Patents

Literature

71 results about "Depressed structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

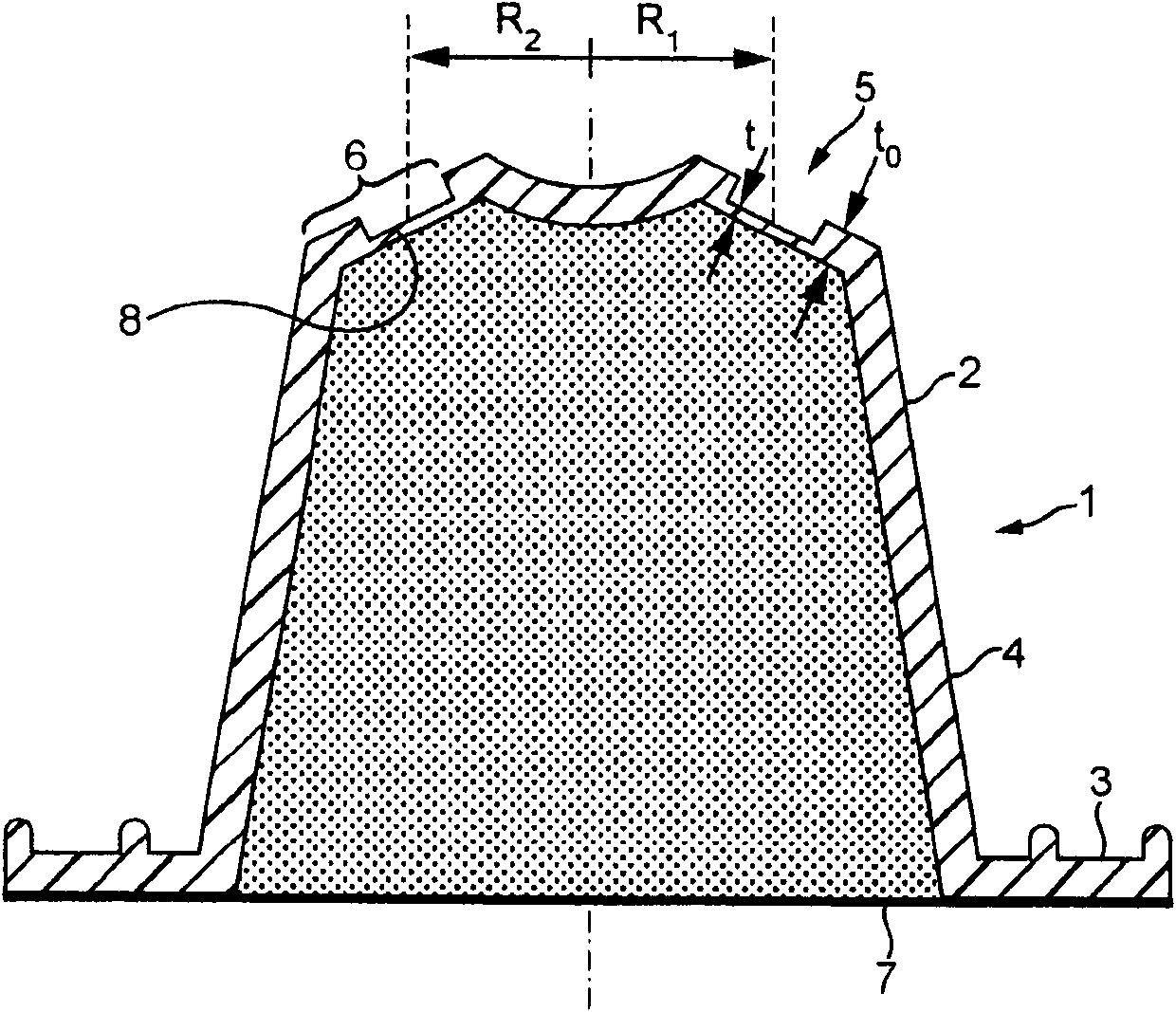

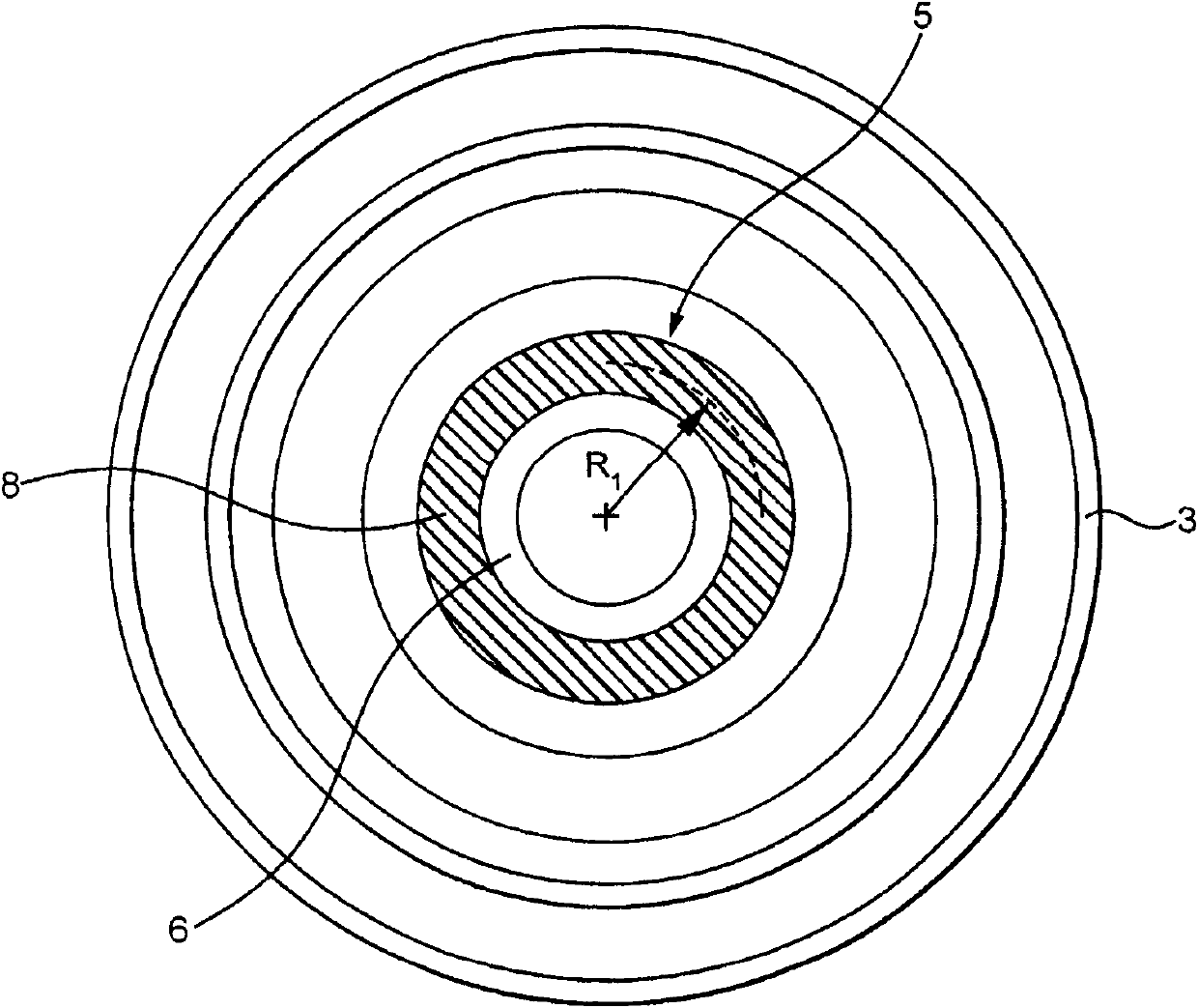

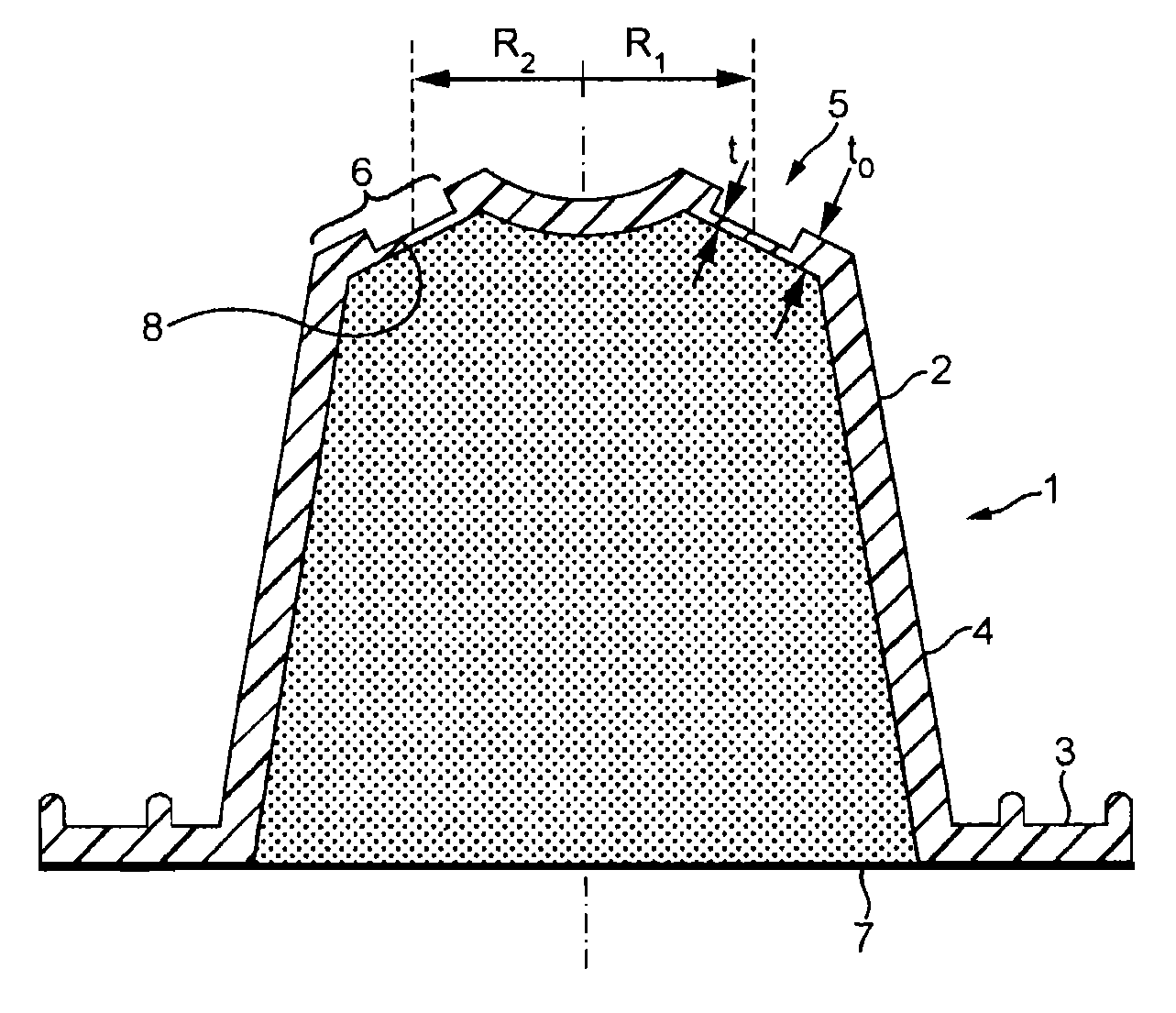

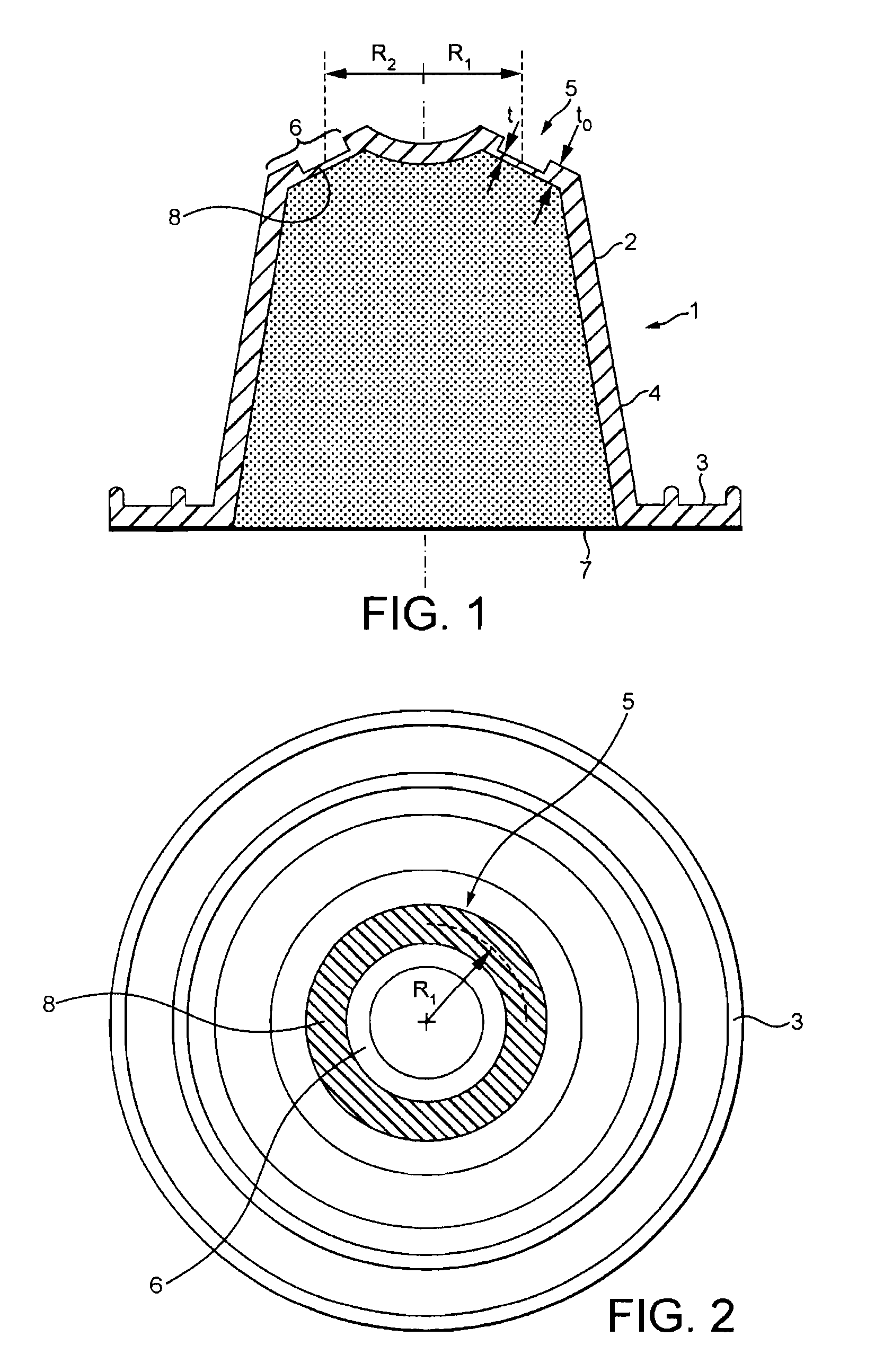

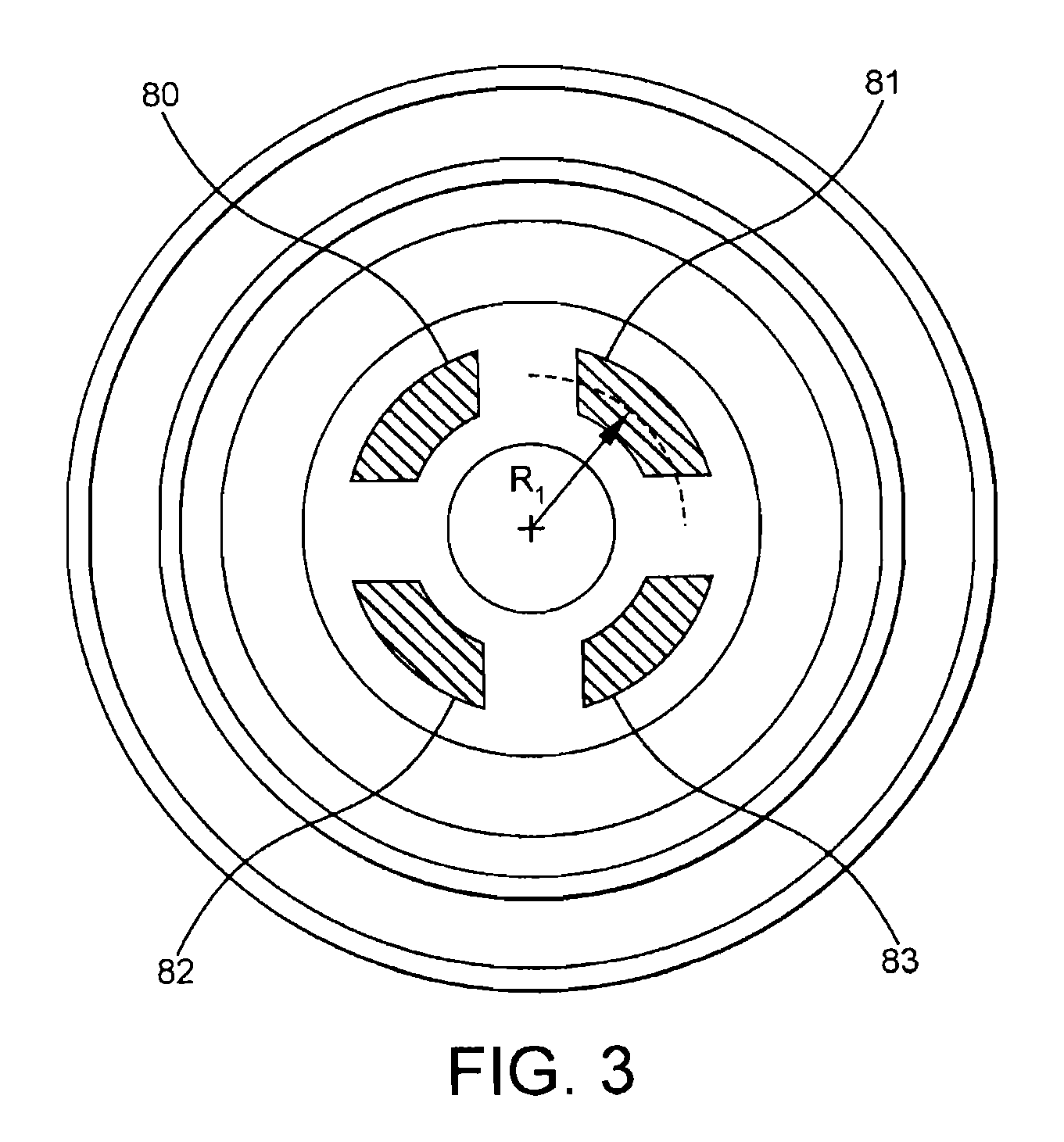

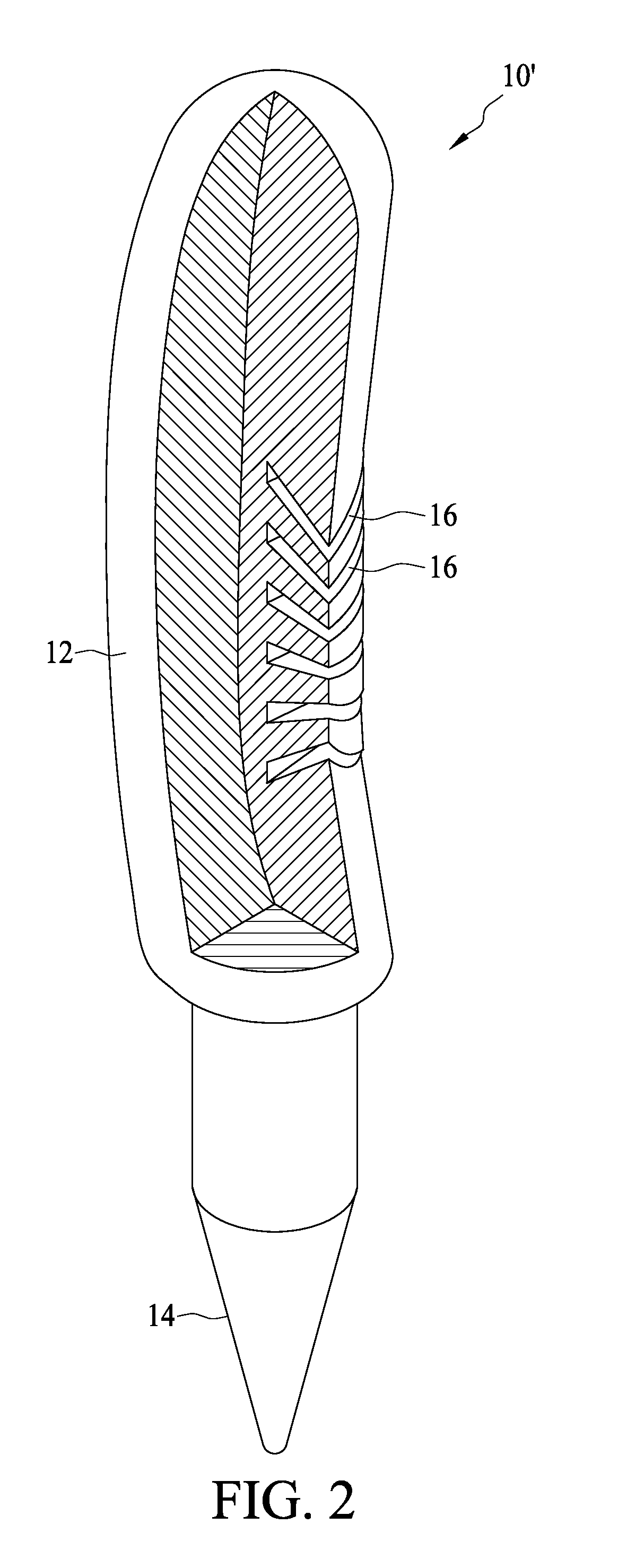

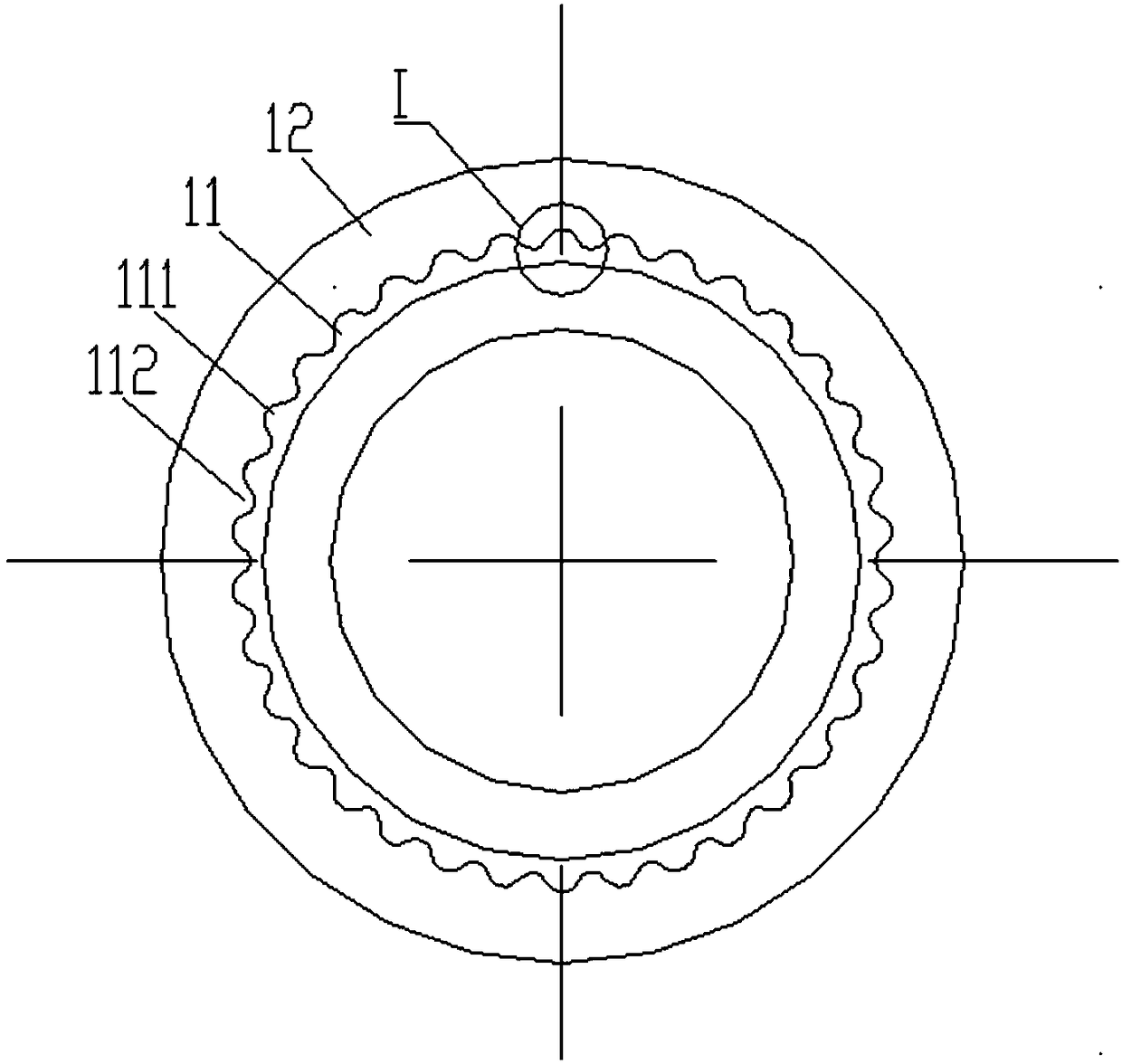

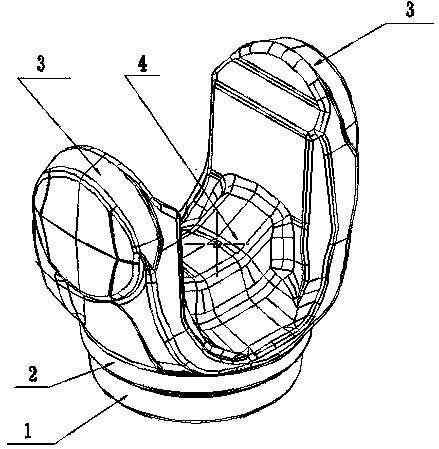

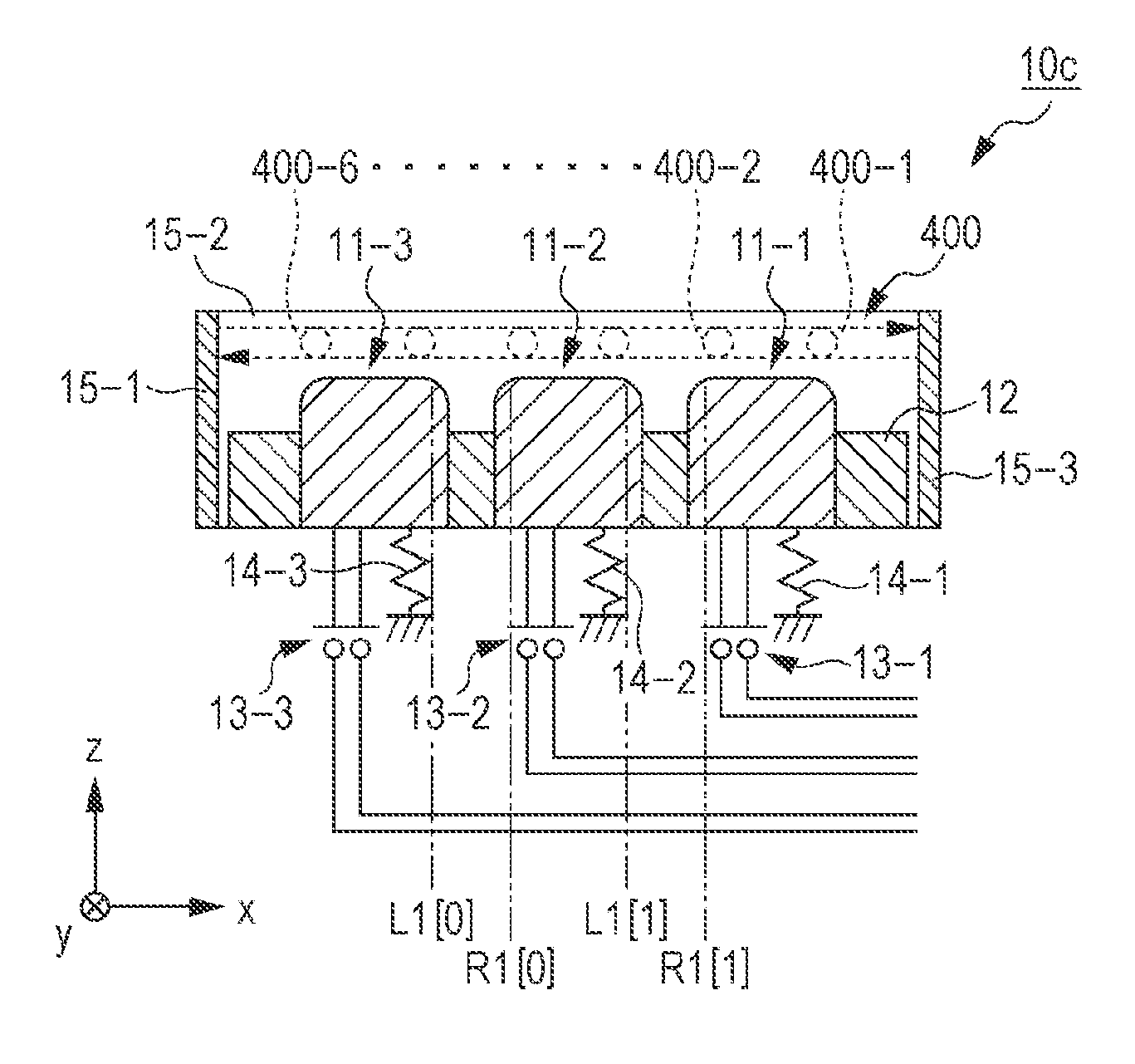

Capsule for the preparation of a coffee extract having a structure facilitating perforation for injection of water

ActiveUS20110041702A1Improve permeabilityReduce thicknessFlexible coversWrappersEngineeringMaterial Perforation

