Multi-cutter head for milling main journal of crankshaft and manufacturing process of multi-cutter head

A main journal and multi-cutter technology, which is applied in the direction of manufacturing tools, milling cutters, milling machine equipment, etc., can solve the problems of inconvenient loading and unloading of workpieces, poor crankshaft rigidity, and easy vibration, etc., to achieve convenient and ingenious adjustment, high service life, Easy to guarantee the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

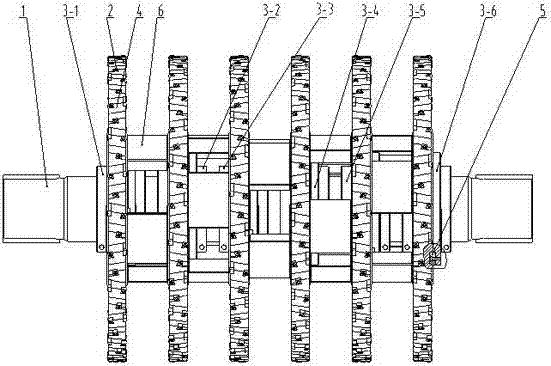

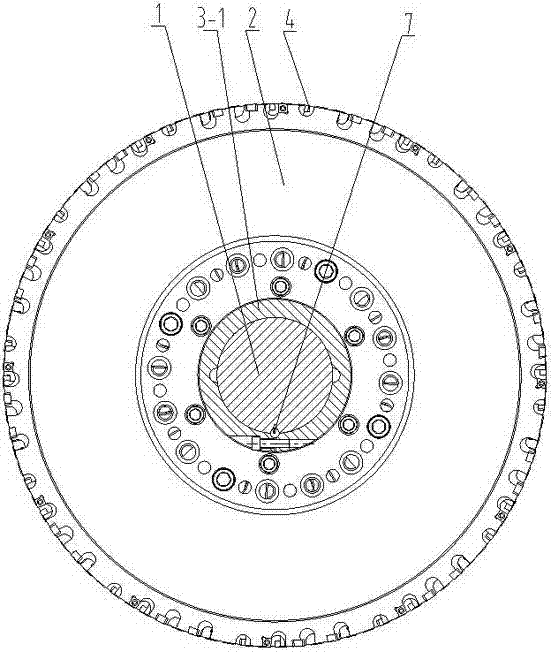

[0037] refer to Figure 1-Figure 7 , taking the processing of a six-cylinder crankshaft as an example, the present invention includes a main shaft 1, 6 identical cutterheads 2 and 6 cutterhead seats 3-1, 3-2, 3-3, 3-4, 3 with specific design angles -5, 3-6, 12 groups of blades 4 are installed on the circumferential surface of each cutterhead 2, each group includes 6 blades, the positions of the 12 groups of blades 4 relative to the cutterhead 2 are consistent, and the blades with the same function are evenly distributed on the cutterhead Each blade is set at a different busbar position, and the six cutterheads 2 are fixed to the six cutterhead seats 3-1, 3-2, 3-3, Between 3-4, 3-5, and 3-6, six cutterhead seats 3 are locked on the main shaft 1 through round keys and locking screws, and a detachable adjustment pad is set between the cutterhead 2 and the cutterhead 2 6. The cutter head 2 is provided with a plurality of round holes 10, and the adjustment block 6 is provided with...

Embodiment 2

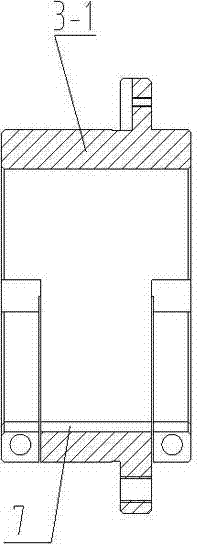

[0040] refer to figure 2 The difference between embodiment 2 and embodiment 1 is that the cutter head seat 3 is fixed on the circumferential direction of the main shaft 1 through the round key 7 and the V-shaped groove 8 of the main shaft 1, so that the cutter head Dislocation distribution of the upper blade, uniform force and small vibration during milling, easy to ensure accuracy.

[0041] The concrete steps and process of making this invention are:

[0042] The first step is to select alloy tool steel to process and manufacture multiple cutterhead seats according to the design drawings, respectively to ensure the end face key angle of each specific design, to ensure the corresponding dimensional accuracy, shape tolerance and surface roughness requirements, and to quench and temper.

[0043] The second step is to process and manufacture multiple cutterheads (corresponding to the number of crankshaft main journals) according to the design drawings, to ensure the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com