Method for preventing slag from being accumulated at center of high-chromium vanadium-bearing titanomagnetite hearth

A technology of vanadium-titanium magnetite and high-chromium type, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of increasing the difficulty of blast furnace vanadium-titanium magnetite, high melting temperature, and poor desulfurization ability, and achieve optimal thermal Stability, improvement of slag accumulation, effect of preventing slag accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

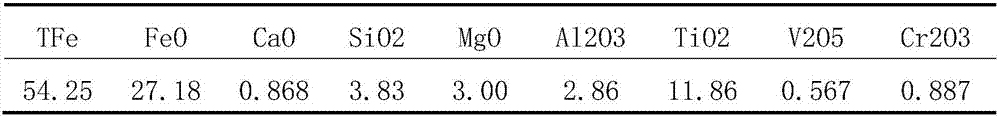

[0015] There are high-chromium vanadium-titanium magnetite concentrates, the main components of which are shown in Table 1 below:

[0016] Table 1 High chromium vanadium titanium magnetite concentrate

[0017]

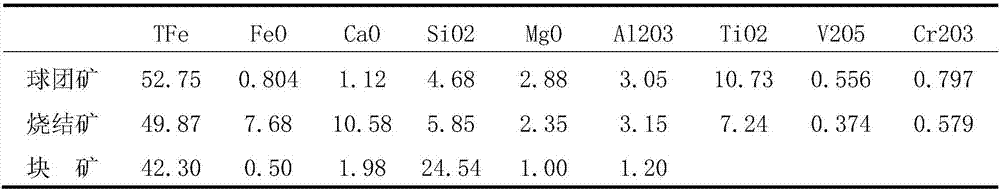

[0018] The main components of the pellets and sinter produced from high-chromium vanadium-titanium magnetite concentrate and the lump ore fed into the furnace at the same time are shown in Table 2:

[0019] Table 2 Main components of high-chromium vanadium-titanium pellets and sinter

[0020]

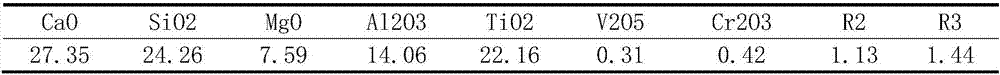

[0021] When pellets and sinters are in accordance with the proportion of pellets: sinter: lump ore is 16%: 82%: 2%, as iron-containing raw materials, with 430kg / t coke and 145kg / t injection pulverized coal into For blast furnace smelting, the final slag-iron ratio is 640kg / t, and the main components of the slag are shown in Table 3:

[0022] Table 3 Main components of high chromium and high titanium blast furnace slag

[0023]

[0024] It can be seen from Table 3 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com