Powder spreading device for rapid forming equipment

A technology of forming equipment and powder spreading device, which is applied to the component field of rapid forming equipment, can solve the problems of difficult adjustment of powder spreading area, difficult powder restraint, complicated structure, etc., and achieves the effects of simple control, low cost, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

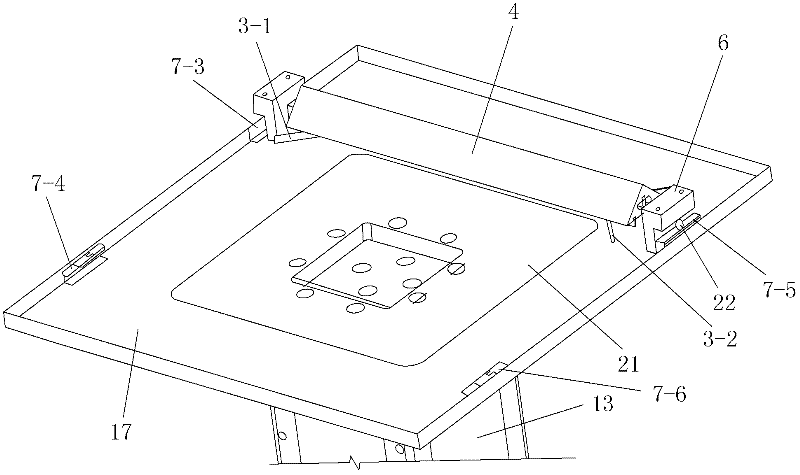

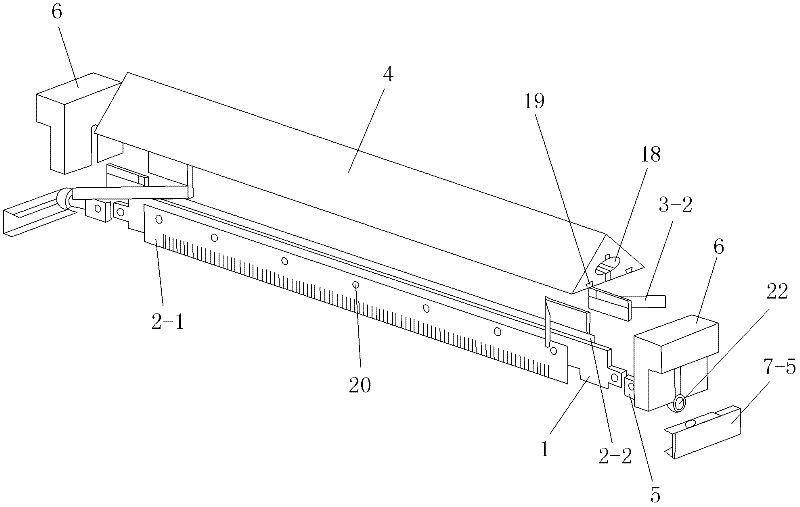

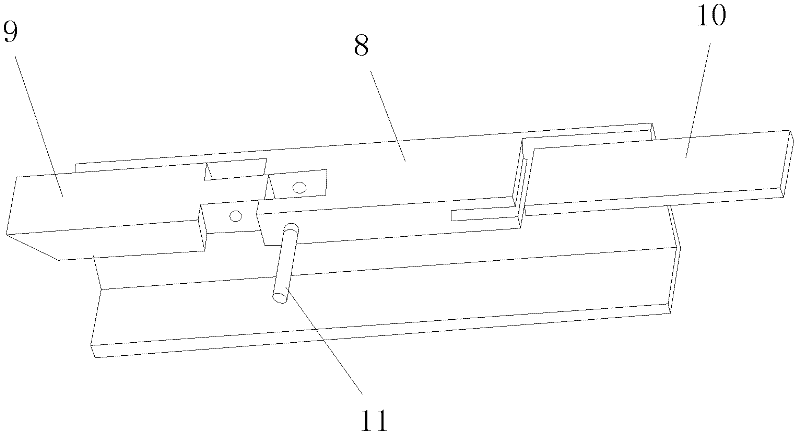

[0047] Such as figure 1 , figure 2 and Figure 5 As shown, the present invention includes a moving mechanism that is driven by a driving mechanism to move back and forth horizontally and linearly on the forming work platform 17 of the rapid prototyping equipment, a scraper mechanism that is fixedly installed at the bottom of the moving mechanism, and a scraper mechanism that is movably installed on the moving mechanism. The left side wing 3-1 and the right side wing 3-2 on the left and right sides of the bottom of the mechanism, the left side wing 3-1 and the right side wing 3-2 have the same structure and they are arranged symmetrically on the scraper mechanism left and right sides. The moving mechanism includes a horizontally arranged push block, a connecting rod 1 installed at the bottom of the push block, and a left traveling mechanism and a right traveling mechanism respectively symmetrically installed at the left and right ends of the connecting rod 1. The connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com