Side feed conveying system for conveying filler with low bulk density

A technology of bulk density and conveying system, which is applied in the field of side feeding conveying system, can solve the problems of limited conveying capacity, insufficient conveying capacity and inaccurate feeding of co-rotating twin-screws, etc., so as to increase feeding capacity, reduce resistance, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

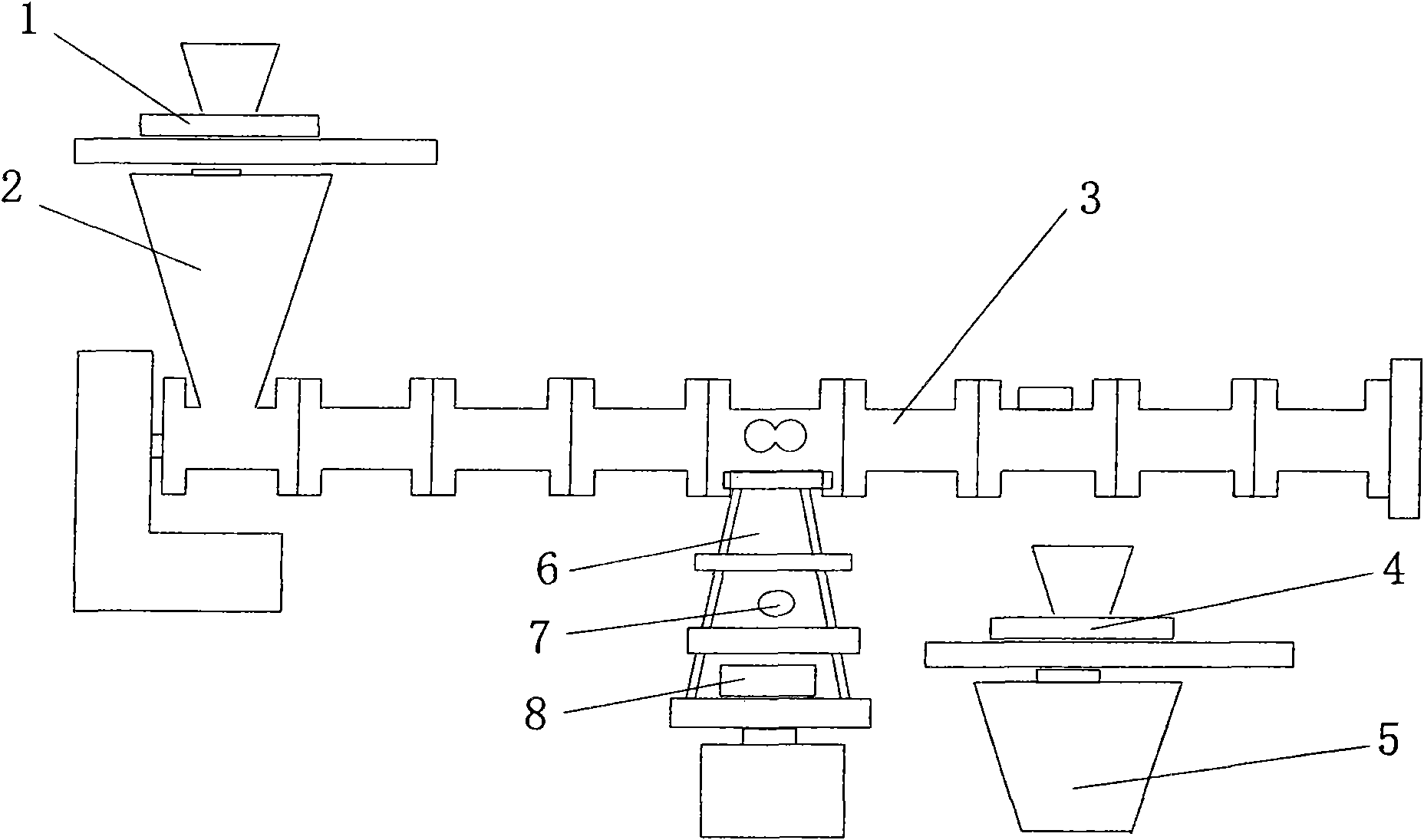

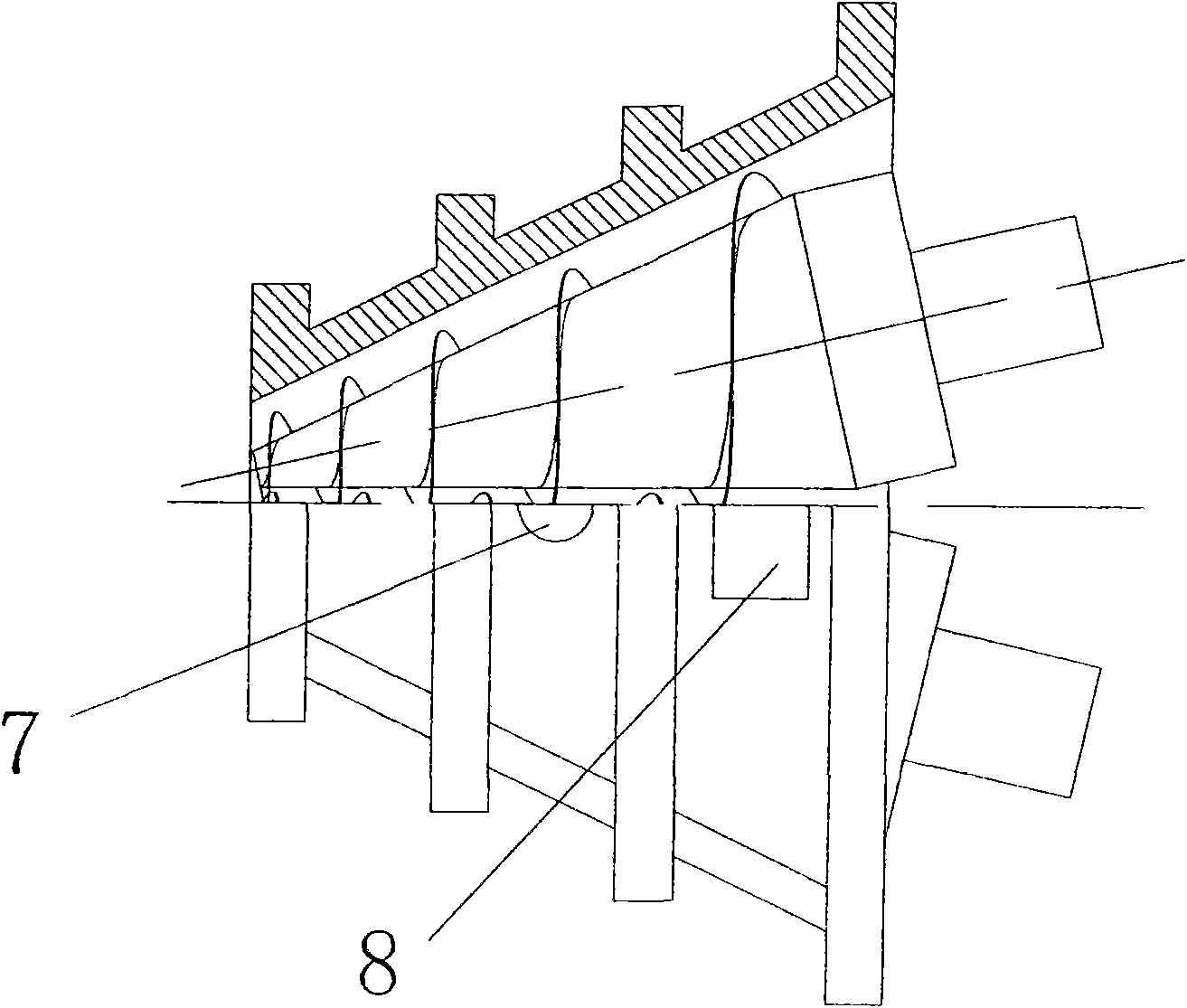

