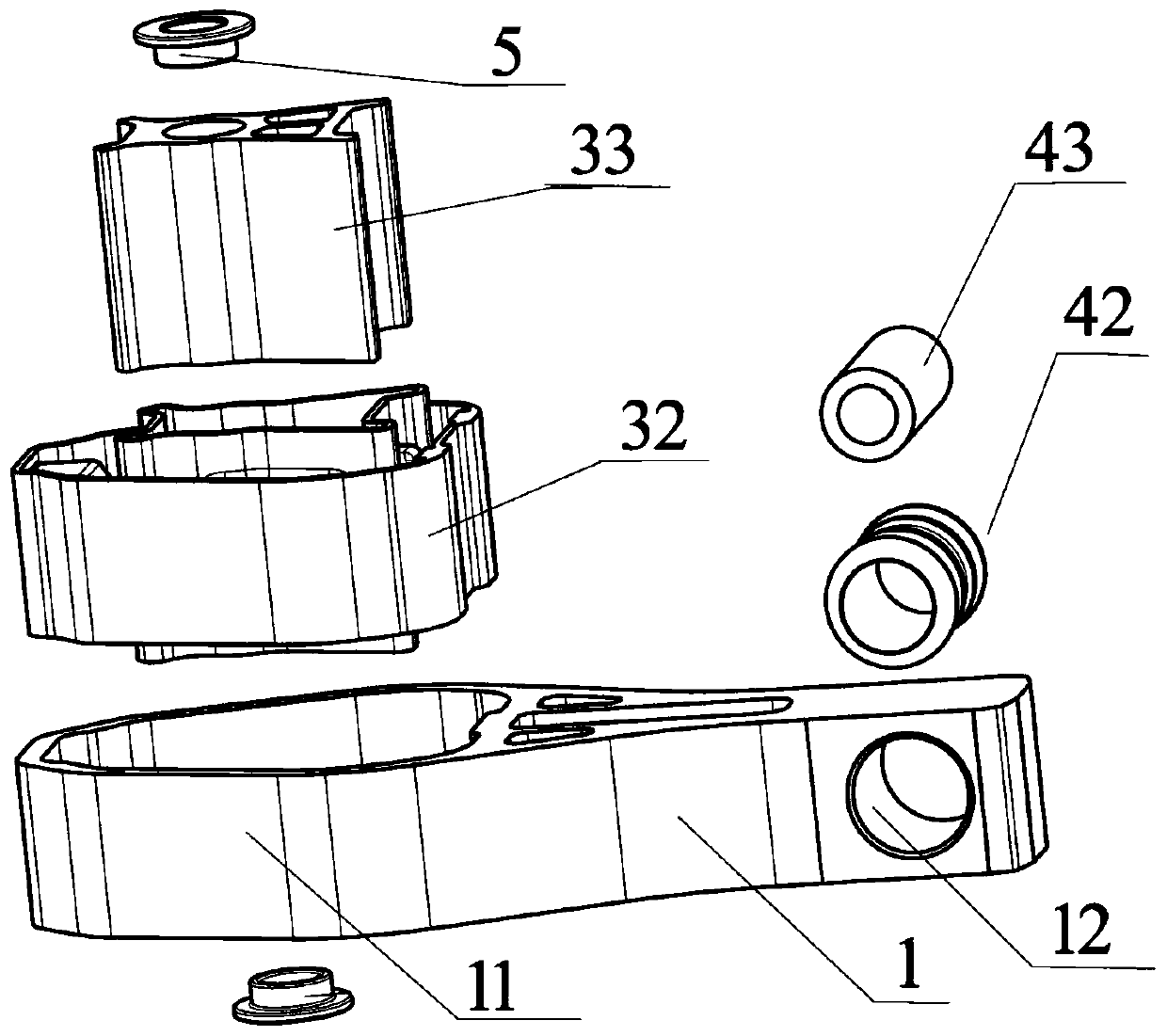

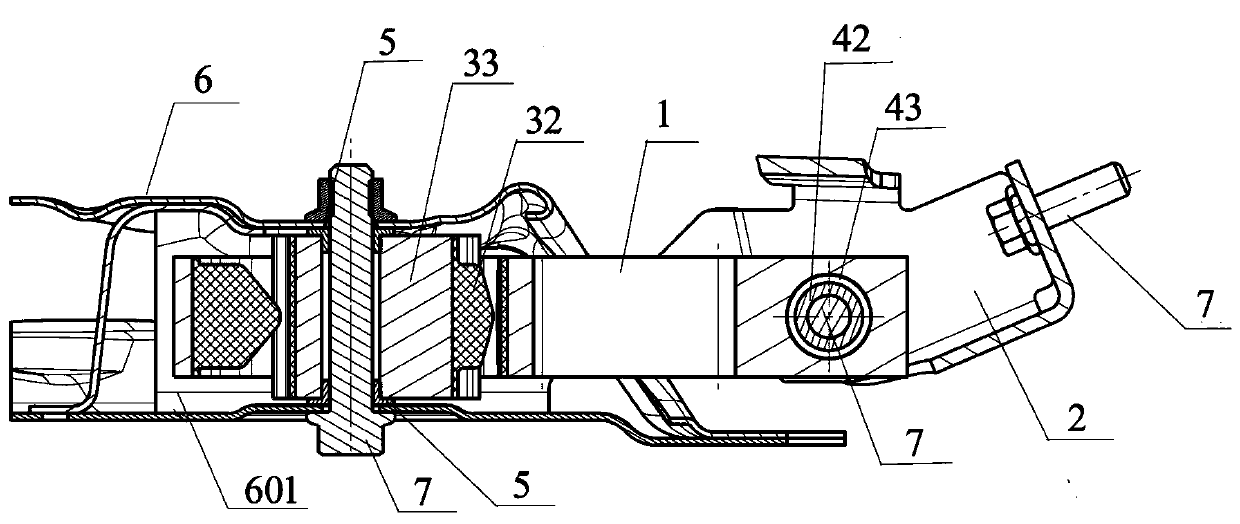

[0028] Such as Figure 1-6 As shown, a powertrain anti-torsion tie rod structure includes a torsion tie rod skeleton 1, and two ends of the torsion tie rod skeleton 1 are respectively provided with a hollow large bushing installation sleeve 11 and a small bushing installation sleeve 12, and the large bushing is installed The sleeve 11 is fixedly connected with a large bush 3, and the small bush installation sleeve 12 is fixedly connected with a small bush 4. The large bush 3 includes a large bush rubber ring 32 and a large bush inner lining 33. The large bush rubber The ring 32 is located between the large bush installation sleeve 11 and the large bush inner lining 33 and is fixed as a whole by vulcanization. The small bush 4 includes a small bush rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com