Paint spraying equipment for new energy automobile parts

A technology for new energy vehicles and paint spraying equipment, applied in the direction of spraying devices, etc., can solve the problems of low work efficiency, affecting physical health, laborious and laborious, and achieve the effect of preventing uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

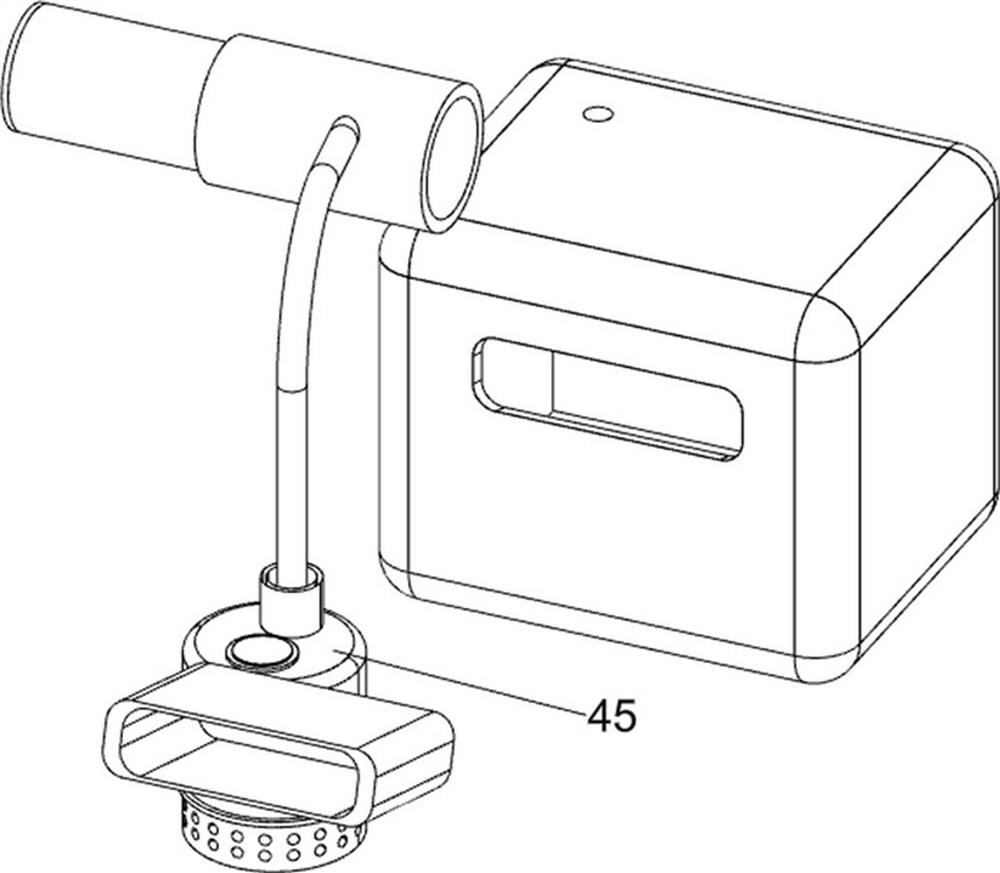

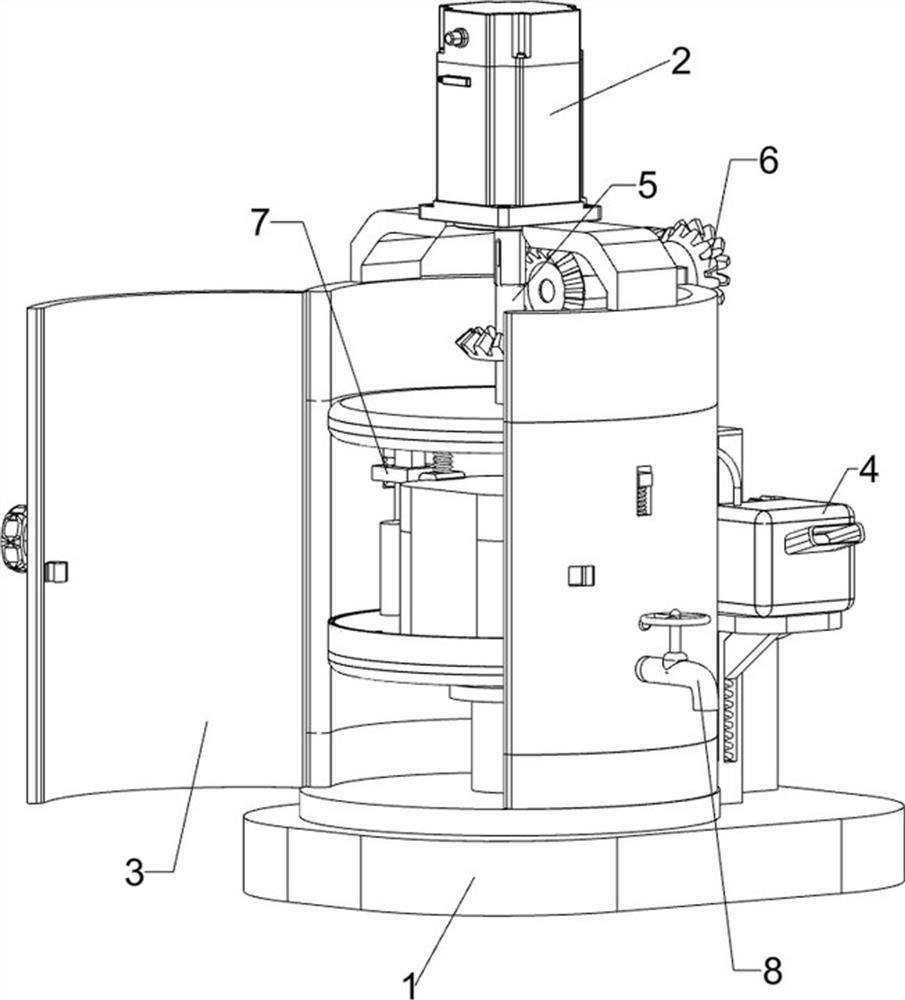

[0076] A new energy vehicle parts painting equipment, such as figure 1 As shown, it includes a bottom plate 1, a servo motor 2, a placement component 3, and a painting mechanism 4. The top front of the bottom plate 1 is provided with a placement component 3, the top of the placement component 3 is provided with a servo motor 2, and the rear side of the top of the bottom plate 1 is provided with a painting mechanism. 4.

[0077] When people want to paint the parts of the car, they put the parts on the 3 parts of the placement assembly, then put the paint into the 4 parts of the paint spraying mechanism, start the 4 parts of the paint spraying mechanism, and the 4 parts of the paint spraying mechanism spray paint on the parts, and people turn it manually Place the 3 parts of the assembly so that the paint is sprayed evenly, and after painting, close the 4 parts of the painting mechanism.

