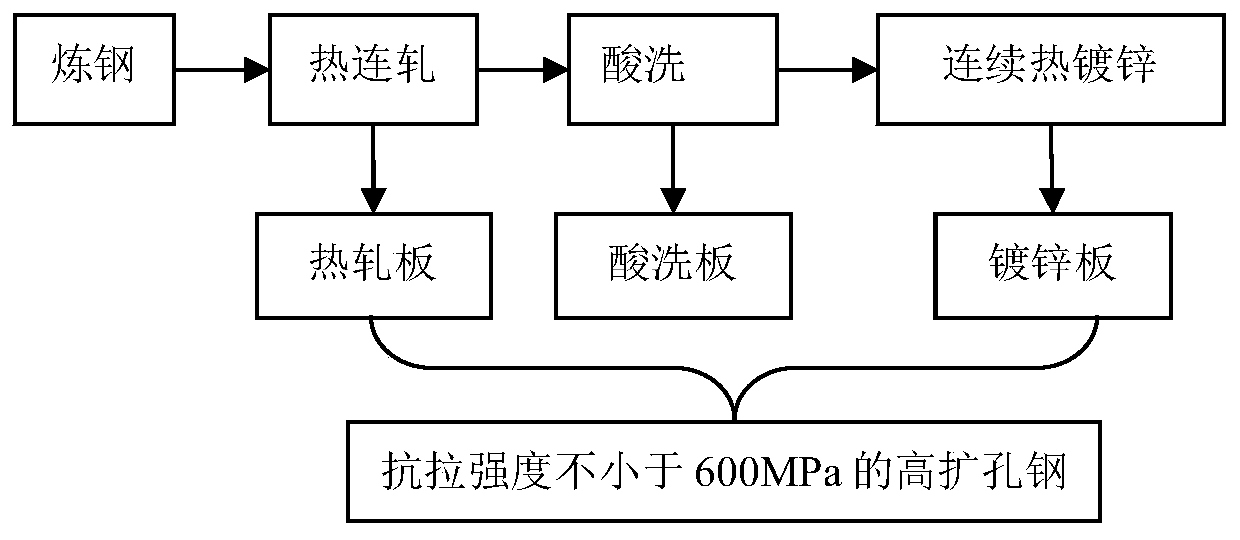

Preparation method for high chambering steel plate with strength of extension not smaller than 600 MPa

A technology of tensile strength and steel plate, which is applied in the field of preparation of high reaming steel plate, can solve problems such as uneven structure and performance, poor plate shape, etc., and achieve the effect of good performance consistency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Specifically, a method for preparing a high hole-expanding steel plate with a tensile strength not less than 600MPa, comprising the following steps: hot metal desulfurization, converter smelting, LF refining, continuous casting, hot rolling; the hot rolling is specifically slab heating , rough rolling, finish rolling, laminar flow segmental cooling, coiling, stacking and slow cooling; the chemical composition of the steel plate is calculated by mass percentage: C 0.06-0.10%, Si0.20-0.30%, Mn 1.30-1.70 %, P≤0.020%, S≤0.010%, Nb 0.040~0.060%, N≤0.0060%, Al 0.015~0.060%, and the balance is Fe and unavoidable impurities.

[0025] The choice of C content range mainly considers the matching of strength, formability and welding performance. If the C content is lower than 0.06%, the carbon content in bainite will be reduced and its strength will be affected; if it is higher than 0.10%, the formability and weldability of the steel plate will be affected. The resistance will be r...

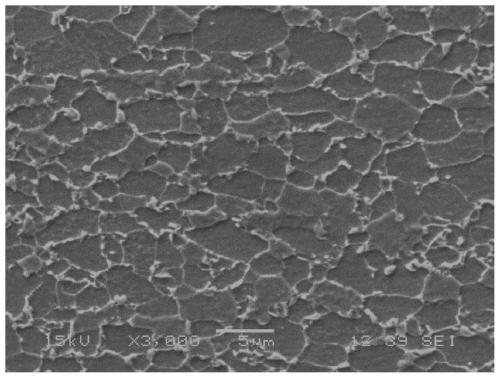

Embodiment 1

[0038] The composition (mass percentage) of the high hole expansion steel is: C 0.07, Si 0.25, Mn 1.49, P 0.009, S 0.002, Nb0.046, Al 0.042, N 0.0034.

[0039] A production method of hot-dip galvanized steel plate, according to the usual process of molten iron desulfurization, converter smelting, and LF refining, through continuous casting into continuous casting slabs, the slabs at a temperature of 620°C are heated and loaded into a heating furnace, and the heating time is It was 139min, and the tapping temperature was 1232°C. The slab is rolled to 38mm by 5-pass reversing rolling mill, and enters the 7-stand finishing rolling unit. The final rolling temperature is 886°C, the thickness of the rolled product is 2.52mm, and the strip speed of the last stand is 8.9m / s; After rolling, cool at 124°C / s for 1.4s, then air cool for 6.1s, then cool at 46°C / s to 500°C for coiling, and the steel coils are finally sent to the slow cooling pit and slowly cooled to room temperature at 0.43...

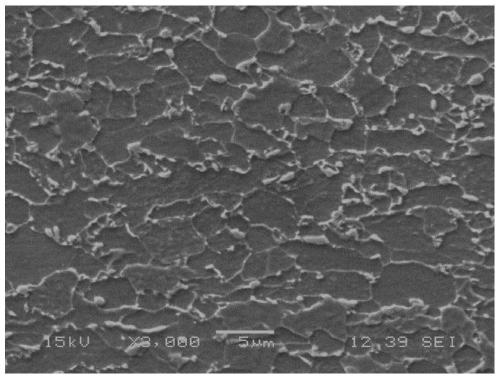

Embodiment 2

[0043] The method is the same as in Example 1, and the differences in process, finished product structure and performance are shown in Tables 1 to 4, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com