Electrode tip for plasma cutting machine

A technology of plasma cutting machine and electrode head, which can be used in plasma welding equipment, welding equipment, metal processing equipment, etc., and can solve the problems of inconvenient realization and complicated processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

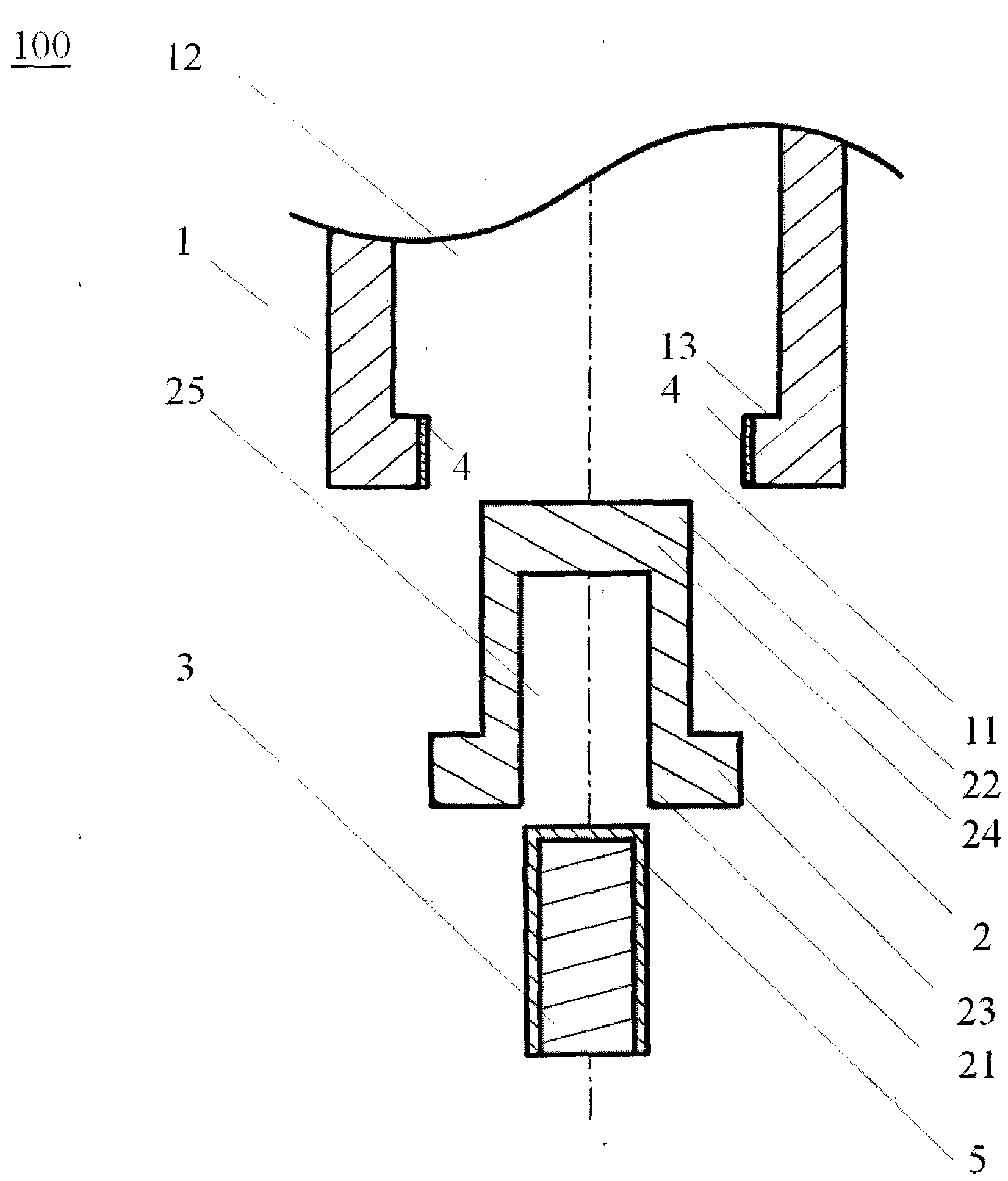

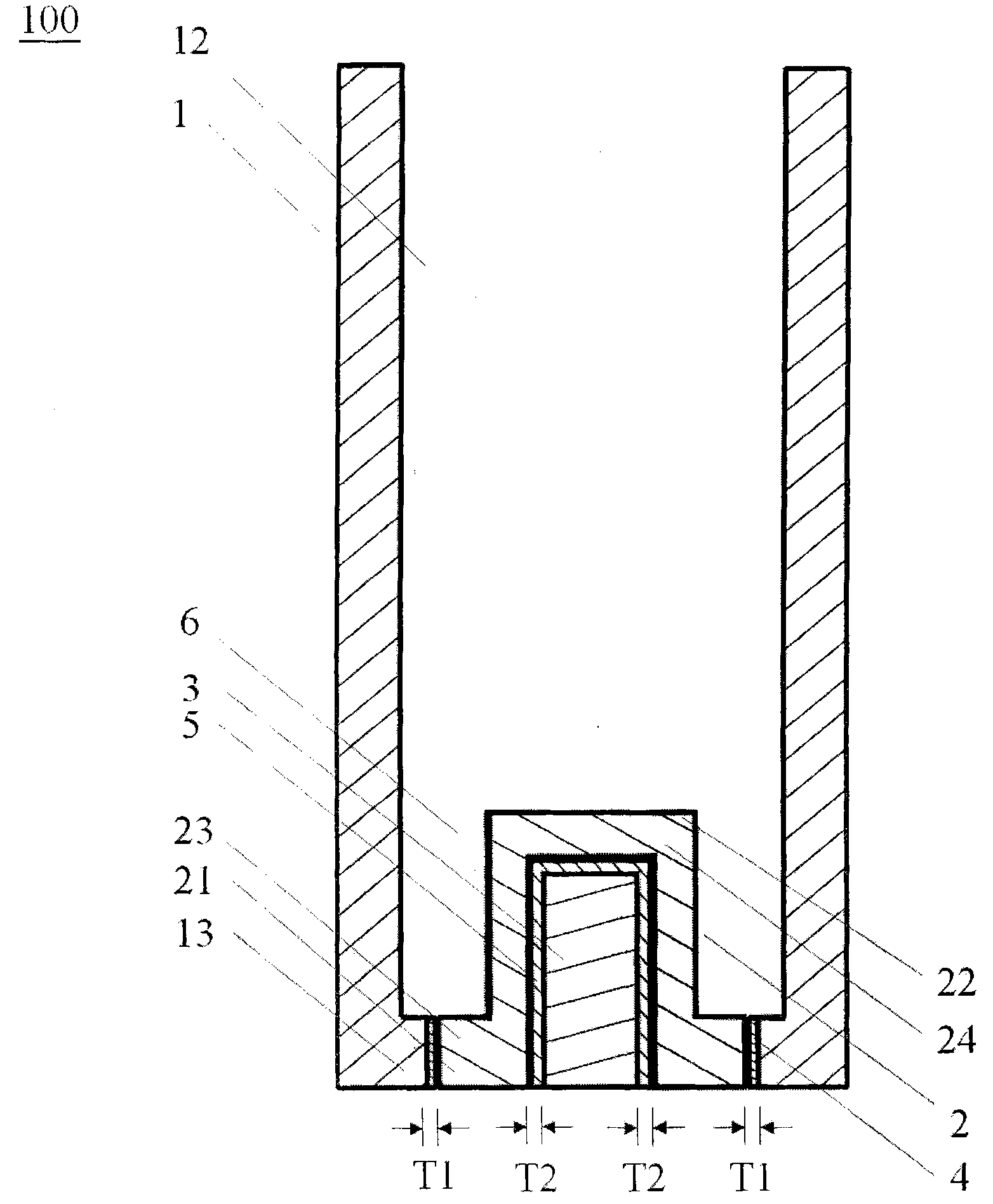

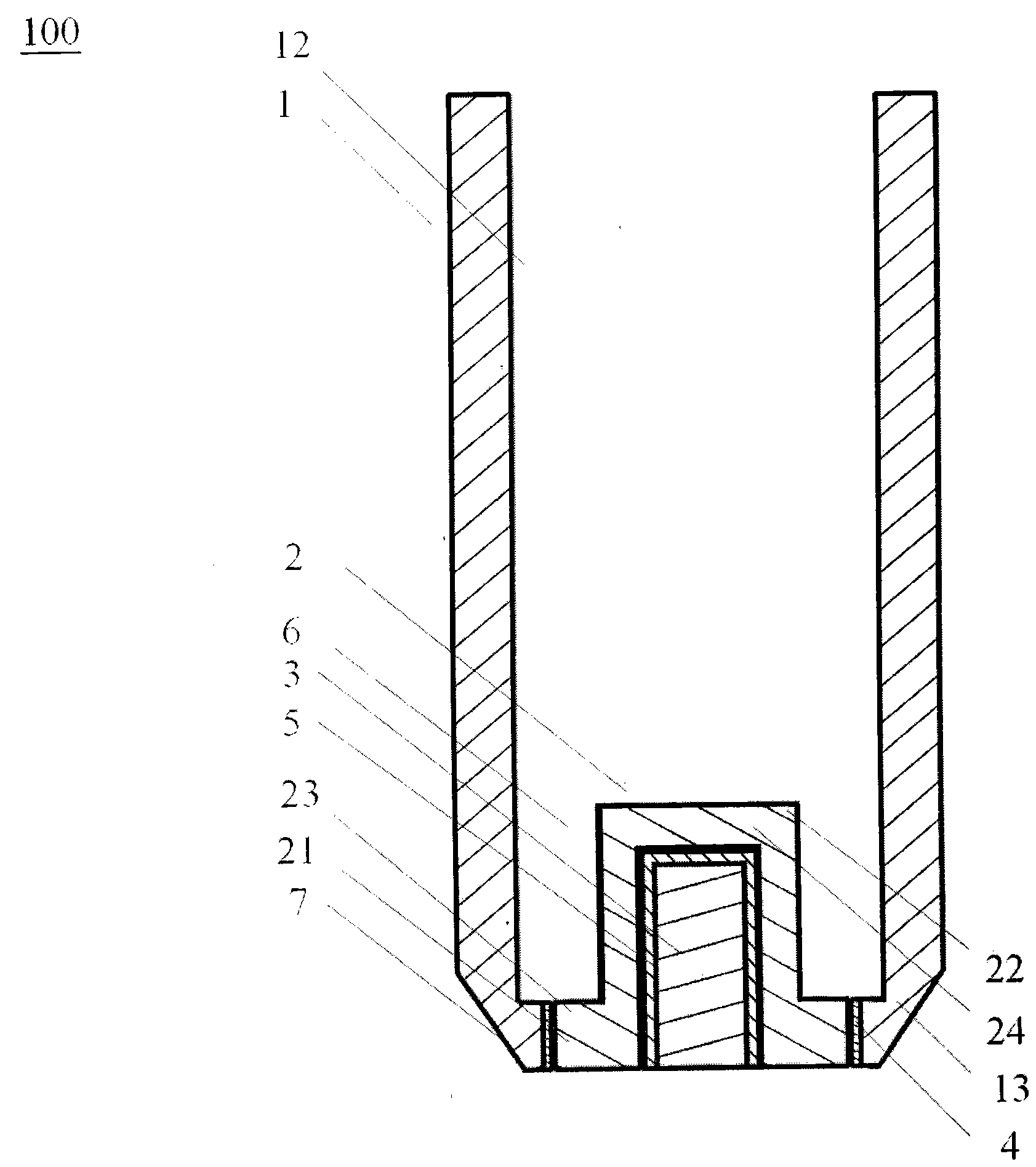

[0043] Since the present invention discloses an electrode tip for a plasma cutting machine, and the relevant principles and implementation methods of the plasma cutting machine used in it are already understood by those skilled in the art, a complete description will not be given in the following description. At the same time, the drawings compared below are intended to express the meanings related to the features of the present invention, and are not and need not be completely drawn according to the actual size, which is stated in advance.

[0044] The electrode tip must have high conductivity, the higher the conductivity, the higher the operating efficiency. In addition to high electrical conductivity, the electrode tip for plasma cutting machine also needs to have high structural strength, high temperature resistance, and high electron emission rate. For example, in terms of metal conductivity, silver is the best, followed by copper, gold, and aluminum. Although the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com