Waste energy echelon utilization method of power battery for electric vehicle

A technology for power batteries and electric vehicles, applied in battery recycling, recycling technology, secondary battery repair/maintenance, etc., can solve the problem of lack of cascade utilization of surplus energy in power batteries, low operational feasibility, and difficulty Realization and other problems, to achieve the effect of avoiding electrolyte deterioration, simple repair method, and good performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

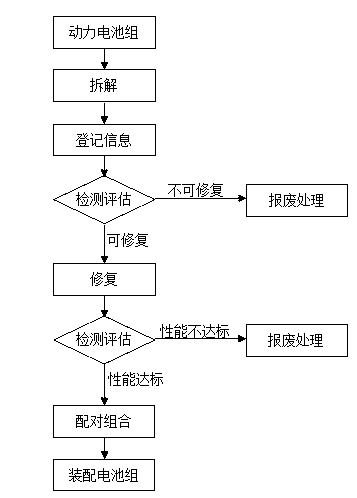

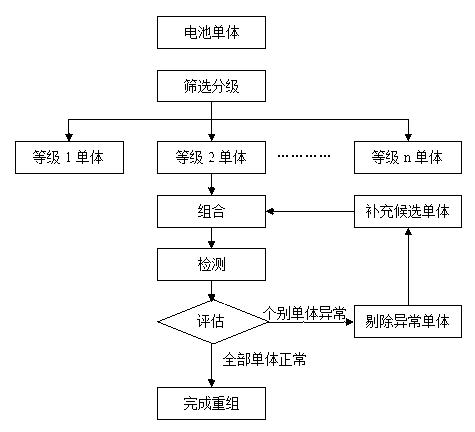

[0071] (1) Dismantling: After discharge or under special conditions without discharge, the waste power battery pack obtained by recycling is dismantled without damage, and the screws on the battery pack are removed with a screwdriver, and the parts other than the battery cells are removed one by one. Use a knife to cut the position that cannot be disassembled with a screwdriver, disassemble the battery pack into a battery module, and then disassemble the battery module into a battery cell, and finally get several battery cells. Special conditions refer to the conditions in which protective measures such as isolating oxygen and lowering the temperature are implemented in the environment of the dismantling process to prevent unsafe phenomena such as combustion and explosion of the power battery. After dismantling, record the basic information of the battery cell, the rated voltage is 3.2V, and the nominal capacity is 60Ah.

[0072] (2) Screening before repair: First, check the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com