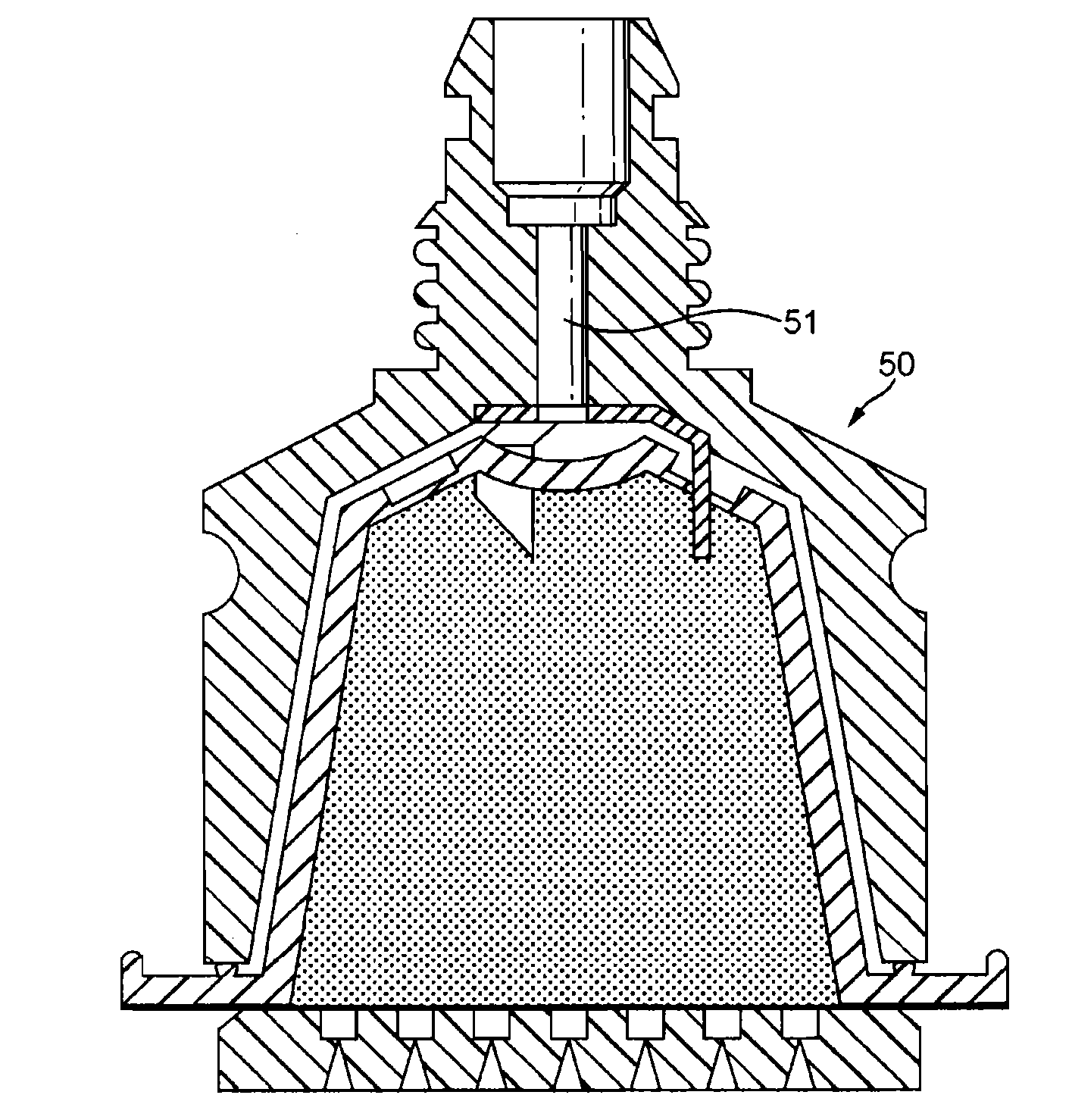

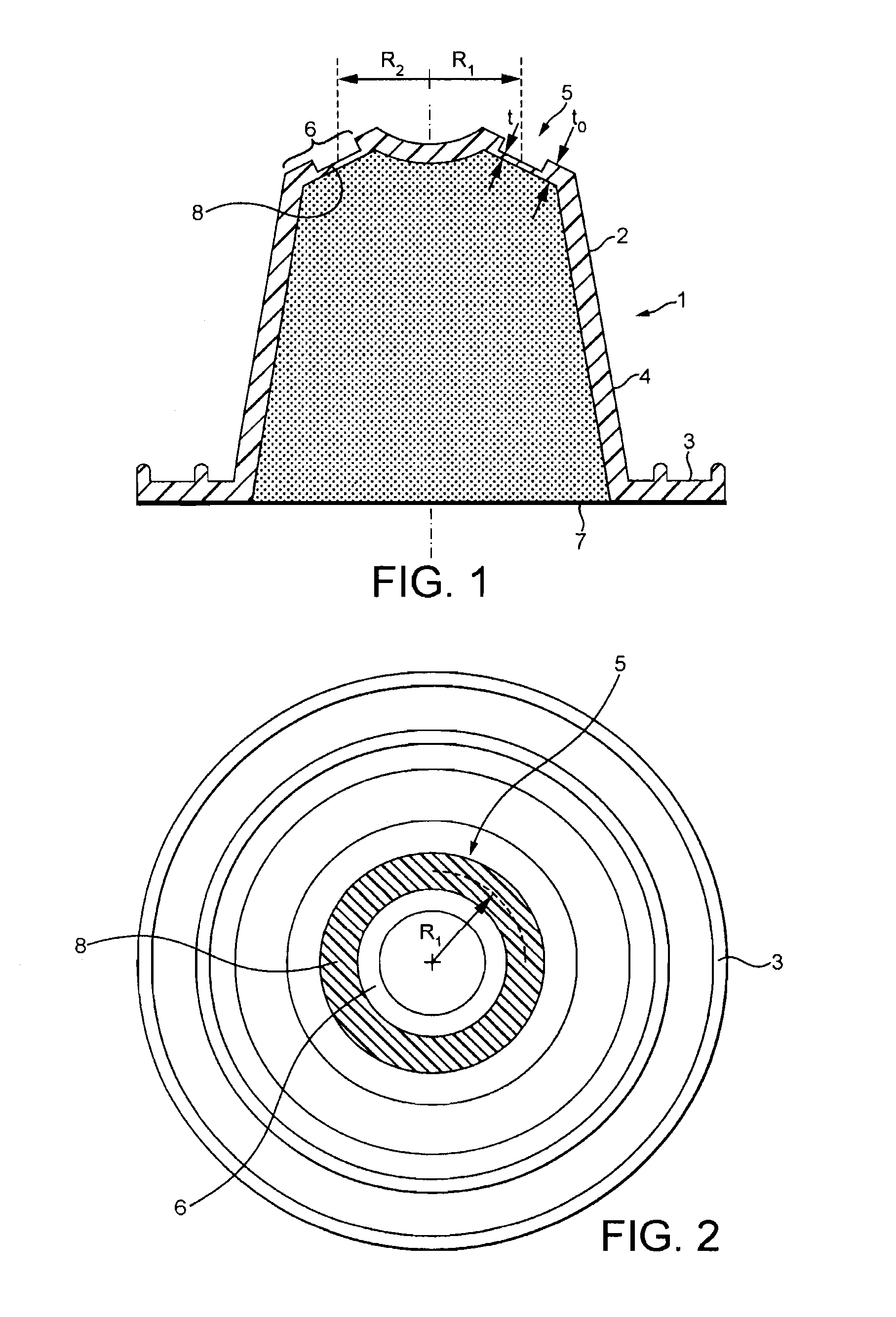

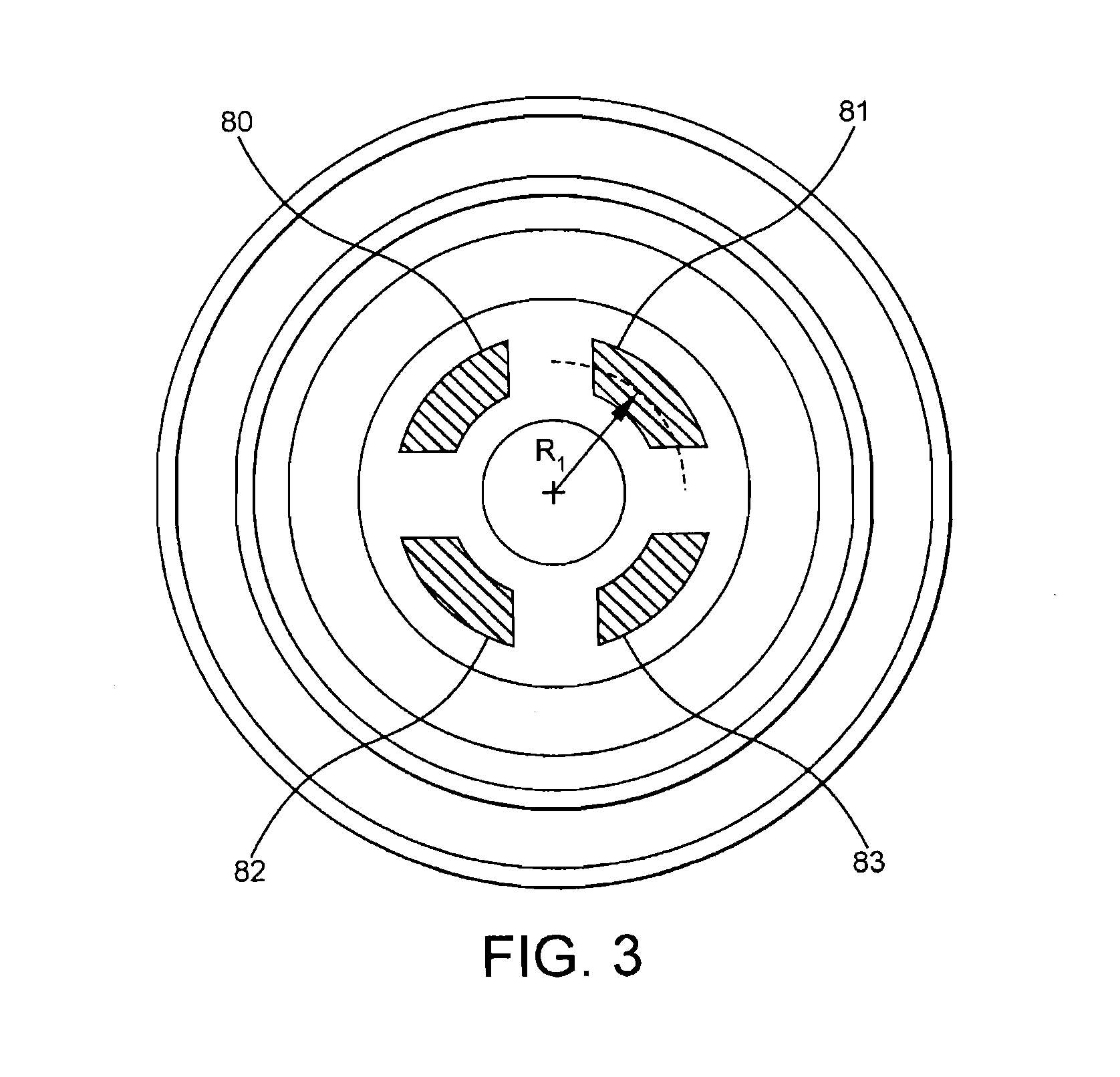

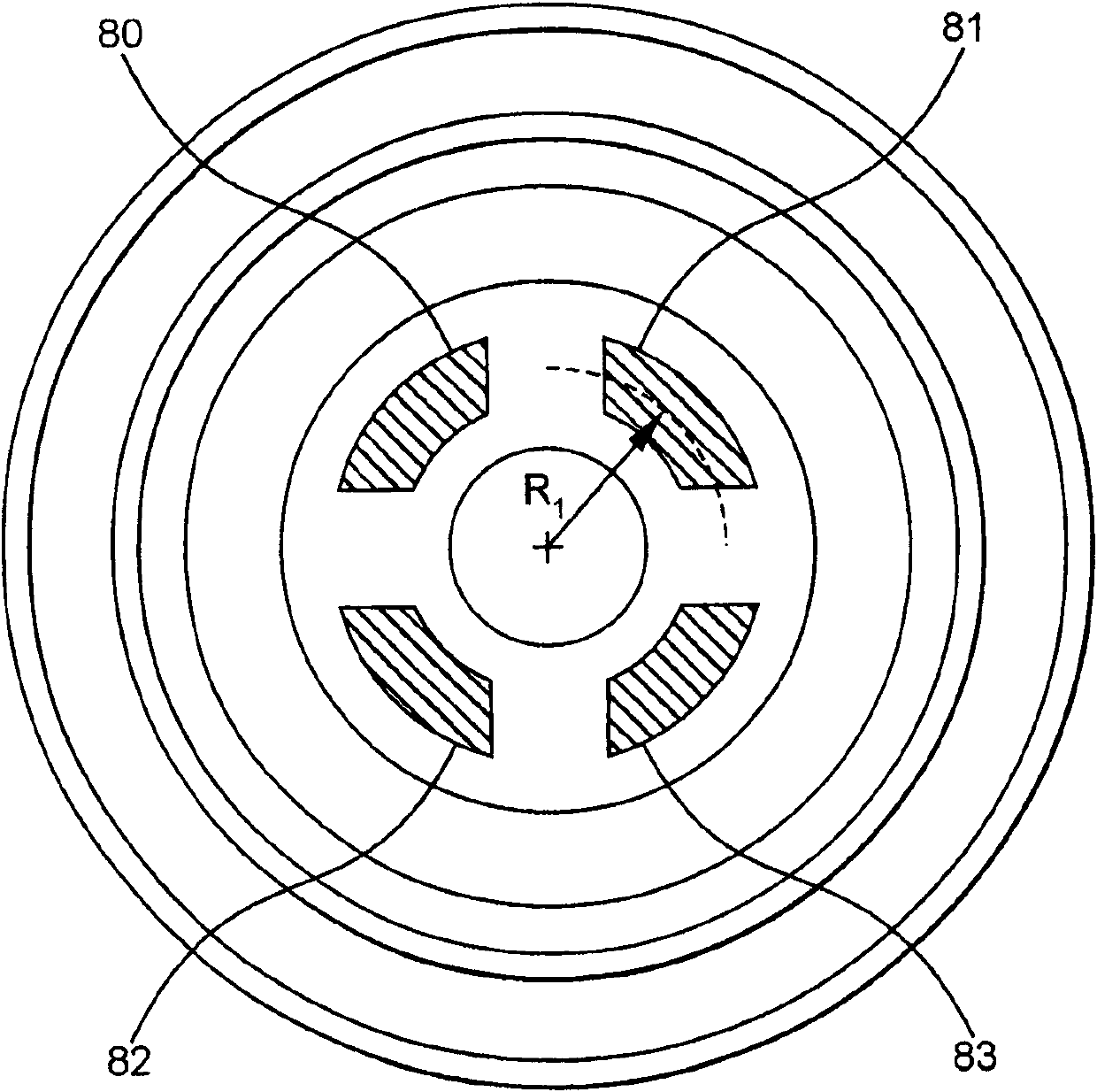

A capsule for the preparation of a coffee extract from coffee contained therein and hot water injected under pressure in the capsule by a water injection device. The capsule has a frusto-conical body with a rim, sidewall, and an inlet wall and a lower delivery wall sealed to the rim and contains a predosed amount of coffee. The inlet wall may have a flat or convex portion and a structure in relief or in recess arranged for facilitating penetration of blades belonging to the injection device and extending on a substantially circular path of predetermined radius R1 equal to the radius R2 of the circular path along which the blades of the injection device extend.

Owner:SOC DES PROD NESTLE SA

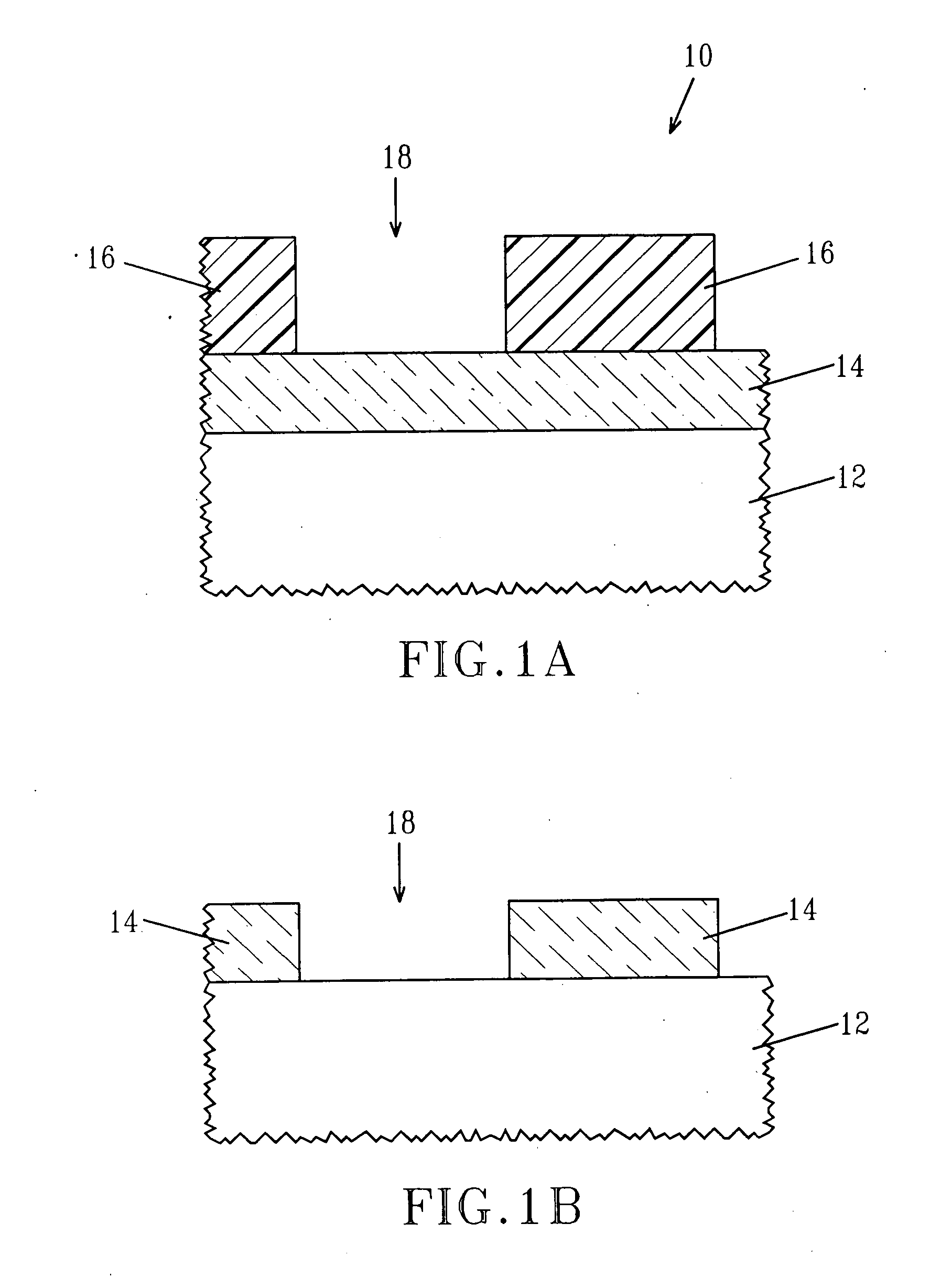

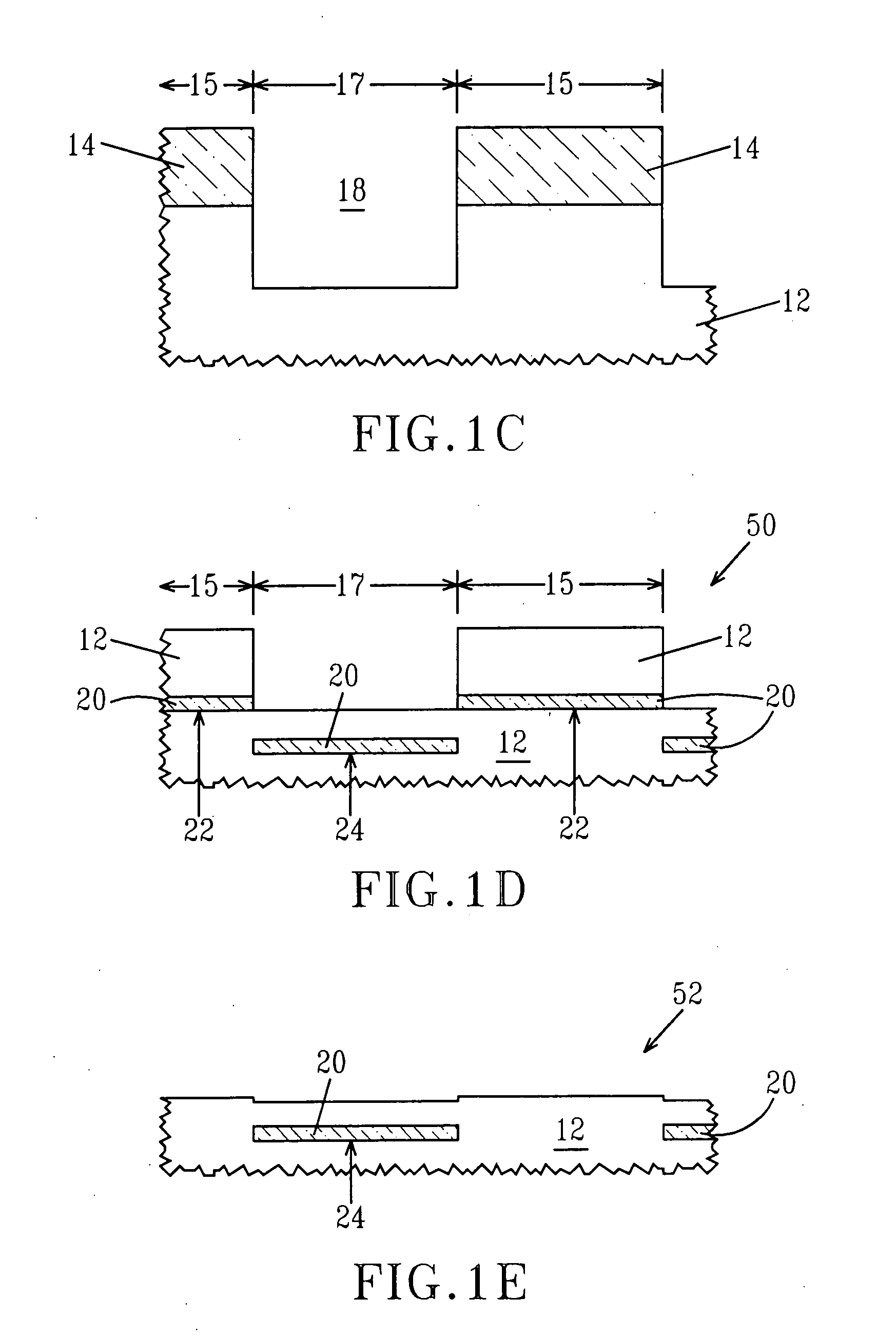

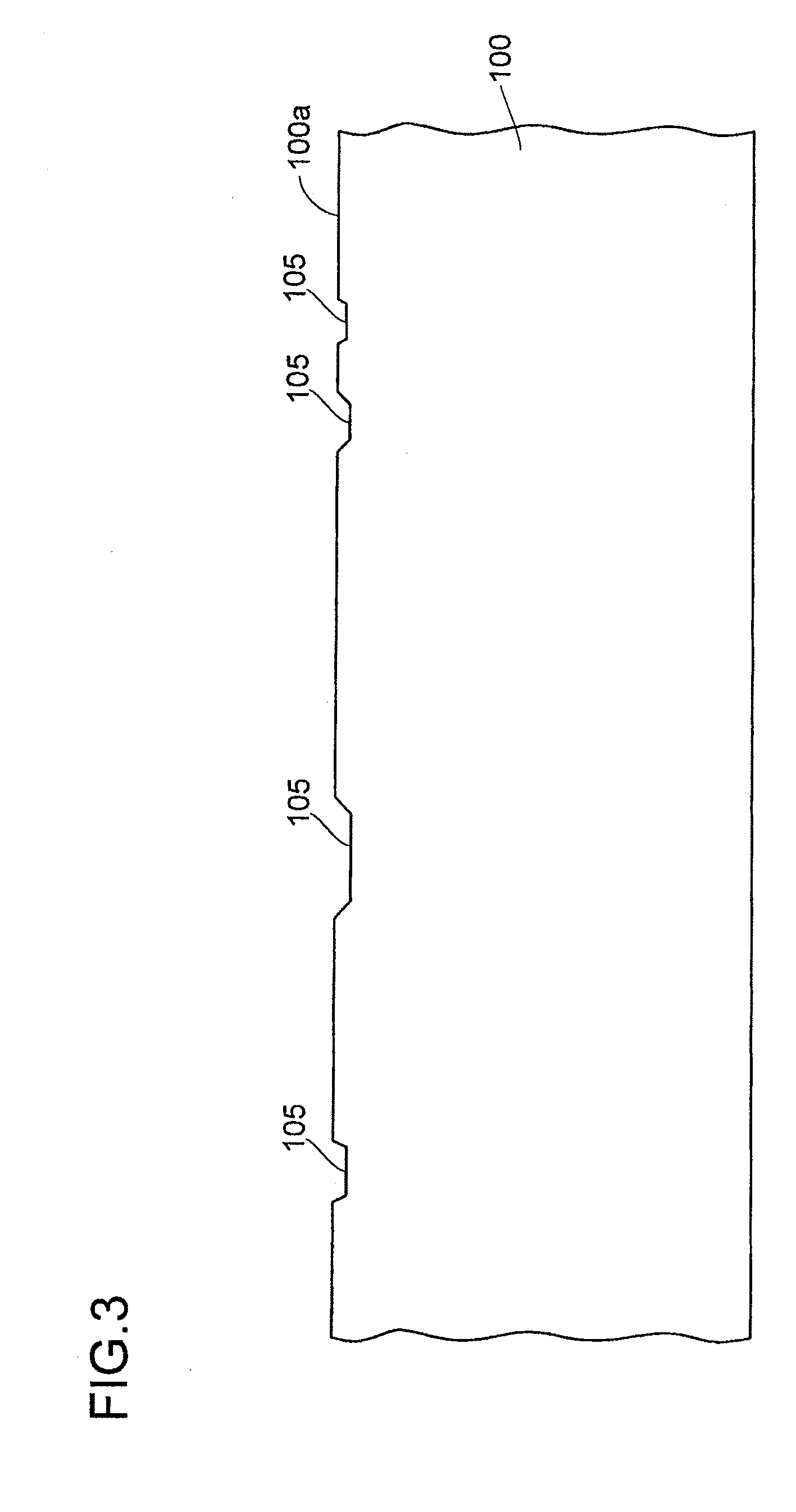

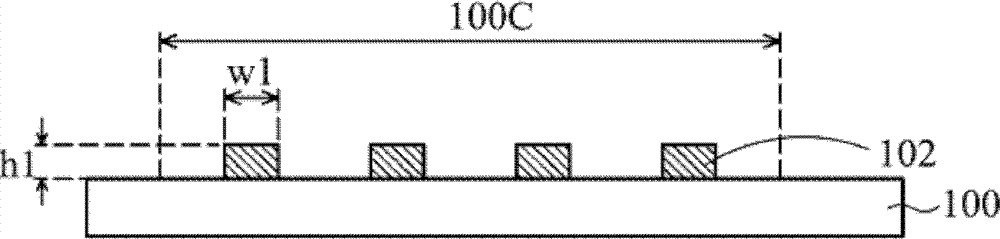

Patterning SOI with silicon mask to create box at different depths

InactiveUS20060040476A1Semiconductor/solid-state device manufacturingSilicon on insulatorDepressed structure

