Universal joint fork forging blank

A technology for forging blanks and universal joint yokes, which is applied in the field of universal joint yokes, can solve the problems of large weight and low strength of universal joints, and achieve the effects of reducing the difficulty of forging and machining, saving materials, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

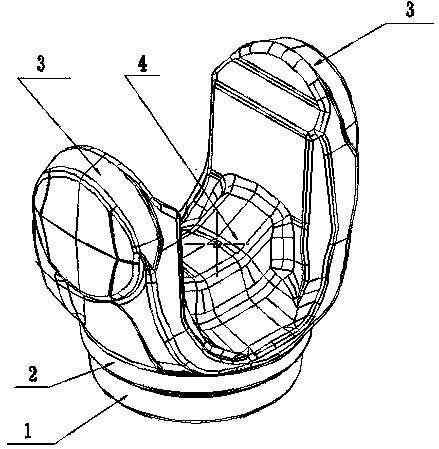

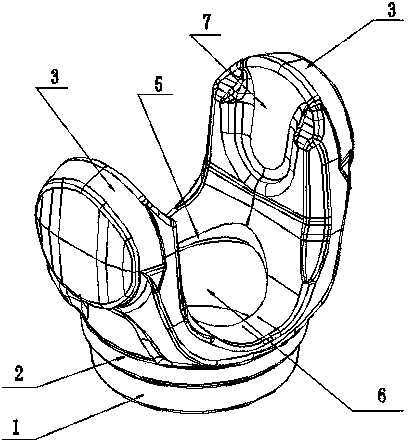

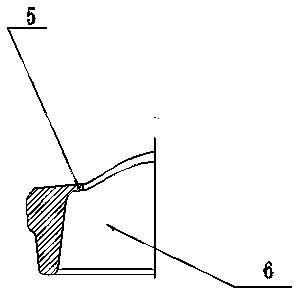

[0011] like figure 2 , image 3 The forged blank of a universal joint yoke shown is composed of a shaft head part 1 and a fork lug part as a whole, and the fork lug part is composed of a flange plate 2 at the end of the shaft head part and fork lugs extending on both sides of the flange plate 3, the flange plate and the shaft head are hollow structures 5; a closed curved rib 6 is provided on the edge of the hollow structure 5, the height of the closed curved rib 6 is 3-6 mm, and the width of the closed curved rib 6 is 3 -6 mm.

[0012] like figure 2 As shown, the inner rail corresponding to the outer ends of the two fork lugs is provided with a "U"-shaped depression 7 that opens outwards, and the depth of the U-shaped depression is calculated with a machining allowance of 2-4 millimeters; like this, it can be Further reduce weight.

[0013] like Figure 4 As shown, according to the principle of engineering mechanics - the torsional shear stress distribution law of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com