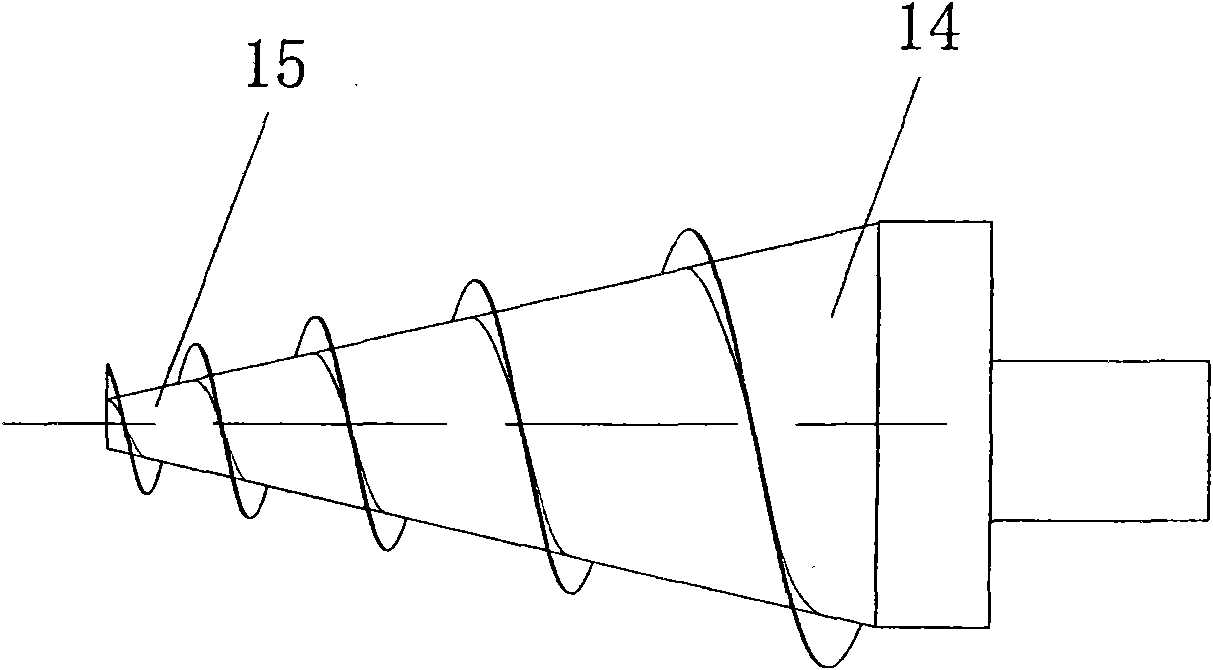

[0023] This embodiment is a side feeding conveying system for conveying low bulk density packing, such as figure 1 As shown, (1 among the figure is the metering scale of extruder main feeding system, and 2 is the hopper of extruder main feeding system.) Comprising hopper 5, screw barrel 6 and screw assembly that are connected with extruder 3, Wherein the hopper 5 is arranged above the feeding port 8 of the screw barrel 6, and the screw assembly is arranged inside the screw barrel 6, and the structure of the hopper 5 is as follows Figure 4 As shown, the bucket wall is a sandwich structure including an outer layer 12 and an inner layer 13, a plurality of baffles 10 are provided in the gap between the outer layer 12 and the inner layer 13, and an exhaust port is provided at the bottom of the inner layer 13 of the bucket wall 9. The hopper cover above the hopper wall is provided with an air outlet 11 for an external exhaust system; a weighing scale 4 is provided above the hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com