Embodiment 2

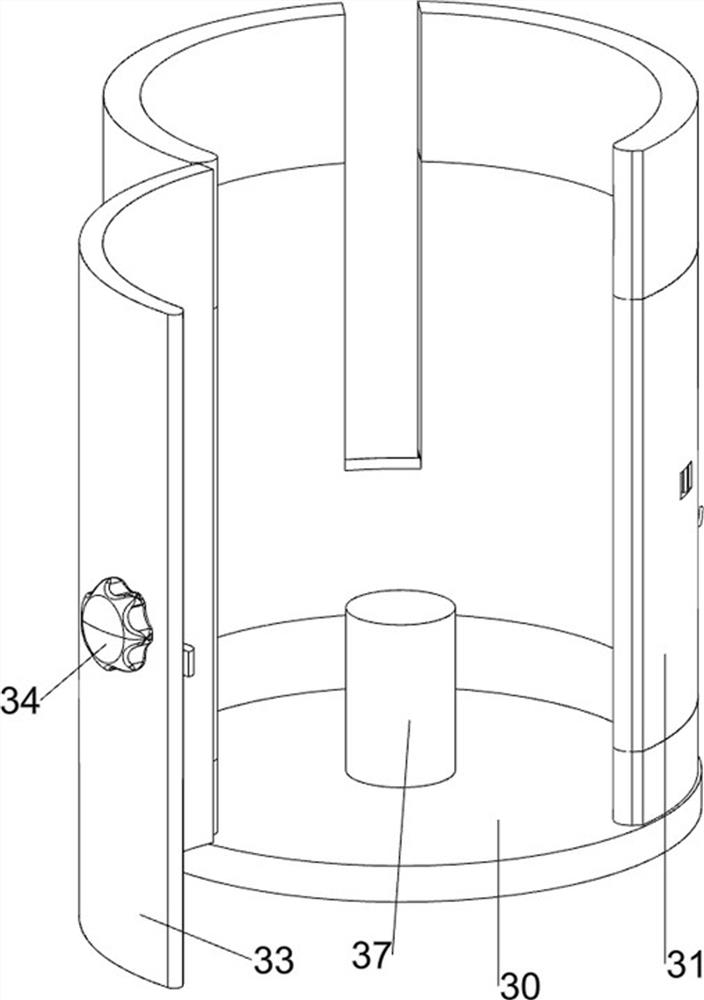

[0079] On the basis of Example 1, such as Figure 2-11 As shown, the placement assembly 3 includes a chassis 30, a protective plate 31, a hinge 32, a door 33, a handle 34, a lock 35, a first spring 36, a support column 37 and a rotating plate 38, and the top left side of the bottom plate 1 is provided with a There is an underframe 30, a support column 37 is arranged in the middle of the top of the underframe 30, a rotating plate 38 is connected to the top of the support column 37, and a protective plate 31 is arranged on the top of the underframe 30, and the top of the protective plate 31 is connected with the servo motor 2, and the protective plate 2 detachable hinges 32 are installed on the left side of the 31, and a detachable door 33 is installed between the left sides of the hinges 32. The lock 35 has two first springs 36 between the right side of the lock 35 and the protective plate 31 .

[0080] People put the parts on the rotary plate 38, then the door 33 is closed, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com