Large and heavy numerical control static-pressure revolving platform

A rotary table and static pressure technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reducing processing efficiency and precision, structural rigidity and assembly process affecting dynamic characteristics, etc., to improve efficiency, The effect of improving indexing accuracy and accuracy retention, increasing bearing capacity and dynamic stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical content of the present invention is described:

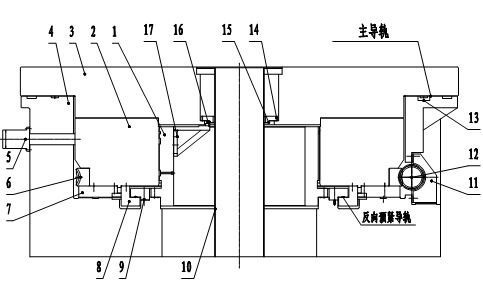

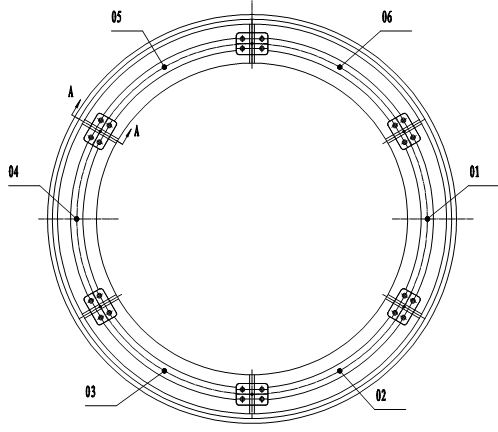

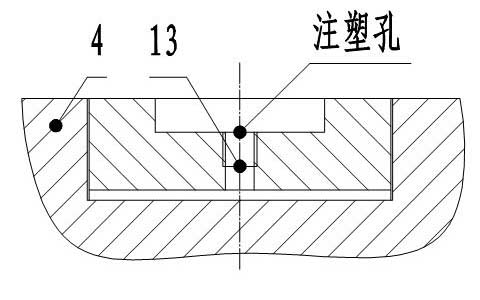

[0032] figure 1It is a schematic diagram of the structure of a large and heavy CNC static pressure rotary table, which mainly includes 6 major parts: the base 4 and the mandrel 1 form the supporting part; The moving coil 8 and the fixed coil 9 of the guide rail form a closed guide rail part; the worm 12 and the worm bracket 11 form the worm part; the circular light ring support 14, the circular light ring 15, the reading head 16 and the reading head support 17 form a circular grating full-closed-loop part; the lock Tight oil cylinder 5, guide sleeve 18 and damping copper block 19 form radial locking parts. The turntable is a floor-standing structure, and the rigidity of the supporting parts is large; the rotary index relies on the static pressure mandrel for precise positioning, the radial runout is 0.01mm, and the rigidity is greater than 0.01mm / t; there is a chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com