Method for forming part drawing modeling with dent structure

A technology of concave structure and parts, which is applied in the field of parts forming, can solve the problems of increasing defective rate, wrinkling on the surface of parts, and stacking, so as to prevent wrinkling and stacking, avoid wrinkling and stacking, and improve forming quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Next, with reference to the accompanying drawings, a detailed description will be given of the forming method of the drawing-formed part having a concave structure provided by the present invention.

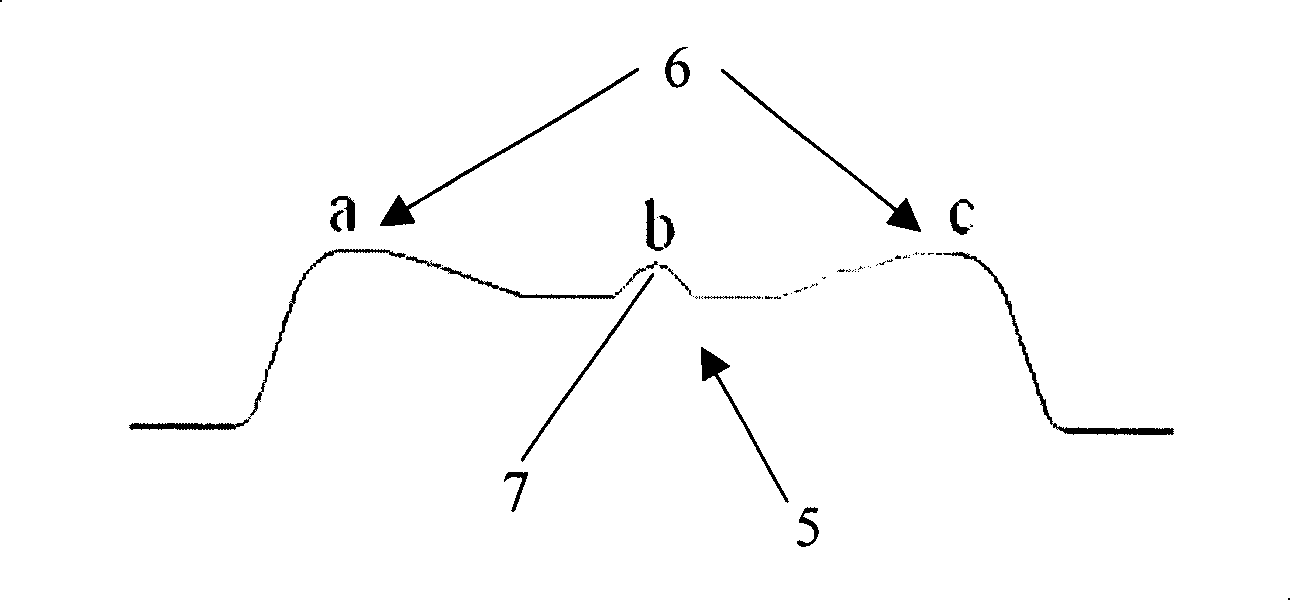

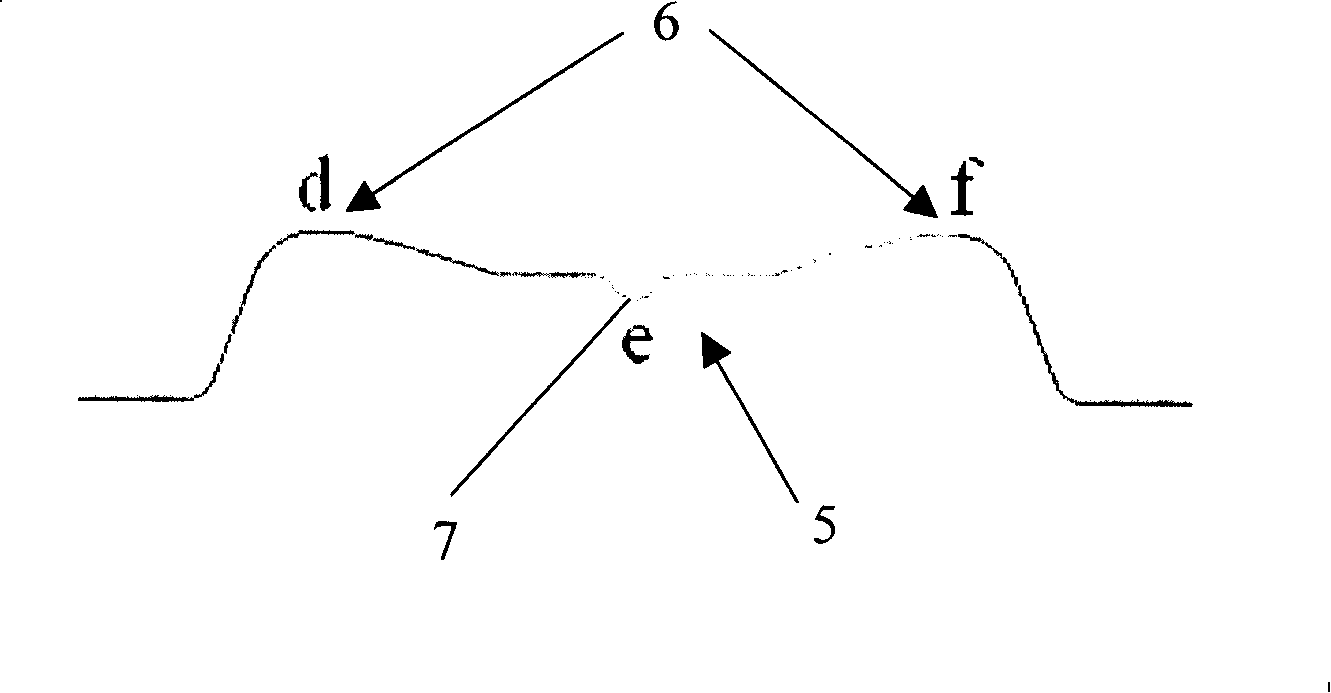

