Wall assembling production line

An assembly line, assembly line technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of large usage, pollution, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with accompanying drawing:

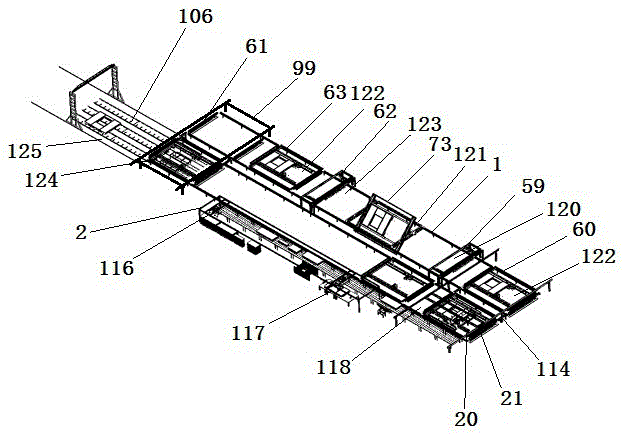

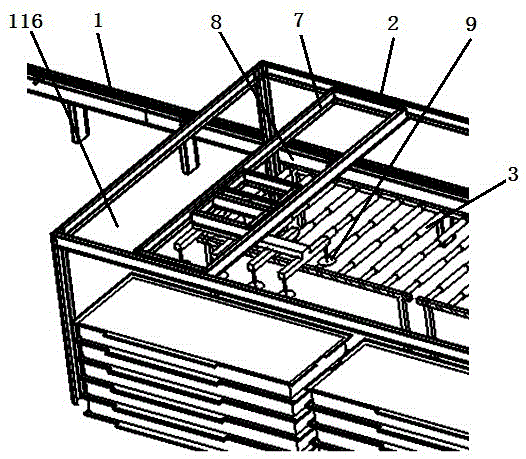

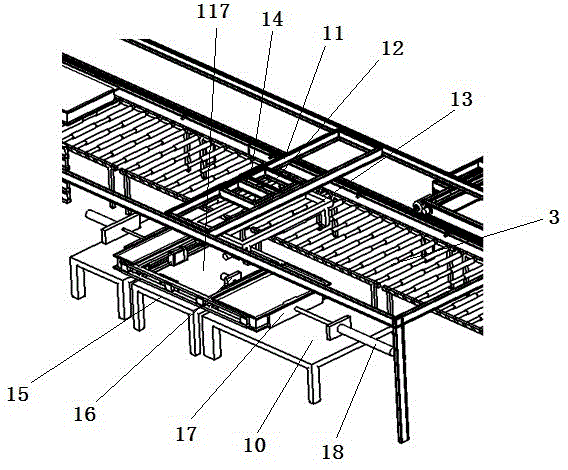

[0034] As shown in the accompanying drawings, a wall assembly line is characterized in that it includes an assembly line track 1, a distribution track 2 and a control system, a distribution track 2 is provided on one side of the assembly line track 1, and a wall is provided below the distribution track 2. Panel conveying line 3, the wallboard conveying line 3 is provided with a vacuum suction cup manipulator distributing station 116 and a pre-installation station 117, and the assembly line track 1 is provided with an assembly station 118 and a forward nailing preparation station in sequence 119. Forward nailing station 120, turning station 121, reverse nailing preparation station 122 and reverse nailing station 123, wherein: the assembly line track 1 is provided with a linear guide rail 33, and the linear guide rail There is a connecting shaft 6 in a linear array on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com