Rubber bushing compacting mould

A rubber bushing and die technology, applied in metal extrusion dies, metal extrusion, manufacturing tools, etc., can solve problems such as chemical bond damage, rubber layer cracking, rubber bushing damage and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

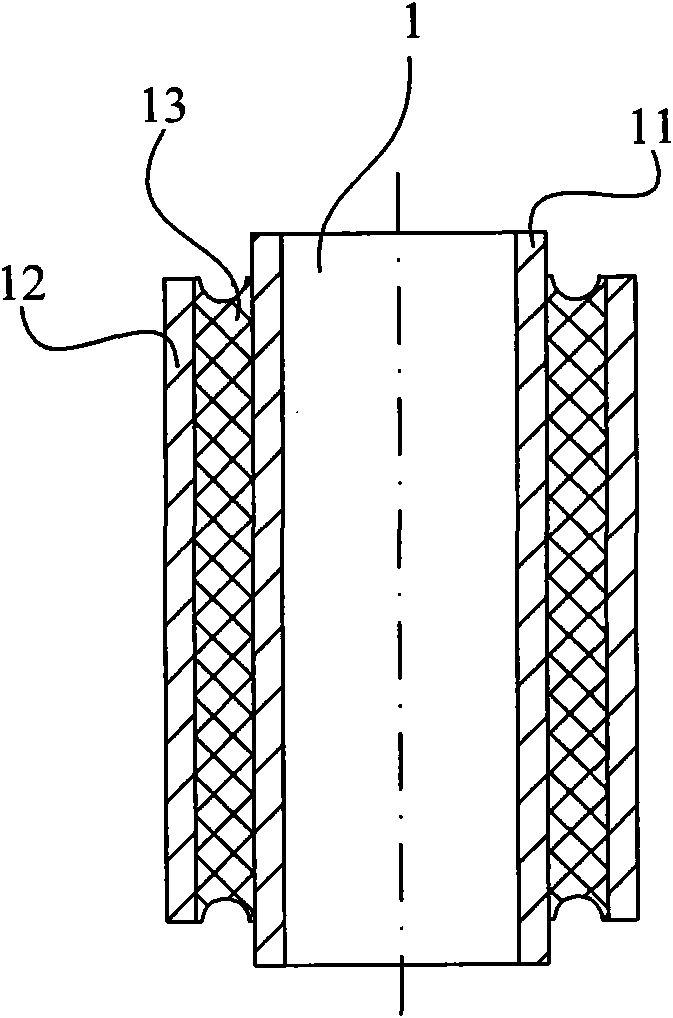

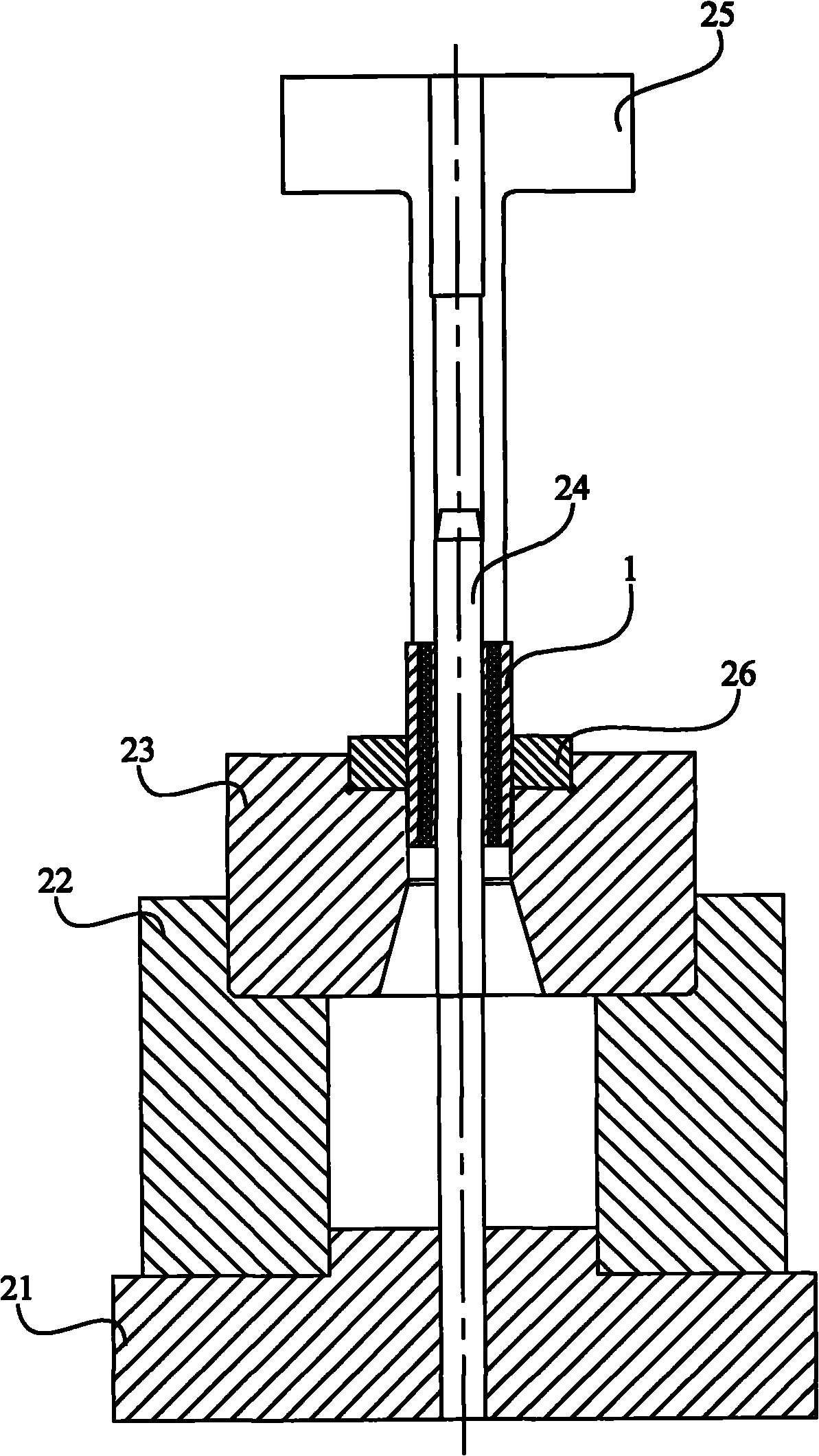

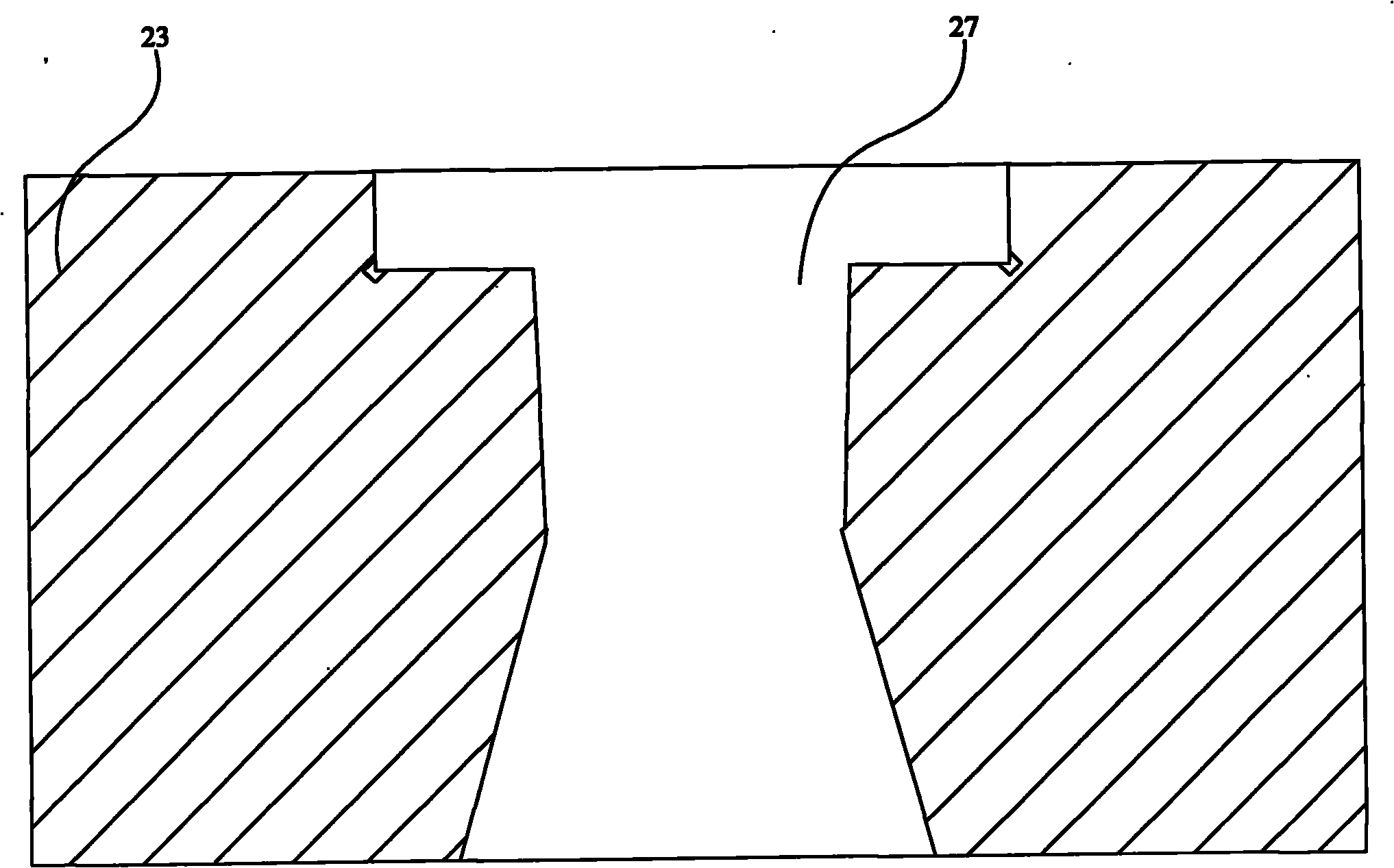

[0013] figure 2 It is the structural representation of the embodiment of the rubber bush extrusion die of the present invention, as figure 2 As shown, it includes a base 21, a support ring 22, an extrusion block 23, a guide post 24 and an indenter 25. During the extrusion process, the electronic tension machine is loaded on the upper end surface of the indenter 25, and the rubber bushing 1 is pressed downward. displacement compression. The guide post 24 is fixedly installed on the base 21. Under the positioning and guiding action of the guide post 24, the central axis of the rubber bush 1 will not deviate from the axis of the squeezed part of the rubber bush extrusion die during the extrusion process, avoiding the occurrence of If the amount of shrinkage is uneven or the coaxiality is seriously out of tolerance, the shape and position tolerance of the rubber bushing during the entire shrinkage process is guaranteed. The squeeze block 23 is provided with a through hole 27, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com