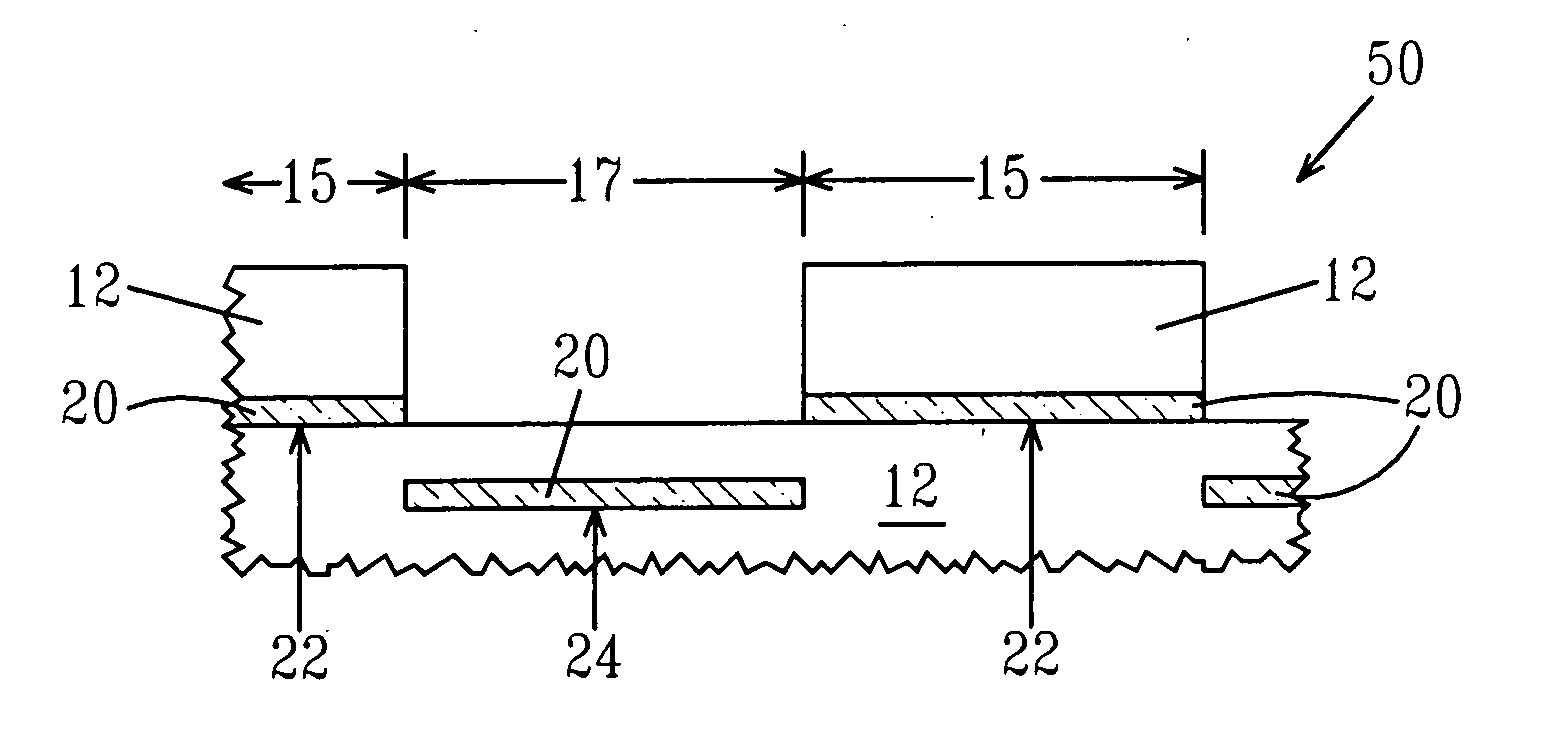

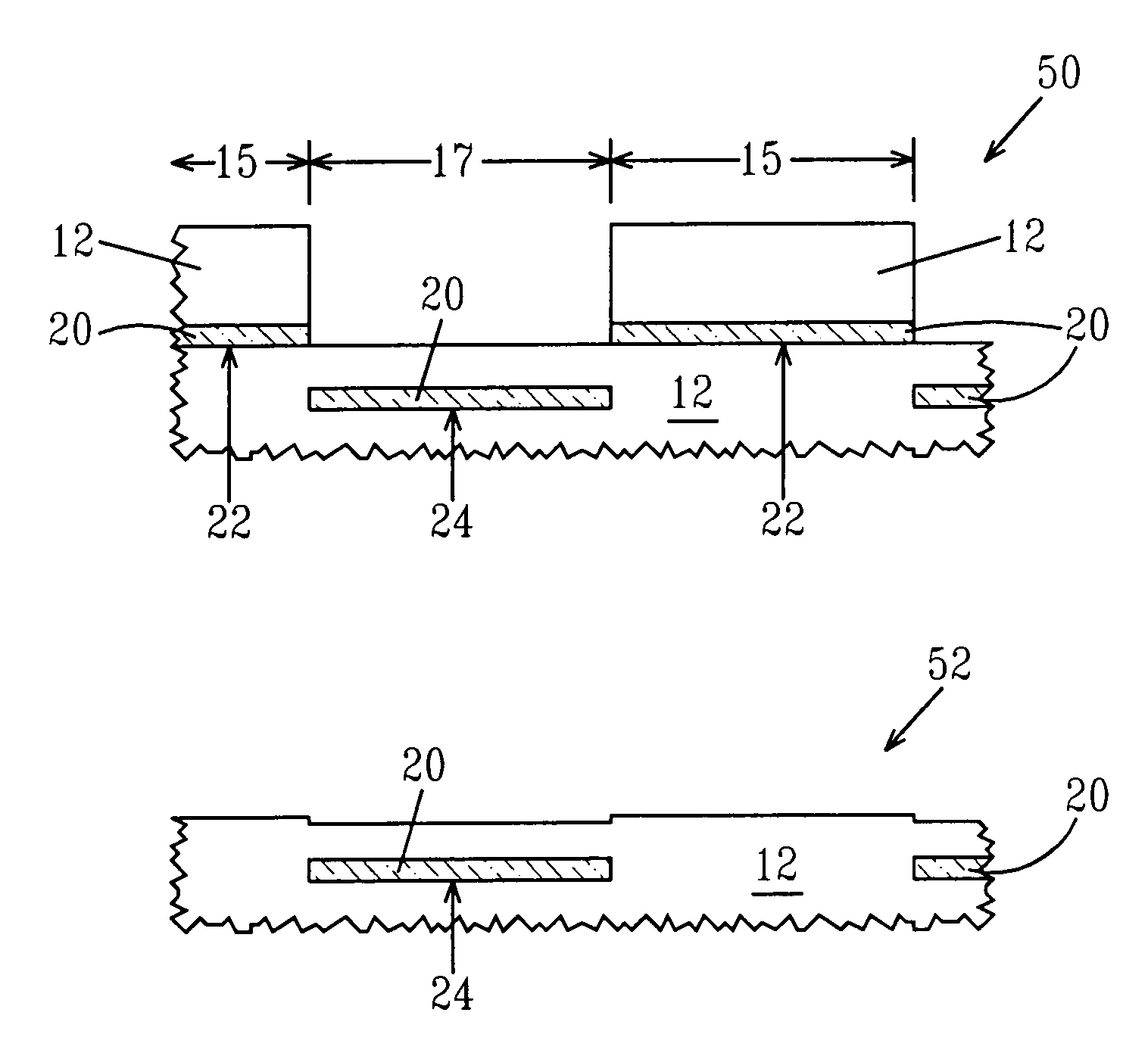

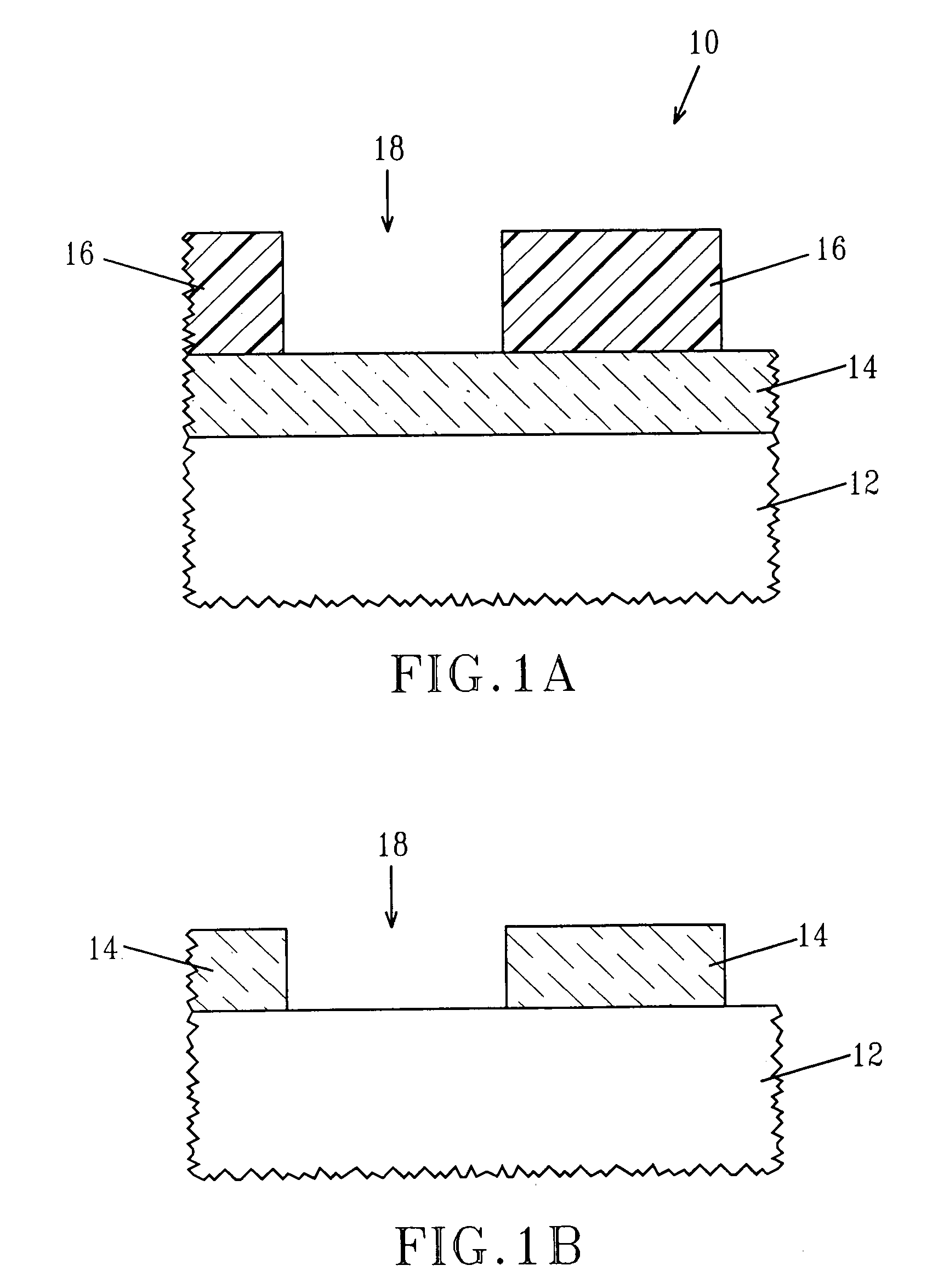

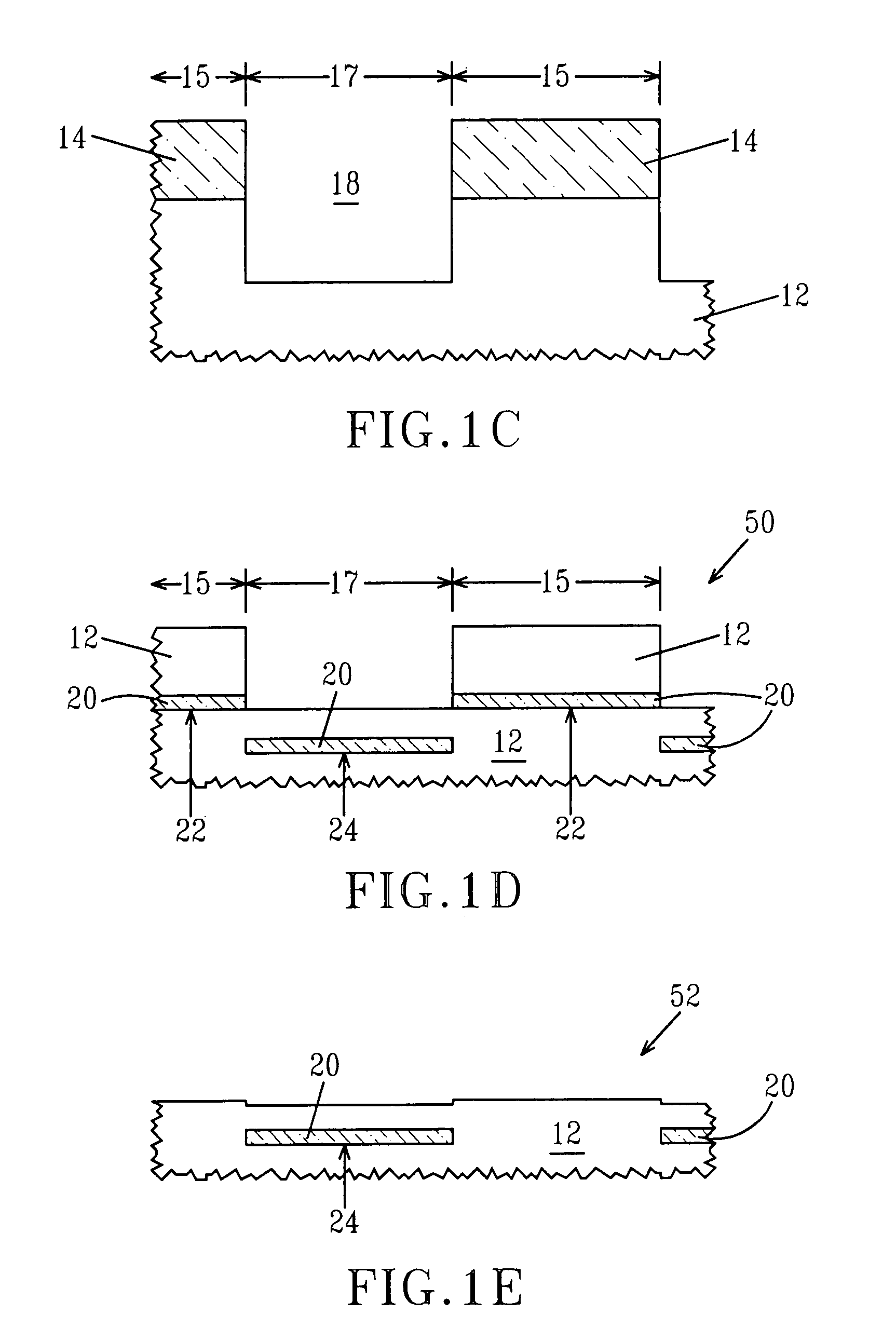

The present invention provides a method of fabricating a patterned silicon-on-insulator substrate which includes dual depth SOI regions or both SOI and non-SOI regions within the same substrate. The method of the present invention includes forming a silicon mask having at least one opening on a surface of Si-containing material, recessing the Si-containing material through the at least one opening using an etching process to provide a structure having at least one recess region and a non-recessed region, and forming a first buried insulating region in the non-recessed region and a second buried insulating region in the recessed region. In accordance with the present invention, the first buried insulating region in the non-recessed region is located above the second buried isolation region in the recessed region. A lift-off step can be employed to remove the first buried insulating region and the material that lies above to provide a substrate containing both SOI and non-SOI regions.

Owner:IBM CORP

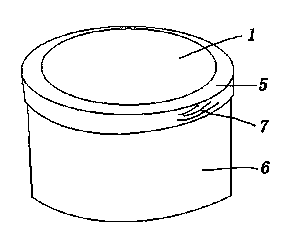

Capsule for the preparation of coffee extract having a structure facilitating perforation for injection of water

The invention relates to a capsule for the preparation of coffee extract having a structure facilitating perforation for injection of water. The capsule for the preparation of a coffee extract from coffee contained therein and hot water injected under pressure in the capsule by a water injection device. The capsule has a frusto-conical body with a rim, sidewall, and an inlet wall and a lower delivery wall sealed to the rim and contains a predosed amount of coffee. The inlet wall may have a flat or convex portion and a structure in relief or in recess arranged for facilitating penetration of blades belonging to the injection device and extending on a substantially circular path of predetermined radius R1 equal to the radius R2 of the circular path along which the blades of the injection device extend.

Owner:NESTEC SA

Patterning SOI with silicon mask to create box at different depths

InactiveUS7115463B2Semiconductor/solid-state device manufacturingSilicon on insulatorDepressed structure

The present invention provides a method of fabricating a patterned silicon-on-insulator substrate which includes dual depth SOI regions or both SOI and non-SOI regions within the same substrate. The method of the present invention includes forming a silicon mask having at least one opening on a surface of Si-containing material, recessing the Si-containing material through the at least one opening using an etching process to provide a structure having at least one recess region and a non-recessed region, and forming a first buried insulating region in the non-recessed region and a second buried insulating region in the recessed region. In accordance with the present invention, the first buried insulating region in the non-recessed region is located above the second buried isolation region in the recessed region. A lift-off step can be employed to remove the first buried insulating region and the material that lies above to provide a substrate containing both SOI and non-SOI regions.

Owner:INT BUSINESS MASCH CORP

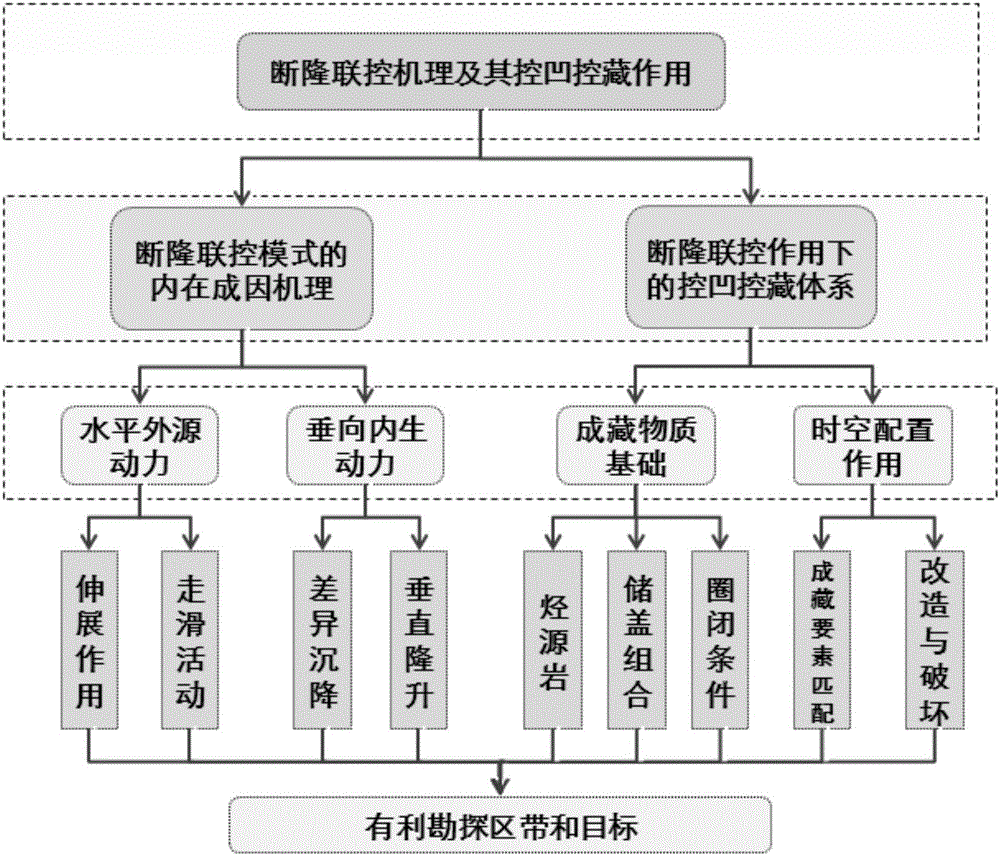

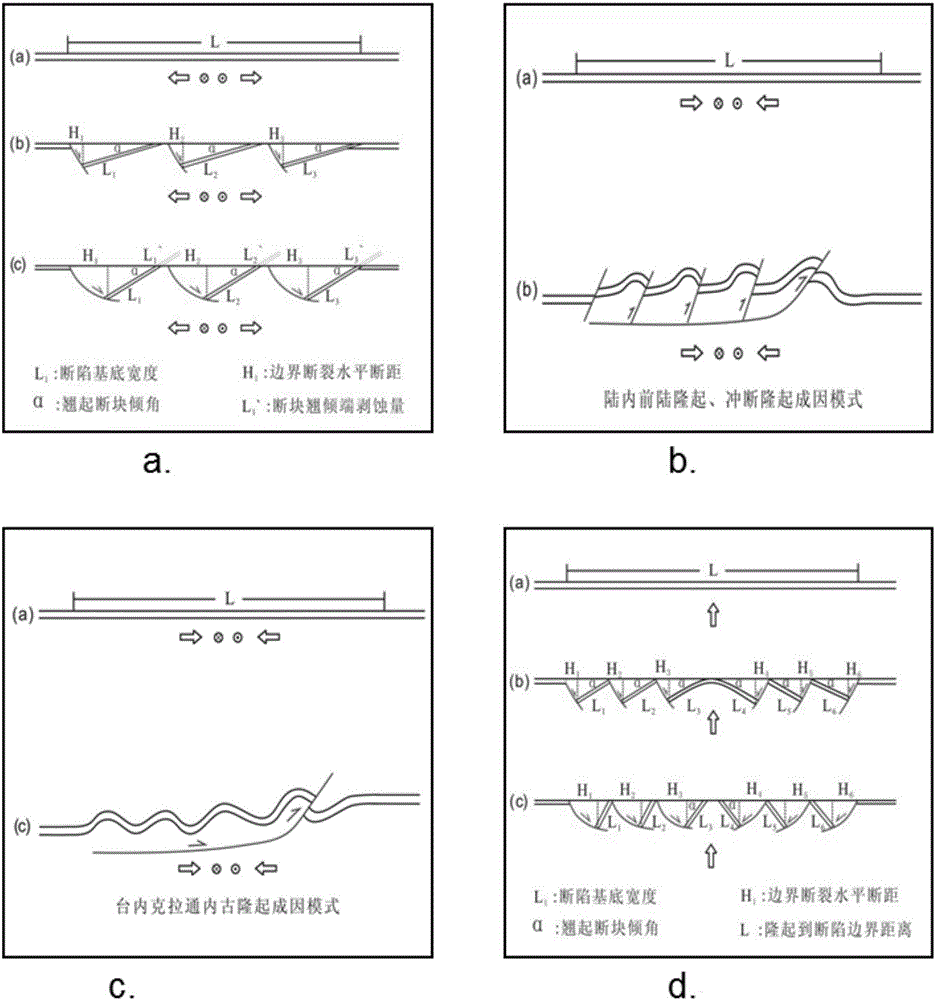

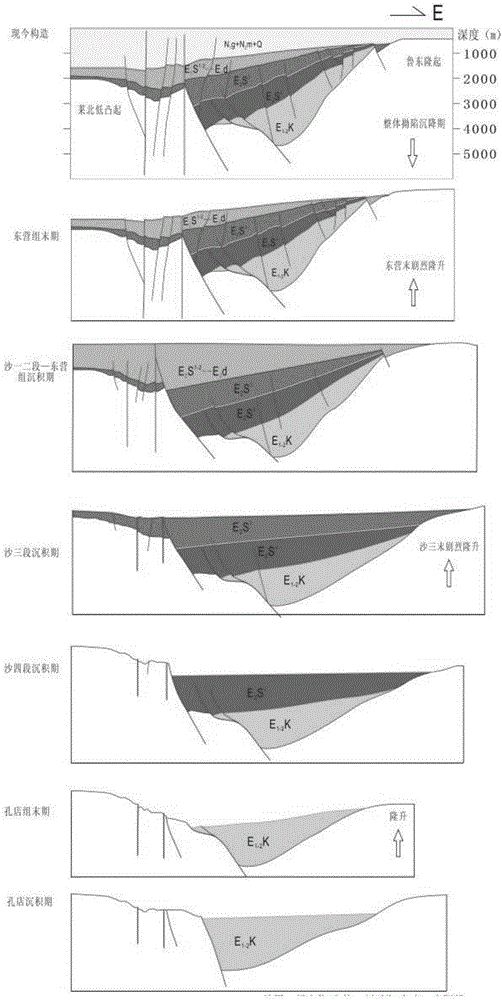

Petroliferous basin analysis method based on fracture-uplift linkage

ActiveCN106324701AMentoring Potential EvaluationGood exploration resultsGeological measurementsSystems researchBiological activation

Owner:CHINA NAT OFFSHORE OIL CORP +1

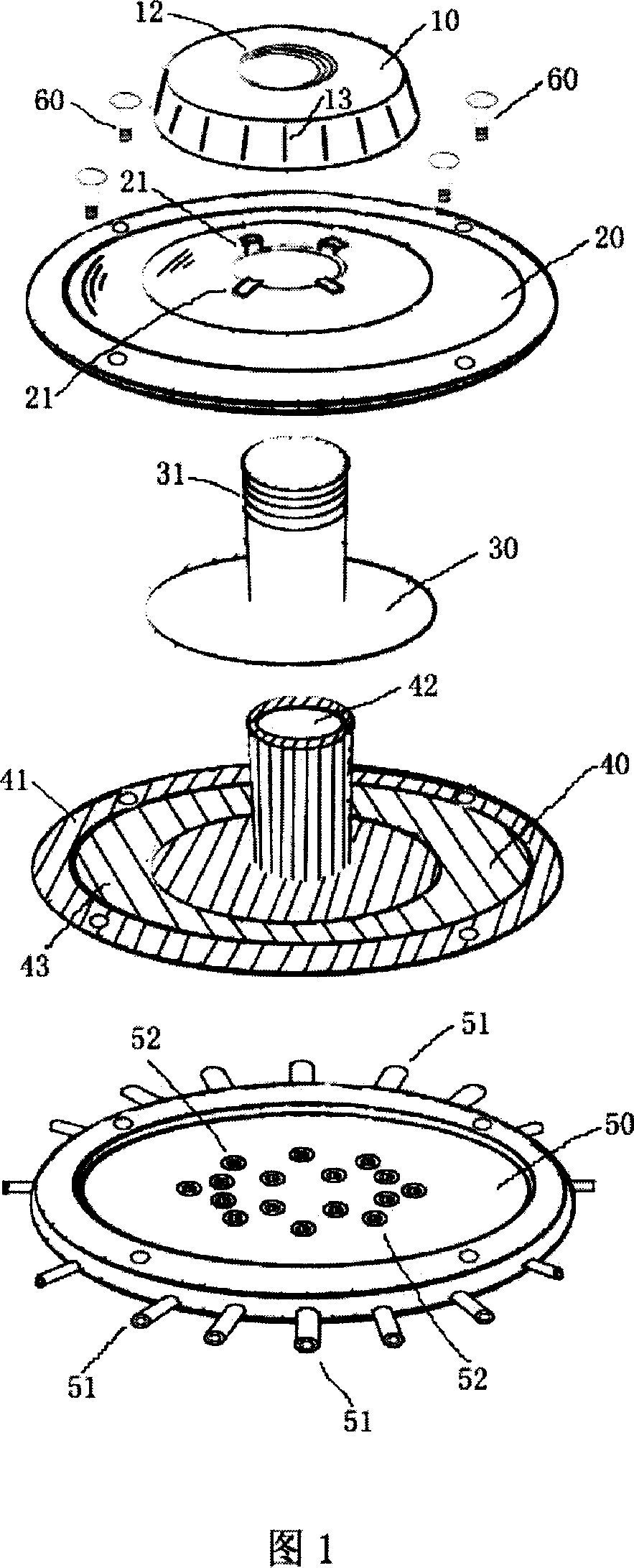

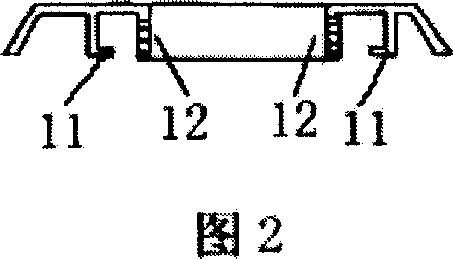

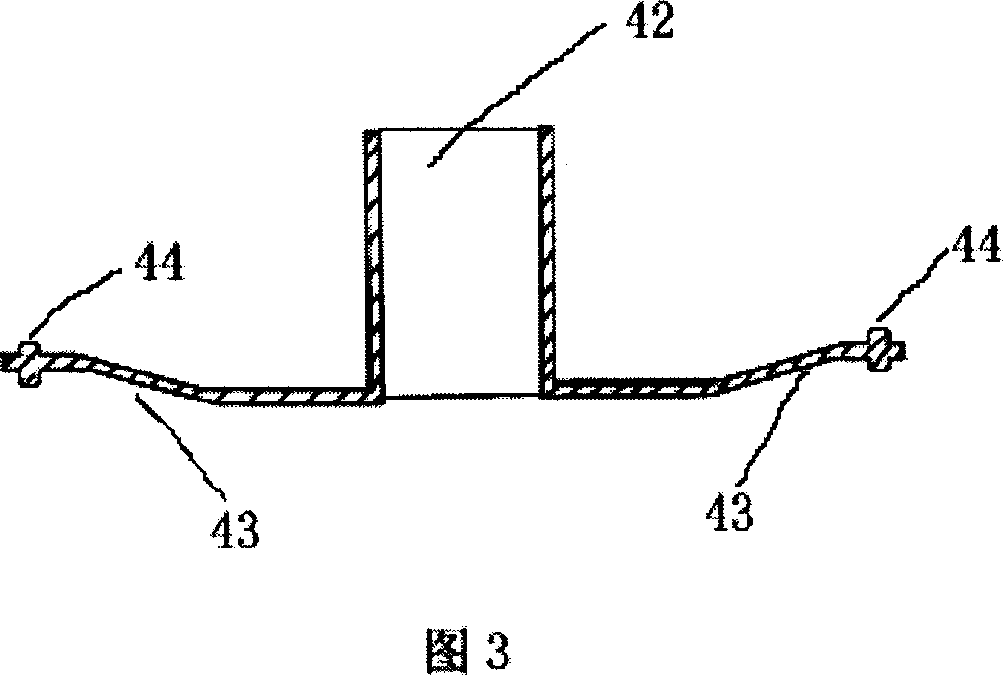

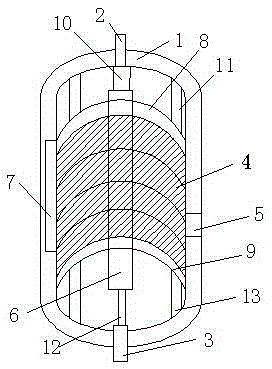

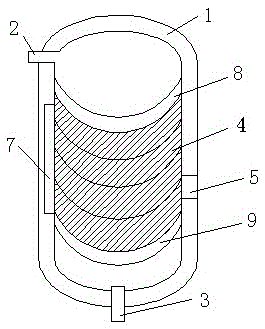

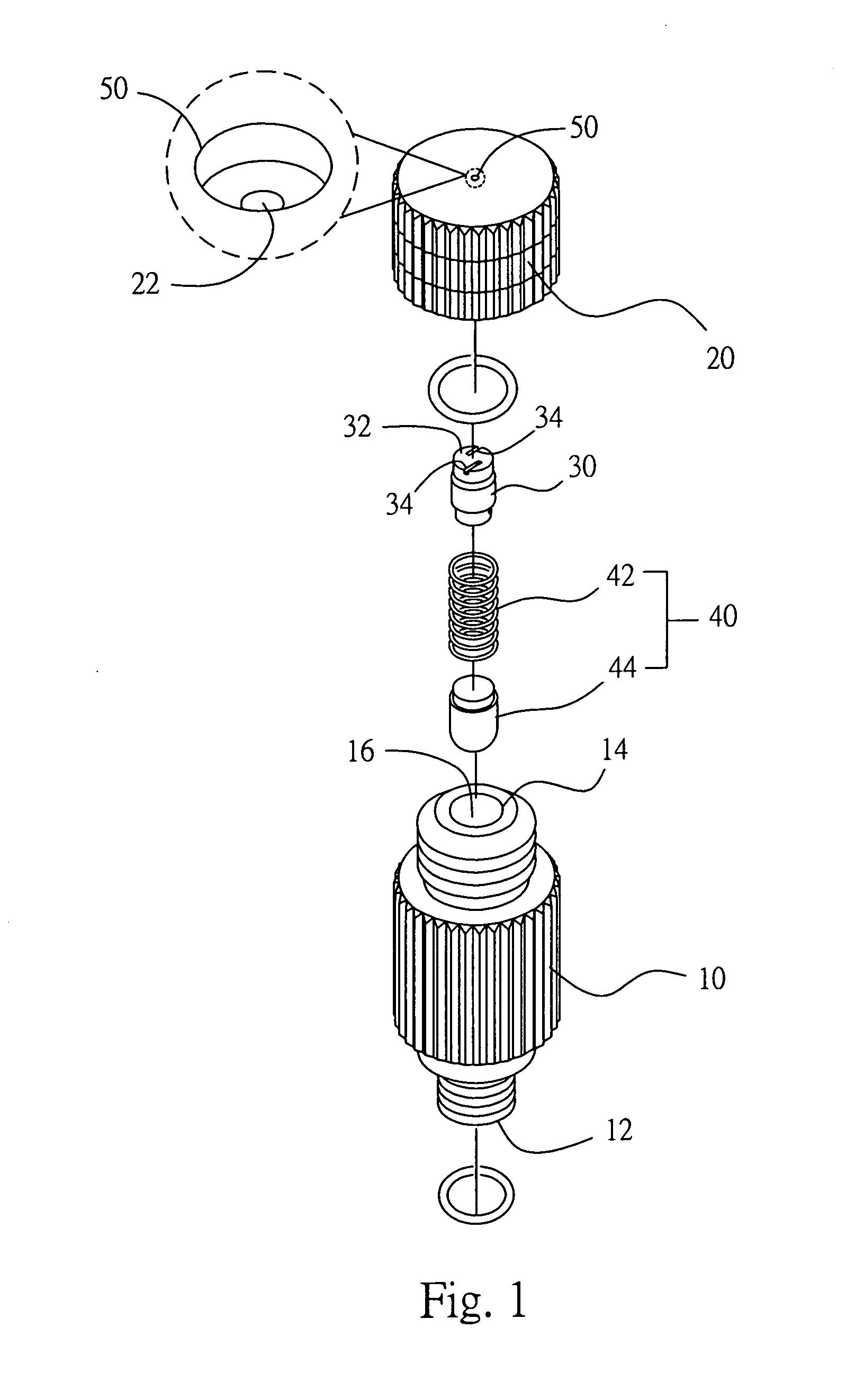

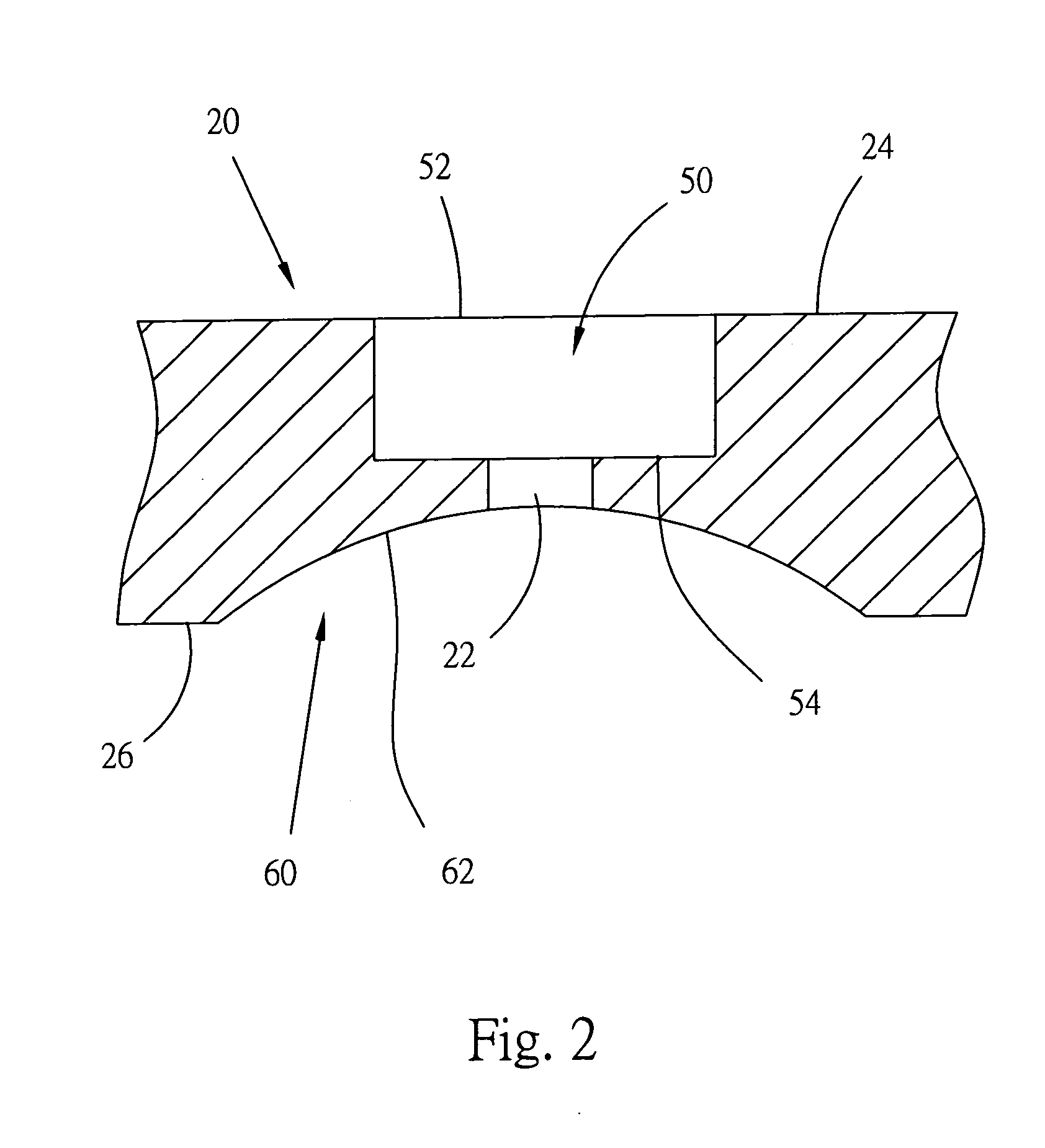

Multichannel bidirectional air-valve for charging or releasing air to multiple independence air bags

InactiveCN101063492AGuaranteed air tightnessGuaranteed inflationMultiple way valvesEngineeringAirbag deployment

The invention discloses a multichannel two-way air valve used for gas charging or discharging for a plurality of independent gasbags, comprising a hand-operated knob, an upper cap, a sleeve with moving seal rubber lamination, a seal rubber lamination, a base and a clamping bolt, wherein the clamping structures of hand-operated knob and upper cap fix the hand-operated knob on the upper cap to rotate only clockwise or counterclockwise but not move up and down, the sleeve with moving seal rubber lamination and the seal rubber lamination are connected to be an integration by adhesion or welding, when the hand-operated knob rotates, the thread on the depressed structure in the middle of hand-operated knob can drive the sleeve with moving seal rubber lamination to move up and down with the seal rubber lamination to make the seal rubber lamination emerged or cover the inner gas ports of the air cocks connected with each gasbag, the only exit of the seal rubber lamination is a tubular structure arranged in the middle and connected with the inflator air cock. The invention has better air impermeability, practicability and easy operation.

