Welding method of electric resistance welding

A welding method and resistance welding technology, applied in the field of resistance welding, can solve the problems of unable to achieve surface-to-surface sealing welding, unable to guarantee surface-to-surface sealing welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

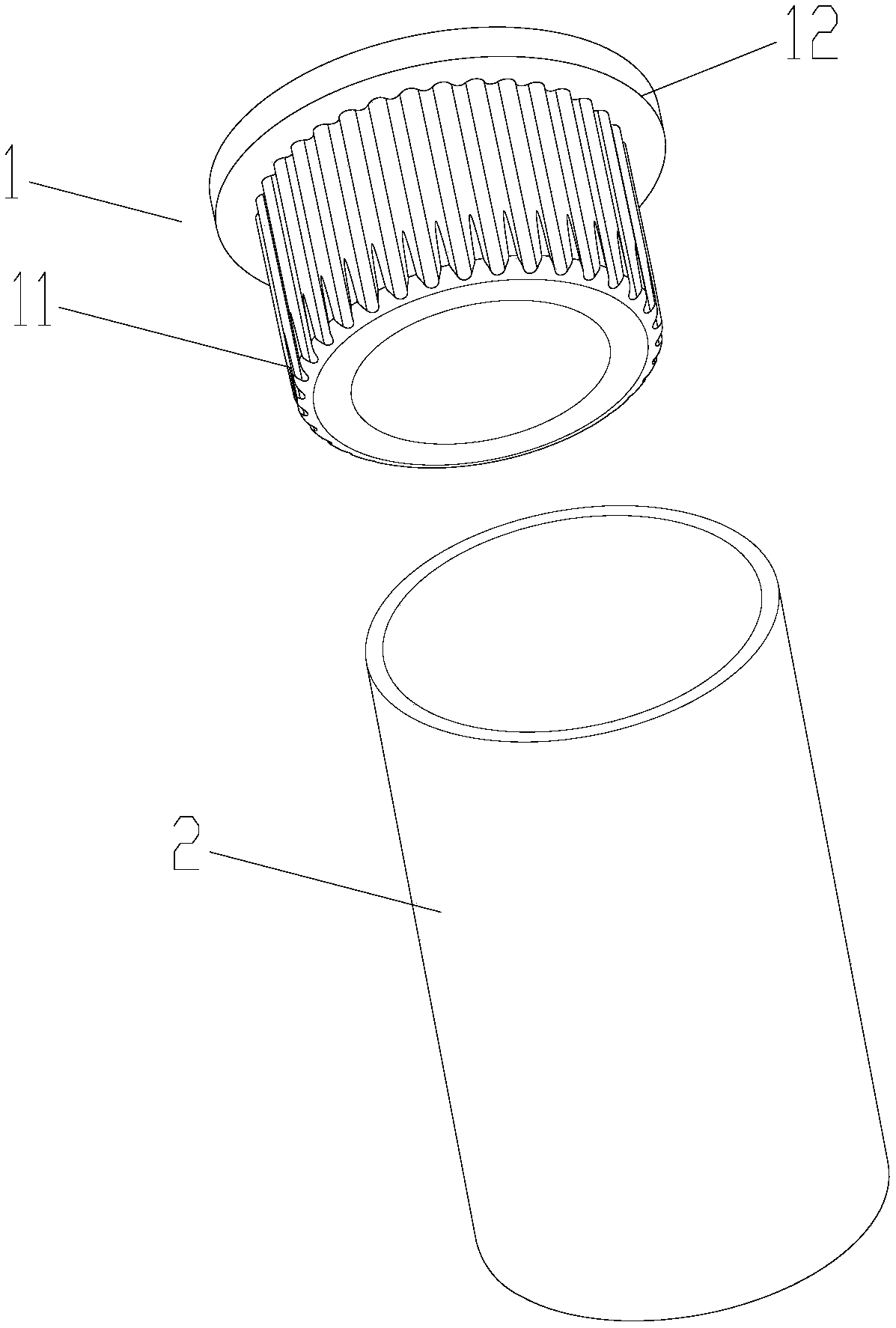

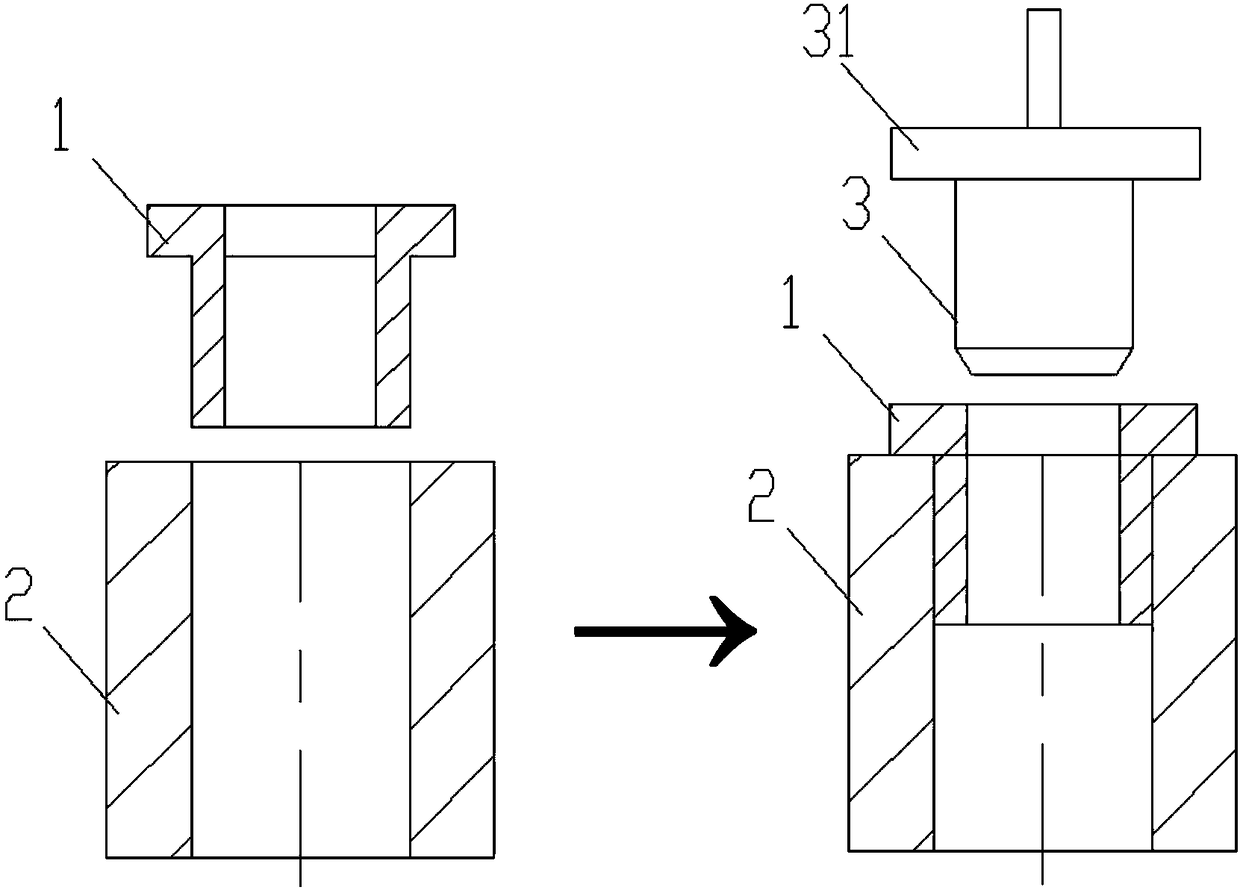

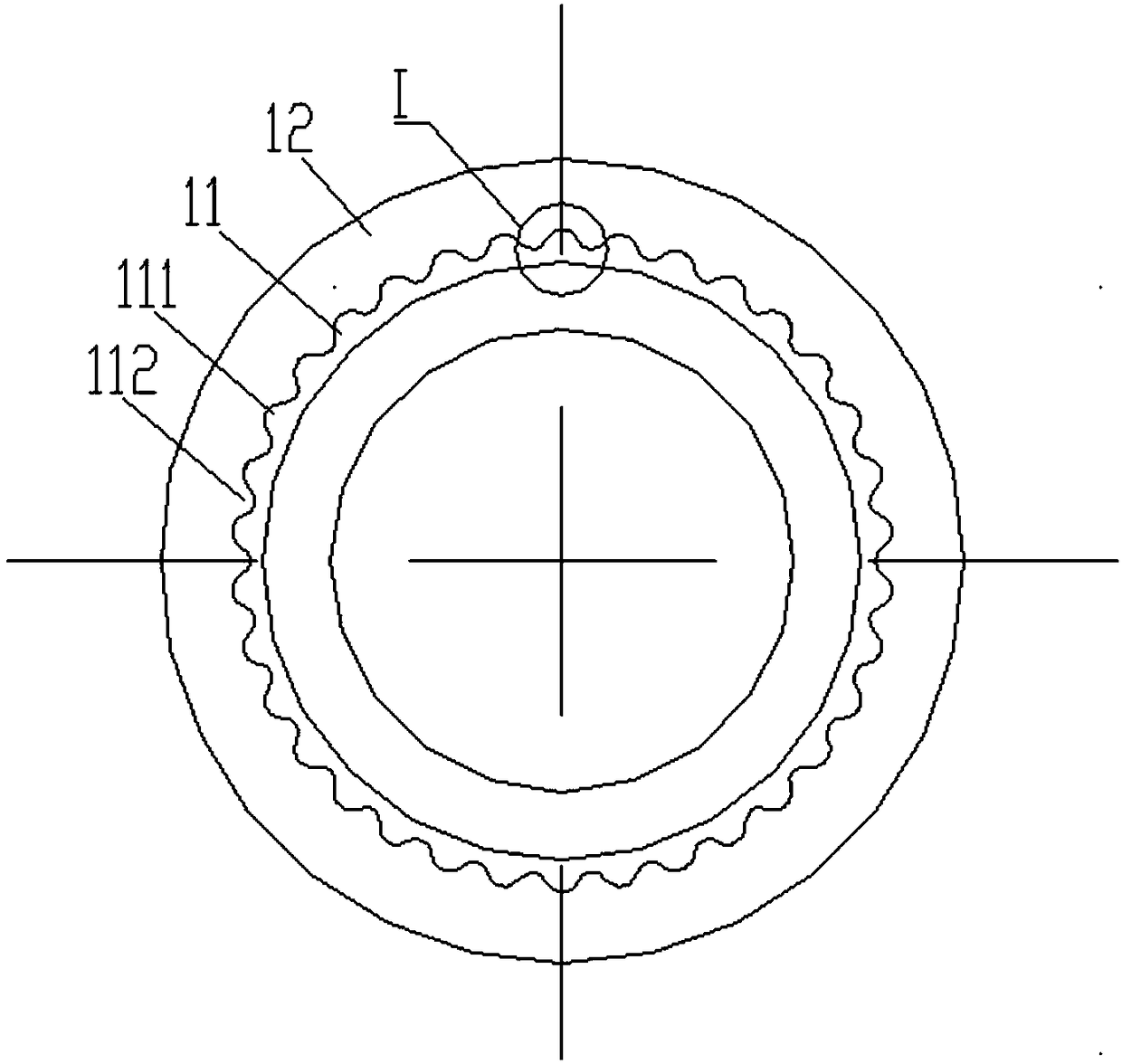

[0038] Such as Figure 1-Figure 4 , In this embodiment, in this embodiment, the metal pipe fitting 2 is an iron or stainless steel pipe, and the metal pipe fitting 1 is a copper pipe and is provided with a surface treatment portion 11 on its outer surface (because copper is soft and has a low melting point). The surface treatment part 11 is a plurality of vertical linear grooves and thus has a structure of a plurality of protrusions 111 and depressions 112 . In this embodiment, the height H of the protrusion 111 is 0.4 mm, the distance P between the vertical linear grooves is 1 mm, and