Structure for connecting swing arm lining with sub vehicle frame

A technology for connecting structures and sub-frames, which is applied to substructures, suspensions, vehicle components, etc., can solve problems such as cumbersome assembly, difficulty in control, and easy generation of abnormal noise, so as to reduce frequent operations, save installation space, and simplify assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

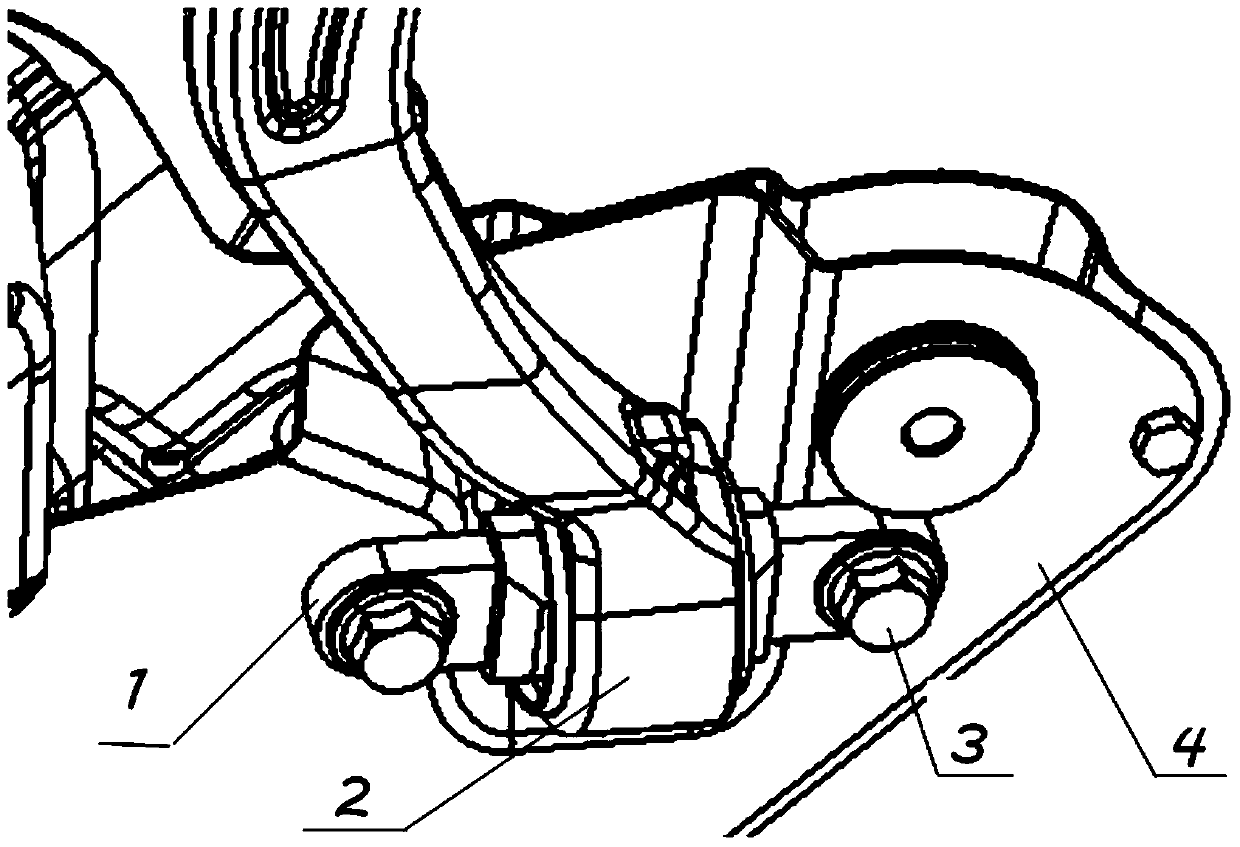

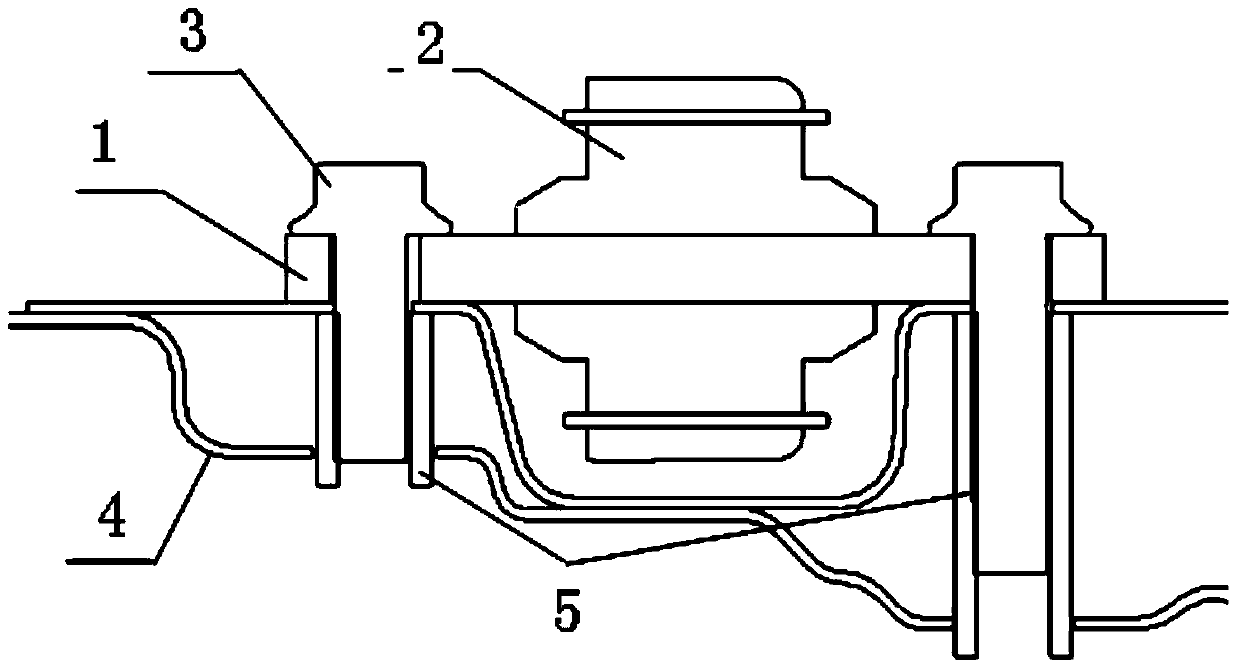

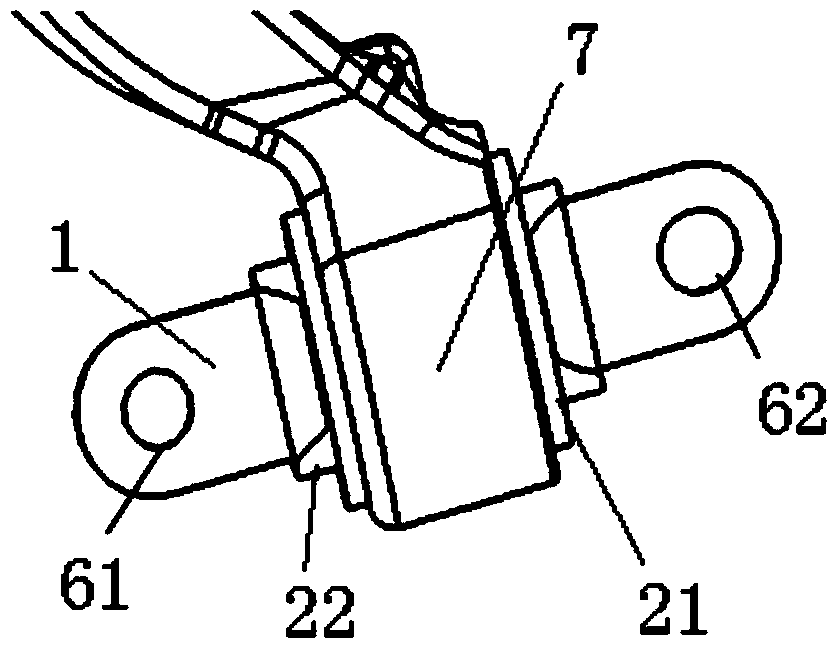

[0043] Figure 1 to Figure 4 It is a structural schematic diagram of a specific embodiment of the present application. The features and advantages of the present invention will be further elaborated below in conjunction with the description of the drawings and specific embodiments.

[0044] The invention relates to a connection structure between a swing arm bush and a subframe, such as figure 1 As shown, this structure includes a subframe 4 , a swing arm bush 2 and a bolt 3 ; the subframe 4 is connected to the swing arm bush 2 through the bolt 3 .

[0045] The swing arm bushing 2 and the swing arm sleeve 7 are an interference fit, which ensures a reliable connection by virtue of this interference. The swing arm bushing 2 is press-fitted with the swing arm bushing 7 with interference, and there are certain requirements for the pull-out force of the swing arm bush. If the pull-out force of the swing arm bush is insufficient and bears a large impact force during driving, the s...

Embodiment 2

[0052] In this embodiment, the structure of the sub-frame is the same as that of Embodiment 1.

[0053] The swing arm bushing in this embodiment includes an inner frame, an inner sleeve, a vulcanized rubber body between the inner frame and the inner sleeve, an intermediate rubber body and an outer tube of the bushing, which are sequentially arranged from inside to outside. In this embodiment, the arrangement of the vulcanized rubber body and the intermediate rubber body can achieve different elastic deformations, which is beneficial to the stability of the swing arm bushing. In this embodiment, the vulcanized rubber body and the intermediate rubber body have different thicknesses, wherein The thickness of the vulcanized rubber body is greater than the thickness of the intermediate rubber body, and the thickness of the vulcanized rubber body is 1.1-1.5 times of the thickness of the intermediate rubber body, and the elastic coefficient of the vulcanized rubber body is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com