Owner:冷博

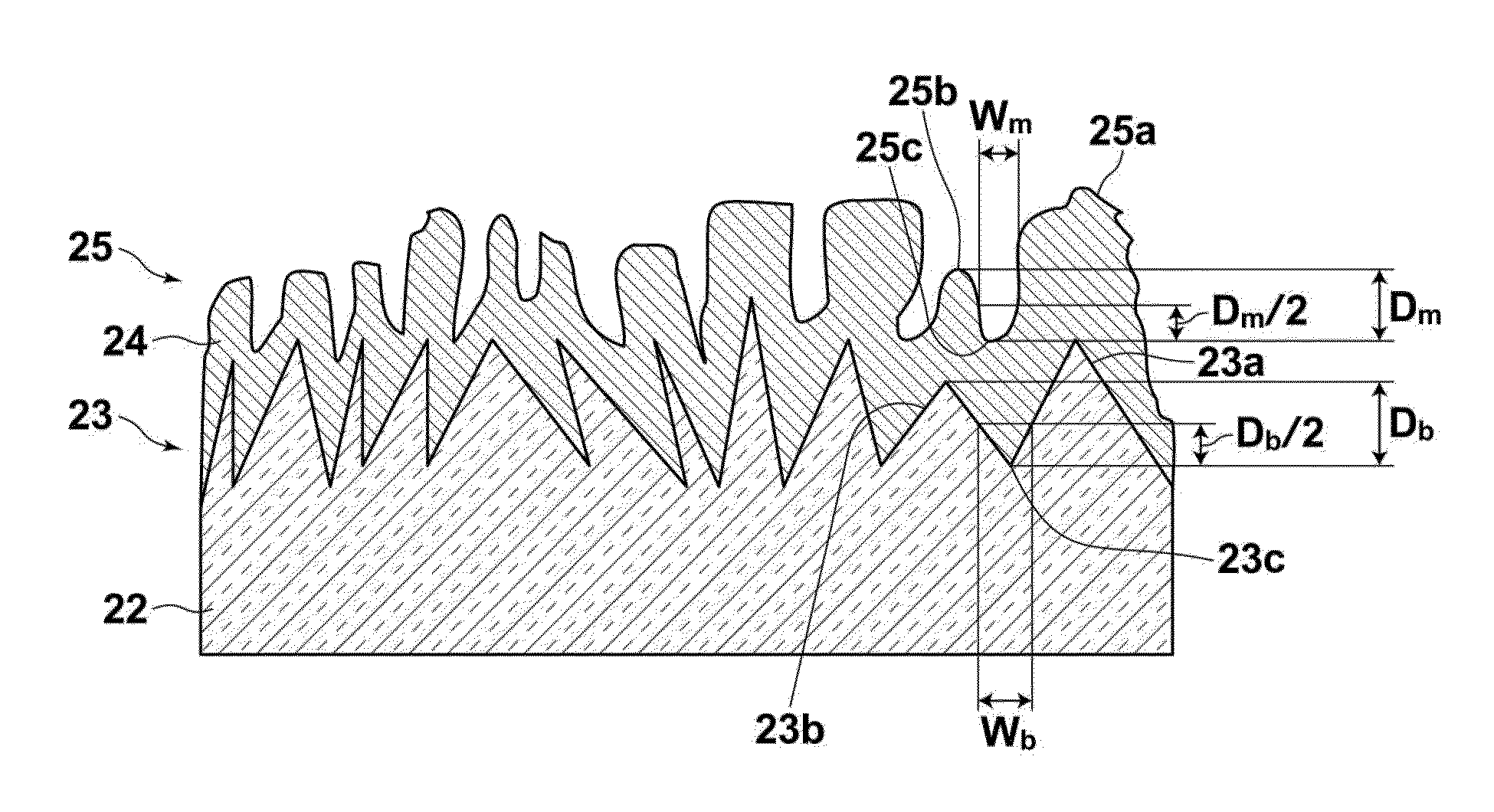

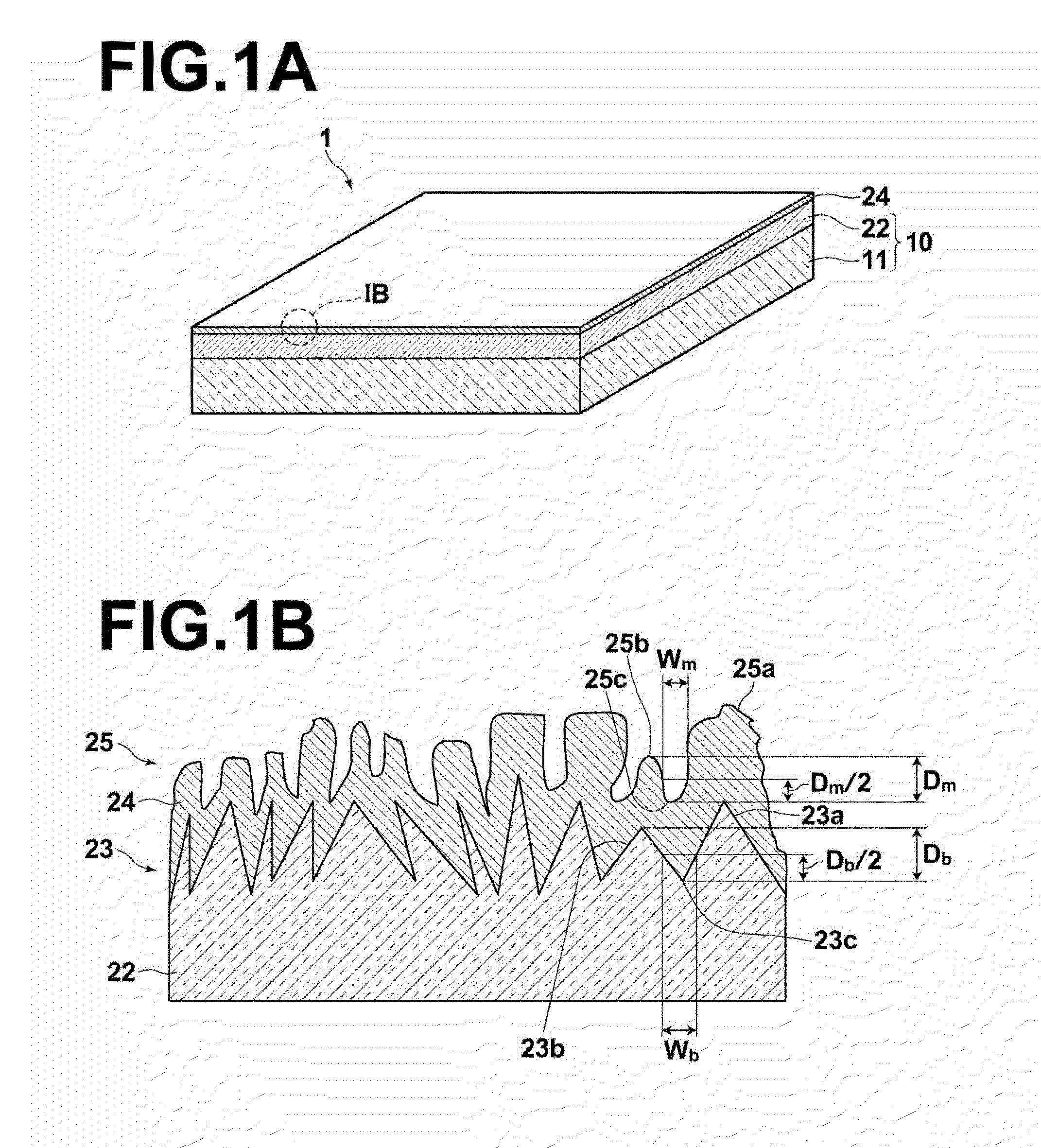

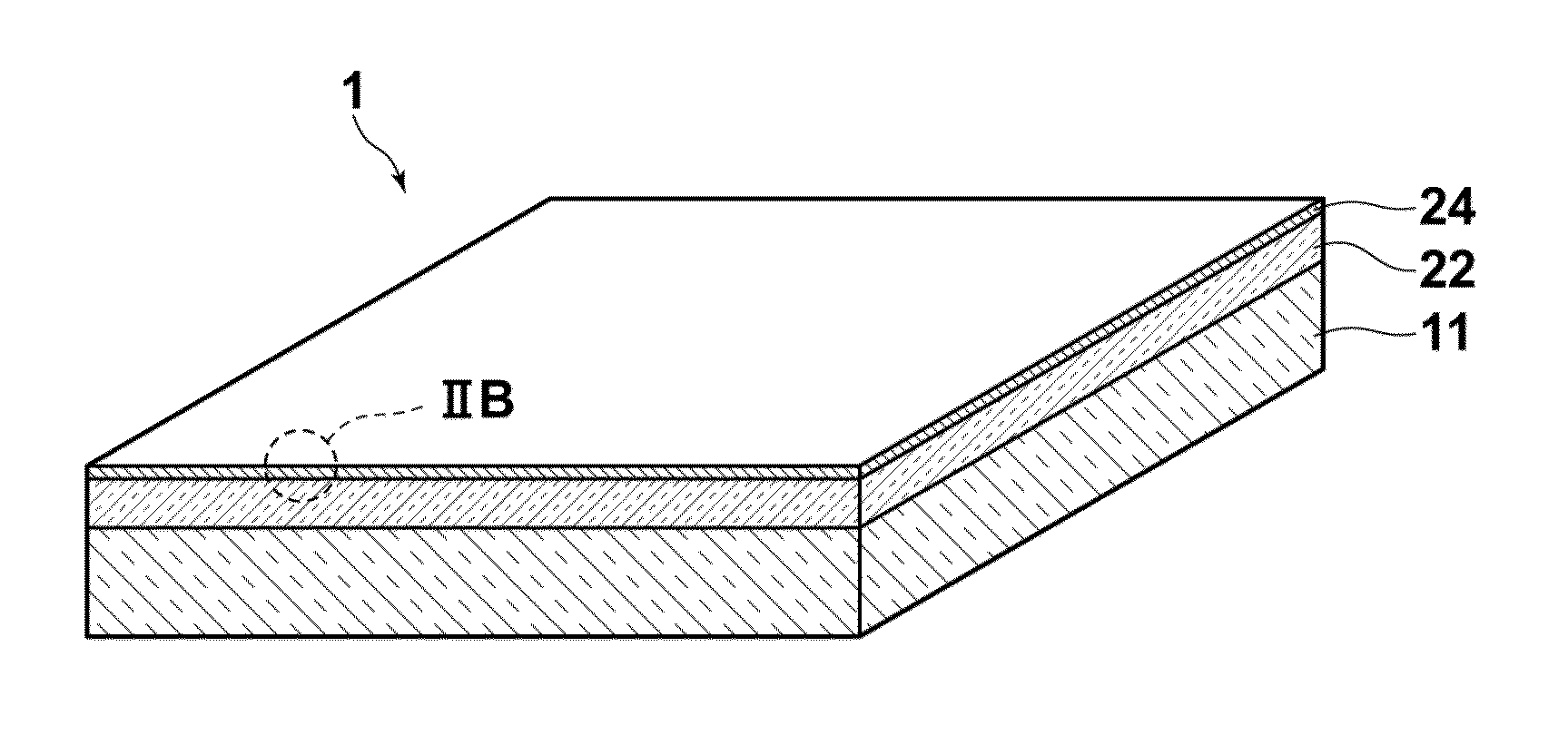

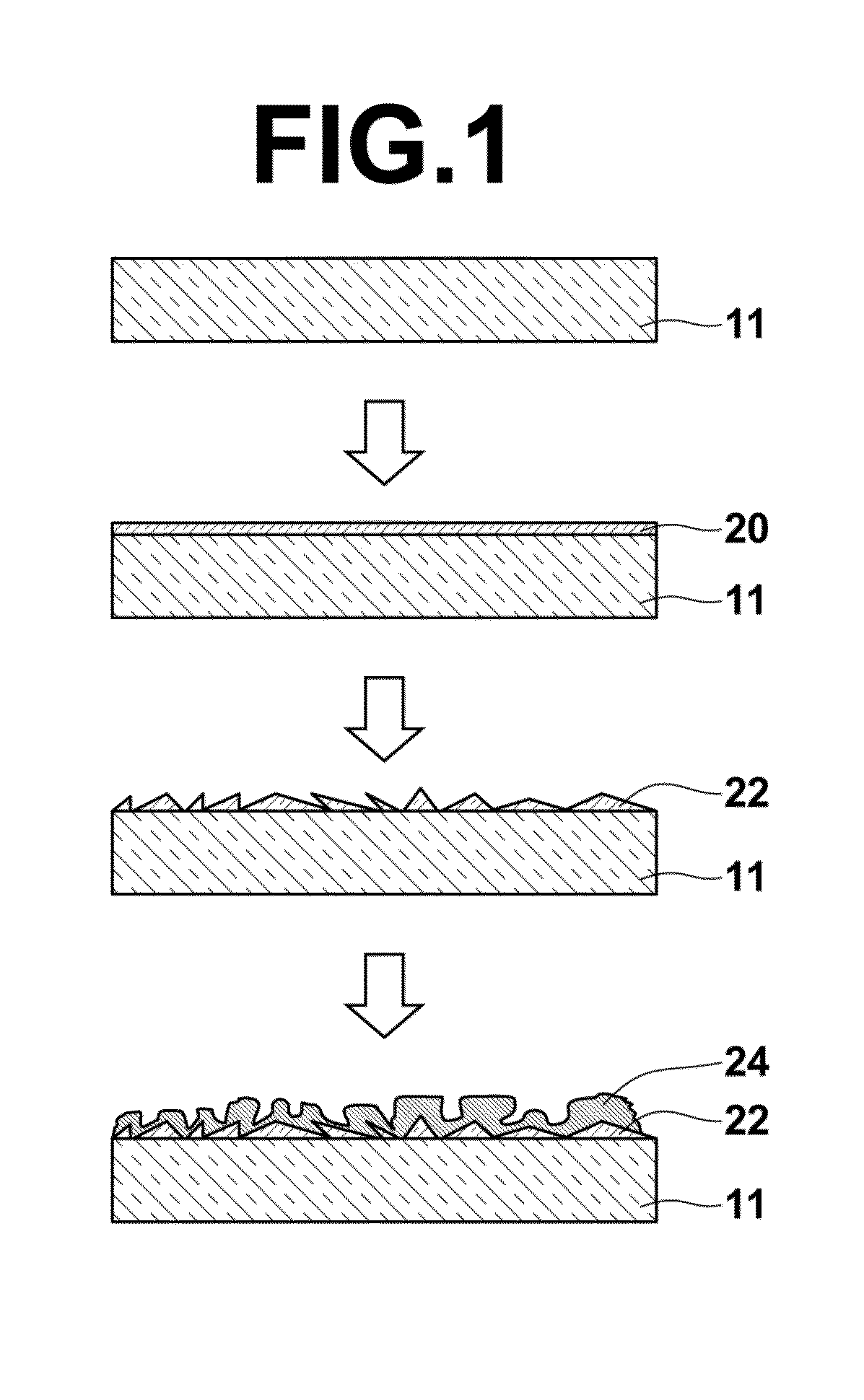

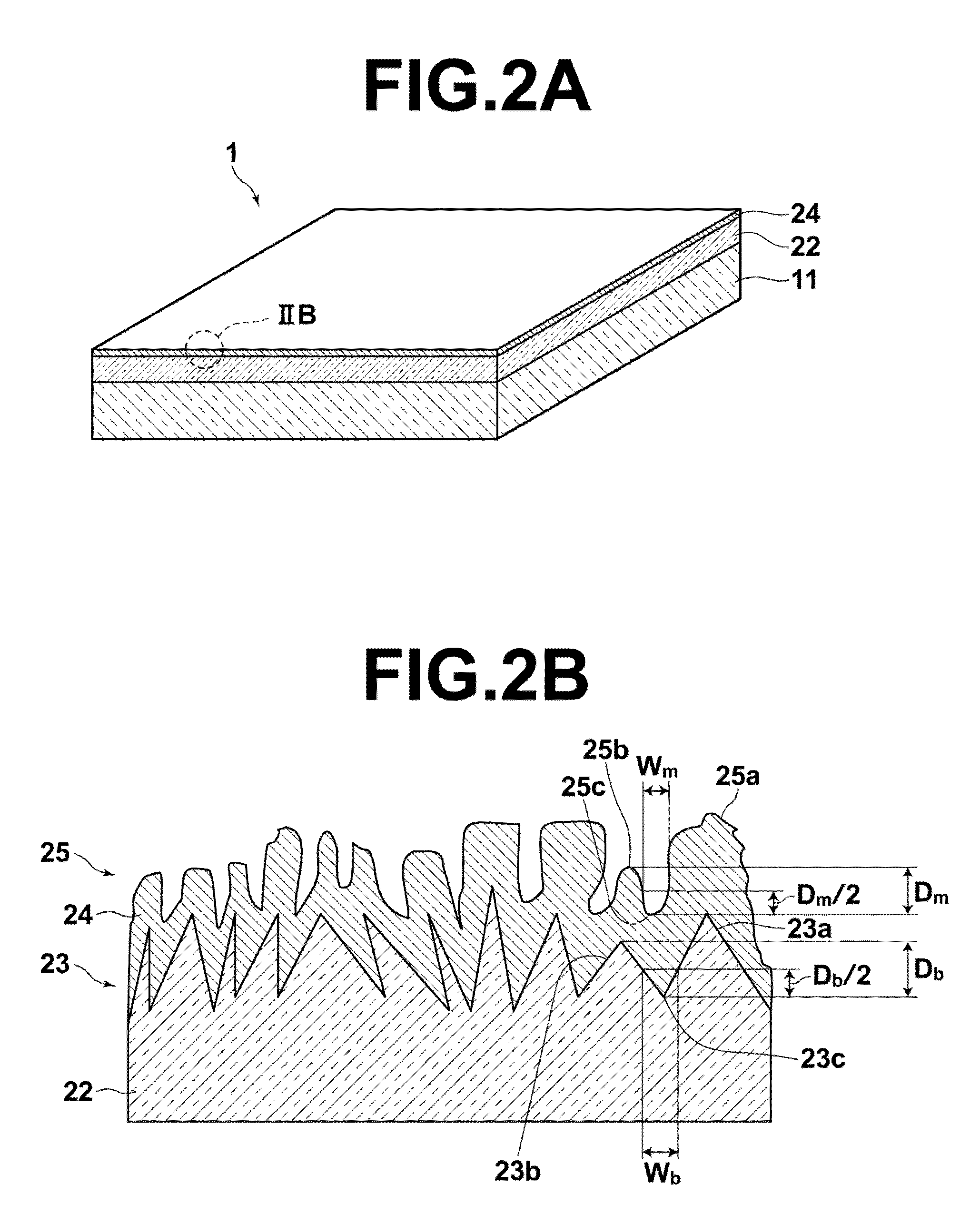

Optical electrical field enhancing device and measuring apparatus equipped with the device

InactiveUS20140016127A1High sensitivityConvenient lightingRadiation pyrometryLaser using scattering effectsMeasurement deviceEngineering

An optical electrical field enhancing device includes: a transparent substrate having a structure of fine protrusions and recesses on the surface thereof; and a metal structure layer of fine protrusions and recesses formed on the surface of the structure of fine protrusions and recesses. The metal structure layer of fine protrusions and recesses has a structure of fine protrusions and recesses, in which the distances among adjacent protrusions are less than the distances among corresponding adjacent protrusions of the structure of fine protrusions and recesses of the transparent substrate.

Owner:FUJIFILM CORP

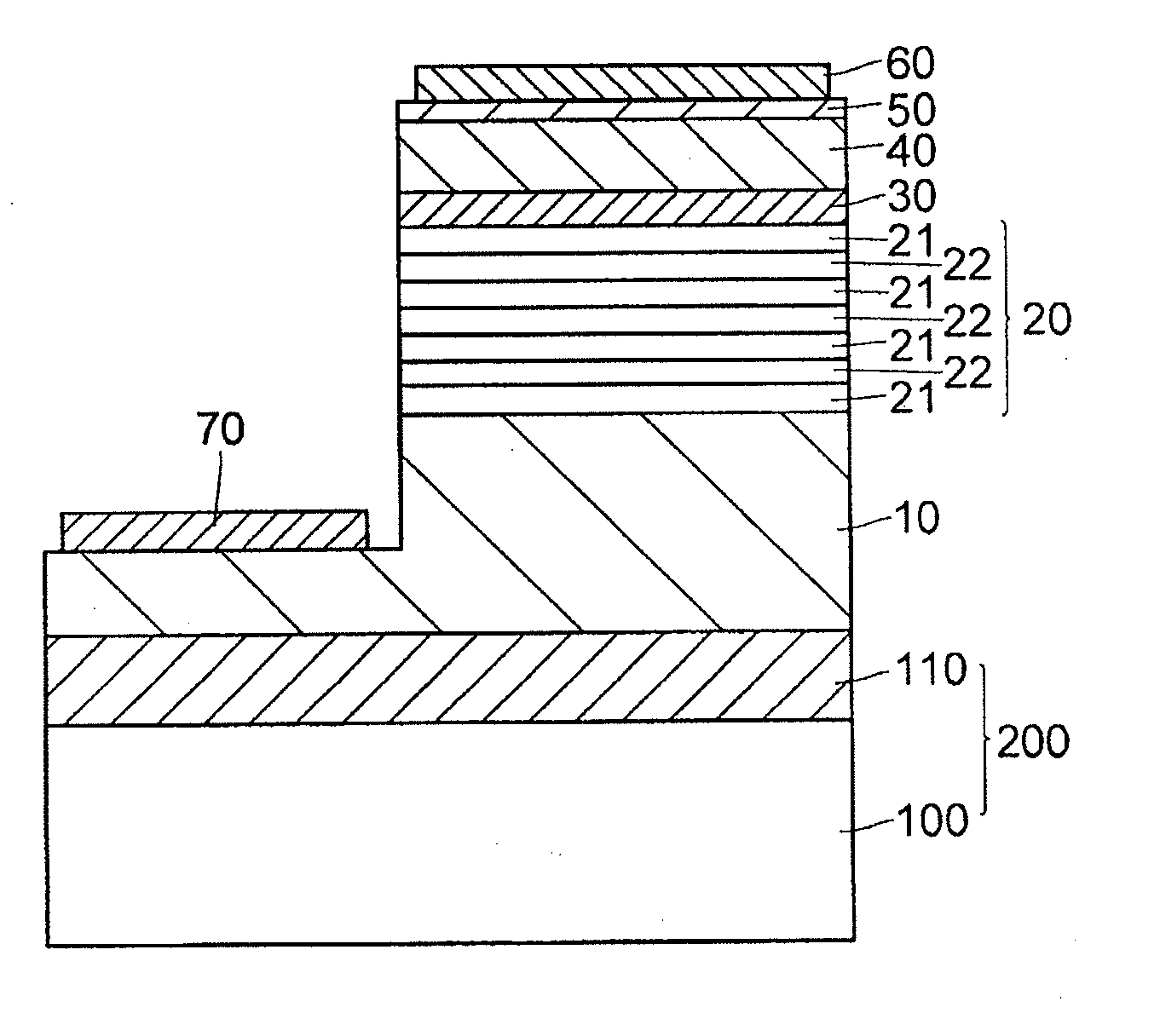

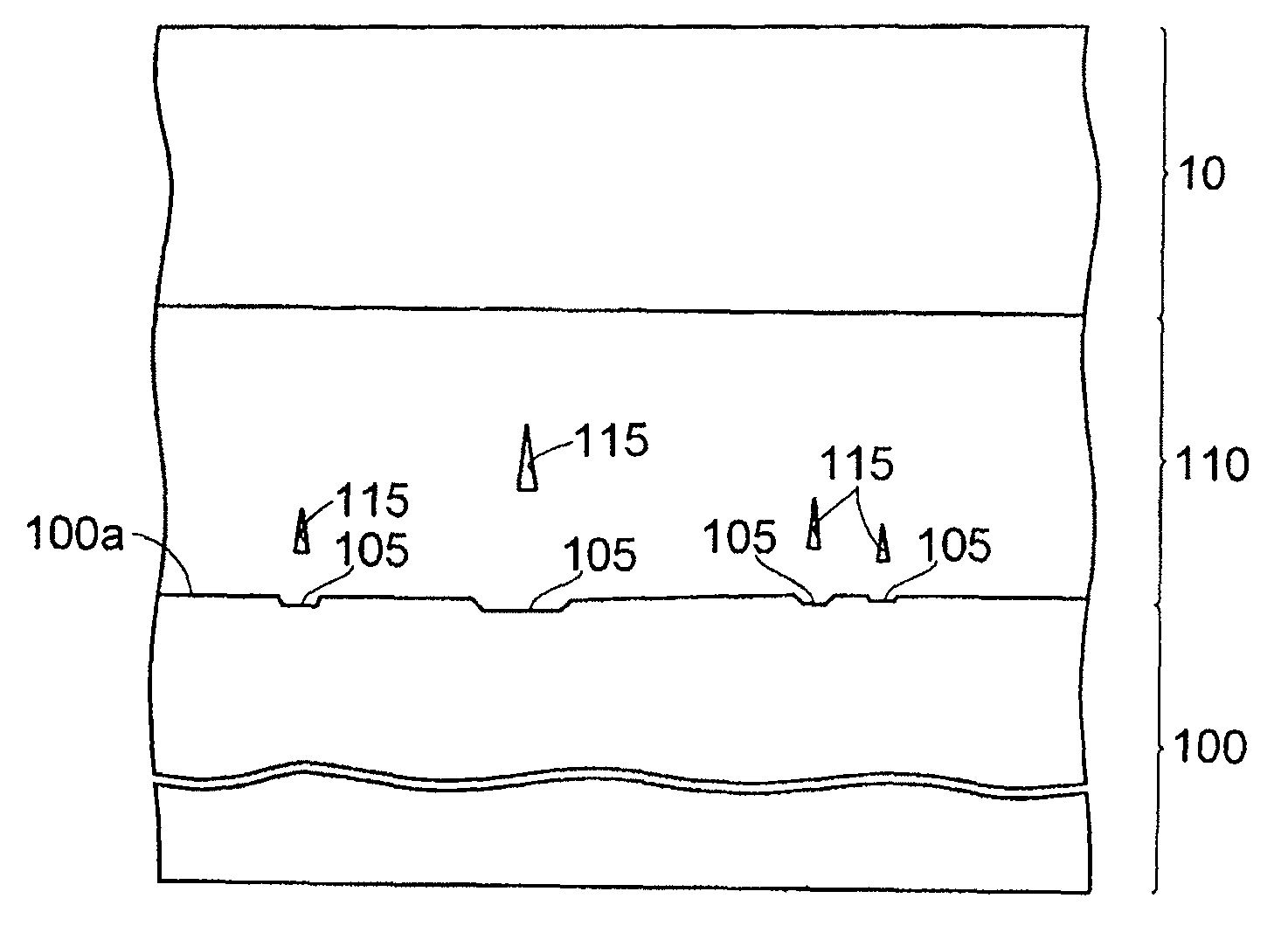

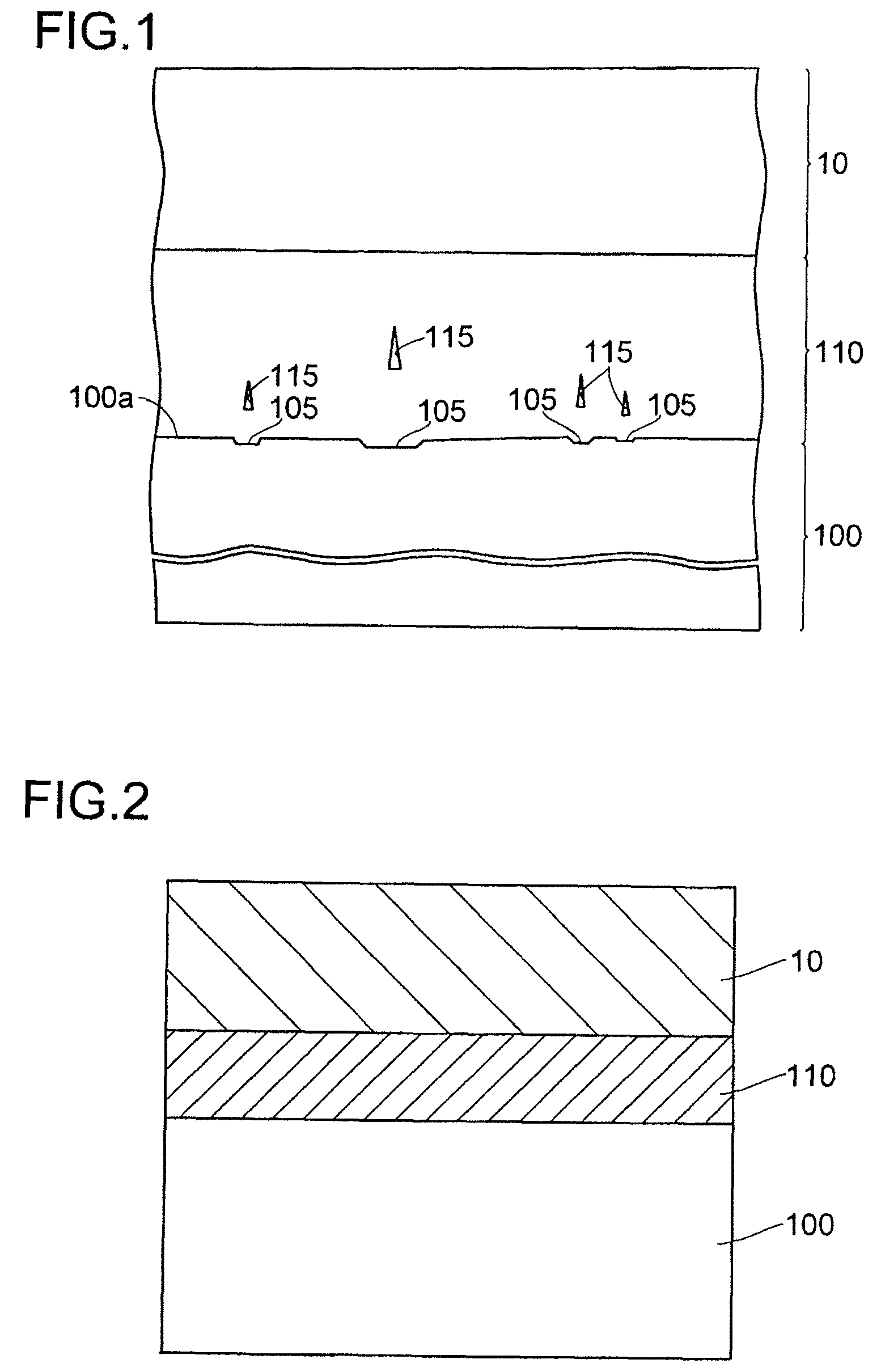

Crystal growth method and semiconductor device

ActiveUS20120007039A1Relieve pressureCrack suppressionSemiconductor/solid-state device manufacturingSemiconductor devicesDislocationCrystal growth

A method of crystal growth is provided which can suppress development of dislocations and cracks and a warp in a substrate. The method of crystal growth of a group III nitride semiconductor has: a step of heating a silicon substrate; and a step of forming a depressed structure on the substrate surface by advance-feeding onto the heated silicon substrate a gas containing at least TMA (trimethylaluminum).