[0012] The method for forming a part with a concave structure by drawing according to the present invention includes: drawing and molding a sheet, wherein the drawn-shaped part includes a concave area 5 and a protruding area 6 located around the concave area 5, In addition, a suction rib 7 is formed in the recessed area 5 ; and then the drawn and shaped workpiece is punched to cut off the suction rib 7 .

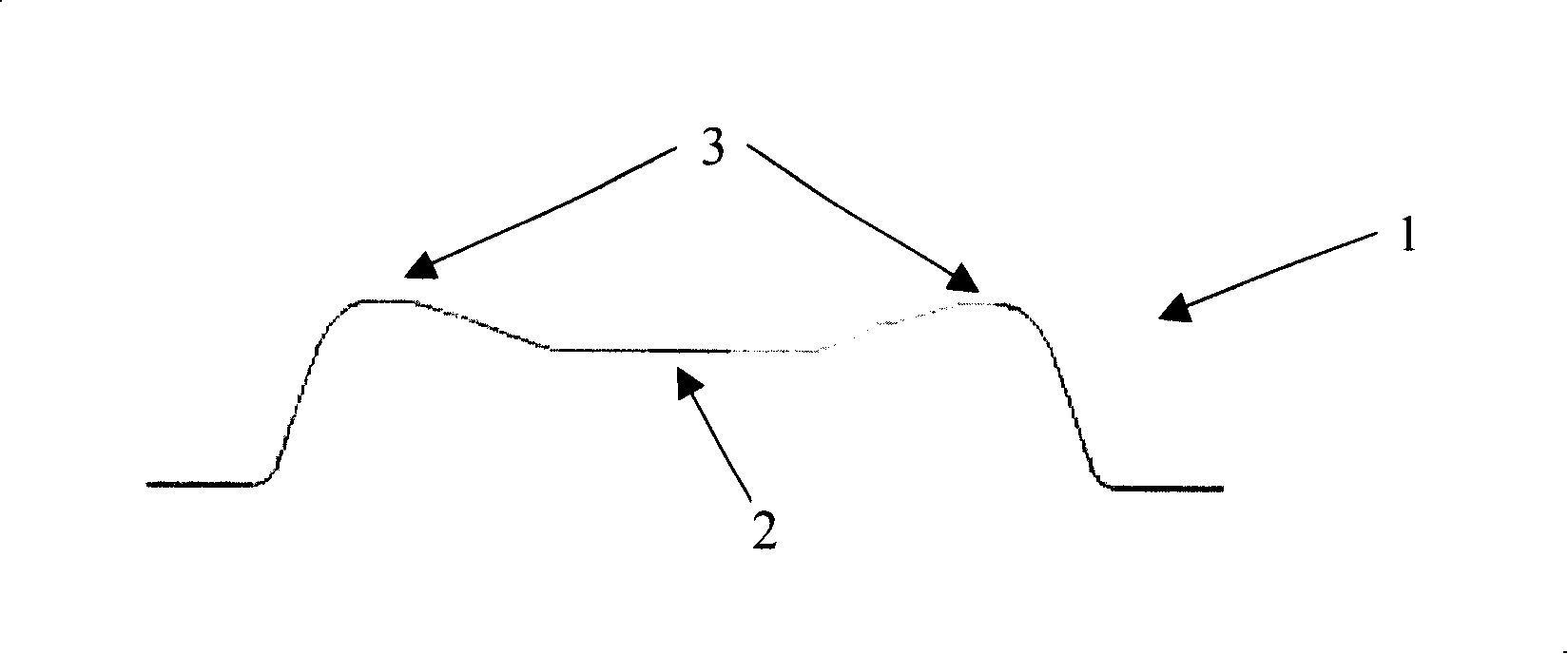

[0013] Since the drawing shape of the part to which the present invention is applicable has a concave structure, such as figure 1 As shown, the center is low and the periphery is high, that is, there is a recessed portion 2 and a protruding portion 3 located around the recessed portion 2 . Therefore, when the sheet is drawn and shaped, it needs to be formed into a corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com