the arc radius of the top of the protrusion is 0.4 mm. In the cross-section of the surface treatment part 11 , the protrusions 111 and the depressions 112 are regularly arranged alternately. Most preferably, as in this embodiment, the cross-sections of the protrusions 111 and the depressions 112 are sinusoidal.

[0039] The two metal pipe fittings 1 and 2 are interference fit, and the surfaces ...

Embodiment 2

[0043] Such as Figure 5-Figure 6 As shown, in this embodiment, the top of the metal pipe fitting 1 does not need to be provided with a flange, but a limiting step 21 is provided on the inner wall of the metal pipe fitting 2 to play a role of limiting. The metal pipe fitting 2 is an iron or stainless steel pipe, and the metal pipe fitting 1 is a copper pipe and has a surface treatment part 11 on its outer surface. The surface treatment part 11 is a textured knurled surface, and the grid is rhombus.

[0044] Others are the same as embodiment 1.

Embodiment 3

[0046] Such as Figure 7-Figure 9 As shown, in this embodiment, the top of the metal pipe fitting 1 does not need to be provided with a flange, but a limiting step 21 is provided on the inner wall of the metal pipe fitting 2 to play a role of limiting. The metal pipe fitting 2 is an iron or stainless steel pipe, and the metal pipe fitting 1 is a copper pipe with a surface treatment part 11 on its outer surface. In this embodiment, the height H of the protrusion 111 is 0.3 mm, the distance P between the vertical line grooves is 0.6 mm, and the arc radius of the top of the protrusion is 0.3 mm. In the longitudinal section of the surface treatment part 11 , the protrusions 111 and the depressions 112 are regularly and alternately arranged. Most preferably, as in this embodiment, the cross-sections of the protrusions 111 and the depressions 112 are sinusoidal.

[0047] The two metal pipe fittings 1 and 2 are clearance fit. After the two are socketed, the pressure of outward expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bump height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com