Owner:THE RITSUMEIKAN TRUST +1

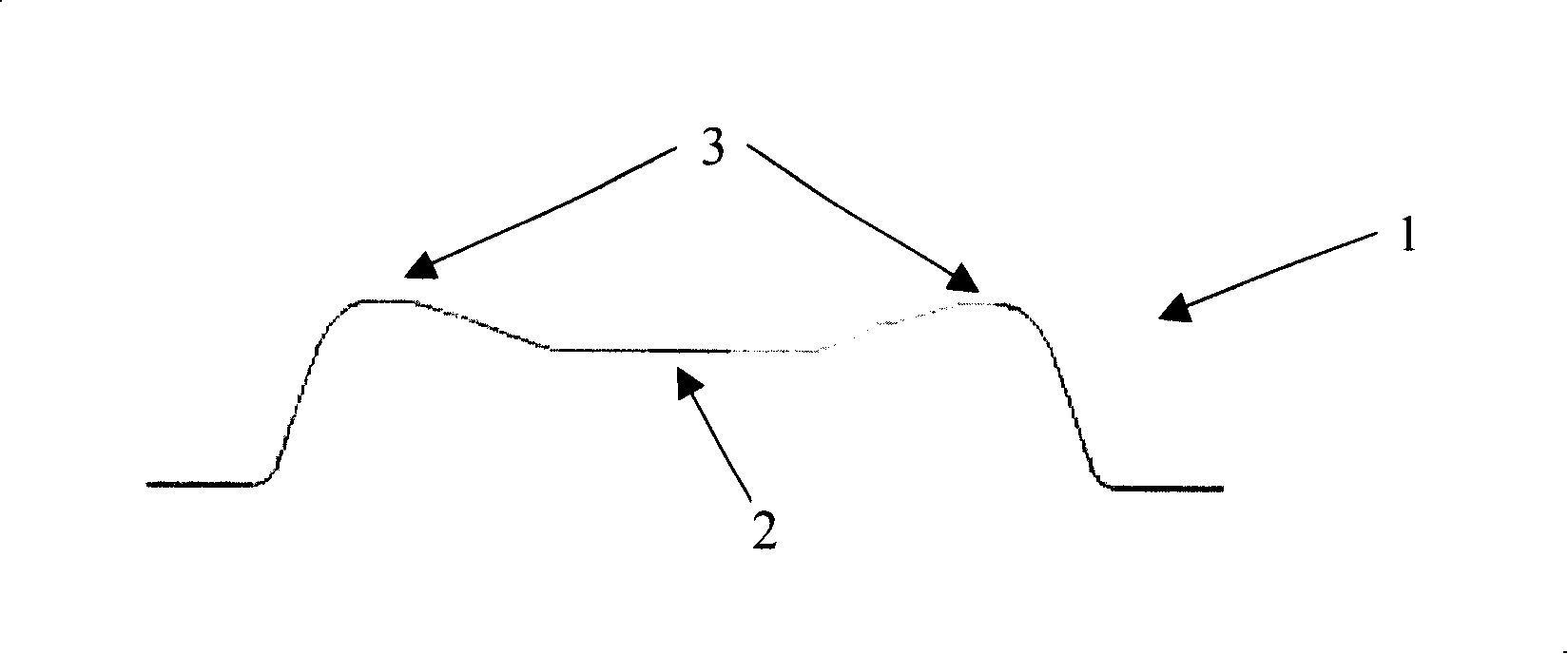

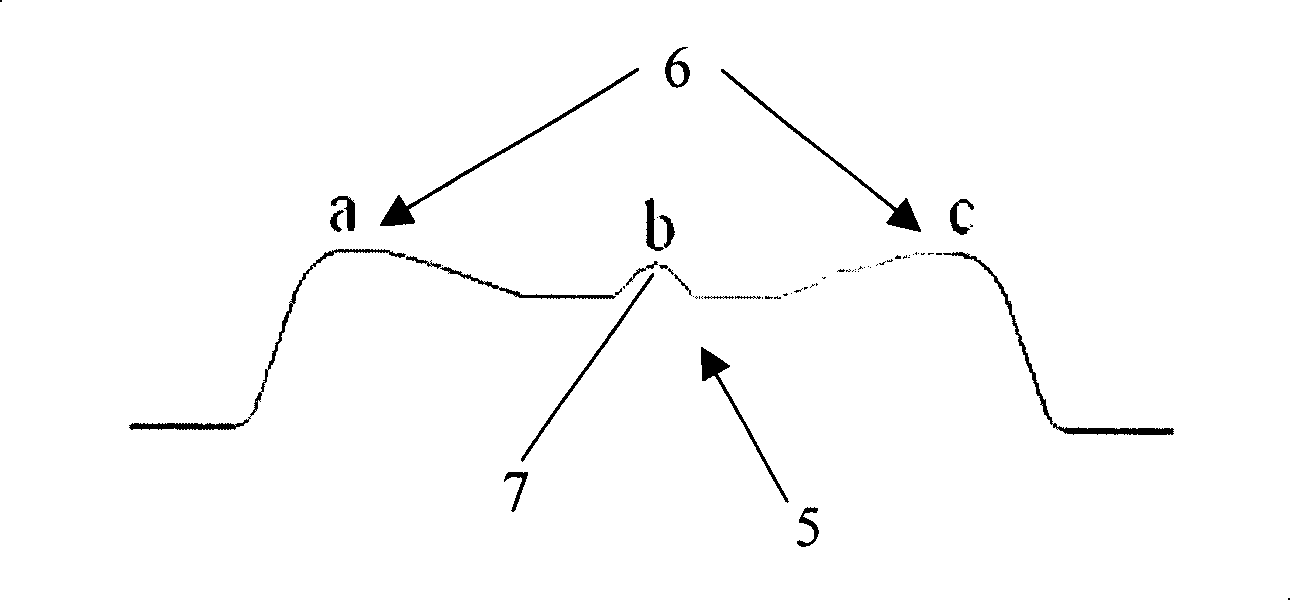

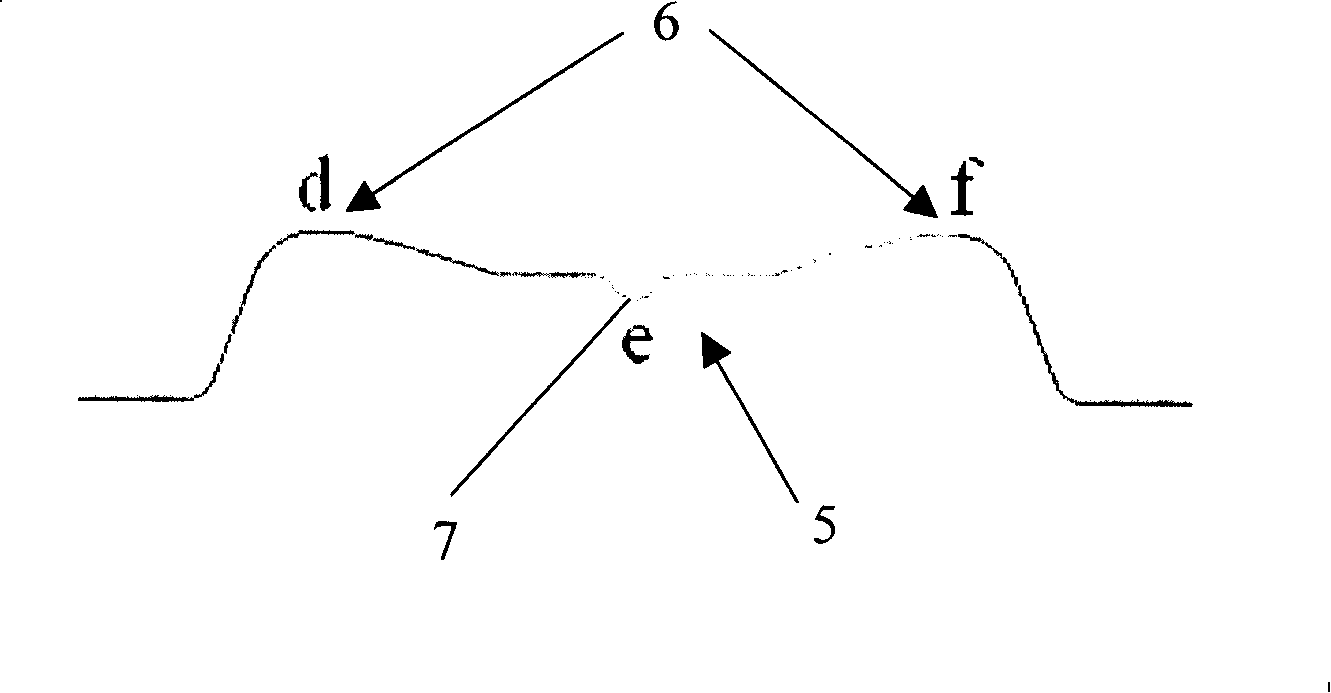

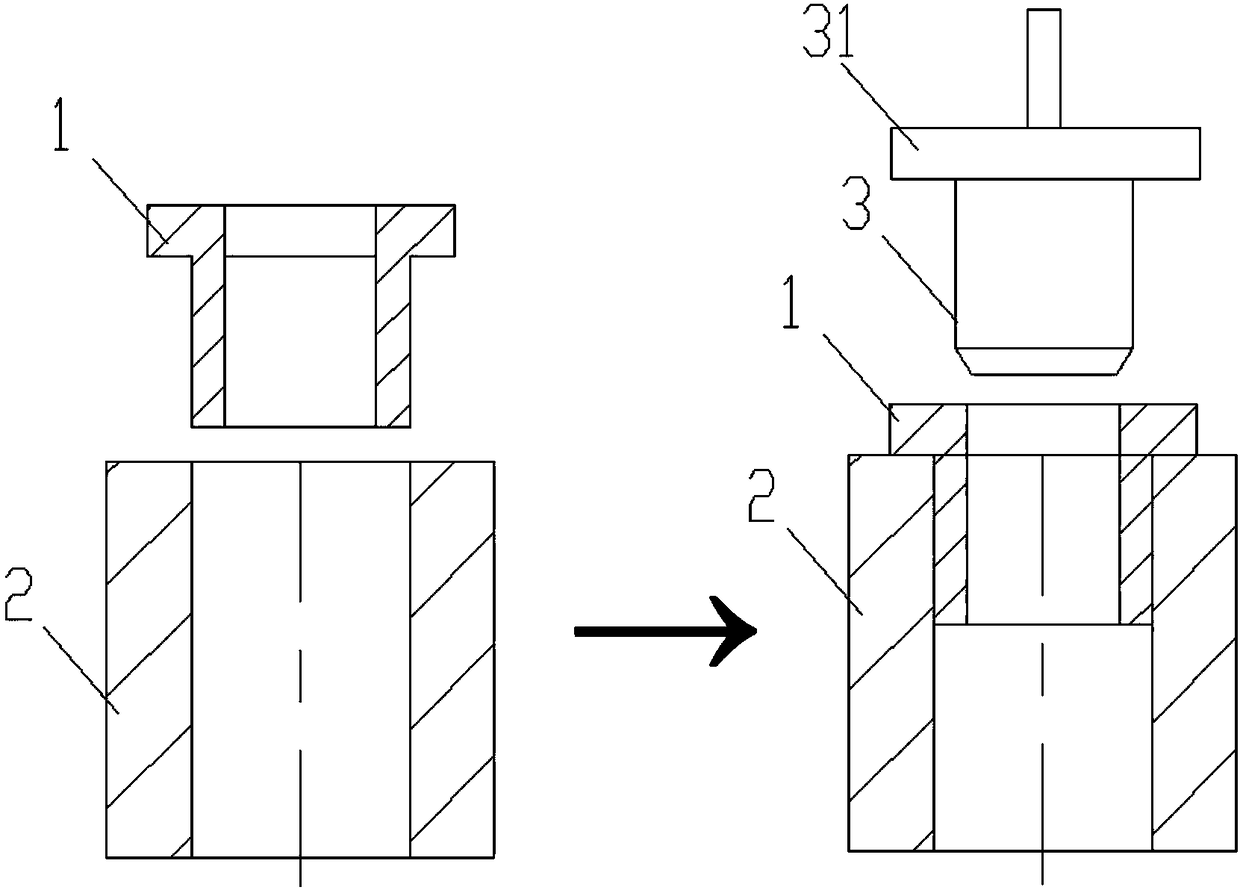

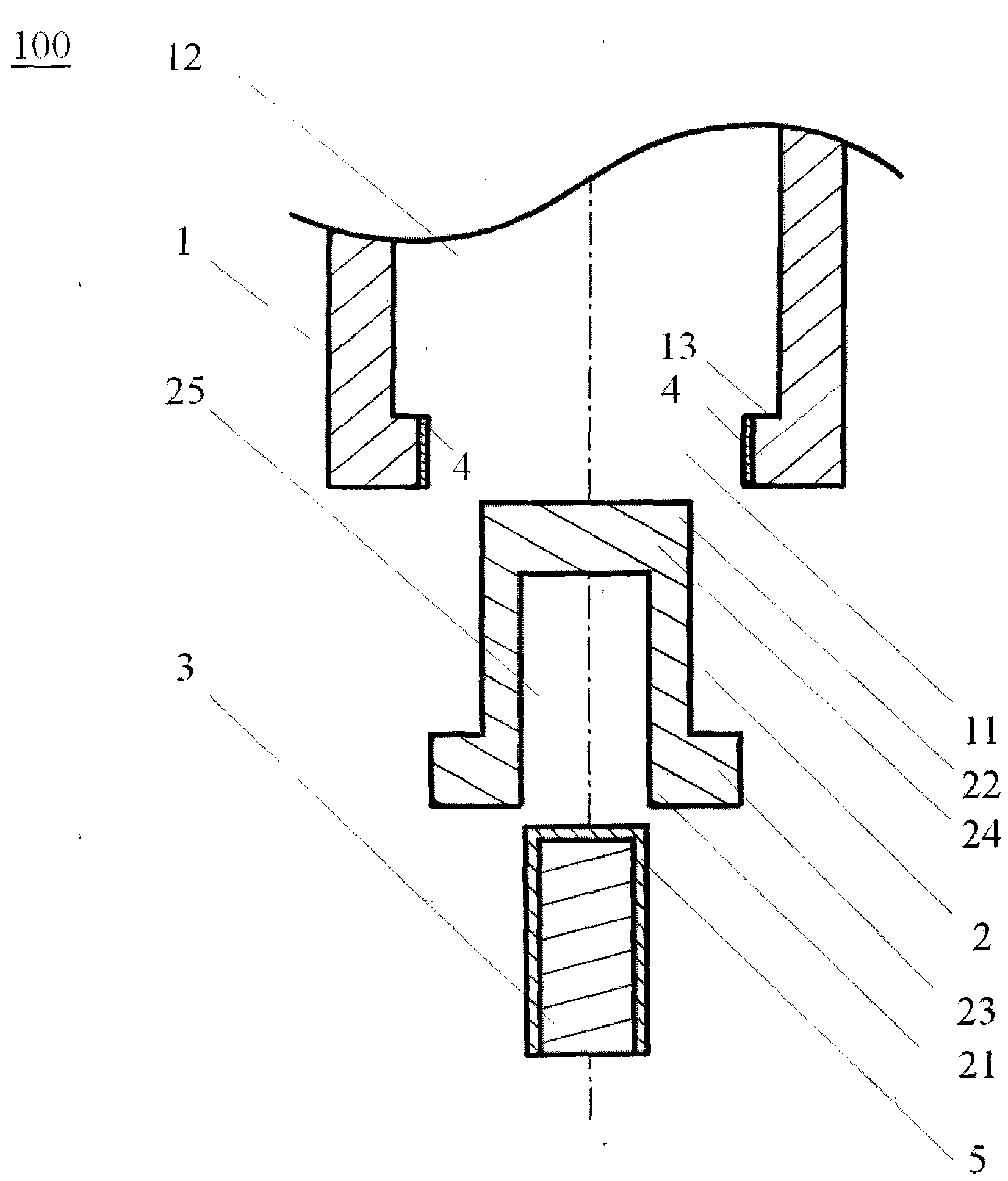

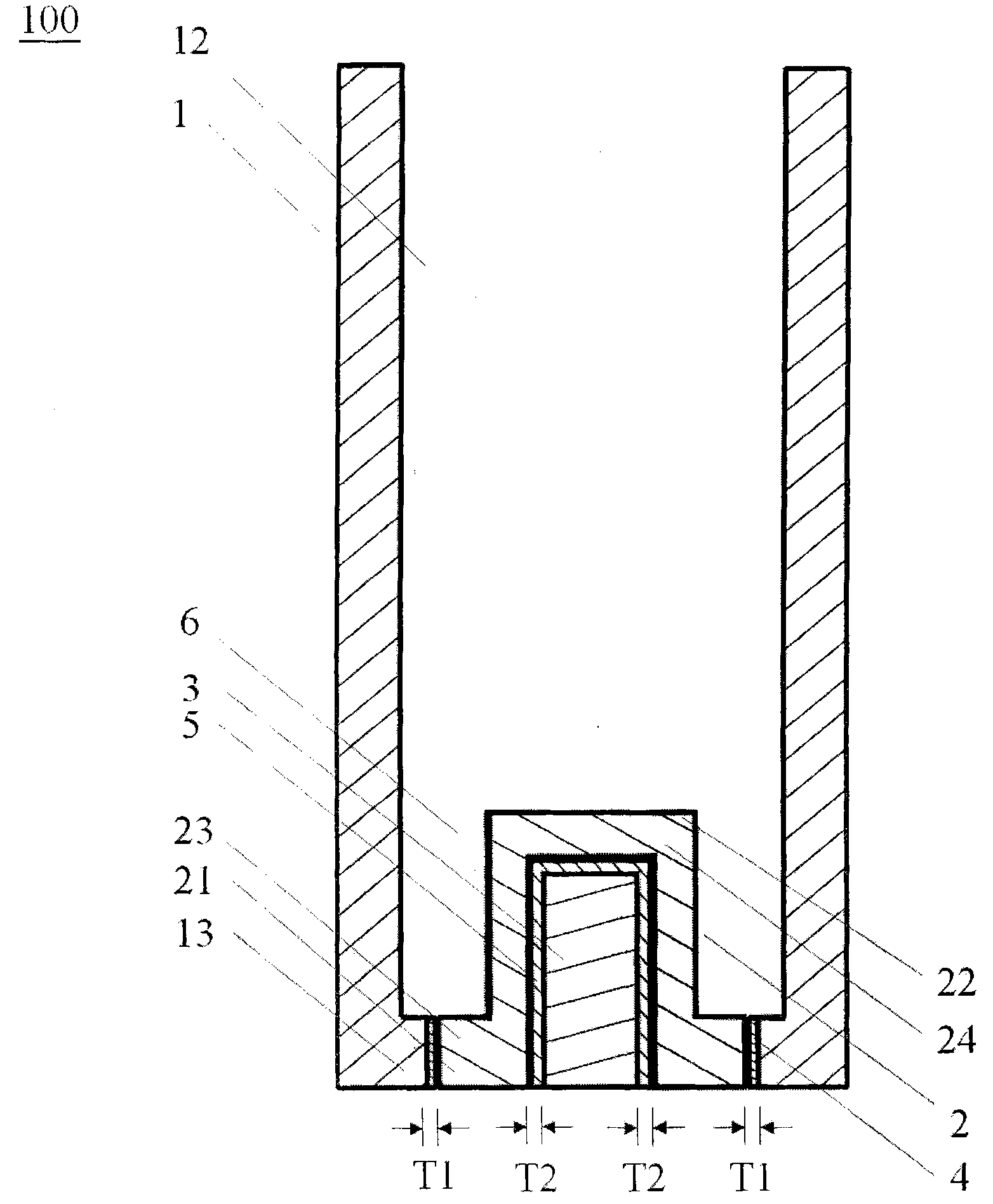

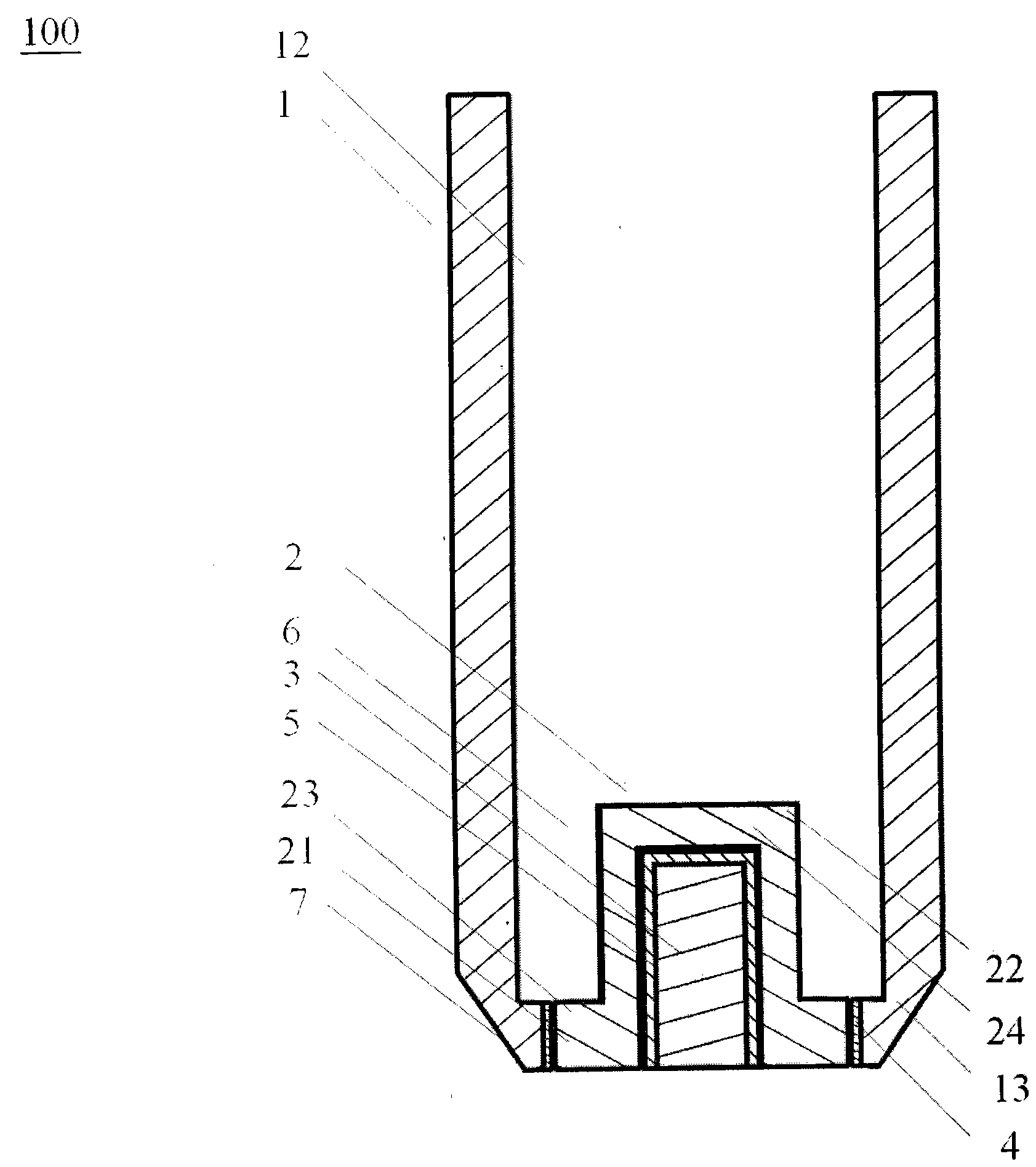

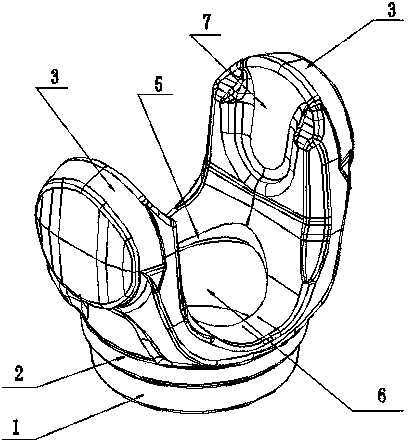

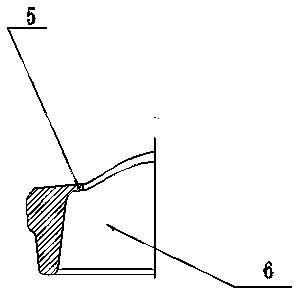

Method for forming part drawing modeling with dent structure

The invention relates to a molding method for drawing and molding a part with depressed structure. The molding method comprises the steps that: a panel is draw and molded, the draw and molded part comprises a depressed area (5) and a protruding area (6) located around the depressed area (5), and a material gathering bar (7) is formed in the depressed area (5); then the draw and molded part is die cut so as to die cut the material gathering bar (7). During the drawing and molding process of the molding method for drawing and molding the part with the depressed structure, as the gathering bar is formed in the depressed area of the part, so the flow of the material can be well controlled during the drawing process; therefore, material accumulation is hard to occur in the transitional part from the protruding area to the depressed area, thus avoiding the wrinkle and laminated material on the surface of the part after drawing molding, enhancing the molding quality of the parts and reducing the defective rate.

