Dynamic balance inspection of assembled crank link mechanism of single-cylinder engine

A crank linkage mechanism and detection method technology, applied in the static/dynamic balance test, machine/structural component test, measuring device, etc., can solve the problems that cannot be used in mass production, time-consuming and labor-intensive, etc., to achieve convenient inspection, The operation saves time and effort, and the effect of good performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

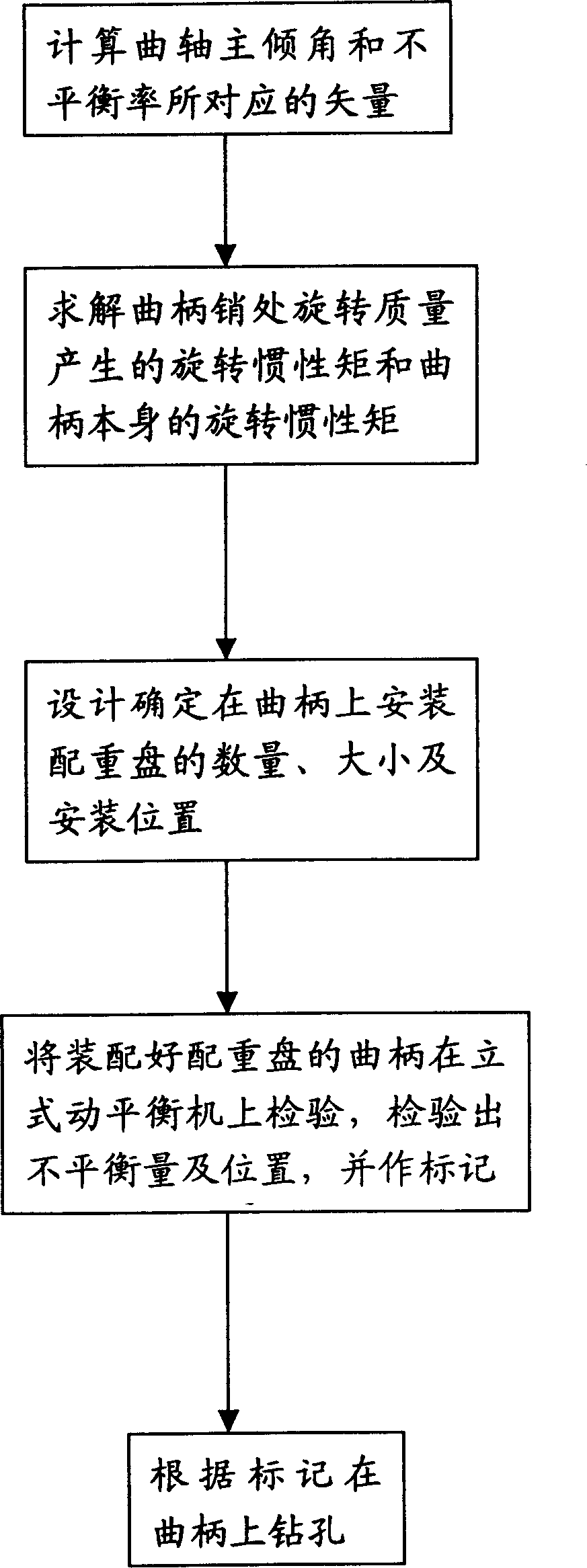

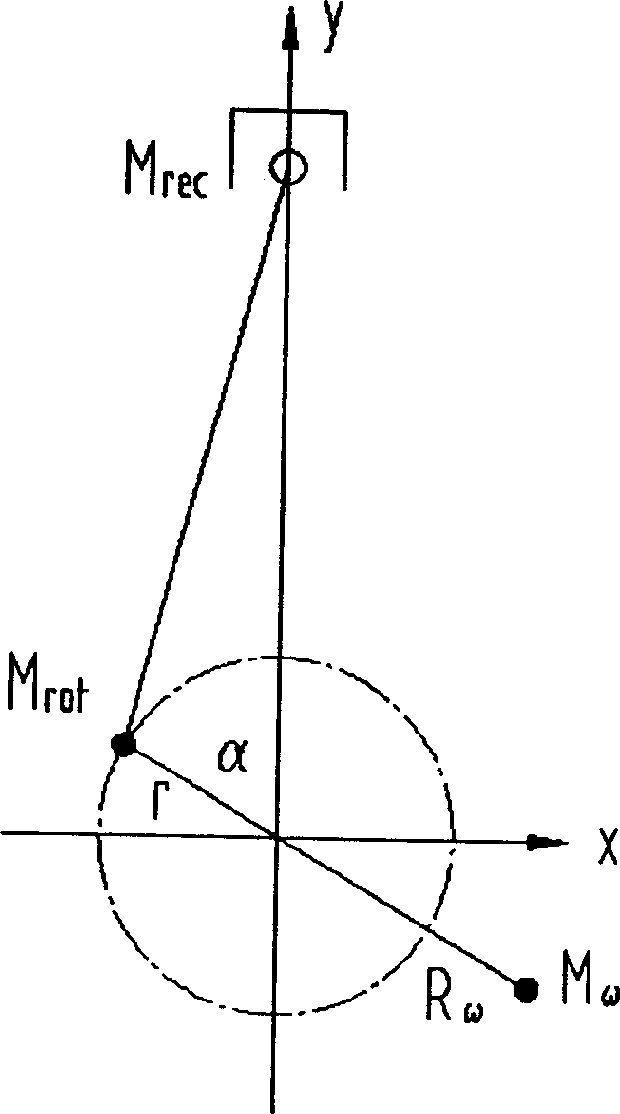

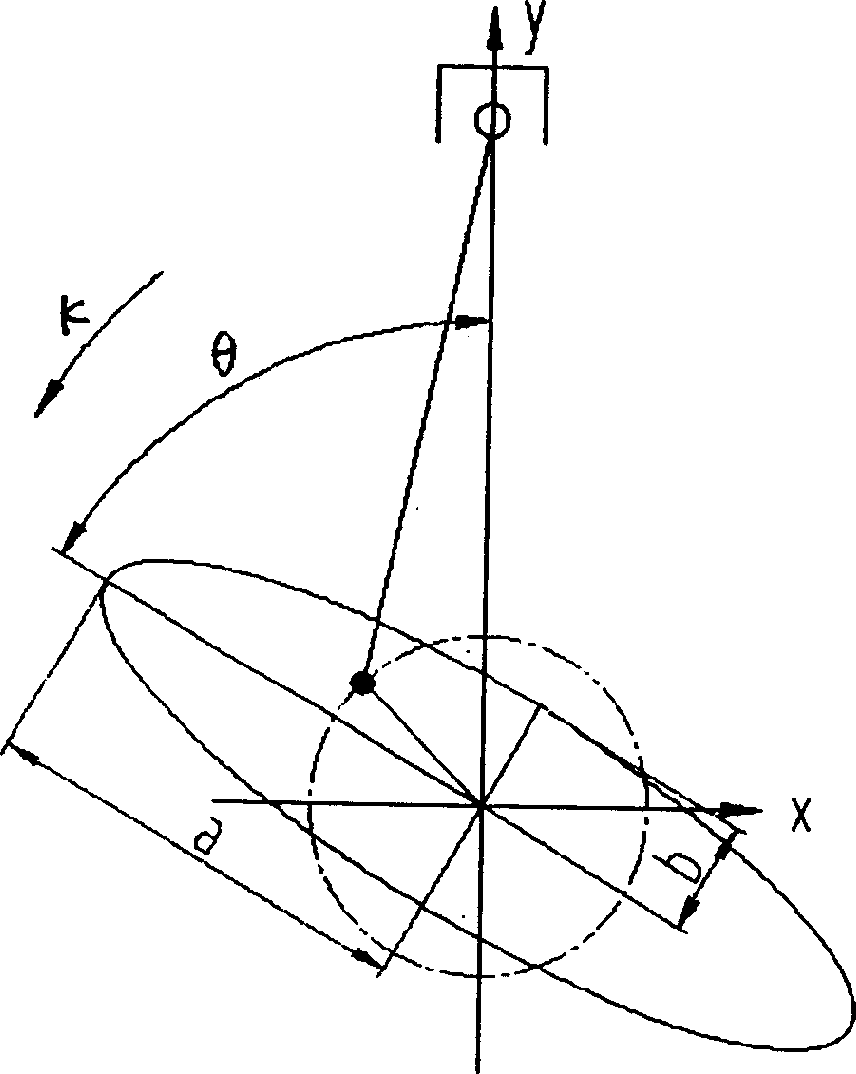

[0026] Taking LF163FML-2 single-cylinder motorcycle engine as an example, according to a large number of experiments, it is shown that the vibration effect of the whole vehicle is the best when the crankshaft main inclination angle θ=80° and unbalance ratio γ=21%. The engine crank radius r=31.1mm; the total mass of piston, piston ring, piston pin and piston pin collar Mp=195g; the mass of connecting rod M L =200g, distance L from the center of mass of the connecting rod to the center of the small end of the connecting rod A =72.75mm; the distance L from the center of mass of the connecting rod to the center of the big end of the connecting rod B =32.75mm; the center distance of connecting rod size head hole L=L A +L B =105.5mm; crank pin mass M Q =265g; Connecting rod big head needle roller bearing M Z = 35g. Such as figure 1 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com