Swing arm bushing rubber and framework pull-off test tool

A technology for tensile testing machines and bushings, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as unreliable results, high skill requirements for testers, and impact on safety, so as to achieve fast bushing switching speed and improve test performance. High efficiency and high reliability of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

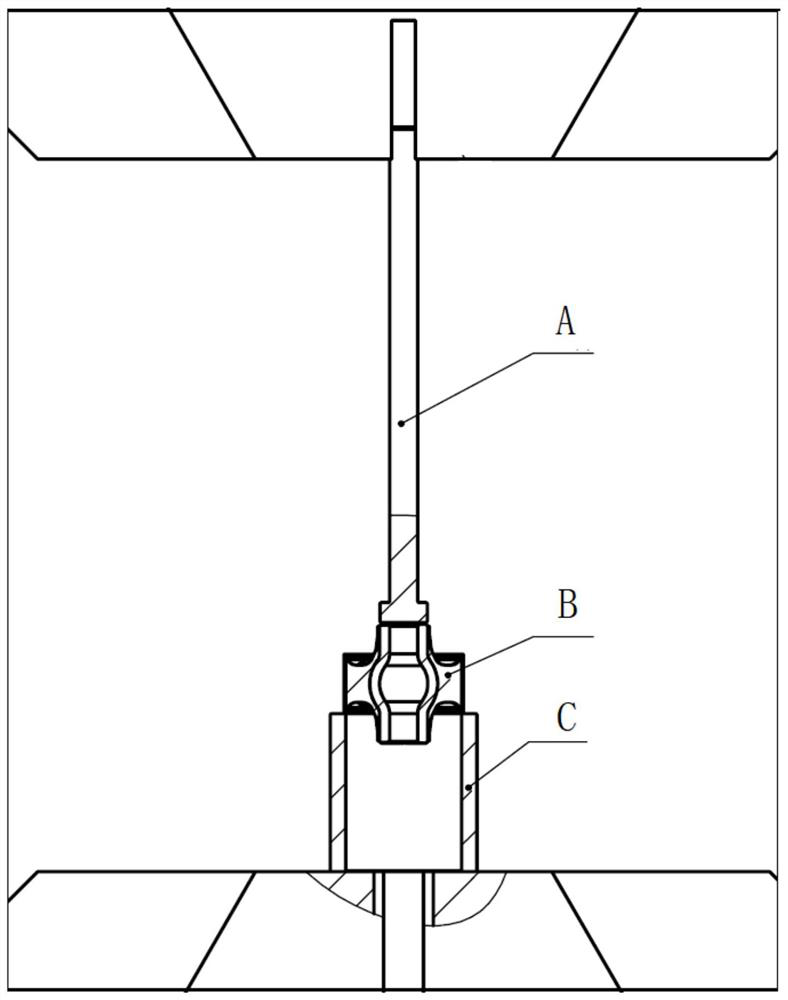

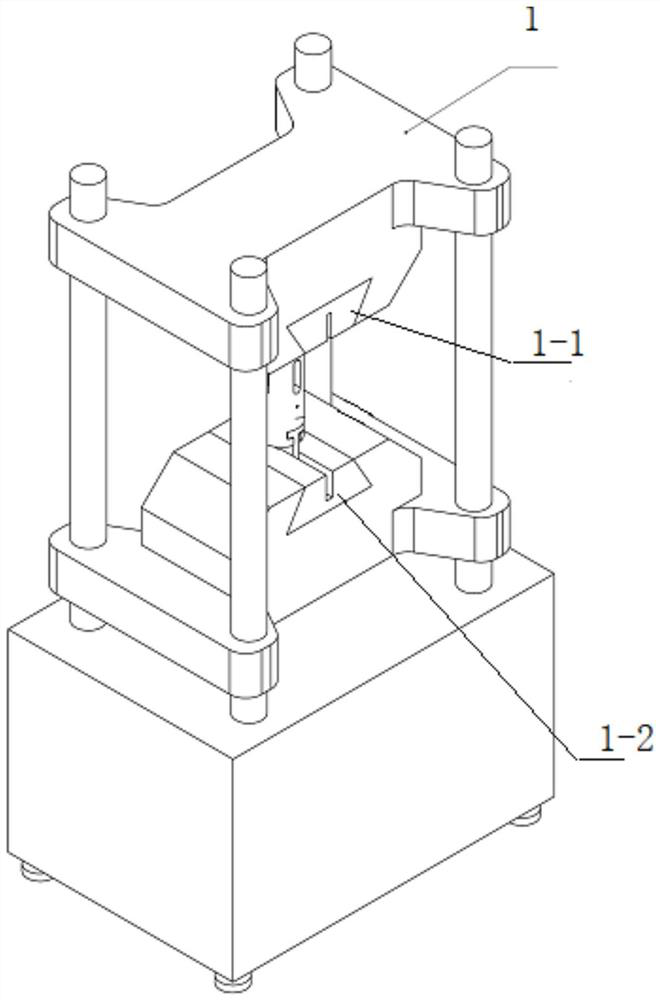

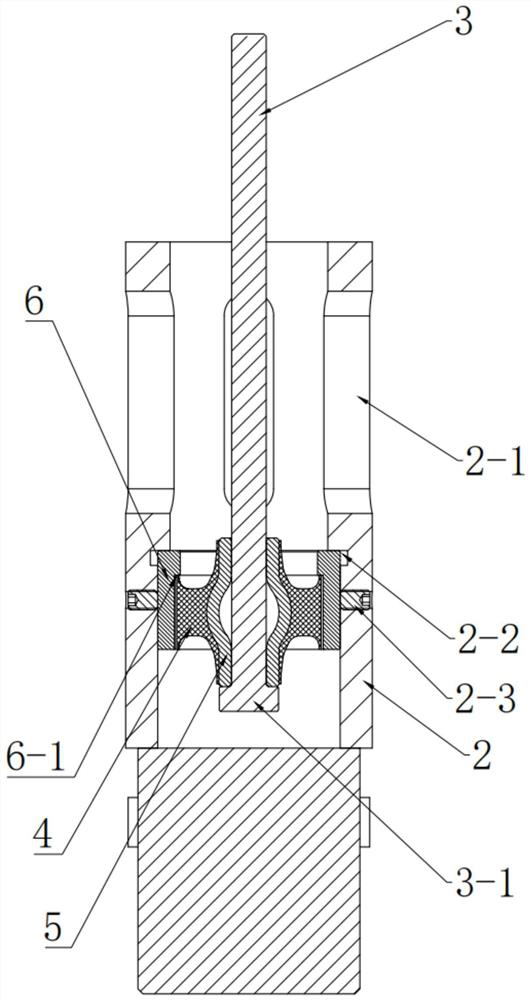

[0023] Example: such as Figure 2-Figure 4 As shown, the swing arm bushing rubber and skeleton pull-off test tool mainly includes a tensile testing machine 1, a bushing outer positioning seat 2 and a pull rod 3, and the tensile testing machine 1 is provided with a fixed bushing outer positioning seat 2 The lower clamping mechanism 1-1 and the upper clamping mechanism 1-2 for fixing the pull rod 3, the outer frame 4 is fixed in the bushing outer positioning seat 2, the pull rod 3 is connected with the inner frame 5, and the upper clamping mechanism 1-2 Moving up drives the pull rod 3 to disengage the inner frame 5 from the outer frame 4 . The detachment process is realized in the outer positioning seat 2 of the bush, so the problem of the pop-up of the bush will not occur.

[0024] An observation hole 2-1 is provided on the outer positioning seat 2 of the bush for close-range observation of the degumming process, with high safety performance.

[0025] The bushing outer positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com