Owner:BYD CO LTD

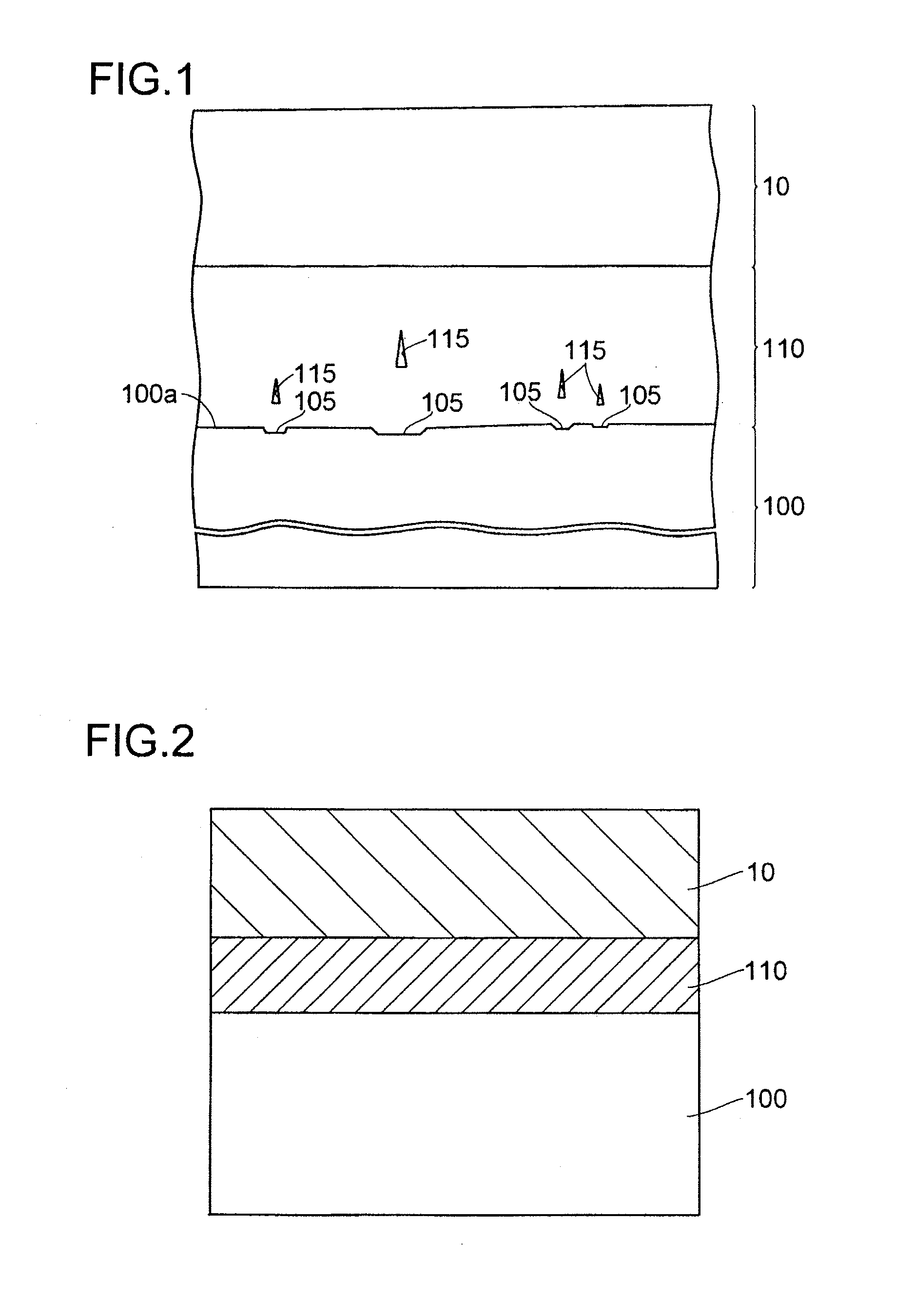

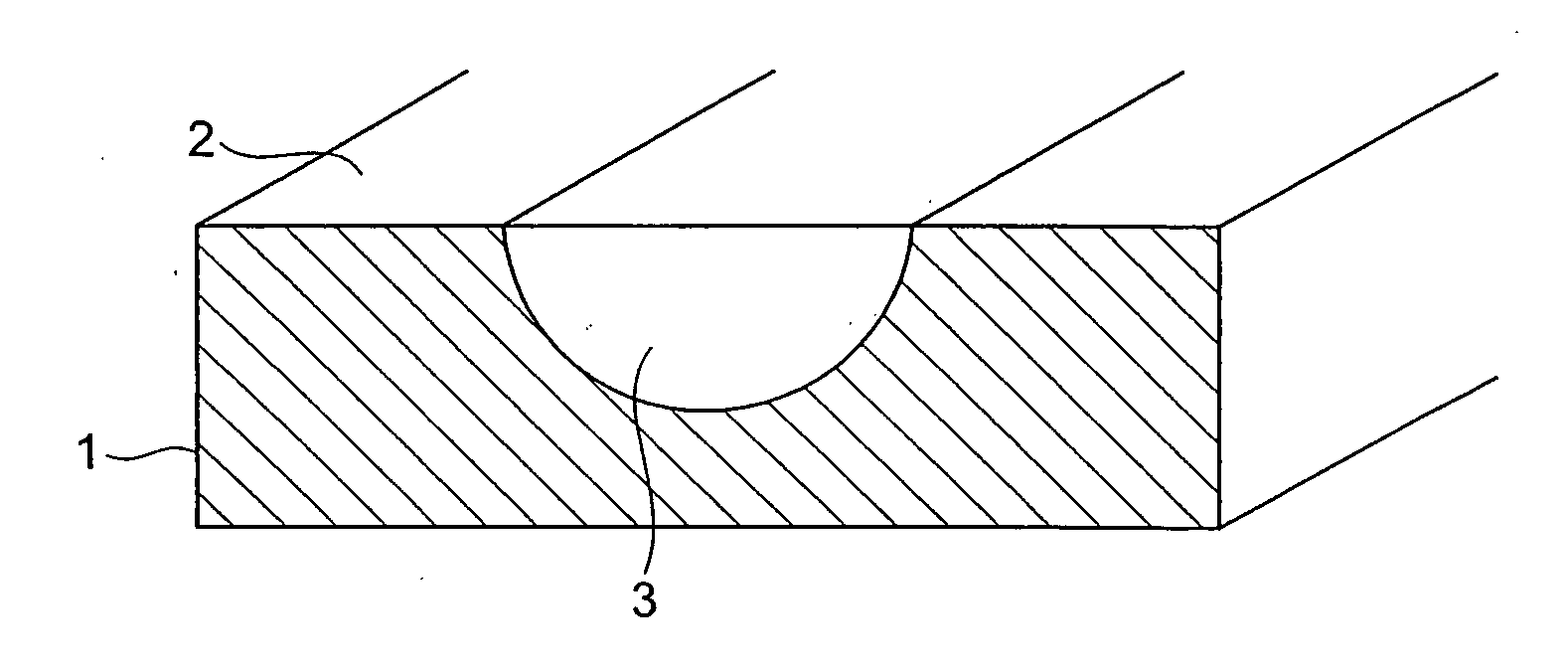

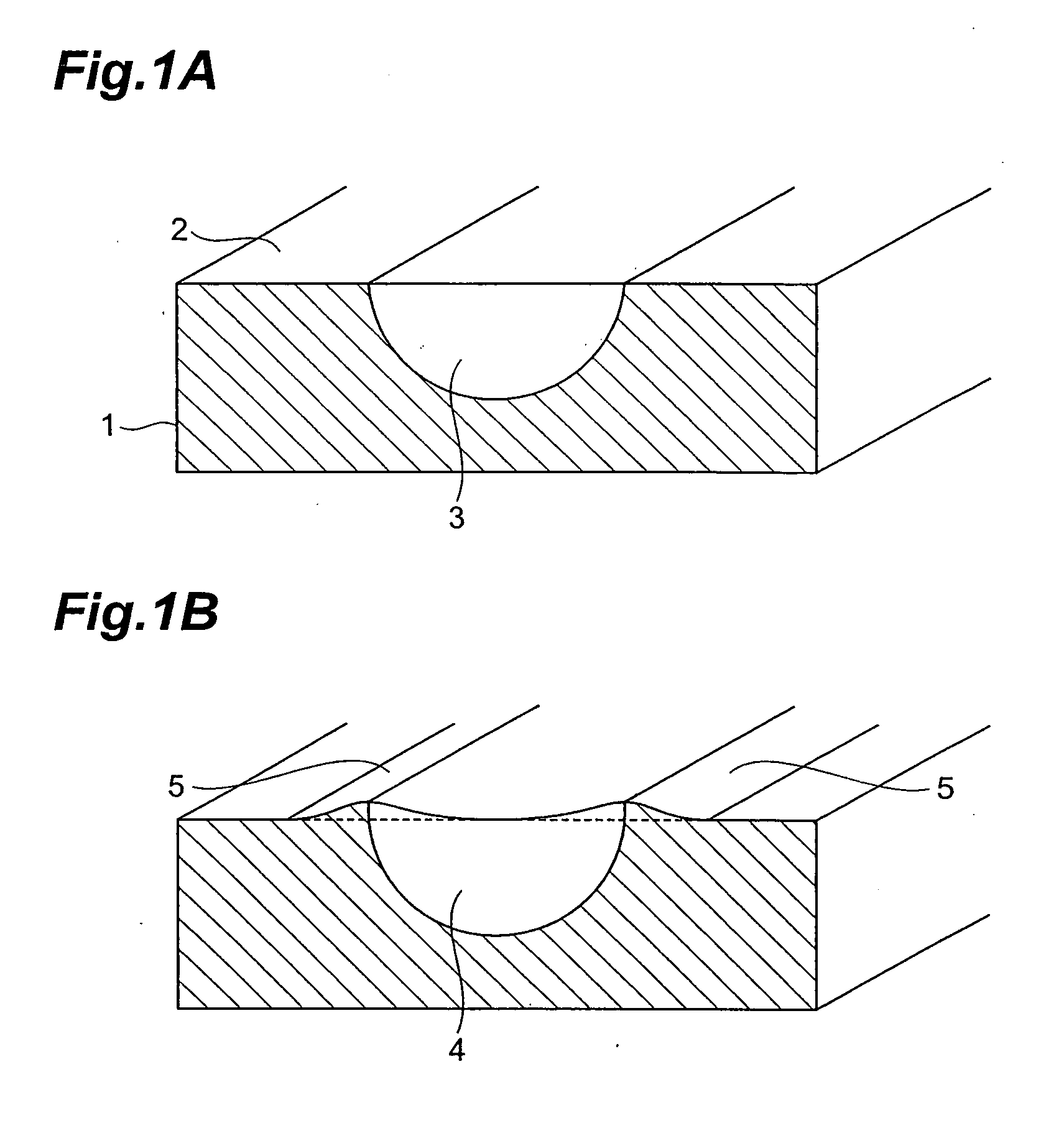

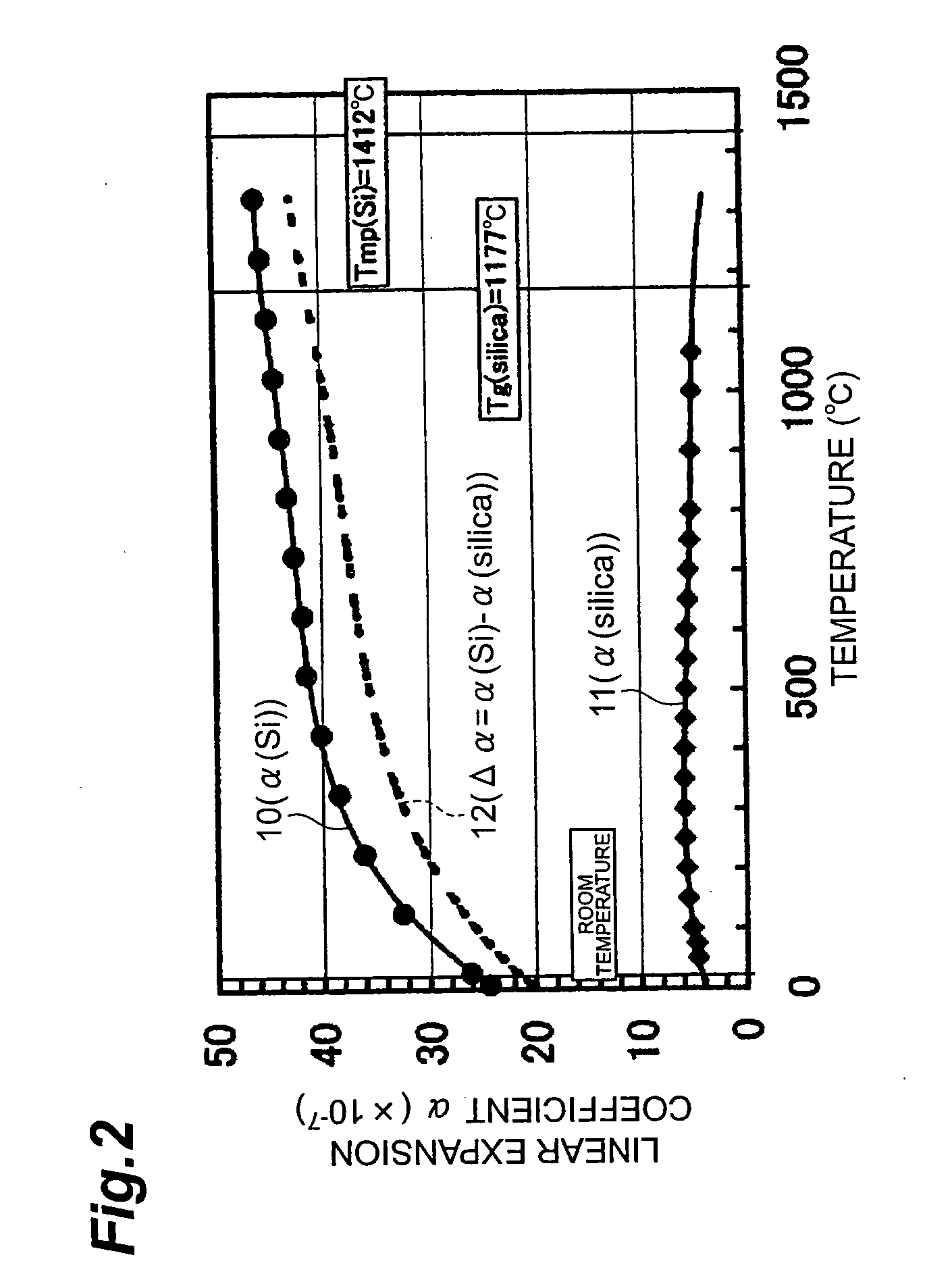

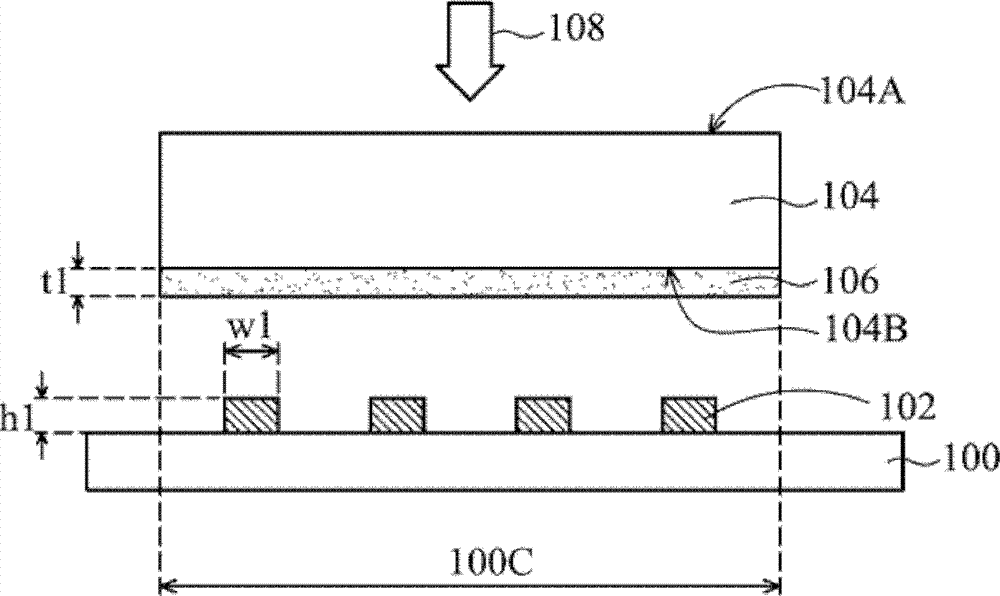

Silicon Substrate and Method of Forming the Same

InactiveUS20070275254A1Decreasing minimum transmission lossDecrease of TgLayered productsNanoopticsVitrificationVitreous Bodies

A silicon substrate 1 has a structure in which a depression of a silicon crystal is formed on at least one principal surface 2 side of a crystalline silicon substrate and which has a vitreous region 3 filled in the depression and consisting primarily of silicon oxide. The vitreous region 3 is formed so that the glass transition temperature Tg thereof is lower than that of pure silica glass and not more than 900° C. This configuration realizes the silicon substrate in which internal strain is reduced between glass and the silicon crystal, and a forming method thereof.

Owner:HAMAMATSU PHOTONICS KK +1

Semiconductor device having aluminum nitride layer with void formed therein

ActiveUS8698168B2Suppress development of crackReduce misalignmentSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDislocation

Owner:THE RITSUMEIKAN TRUST +1

Capsule for the preparation of a coffee extract having a structure facilitating perforation for injection of water

ActiveUS9162815B2Convenient introductionMaximize flowFlexible coversWrappersMaterial PerforationInjection device

A capsule for the preparation of a coffee extract from coffee contained therein and hot water injected under pressure in the capsule by a water injection device. The capsule has a frusto-conical body with a rim, sidewall, and an inlet wall and a lower delivery wall sealed to the rim and contains a predosed amount of coffee. The inlet wall may have a flat or convex portion and a structure in relief or in recess arranged for facilitating penetration of blades belonging to the injection device and extending on a substantially circular path of predetermined radius R1 equal to the radius R2 of the circular path along which the blades of the injection device extend.

Owner:SOC DES PROD NESTLE SA

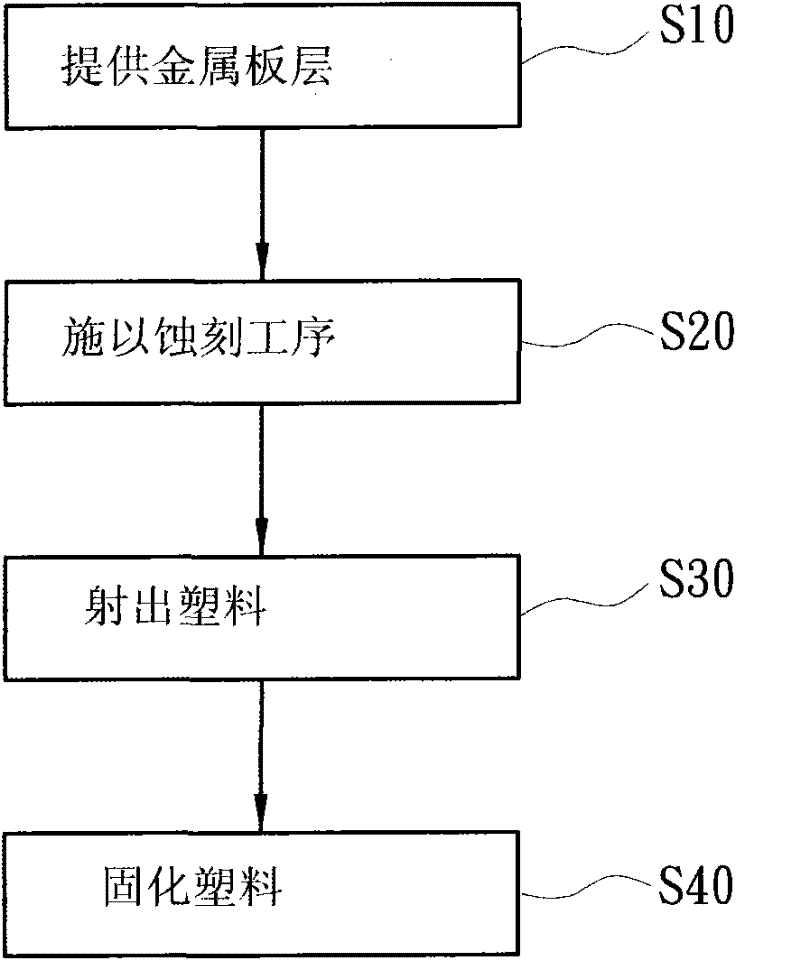

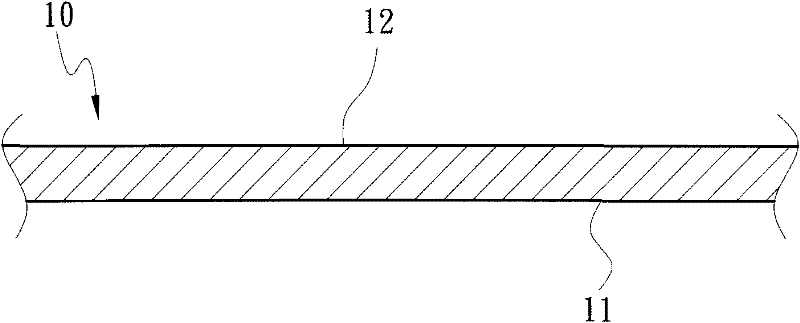

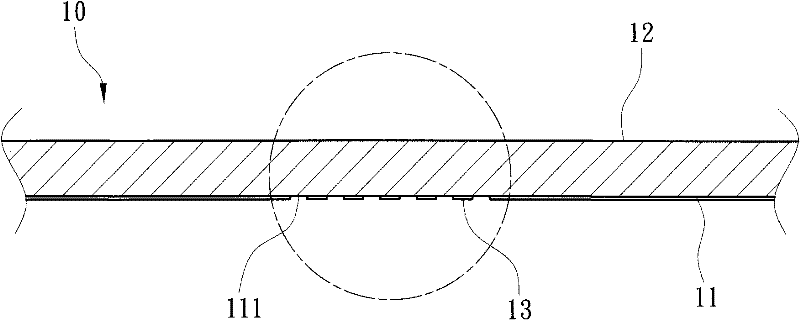

Method for manufacturing in mode forming film with metal surface

InactiveCN102223774AReduce settingsSteps to Save SetupMetal layered productsElectrical apparatus casings/cabinets/drawersInjection mouldingJoint surface

A method for manufacturing an in mode forming film with a metal surface comprises the following steps: firstly, providing a metal plate layer which possesses a joint surface presetting at least one etching area; then, performing an etching operation on the etching area of the joint surface so that a plurality of depressed structures are inwardly formed on the etching area surface; after finishing etching the metal plate layer, ejecting plastic with an injection moulding pressure to the joint surface of the metal plate layer so that the plastic which is under an compression of the injection moulding pressure clads the depressed structures of the etching area; finally, bearing the metal plate layer after the plastic is solidified, wherein the solidified plastic forms a close bonding relationship with the depressed structures. Therefore, an adhesion layer doses not need to be additionally arranged between the metal plate layer and the ejected plastic. Manufacturing costs are saved and processing operations can be reduced during the making programs.

