Optical adhesive and manufacturing method and flexible display screen thereof

A flexible display and manufacturing method technology, applied in the field of optical glue and flexible display, can solve problems such as difficult to pass the nano-indentation pencil hardness test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

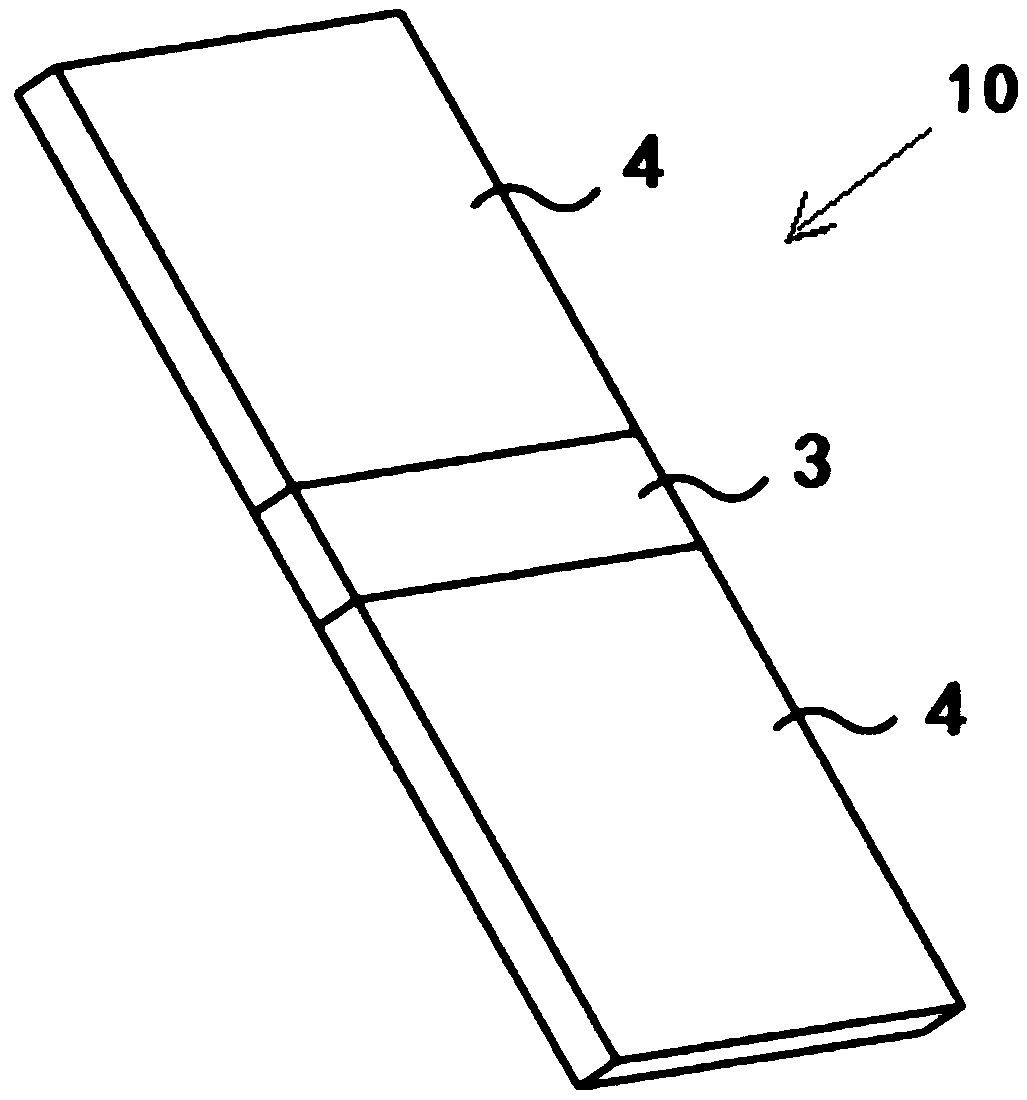

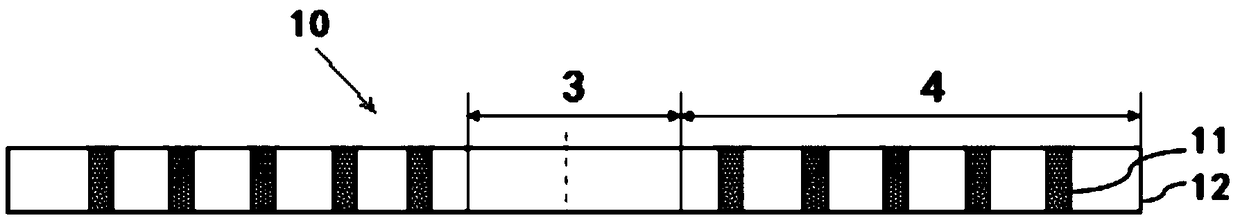

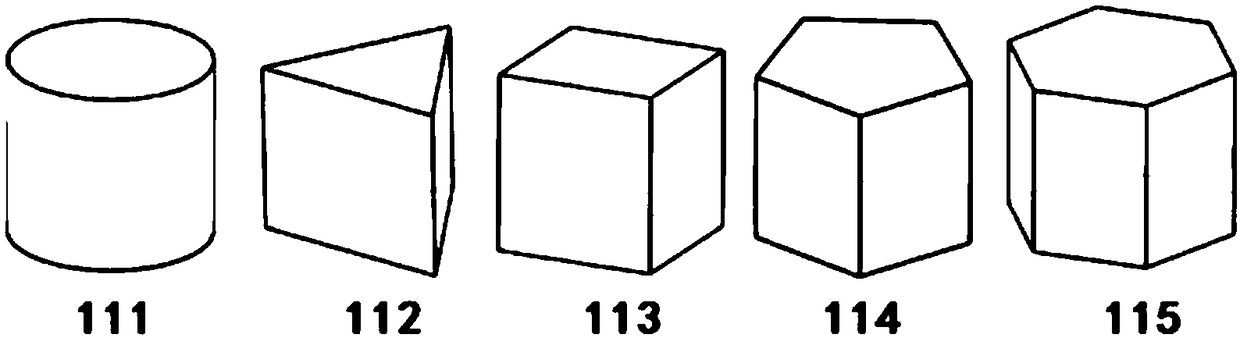

[0033] see figure 1 As shown, in one embodiment of the present invention, an optical glue 10 is proposed, including a first section 3 and a second section 4 arranged on both sides of the first section 3, the first section 3 Including the OCA glue layer 12 , the second section 4 includes the OCA glue layer 12 and the support pillars 11 arranged in the OCA glue layer 12 .

[0034] Wherein the elastic modulus of the support column 11 is 50-250GPa; the elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com