Reinforcing structure of suspension installation points for automobile

A technology to strengthen the structure and installation points, which is applied in the direction of control devices, power devices, vehicle components, etc., can solve the problems that cannot be satisfied, the production process is not easy to control, and the structure and process cannot be realized, so as to improve the dynamic stiffness and static stiffness. Improve NVH performance and process is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

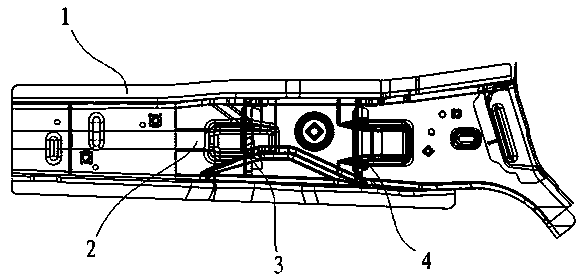

[0026] The suspension mounting point reinforcement structure for automobiles in this embodiment includes a front longitudinal beam inner panel body reinforcement plate 1, a suspension support plate 2 and a front longitudinal beam inner panel body 3, wherein:

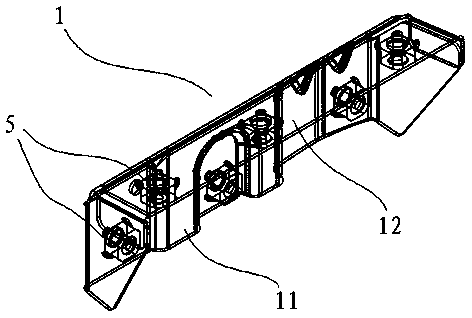

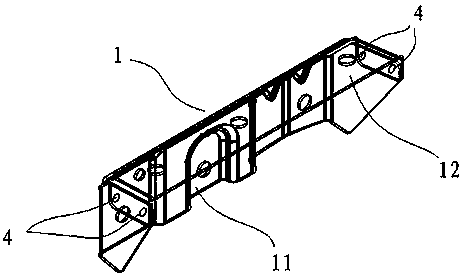

[0027] Such as figure 2 , 3 As shown, the front longitudinal beam inner panel body reinforcement plate 1 includes a support plate 11 and a top plate 12 which are integrally bent from the plate, the support plate 11 is perpendicular to the top plate 12, and the ends of the support plate 11 and the top plate 12 are bent Fold and connect and fix with double-layer solder joints 4, wherein each side has two double-layer solder joints 4.

[0028] Such as Figure 4 As shown, the suspension support plate 2 is a box-shaped structure with a top end and a side opening formed by punching a plate, and a flange 21 is provided on the edge of the suspension support plate 2 .

[0029] Such as Figure 5 , 6 As shown, the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com