Owner:SUZHOU CITY TENGYI TECH

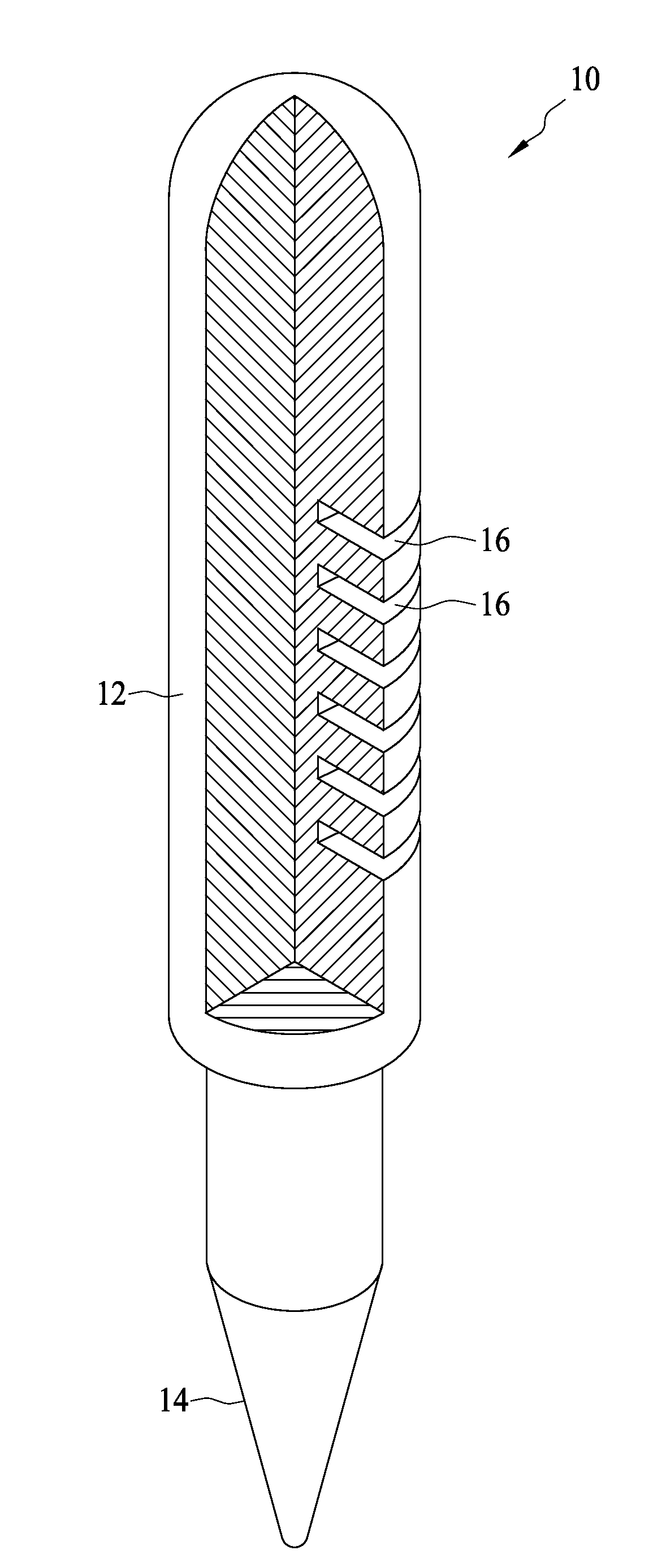

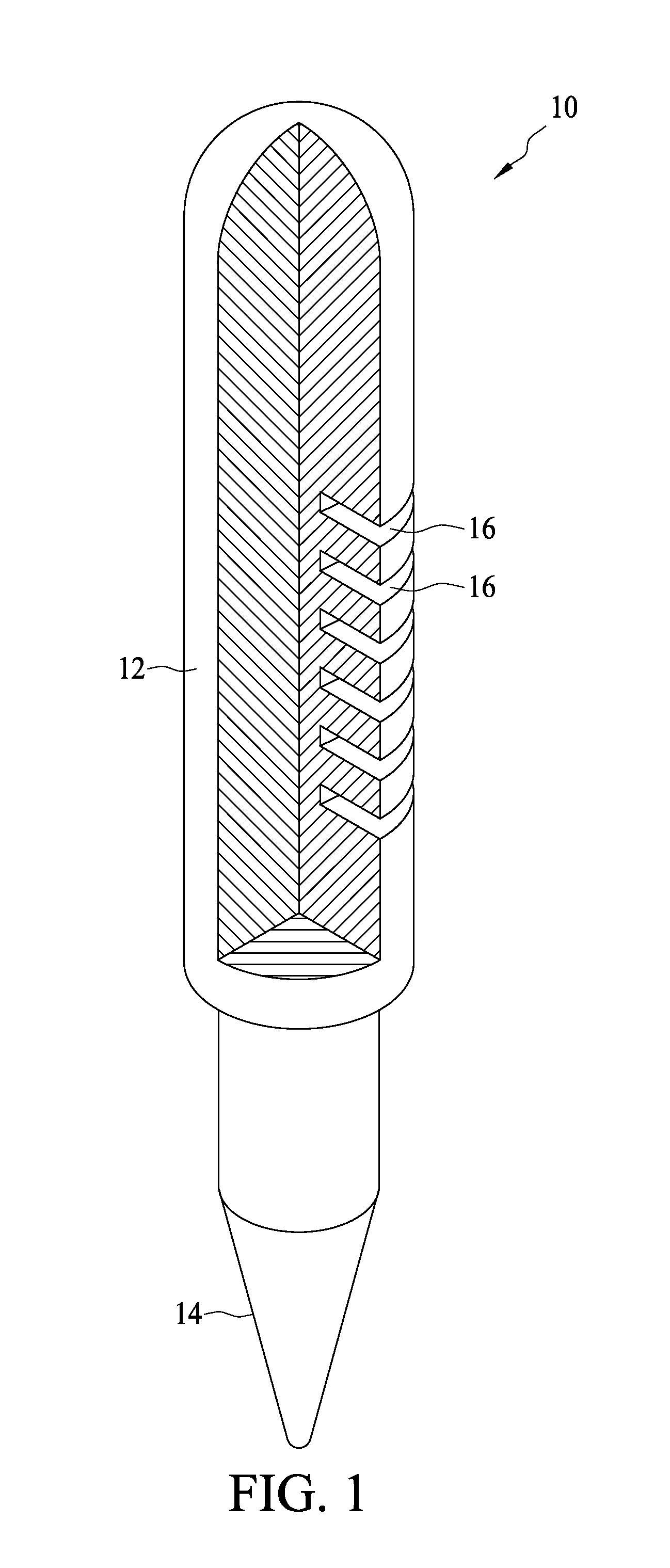

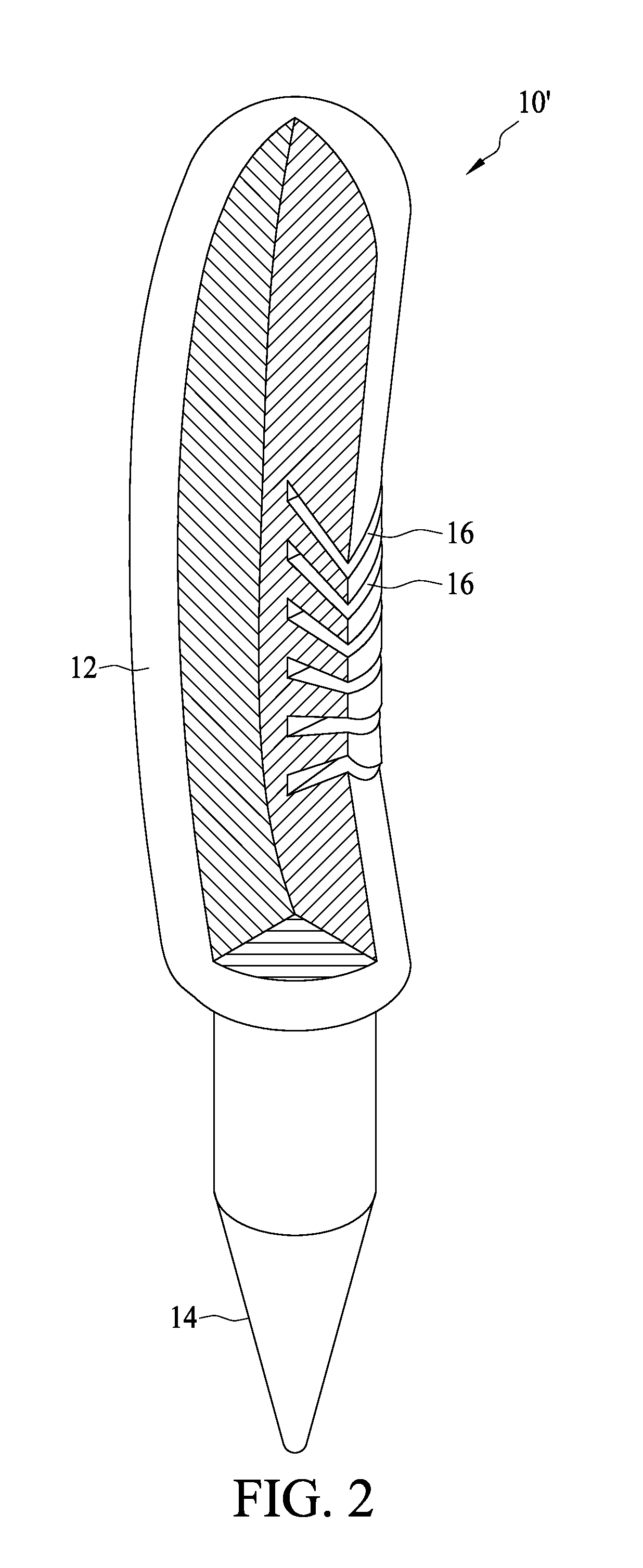

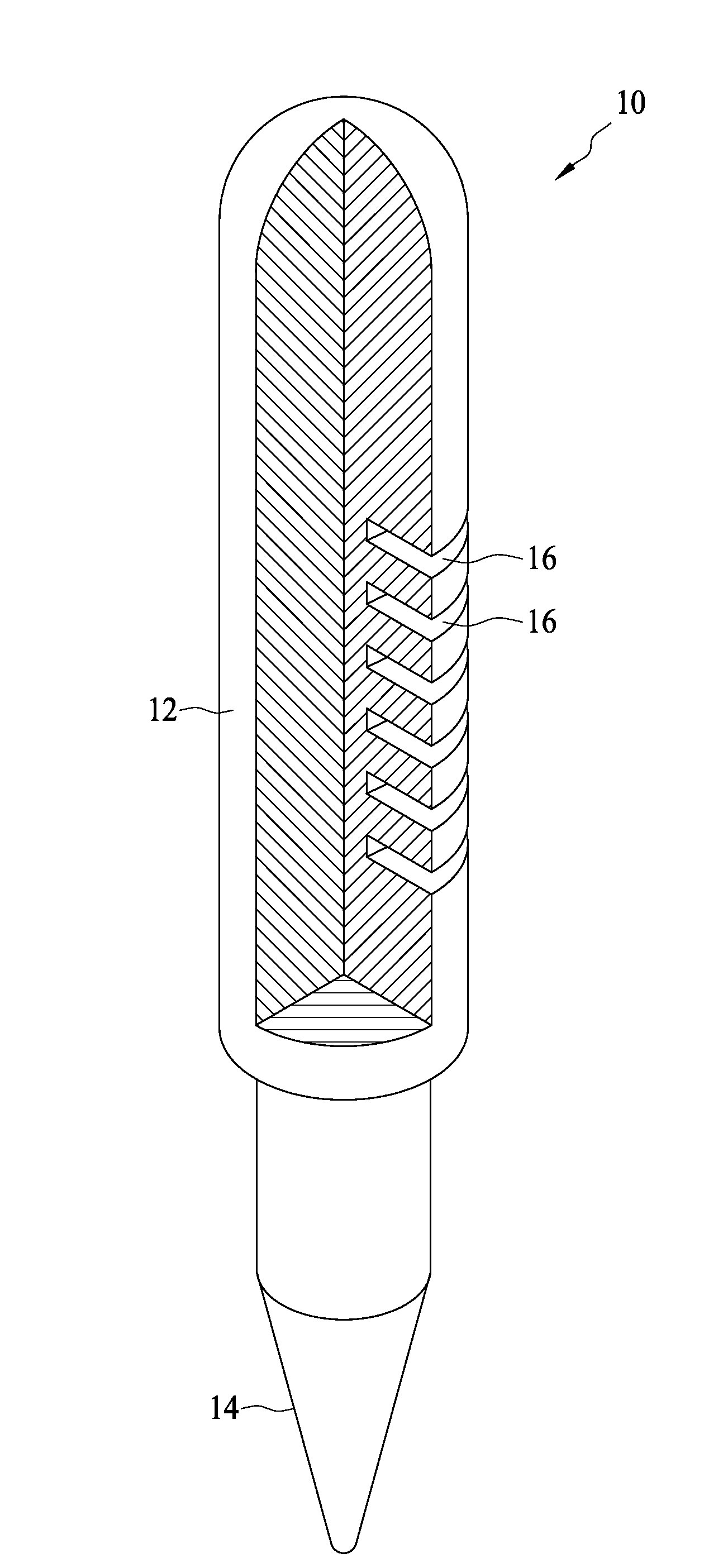

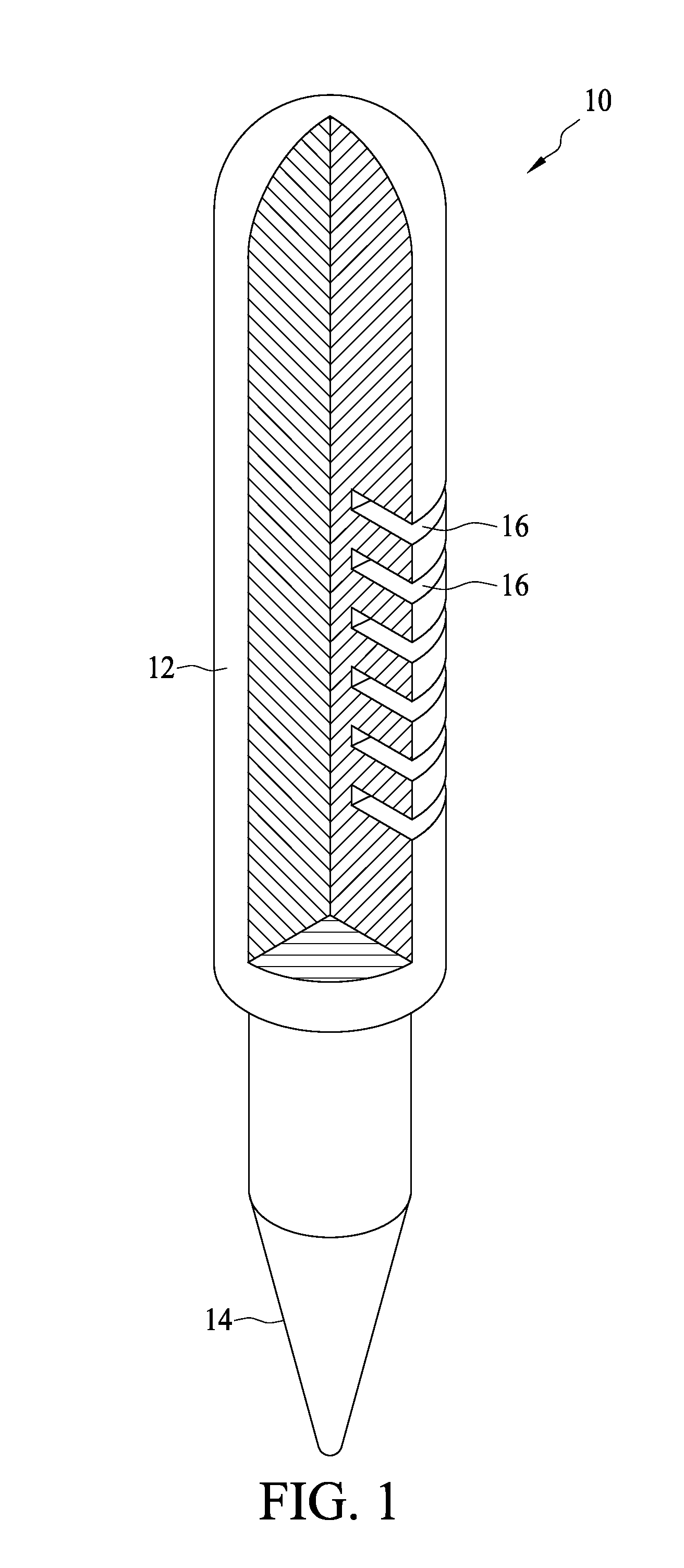

Probe and probe card for integrated circuit devices using the same

ActiveUS20100171519A1Relieve pressureSmall spacingElectrical measurement instrument detailsContactless circuit testingProbe cardBody positions

A vertical probe comprises a linear body, a tip portion connected to one side of the linear body, and at least one slot positioned on the linear body. In particular, the vertical probe includes a depressed structure having a plurality of slots positioned on the linear body in parallel and on one side of the linear body. The present application also provides a probe card for integrated circuit devices comprising an upper guiding plate having a plurality of fastening holes, a bottom guiding plate having a plurality of guiding holes and a plurality of vertical probes positioned in the guiding holes. The vertical probe includes a linear body positioned in the guiding holes, a tip portion connected to one side of the linear body and at least one slot positioned on the linear body.

Owner:STAR TECH INC

Probe and probe card for integrated circuit devices using the same

InactiveUS20090315578A1Small spacingRelieve pressureElectrical measurement instrument detailsIndividual semiconductor device testingProbe cardBody positions

A vertical probe comprises a linear body, a tip portion connected to one side of the linear body, and at least one slot positioned on the linear body. In particular, the vertical probe includes a depressed structure having a plurality of slots positioned on the linear body in parallel and on one side of the linear body. The present application also provides a probe card for integrated circuit devices comprising an upper guiding plate having a plurality of fastening holes, a bottom guiding plate having a plurality of guiding holes and a plurality of vertical probes positioned in the guiding holes. The vertical probe includes a linear body positioned in the guiding holes, a tip portion connected to one side of the linear body and at least one slot positioned on the linear body.

Owner:STAR TECH INC

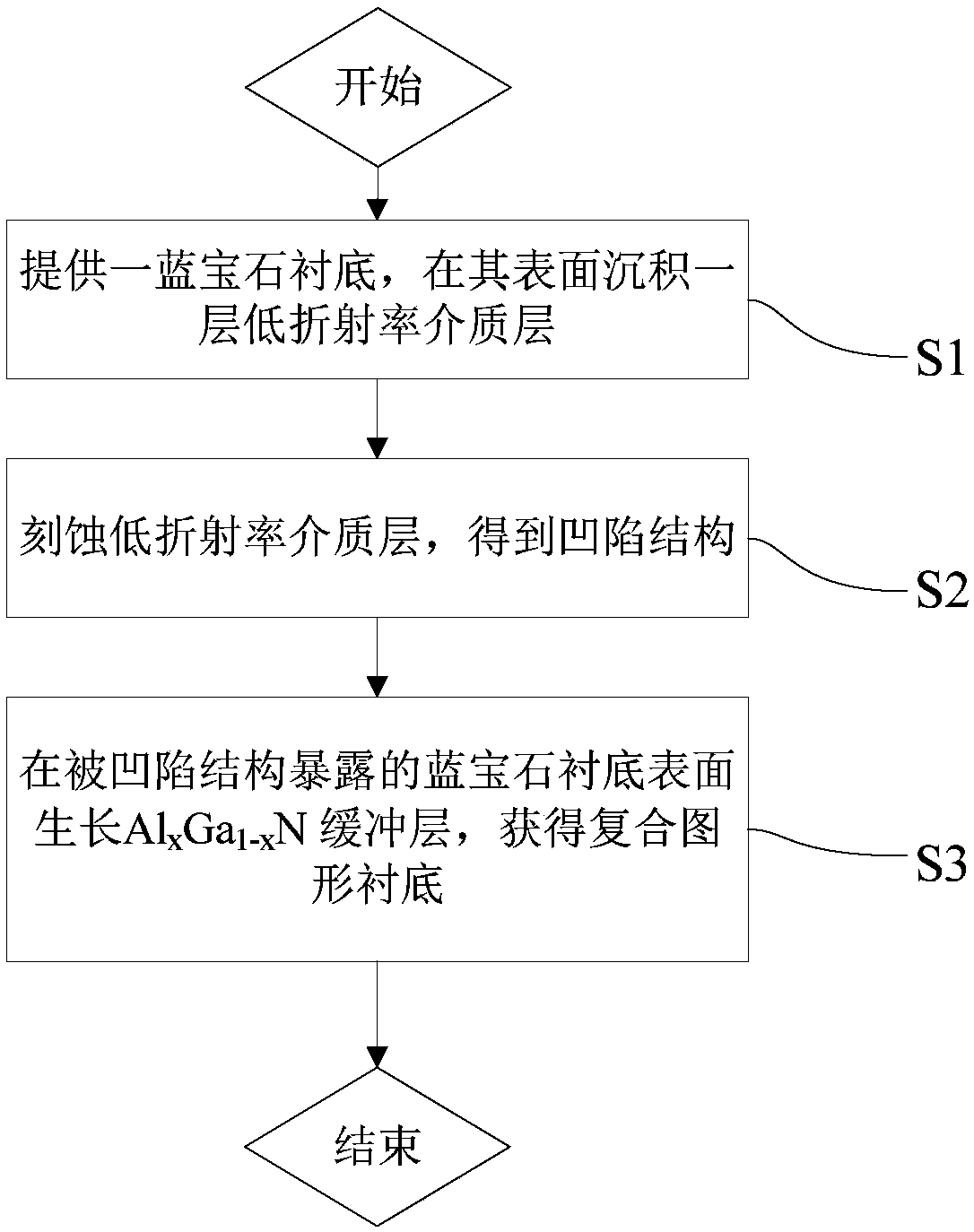

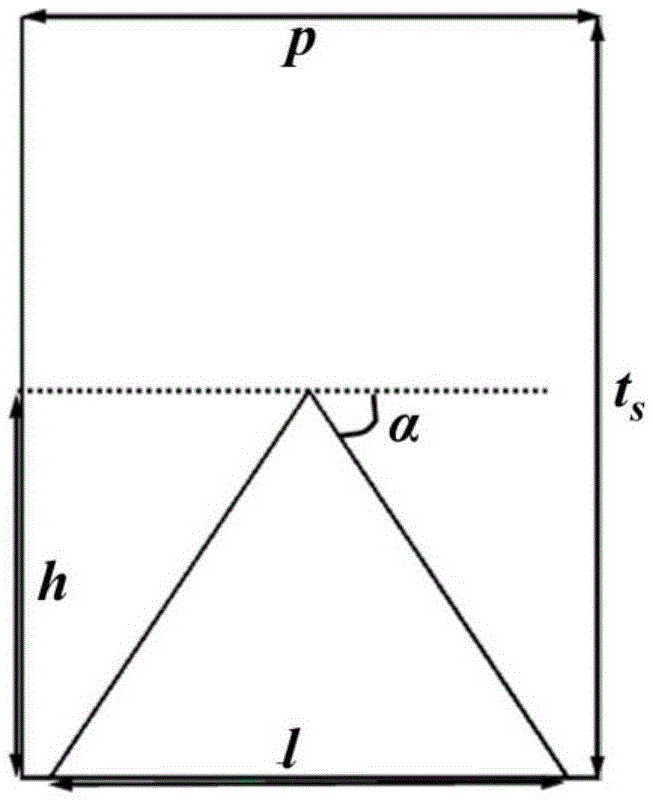

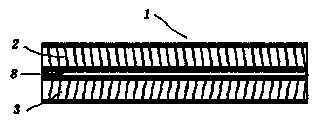

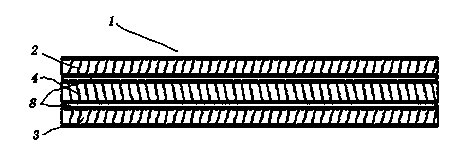

Composite patterned substrate using low-refractive index material as medium and manufacturing method thereof

InactiveCN108346718AReduce refractionLow refractive indexSemiconductor devicesRefractive indexLight reflection

The invention provides a composite patterned substrate using a low-refractive index material as a medium and a manufacturing method thereof. The manufacturing method comprises the following steps: S1,a sapphire substrate is provided, and a low-refractive index medium layer is deposited on the surface of the sapphire substrate, wherein the refractive index of the low-refractive index medium layeris smaller than 1.8; S2, the low-refractive index medium layer is etched to obtain a depressed structure, and the depressed structure exposes the sapphire substrate; and S3, an AlxGa1-xN buffer layergrows on the surface of the sapphire substrate exposed in the depressed structure to obtain a composite patterned substrate, wherein 0< / =X< / =1. The composite patterned substrate reduces refraction oflight inside the chip, light reflection is improved, the extraction efficiency of an LED chip is improved, the production efficiency can be improved, and the production cost is reduced.

Owner:合肥彩虹蓝光科技有限公司

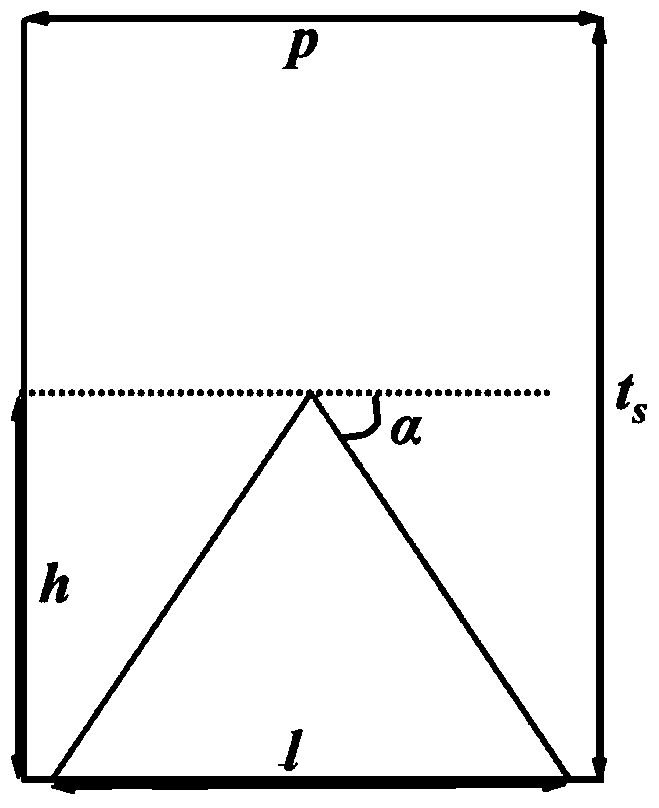

Silicon-based plasma ultra wideband terahertz wave absorber

The invention discloses a silicon-based plasma ultra wideband terahertz wave absorber. The terahertz wave absorber comprises basic units arranged in a periodic array, wherein the front of each basic unit is square and is provided with a hollow rectangular pyramid; the basic units are seamlessly connected; and the material of the terahertz wave absorber is a phosphorus-doped n-type silicon wafer or other semiconductor materials. According to the silicon-based plasma ultra wideband terahertz wave absorber provided by the invention, through a hollow structural design, a wideband plasma resonance effect is generated, so that the absorption rate is strengthened; and meanwhile, the relative bandwidth is greatly improved, the technological process is simplified, and the manufacturing cost is reduced.

Owner:WUHAN UNIV OF SCI & TECH

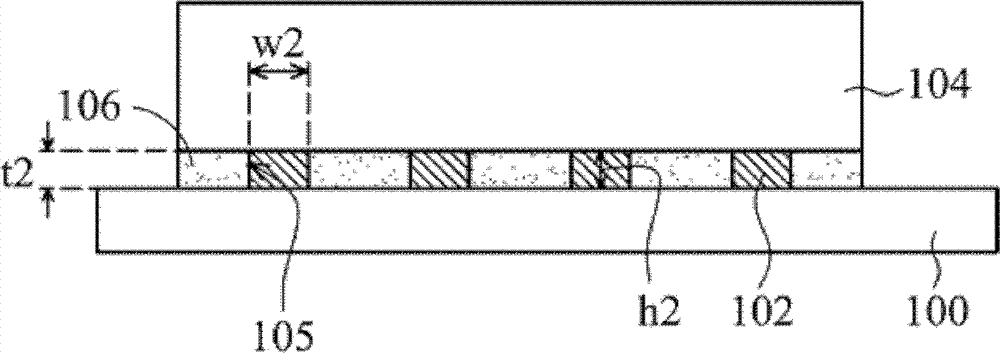

Chip bonding structure and bonding method

InactiveCN103247586ASemiconductor/solid-state device detailsSolid-state devicesDepressed structureElectrical and Electronics engineering

The present invention discloses a chip bonding structure and a bonding method, and the chip bonding structure comprises a baseplate that contains a chip predetermined area, and the surface of the chip predetermined area is provided with a plurality of protrusions on the baseplate; the chip has a luminous front side and a back side corresponding to the luminous front side; and the back side is provided with an eutectic bonding material layer with a plurality of depressed structure, wherein each depressed structure bonds with each protrusion, and that makes the chip fixed on the chip predetermined area of the baseplate.

Owner:LEXTAR ELECTRONICS CORP

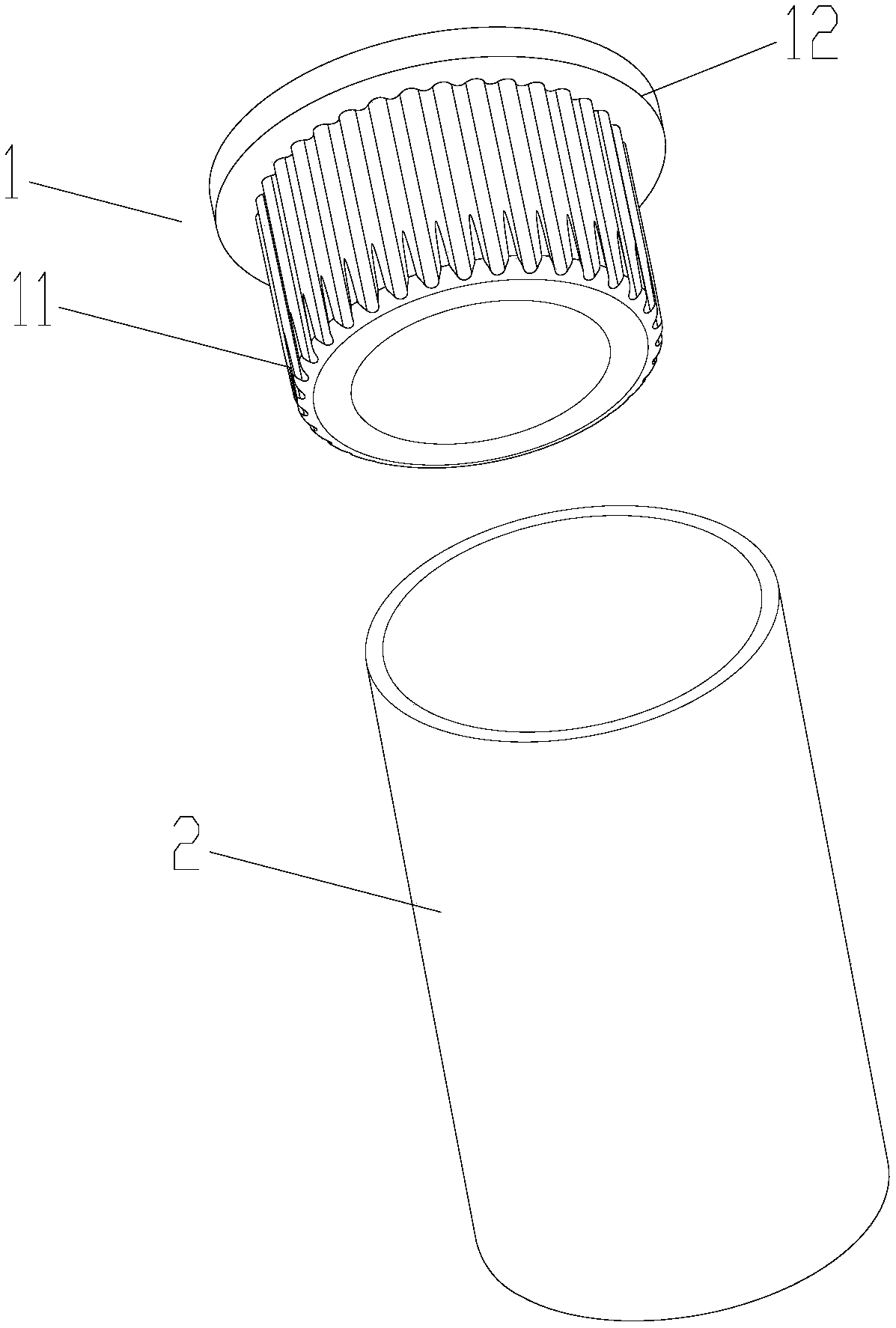

Analog simulated skin and puncture module with analog simulated skin

InactiveCN103778839ASlow down the leak rateImprove product qualityEducational modelsBiomedical engineeringMedical teaching

The invention relates to an analog simulated skin and a puncture module with the analog simulated skin, belonging to the technical field of medical teaching. The analog simulated skin is divided into at least one outer simulated skin layer and an inner simulated skin layer, wherein the edges of the two layers are closely fit to form a sac structure. The puncture module with the analog simulated skin mainly comprises the analog simulated skin and a base, wherein the base mainly comprises an upper cover and a lower cover; the upper cover is hollow and tightly screwed with the lower cover; the lower cover is in a depressed structure, an analog puncture liquid is stored in the depressed structure, and the lower cover is tightly screwed with the upper cover. When a needle is pulled out from the analog simulated skin, the liquid enters the sac in turn, and when the liquid in the sac is with a certain volume and pressure, the liquid penetrates outside from the outer simulated skin layer, thus the sac structure completely reduces the penetration rate of the liquid when the analog simulated skin is punctured, thus the analog simulated skin with the sac structure can be continuously punctured for hundreds of times. Thus, the quality of the products is improved on the basis of present materials, and the cost is reduced.

Owner:天津市医学堂科技有限公司

Center-feeding-type multilayer circulating wastewater treatment separator

InactiveCN106745498ASimple internal structureIncrease filtration rateFatty/oily/floating substances removal devicesLiquid separationPush and pullFilter media

The invention provides a center-feeding-type multilayer circulating wastewater treatment separator, which includes an internally hollowed shell body. A water inlet and a water outlet are disposed on the shell body. A filter medium layer is disposed in the middle of the shell body. The middle part of the upper end surface of the filter medium layer is convex upwardly. The middle part of the lower end surface of the filter medium layer is concaved upwardly towards the interior of the filter medium layer. An elastic pressing board is arranged on the upper end surface of the filter medium layer, while the lower end surface is provided with an elastic jacking board. A first support rod is connected to the middle of the elastic pressing board. A plurality of first push-and-pull rods are connected to periphery of the elastic pressing board. The forces of the first support rod and the first push-and-pull rods on the elastic pressing board are in the same or opposite direction. A vertical separation board is arranged in the middle of the filter medium layer so as to separate the filter medium layer into two parts completely. The separator has simple structure and is high in processing load on the basis of small total size, is greatly increased in processing speed and purifying rate, and is suitable for oil and water separation in different types due to the character of varying structure.

Owner:CHENGDU DESHANNENG TECH CO LTD

Multilayer biconcave laterally-feeding oil-water separator for sewage treatment

InactiveCN106800324ASimple internal structureIncrease filtration rateFatty/oily/floating substances removal devicesLiquid separationFilter mediaEngineering

The invention provides a multilayer biconcave laterally-feeding oil-water separator for sewage treatment. The oil-water separator comprises a hollow shell, wherein the upper end of the shell is provided with a water inlet, the lower end of the shell is provided with a water outlet, and filtering medium layers are arranged in the central part of the shell. Each of the filtering medium layers is of a compressable, reboundable and elastic structure; the upper end surface of the filtering medium layer is of a structure with a downwardly concave central part; the water inlet is formed in the edge of the upper end of the shell; the lower end surface of the filtering medium layer is of a structure with an downwardly convex central part; distances between corresponding parts of the upper and lower end surfaces of the filtering medium layer are identical, i.e., the shapes of the upper and lower end surfaces are identical; an elastic pressing plate is arranged on the upper end surface of the filtering medium layer and an elastic supporting plate is arranged on the lower end surface of the filtering medium layer; and the elastic pressing plate and the elastic supporting plate are provided with water-passing holes and are both movably arranged. The separator is simple in structure, great in treating capacity under the condition of a small integral size, and greatly improved in treating speed and purifying rate; and the characteristic of changeability of the structure of the separator enables the separator to be adaptive to a variety of types of oil-water separation.

Owner:CHENGDU DESHANNENG TECH CO LTD

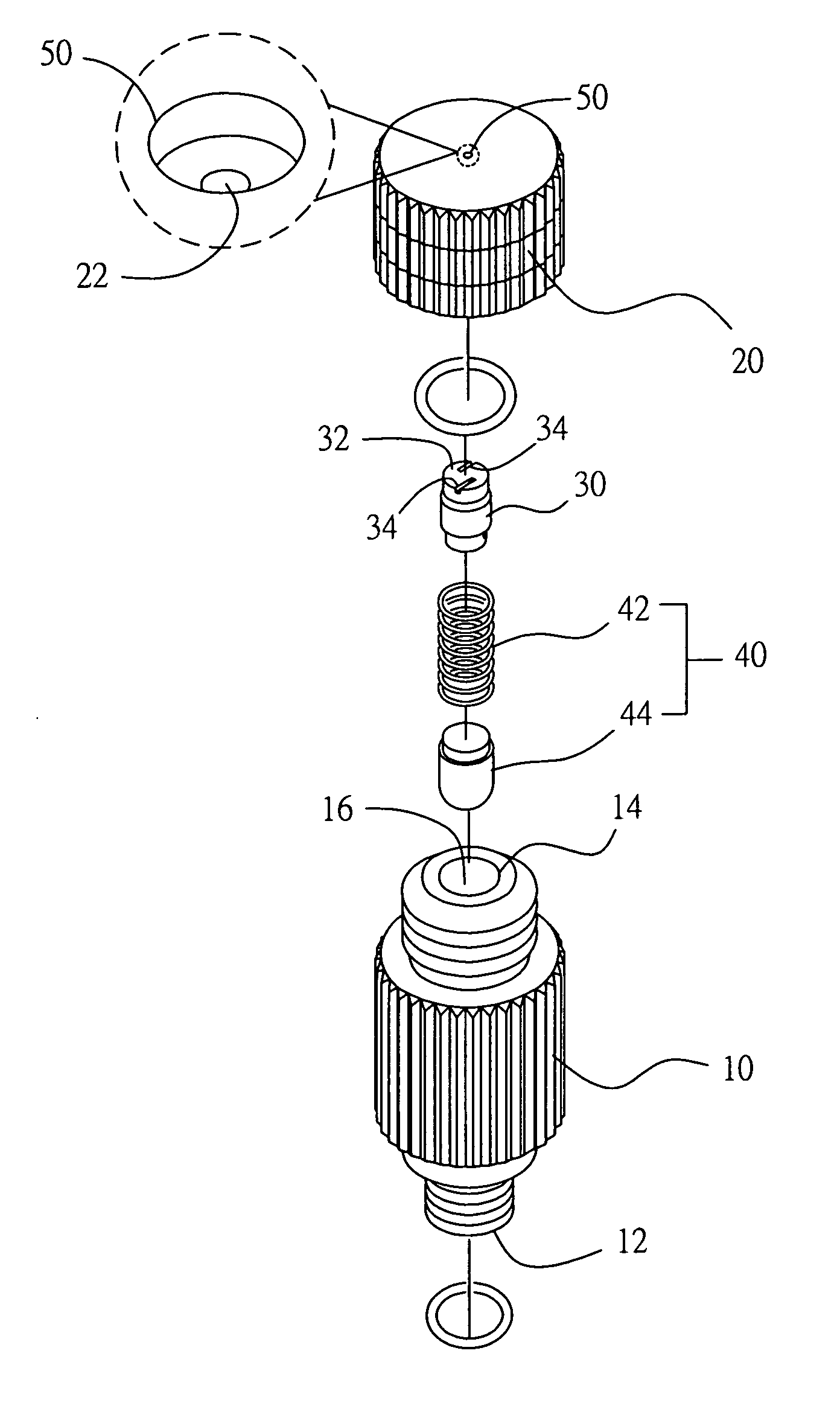

Atomizing nozzle with enhanced structural strength

InactiveUS20130001329A1Improve structural strengthReduce forceAnimal watering devicesMovable spraying apparatusEngineeringUltimate tensile strength

In an atomizing nozzle with enhanced structural strength, a body is connected to a cover, and a rotor is disposed in the body. Furthermore, the cover has a first surface and a second surface, and a depressed structure extends from the first surface of the cover toward the second surface, and has an opening on the first surface and a bottom disposed opposite the opening. A water jetting hole penetrates through the bottom of the depressed structure. Because the water jetting hole is disposed in the depressed structure, the peripheral structure of the water jetting hole has the greater thickness and the higher structural strength. Even if an external force is exerted, the water jetting hole and its periphery cannot deform.

Owner:HSU HUI JU

Welding method of electric resistance welding

The invention discloses a welding method of electric resistance welding. The method comprises at least two metal pipe fittings to be welded, and at least one surface of the to-be-welded surface of themetal pipe fittings is provided with a surface treatment part, the surface treatment part is of a structure with a plurality of protrusions and recesses; and in welding, the protrusions are melted byelectrifying, and then pressure is applied to enable the protrusions melted metal to be squeezed and migrated to the positions of recesses until the migrated protrusions molted metal volume is largerthan or equal to the amount of space required to be filled up by the recesses, and the to-be-welded surface is sealed and welded. According to the electric resistance welding, the metal workpiece tobe welded is pre-machined, the to-be-welded surface is provided with the plurality of protrusions, when electrified welding is carried out, the resistance of protrusion parts reaches the maximum, namely the heating volume is the largest, and the metal of the protrusion parts reaches the softening state firstly; the pressure is applied at the moment, so that the protrusion parts can be deformed tobe filled with the parts which are sunken to the periphery, and the temperature of the protrusion parts is further increased due to the fact that current is further conducted, and the melted metal isfinally enabled the to-be-welded surface of the metal workpiece to be well combined.

