Preparation method of rubber reinforcing agent, automobile plate spring bushing sizing material containing rubber reinforcing agent and preparation method thereof

A technology of rubber reinforcing agent and automobile plate, applied in the rubber field, can solve the problems of low connection strength and few active groups, and achieve the effects of low cost, enhanced strength, improved mechanical properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

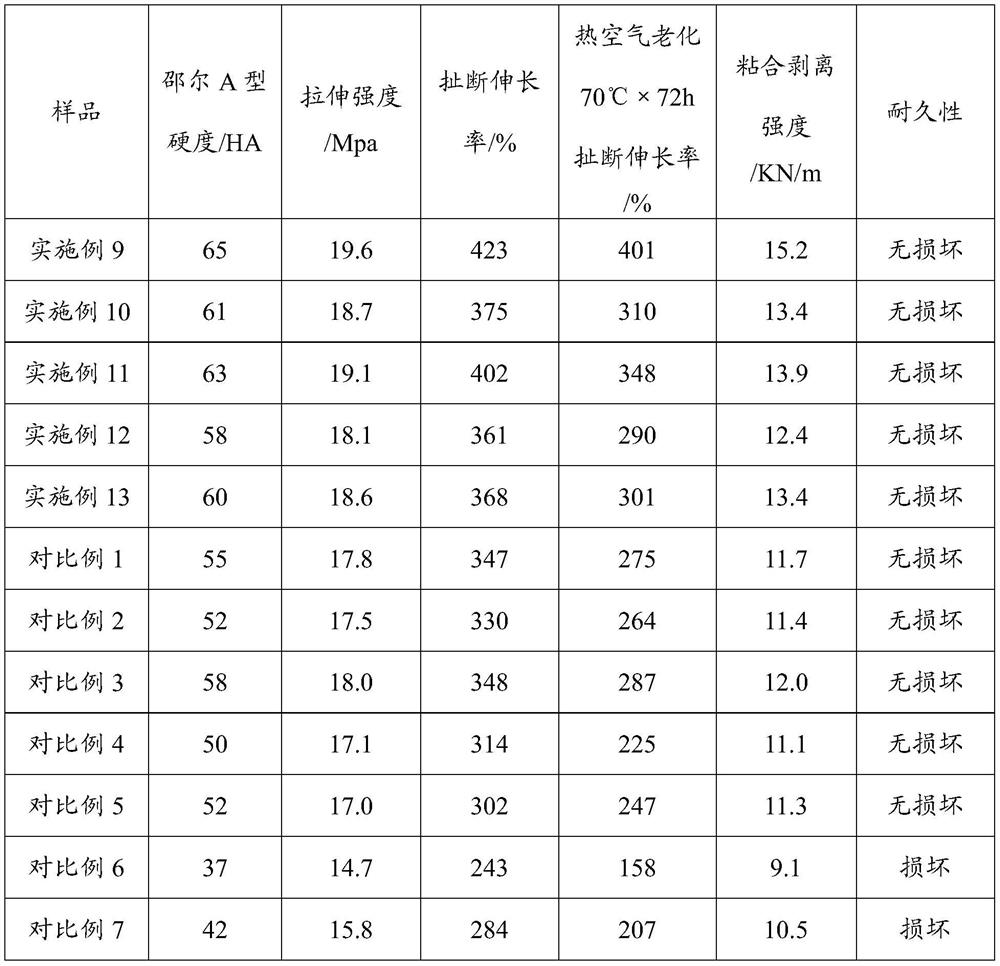

Examples

preparation example Construction

[0028] First, the invention provides a kind of preparation method of rubber reinforcing agent, comprises the steps:

[0029] S1 pickling and pulverizing the rice husk;

[0030] S2 mixes the crushed rice husk in S1 with humic acid and an aqueous ethanol solution, and then puts it into the reactor for reaction to obtain the first intermediate;

[0031] In S3, the first intermediate in S2 is fired; after firing, it is pulverized and ground to obtain a finished product.

[0032] In the present invention, the technological parameter of pickling is, rice husk is put into the HCl solution that mass fraction is 10%, the mass ratio of rice husk and HCl solution is 1:8~15, is preferably 1:8~10, further Preferably 1:10; ultrasonic treatment for 20min-40min, preferably 20min-30min; after ultrasonic treatment, filter, wash until neutral, and then dry.

[0033] In the present invention, a pulverizer is used to pulverize to a size of 1 mm to 10 mm.

[0034] In the present invention, in th...

Embodiment 1

[0060] A kind of rubber reinforcing agent, its preparation method, comprises the steps:

[0061] S1 Put rice husks into HCl solution with a mass fraction of 10%, and the mass ratio of rice husks to HCl solution is 1:10; filter after ultrasonic treatment for 30 minutes, wash to neutrality, and then dry; The rice husk is crushed to 1mm ~ 10mm;

[0062] S2 Mix the crushed rice husk with humic acid and ethanol aqueous solution, and add it into the reactor to react to obtain the first intermediate; the reaction temperature is 100°C, and the reaction time is 20min; the mass ratio of ethanol to water in the ethanol aqueous solution is 3 :1; the mass ratio of rice husk, humic acid, and aqueous ethanol solution is 5:5:10;

[0063] S3 The first intermediate is fired, first at low temperature and then at high temperature. The low temperature firing temperature is 375°C, the low temperature time is 2h, the high temperature firing temperature is 600°C, and the high temperature time is 0.5...

Embodiment 2

[0065] The difference between this example and Example 1 is that the mass ratio of rice husk, humic acid, and aqueous ethanol is 5:3:12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com