Method and device for producing fuel algae in continuous U-shaped tube and application thereof

A production method and a production device technology, which are applied in the fields of oil algae production, carbon dioxide treatment, and bio-oil industrial production, can solve the problems of troublesome collection of mature oil algae, low production efficiency of oil algae, and low yield of vegetable oil, and achieve the whole process of oil extraction Controllable, basically controllable oil content, shortened ripening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

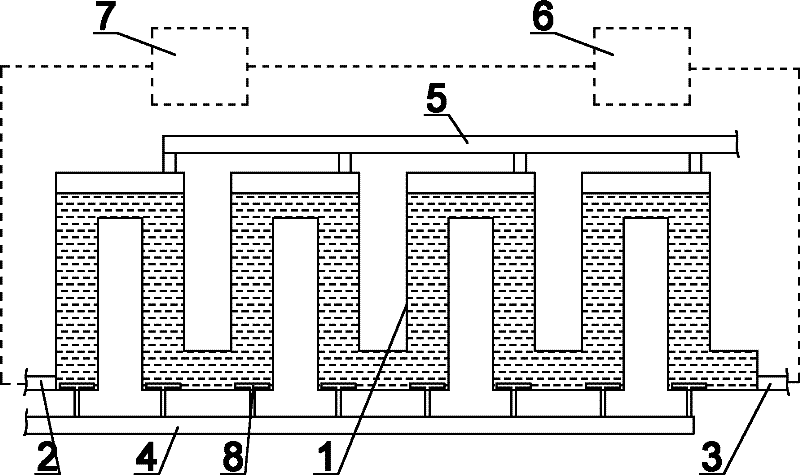

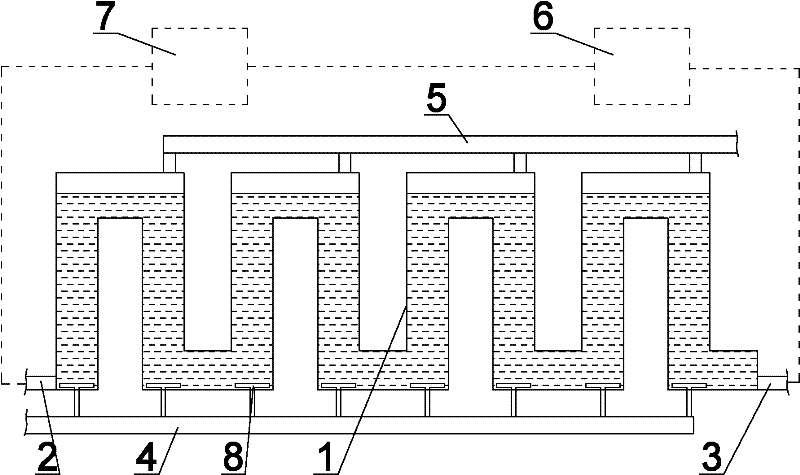

[0023] Embodiments of the invention. Continuous U-tube oil algae production device, such as figure 1 As shown, the U-shaped tube 1 is made of transparent materials such as glass or plastic, and the tops of the U-shaped tubes 1 are connected sequentially to form a continuous channel. The tail end of the tube 1 is provided with a culture solution outlet 3 , a carbon dioxide inlet 4 is installed at the bottom of the U-shaped tube 1 , and a gas collection port 5 is installed at the top of the U-shaped tube 1 .

[0024] In order to realize circular production, the culture solution outlet 3 of the continuous U-shaped pipe 1 is connected to the algae separation tank 6 through a pipeline, and the culture solution of the oil and algae separation tank 6 enters the feeding tank 7 through the pipeline, and the feeding tank 7 is connected to the continuous U-shaped tube 1 The culture medium import 2.

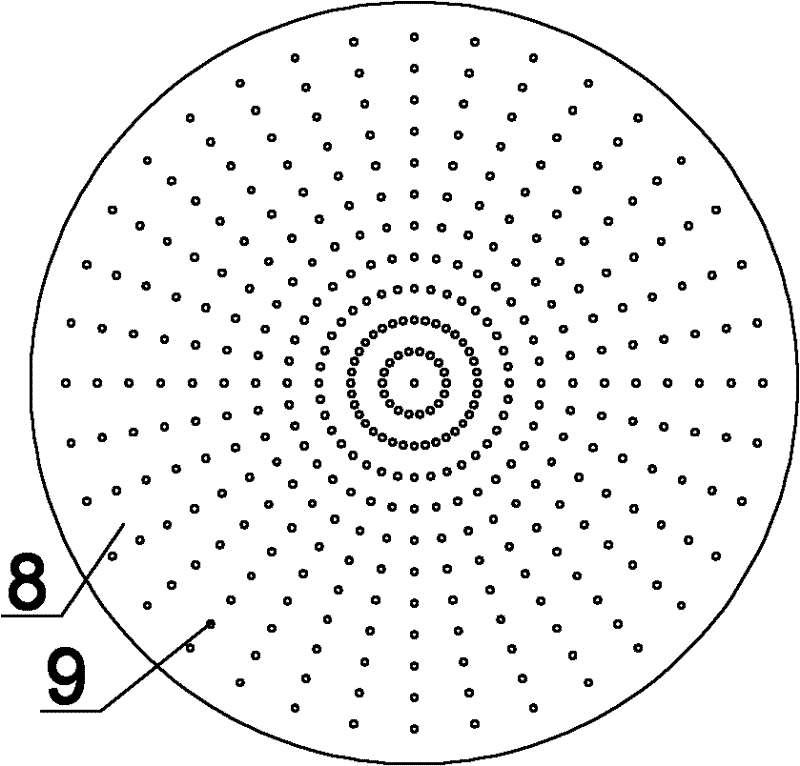

[0025] The carbon dioxide gas inlet 4 at the bottom of the U-shaped pipe 1 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com