Owner:佛山市智晓科技服务有限公司

Electrode tip for plasma cutting machine

InactiveCN102139404AAvoid deformationNot easy to damagePlasma welding apparatusConvex structureEngineering

The invention provides an electrode tip for a plasma cutting machine, which comprises a casing pipe, a carrier, an electrode core, a first hard soldering structure and a second hard soldering structure, wherein the casing pipe is hollow and is provided with a first open end and a second open end; and a first flange protrudes out of the first end towards the interior of the casing pipe. The carrier is cylindrical and is provided with a third end and a fourth end; a second flange protrudes out of the third end along the radial direction toward the exterior; and the second flange is fixedly connected to the first flange of the casing pipe by the first hard soldering structure. A convex structure protrudes out of the fourth end towards the interior of the casing pipe; and a depressed structure is formed at the center of the third end axially from outside towards the interior of the convex structure. The electrode core is arranged in the depressed structure and is fixedly connected to the depressed structure by the second hard soldering structure. The electrode tip for the plasma cutting machine has better strength and heat dissipation effect.

Owner:HEMAO SHANGHAI METAL TECH

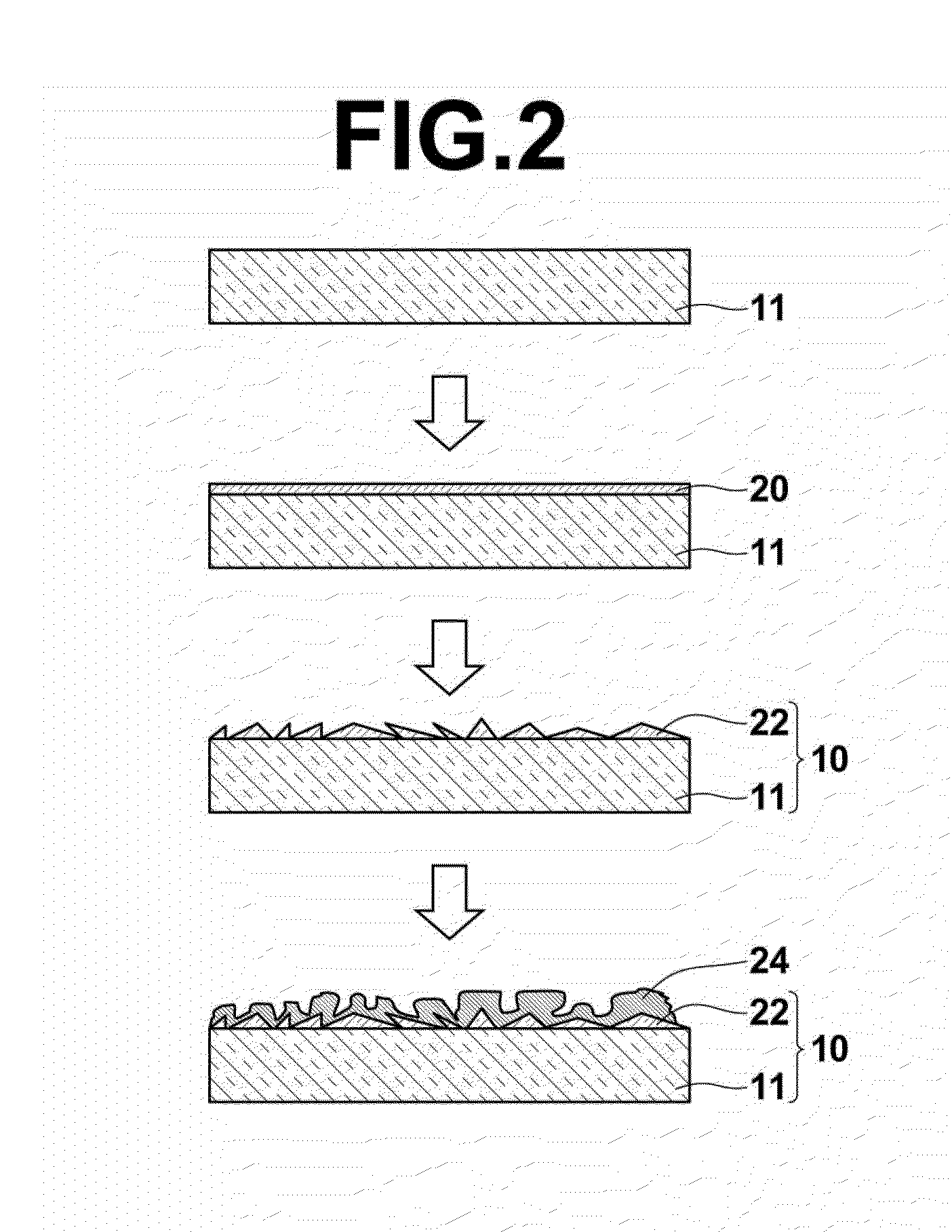

Method for producing optical electrical field enhancing device

InactiveUS20140034235A1Reduce manufacturing costEfficient inductionAdhesive processesRadiation pyrometryOptoelectronicsMetal

A thin film of a first metal or a metal oxide is formed on a substrate. A structure layer of fine protrusions and recesses of the first metal or a hydroxide of the metal oxide is formed by causing the thin film formed on the substrate to undergo a hydrothermal reaction. Thereafter, a metal structure layer of fine protrusions and recesses is formed on the surface of the structure layer of fine protrusions and recesses.

Owner:FUJIFILM CORP

Universal joint fork forging blank

The invention provides a universal joint fork forging blank. The shaft head portion and the fork lug portion form a whole, the fork lug portion is composed of flange plates at the end of the shaft head portion and fork lugs extending from two sides corresponding to the flange plates, and the flange plates and a shaft head are of hollow structures. The edges of the hollow structures are provided with closed curve reinforcing ribs, the height of the closed curve reinforcing ribs is 3-6mm, and the width of the closed curve reinforcing ribs is 3-6mm.The universal joint fork forging blank is characterized in that inner crosspieces corresponding to the outer ends of the fork lugs are provided with outward opening U-shaped recesses, the depth of the U-shaped recesses is calculated according to the remaining machining allowance 2-4mm. The self weight of the blank is greatly reduced, the blank is reinforced through the closed curve reinforcing ribs, and the strength is improved on the basis that materials are saved. In addition, two fork lugs of a universal joint fork are provided with U-shaped recess structures, so that the purposes of saving the materials and meanwhile reducing the forging and machining difficulty. Raw materials are saved by 1.2-2.5Kg for one universal joint fork, and the material cost is saved by 20%-25%.

Owner:SHIYAN YIXING IND DEV

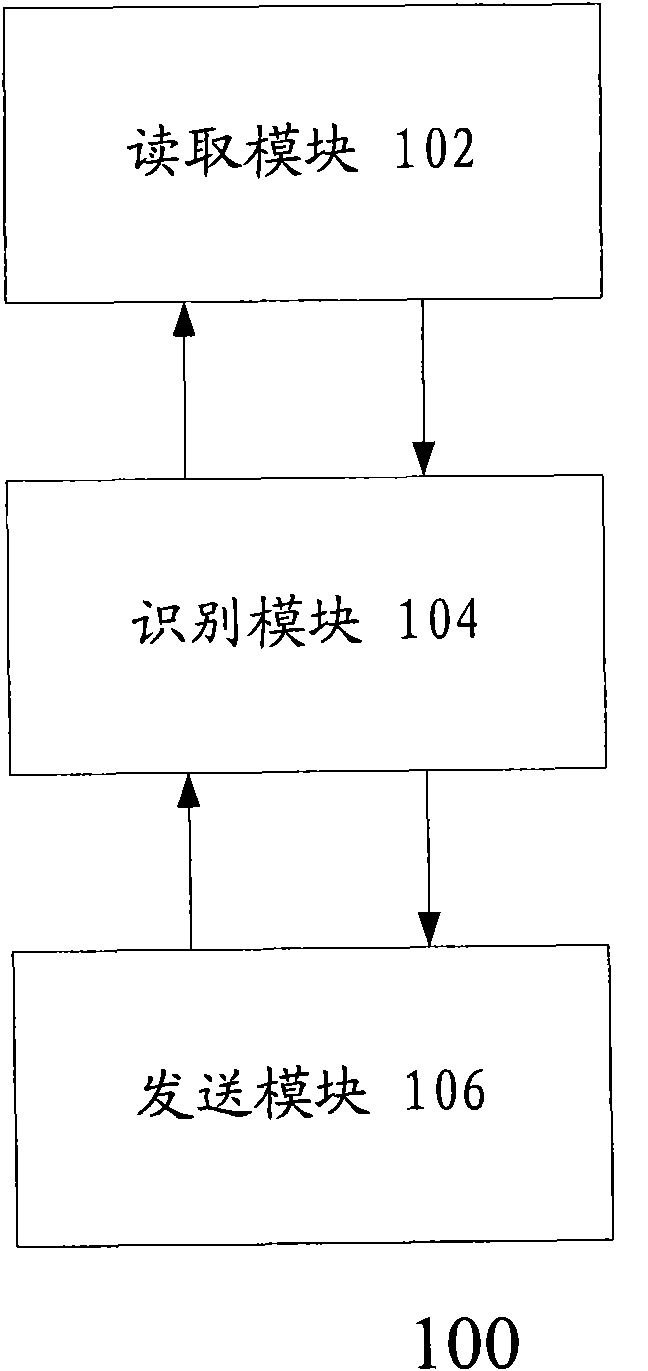

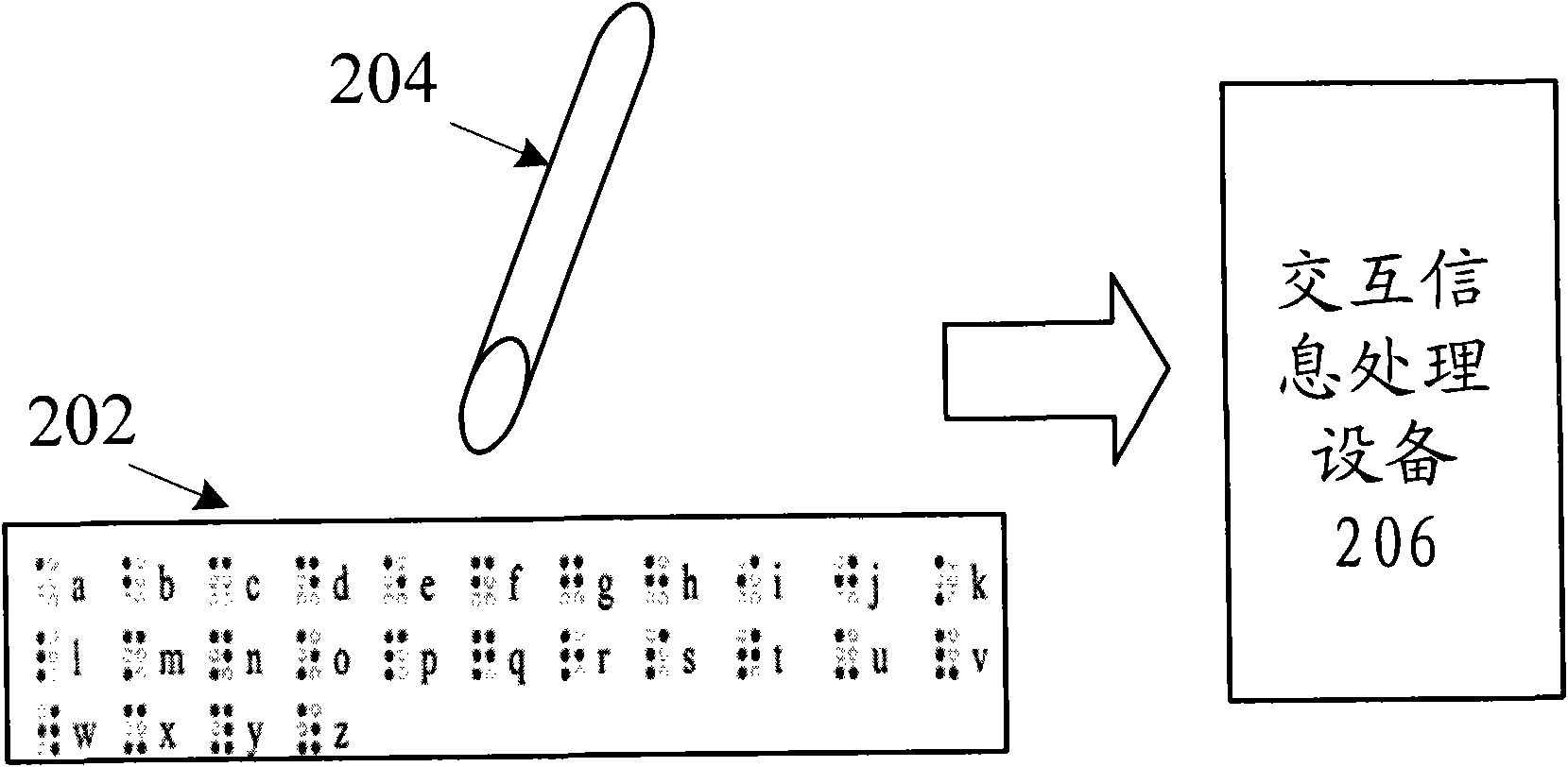

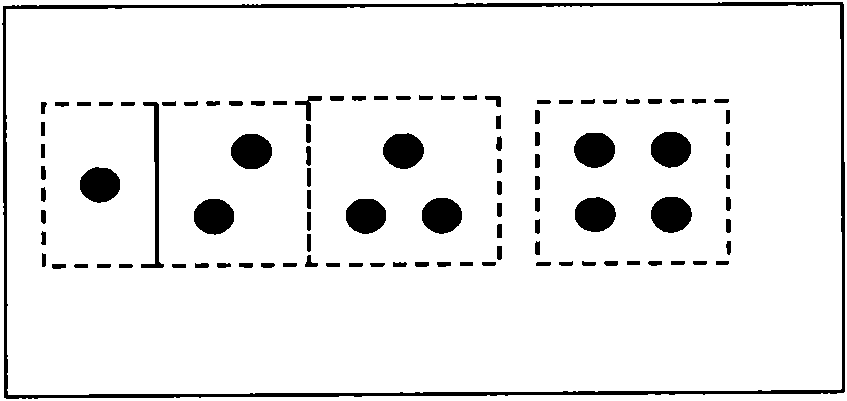

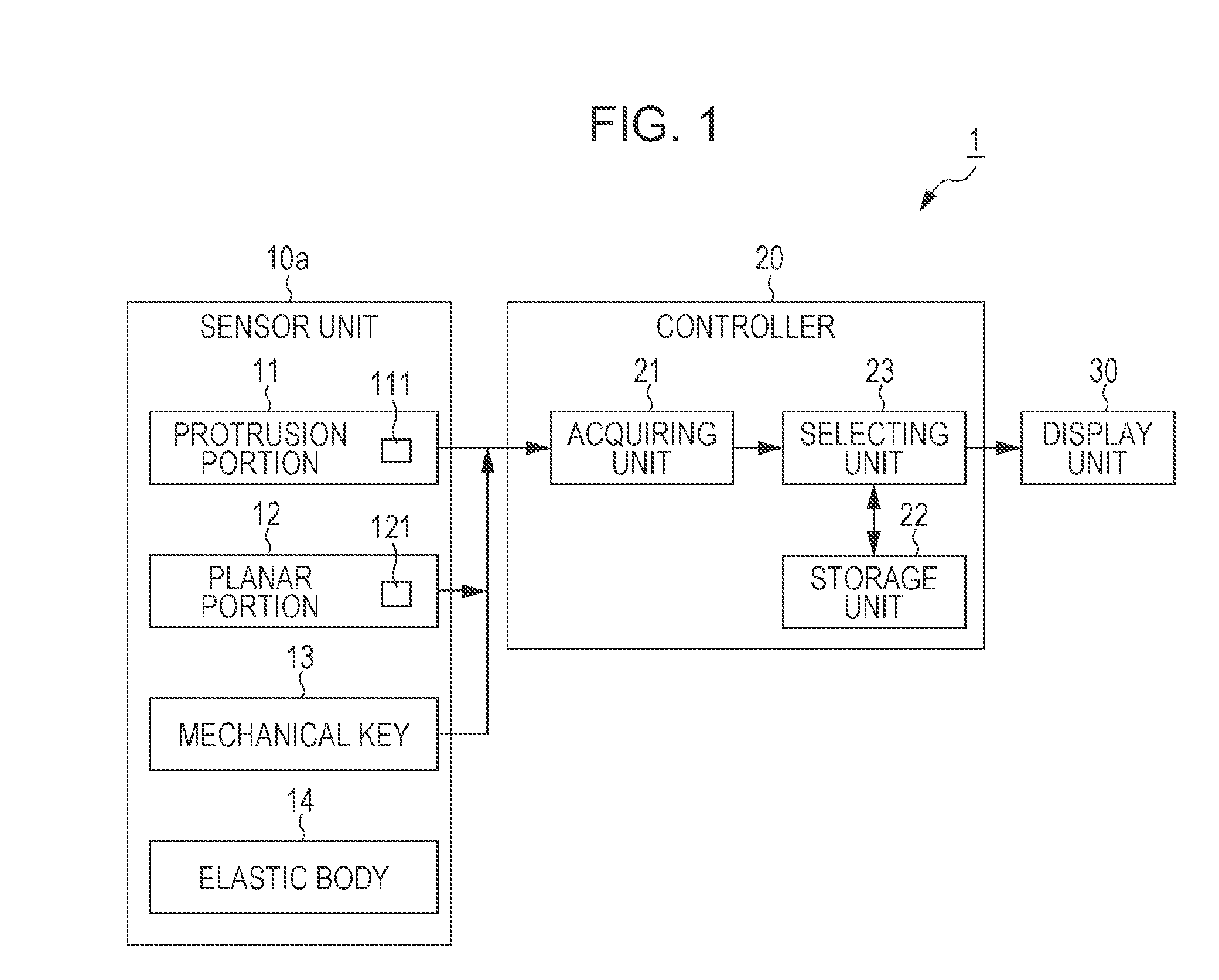

Input device and input method

ActiveCN101770298AImprove convenienceLow priceInput/output for user-computer interactionComputer scienceDepressed structure

The invention provides an input device, which comprises a reading module, an identification module and a transmitting module, wherein the reading module is used for reading at least one convex and / or concave structure to acquire at least one piece of input information; the identification module is connected with the reading module and is used for identifying the at least one piece of input information as at least one input value; and the transmitting module is connected with the identification module and is used for transmitting the at least one input value to processing equipment. The invention also provides an input method, which comprises: a reading step of reading the at least one convex and / or concave structure to acquire the at least one piece of input information; an identification step of identifying the at least one piece of input information as the at least one input value; and a transmitting step of transmitting the at least one input value to the processing equipment. Through the technical scheme of the invention, convenience to user operations is improved and hardware cost is reduced.

Owner:LENOVO SOFTWARE

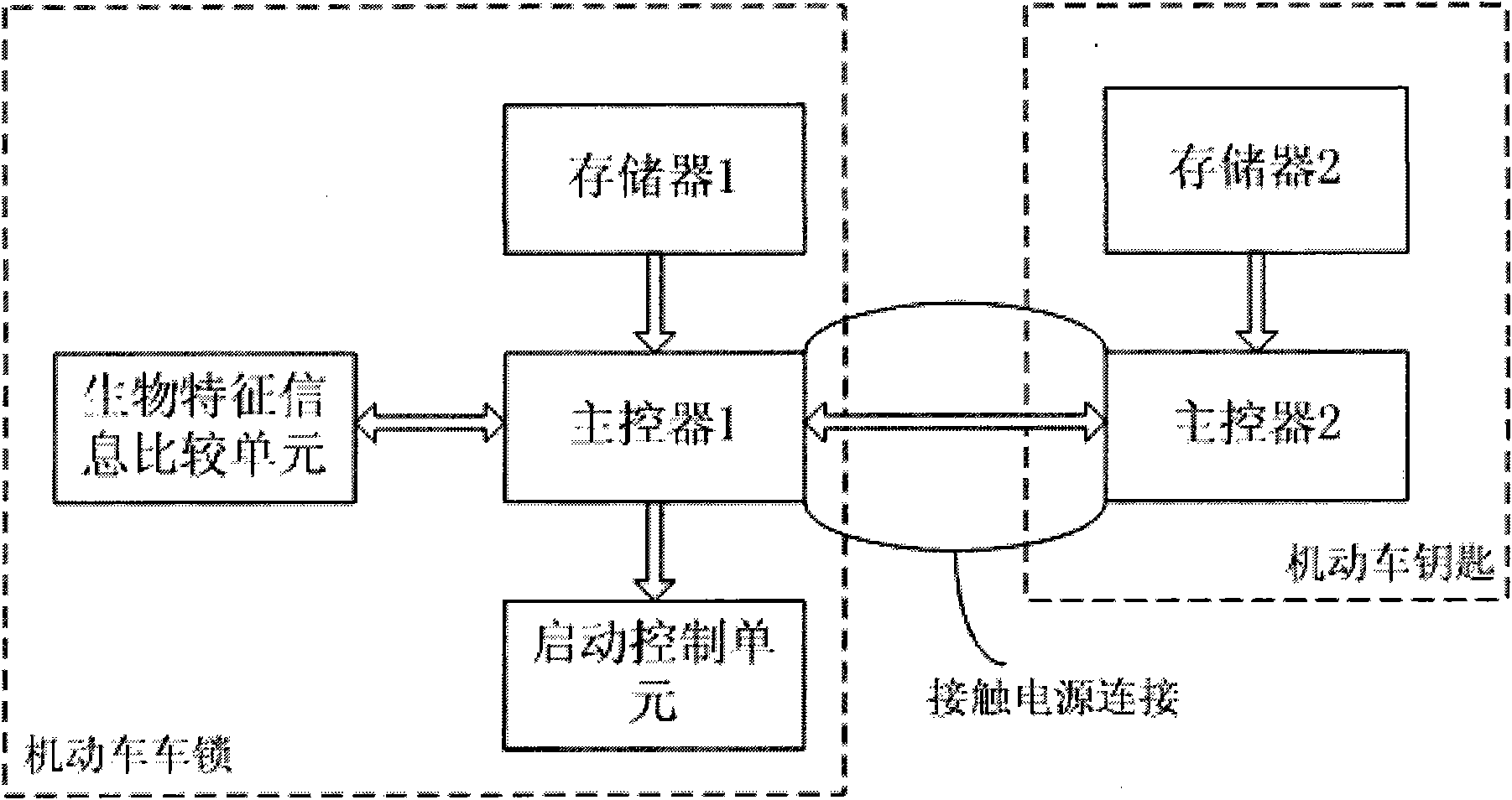

Motor vehicle anti-theft system

The invention provides a motor vehicle anti-theft system. The system comprises a motor vehicle key and a motor vehicle lock, wherein the motor vehicle key and the motor vehicle are in insertion contact; the motor vehicle lock comprises a master controller, a memory, a biological characteristic comparison unit, an engine startup control unit and a motor vehicle keyhole, wherein the shape of the keyhole is matched with that of the motor vehicle key; two sides of the keyhole contacted with the motor vehicle key are connected with the anode and the cathode of a motor vehicle accumulator respectively; a raised metal part is formed in the middle part of two sides of the keyhole contacted with the motor vehicle key, and is connected with the master controller; the motor vehicle key comprises a memory and a master controller; biological characteristic information the same as that stored in the memory of the motor vehicle lock is stored in the memory of the motor vehicle key; two sides of the motor vehicle key are contacted with the keyhole of the motor vehicle lock respectively; a depressed structure is formed on the top end of the two sides of the motor vehicle key, and a metal part inside the depressed structure is in data connection with the master controller of the motor vehicle lock.

Owner:陈一稼

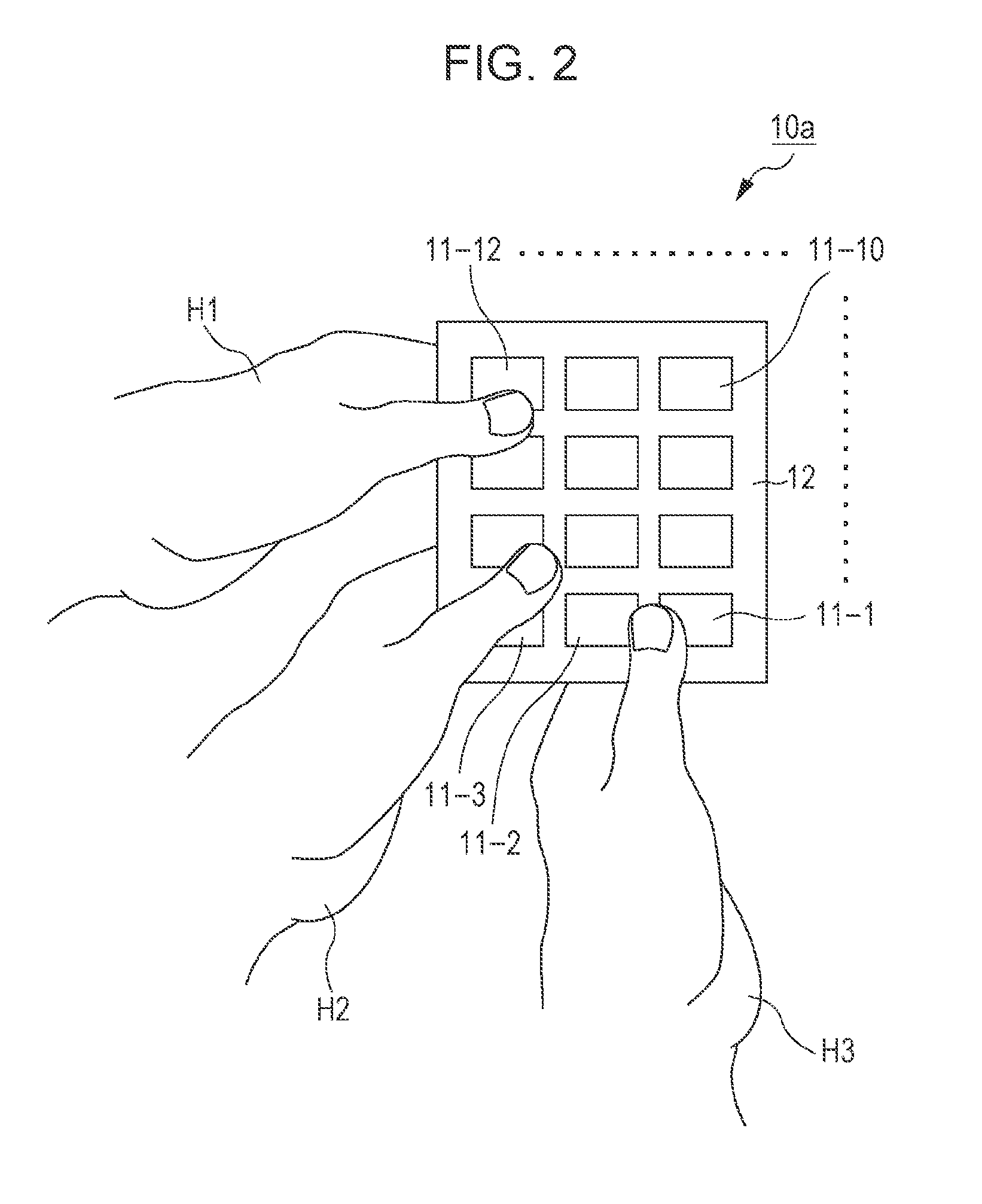

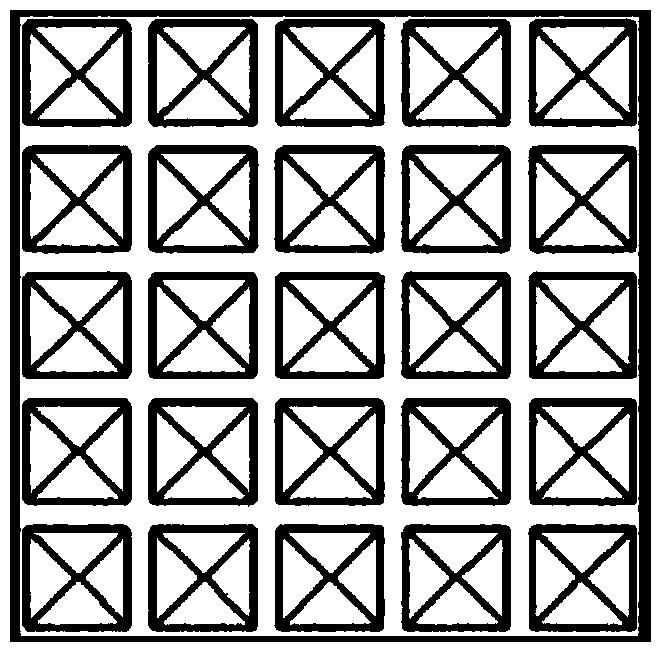

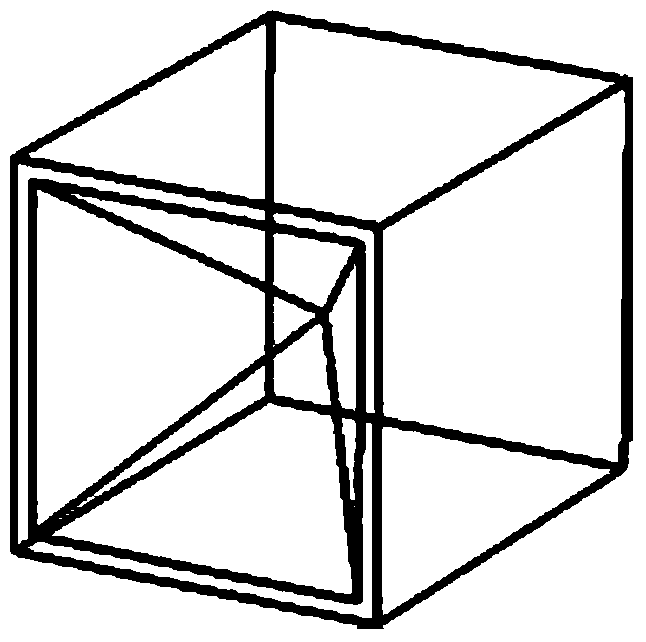

Operation system

InactiveUS20150234424A1Easy to operateDigital data processing detailsInput/output processes for data processingOperational systemComputer science

An operation system includes a sensor unit having a structure with protrusions or depressions on its surface, a display unit, and a selecting unit. The sensor unit detects a position at which a contact body touches the surface and outputs a position signal indicating the detected position. The display unit displays an image corresponding to the surface of the sensor unit and including operation key images. The selecting unit selects an operation key image corresponding to the position of the contact body from the operation key images displayed on the display unit. The position of the contact body at which selection of the operation key image is switched differs between the case where a continuous change in the position signal indicates a first direction and the case where the continuous change in the position signal indicates a second direction which is opposite to the first direction.

Owner:HONDA MOTOR CO LTD

A silicon-based plasmonic ultra-broadband terahertz wave absorber

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com