Conveyer belt type dispensing mechanism

A technology of dispensing mechanism and conveyor belt, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low efficiency and limited effect, and achieve the effect of high efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

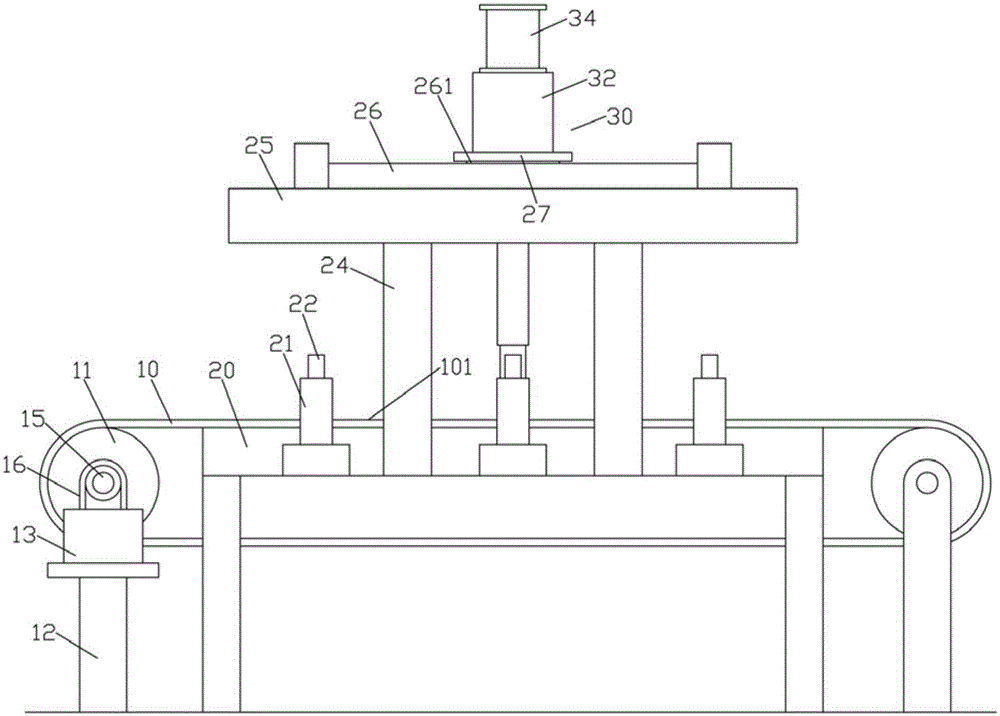

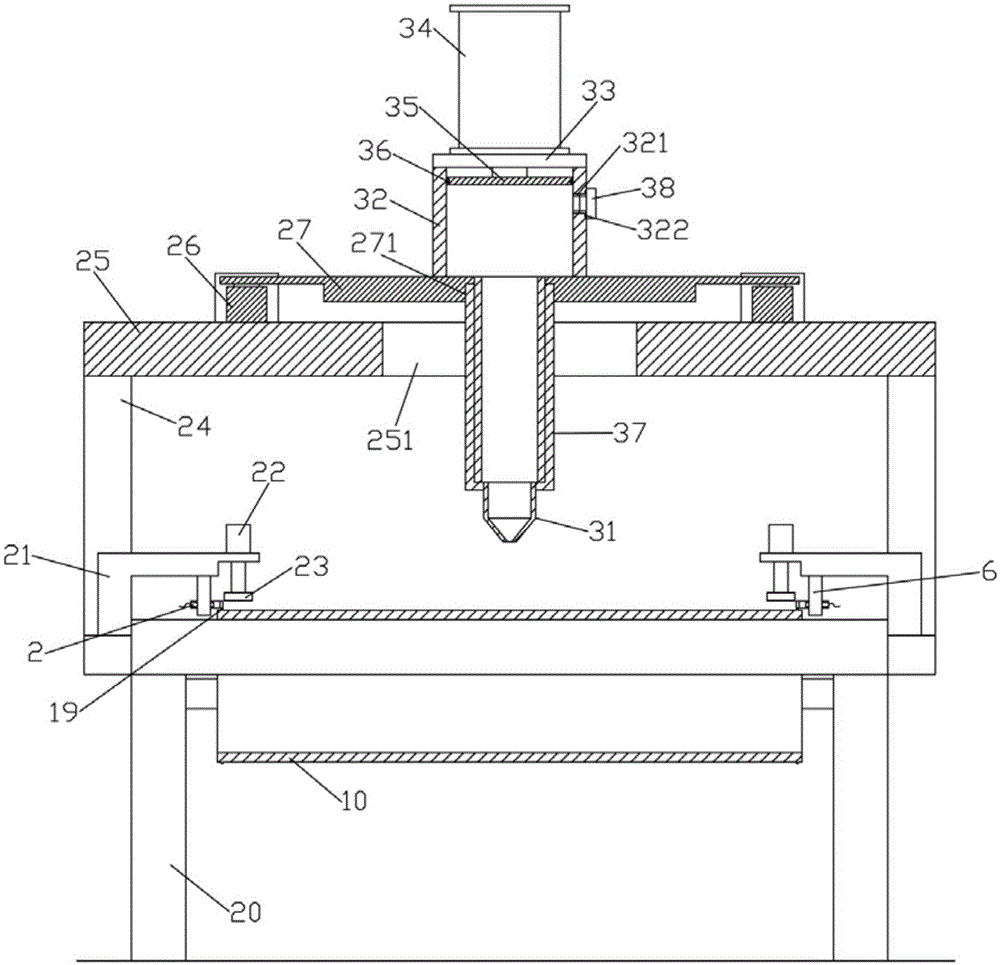

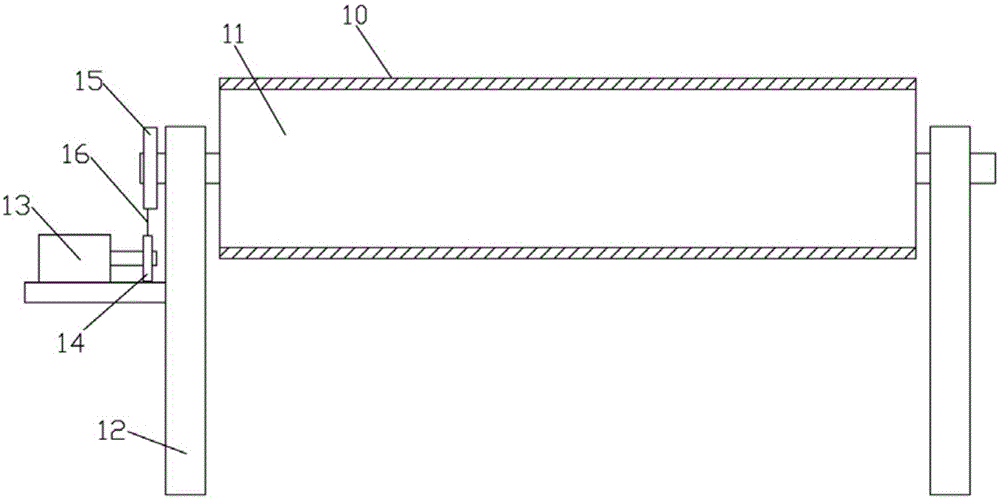

[0016] Examples, see e.g. Figures 1 to 4 As shown, a conveyor belt type dispensing mechanism includes a conveyor belt 10 and a frame 20, the conveyor belt 10 is tensioned on two drive rollers 11, and the two ends of the drive roller 11 are hinged on two vertical legs 12, the vertical legs 12 are fixed on the bottom surface, one of the vertical legs 12 is fixed with a drive motor 13, the output shaft of the drive motor 13 is fixed with a drive wheel 14, and the fixed vertical legs 12 of the drive motor 13 One end of the transmission roller 11 is fixed with a transmission wheel 15, the belt 16 is tensioned on the transmission wheel 15 and the driving wheel 14, the frame 20 is fixed on the ground, the top plate of the frame 20 extends into the conveyor belt 10, and is in the conveying The back side of the conveying part 101 of the top of belt 10, the both sides of the top plate of frame 20 are fixed with a plurality of pressing cylinder fixed mounts 21, and the top of pressing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com