Connection structure of anti-torque pull rod and auxiliary frame and automobile

A technology of anti-torsion pull rod and connecting structure, which is applied in vehicle parts, jet propulsion devices, internal combustion propulsion devices, etc., to improve NVH performance and avoid roaring noise in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] The terms of direction and position mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "top", "bottom" ", "side", etc., are only referring to the direction or position of the drawings. Therefore, the terms used in direction and position are used to illustrate and understand the present invention, but not to limit the protection scope of the present invention.

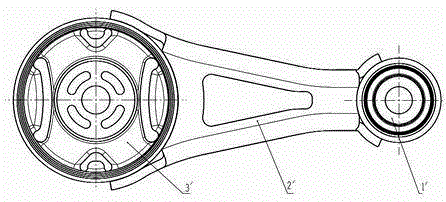

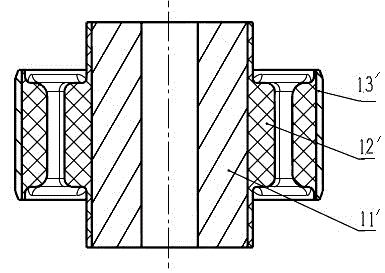

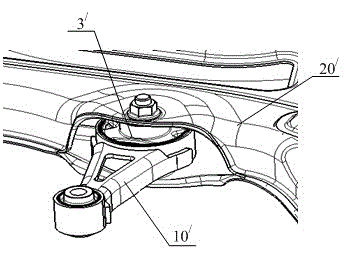

[0041] like Figure 5 to Figure 11 As shown, Embodiment 1 of the present invention provides a connection structure between the torsion tie rod and the subframe, including the torsion tie rod 1 and the subframe mounting part 2; the torsion tie rod 1 includes a small bush 11, a tie rod bracket 12 and a large The bushing 13, the large bushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com