A light-weight high-strength composite material structure and its preparation method

A high-strength composite material and light-weight technology, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems of inability to automate production, unstable performance, complex structure, etc., and achieve easy adjustment of the overall size and fast molding The effect of simplicity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

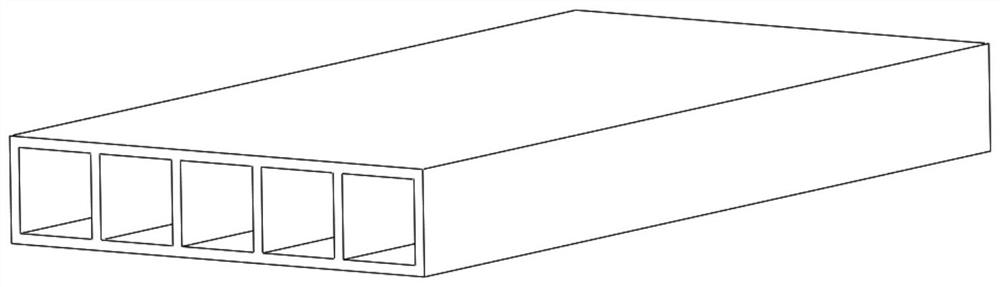

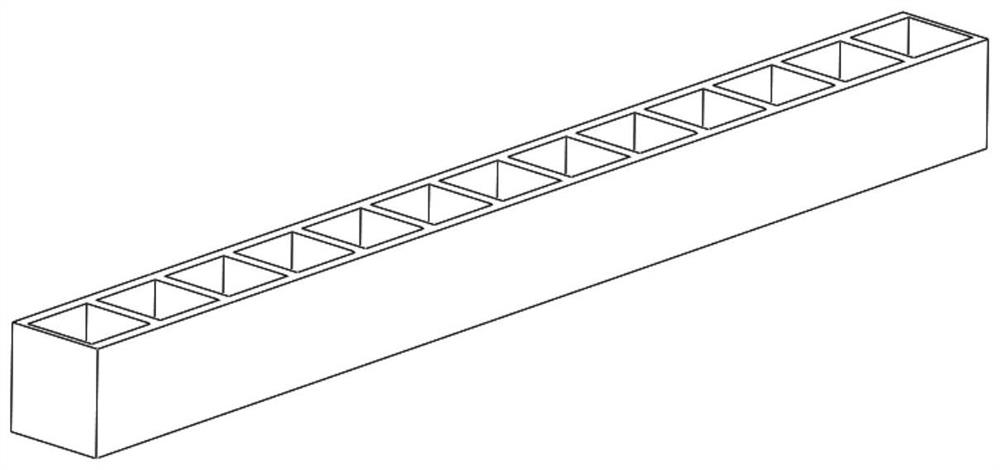

[0031] A lightweight high-strength composite material structure, which includes a hollow box girder structure (such as figure 1 shown) and the support core installed in the inner cavity of the hollow box girder structure (such as figure 2 shown); wherein, the hollow box girder structure includes an upper support plate, a lower support plate, and a plurality of partitions between the upper and lower support plates, the partitions are perpendicular to the upper and lower support plates, and the adjacent two partitions and the upper 1. The lower support plate encloses at least one open cavity, and the cavity is used to install the support core; the support core structure is a grid structure, including a frame and a plurality of horizontal plates and a plurality of vertical plates located inside the frame and arranged at intervals ; The hollow box girder structure and supporting core materials are all made of continuous glass fibers impregnated with epoxy resin glue and then cure...

Embodiment 2

[0036] A lightweight high-strength composite material structure, the preparation method of which comprises the following steps:

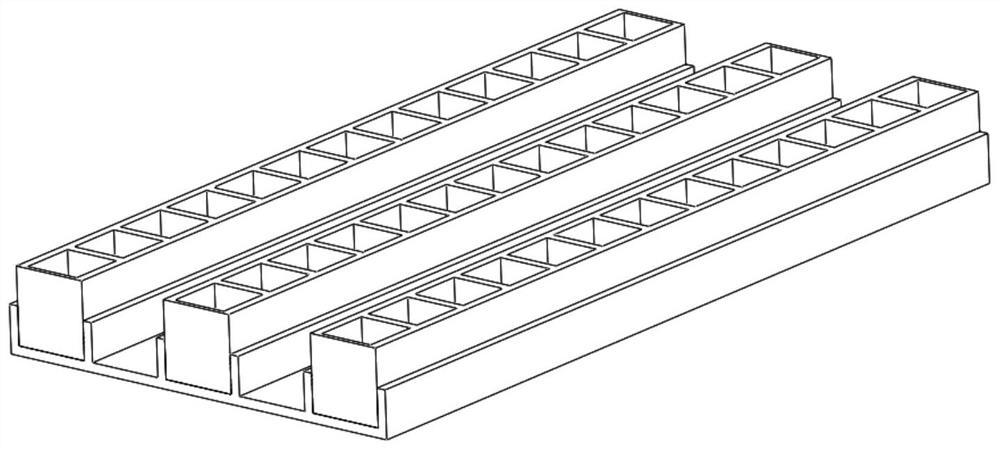

[0037] Such as image 3 As shown, Example 2 adopts the same structure as Example 1, and the same pultrusion and cutting process, but the difference is that in Example 2, carbon fiber is used instead of glass fiber to make the pultrusion profile, and the overall size of the profile is enlarged, and the enlarged hollow The size of the box girder structure is: a hollow box girder structure with a length of 300mm, a thickness of 20mm, a wall thickness of 2mm, and a cavity of a cuboid with a cross-section of 16mmX16m. The frame size of the grid structure: length 300mm, width 16mm, thickness 16mm, wall The thickness is 2mm, and each cell inside the frame is 12mmX12mm. After that, the same method as in Example 1 was carried out to complete the filling and bonding, and the required light-weight and high-strength composite material structure was obtained. ...

Embodiment 3

[0039] A lightweight high-strength composite material structure, the preparation method of which comprises the following steps:

[0040] Such as Figure 4 As shown, Example 3 adopts the same structure as Example 1 and Example 1, and the same pultrusion and cutting process, but the difference is that Example 3 uses a 1:1 hybrid fiber of carbon fiber and glass fiber instead of glass fiber to make pultrusion Profiles, while enlarging the size, reduce the wall thickness of the material, reduce the material density, and change the material properties by increasing the pore density of the filled grid grid. The final size is: length 300mm, thickness 20mm, The hollow box girder structure has a wall thickness of 1mm and a hollow cuboid with a cross section of 18mmX18m, and frame dimensions: length 300mm, width 18mm, thickness 18mm, wall thickness 1mm, and a grid structure with each unit cell inside the frame being 6mmX6mm. After that, the same method as in Example 1 was carried out to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com