Mechanism for controlling ink of roller stamping machine

A technology of roller mechanism and stamping machine, which is applied in stamping, printing and other directions, and can solve problems such as excessive stamp ink, high oil content of sponge wheel, local accumulation of ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

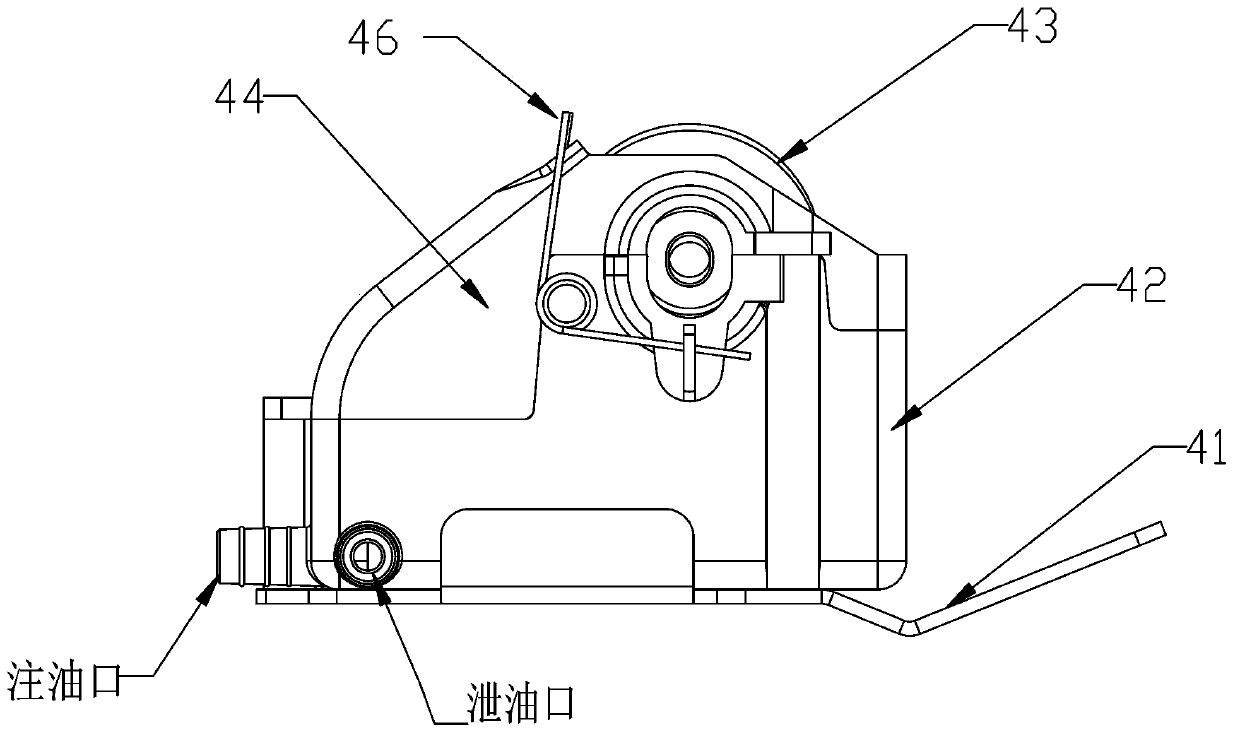

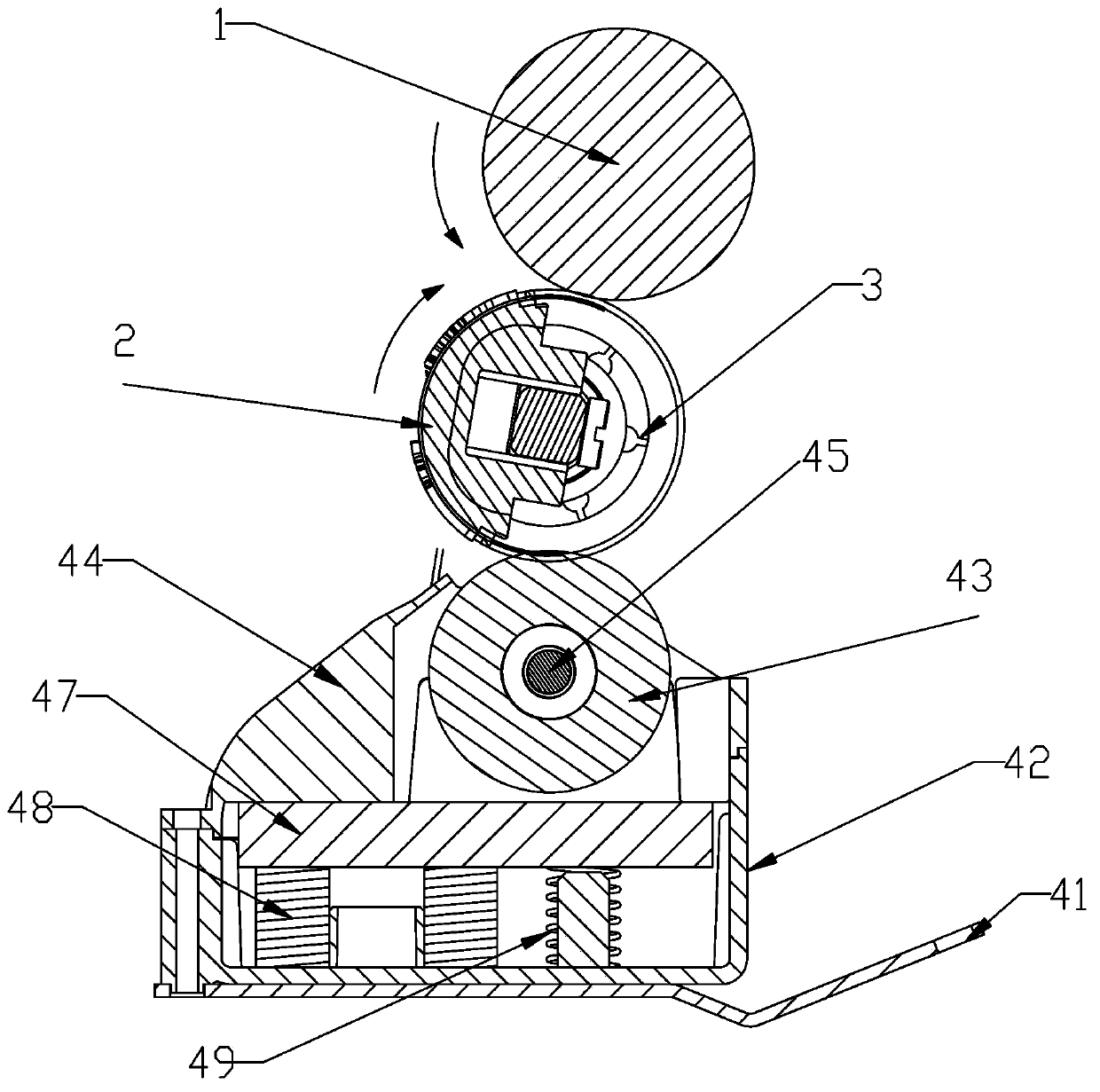

[0013] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

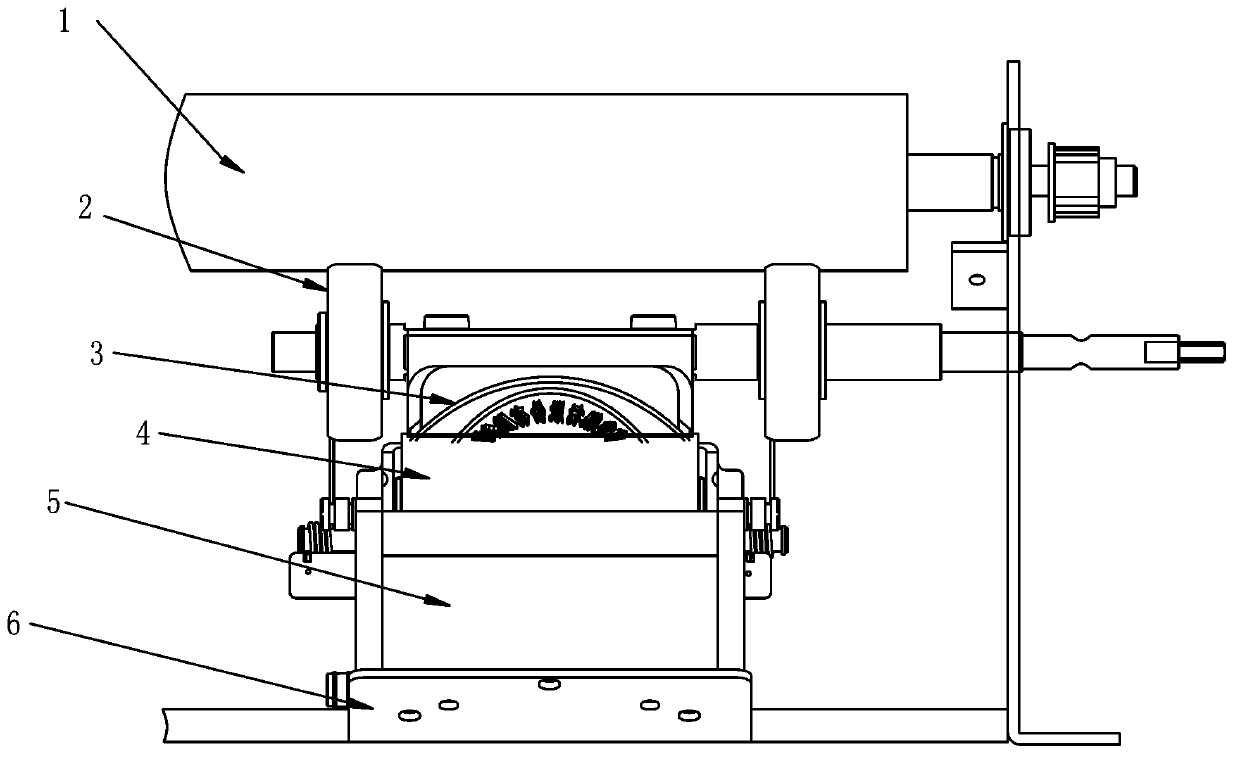

[0014] Such as figure 1 As shown, a mechanism for ink control of a roller stamping machine includes a rubber roller 1, a pickup roller mechanism 2, a stamp wheel 3, an ink cartridge mechanism 4 and a side frame 5, and the pickup roller mechanism 2 includes The pick-up roller and the pick-up roller shaft, the said pick-up roller shaft and the pick-up roller shaft are installed on the side frame 5, the pick-up roller 1 cooperates with the pick-up roller, the two are tangent and maintain a certain amount of interference , forming a paper path.

[0015] Described stamp wheel 3 is fixed on the paper pick-up roller shaft by screw, guarantees stamp wheel 3 and paper pick-up roller to rotate synchronously, and can have certain interference amount contact with paper-feeding rubber wheel, and paper is rolled in wherein when contacting, and to paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com