Automatic brick paving equipment for road for highway engineering

A brick-laying equipment and road technology, which is applied in the field of road automatic brick-laying equipment for highway engineering, can solve the problems that the degree of adhesion between road bricks and the ground is difficult to maintain, affects the effect and service life of the road surface, and is difficult to guarantee the flatness. Achieve the effects of low labor cost, improved processing efficiency and consistent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

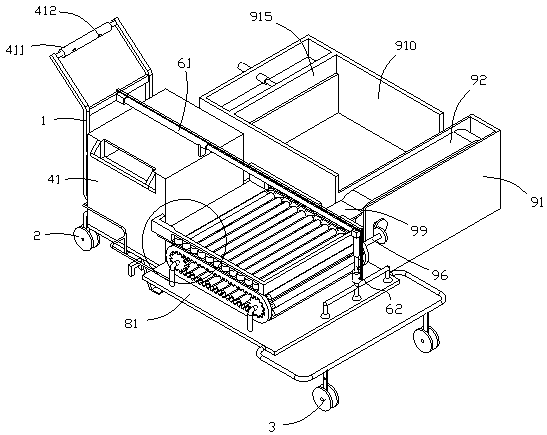

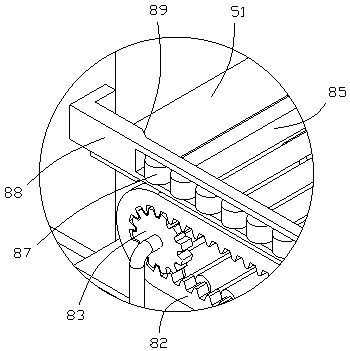

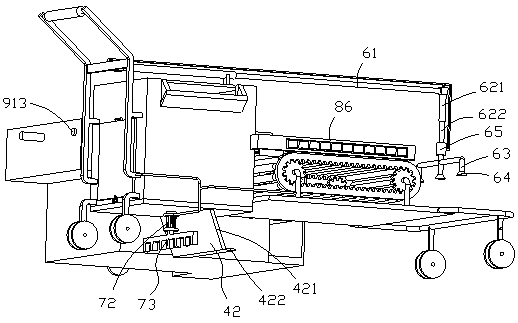

[0026] Such as Figure 1-8 As shown, an automatic road brick paving equipment for highway engineering includes a frame 1, a front wheel 2, a rear wheel 3, a cement paving device and a road brick paving device; the cement paving device is used for laying cement smoothly To the road to form a cement layer on the road, which includes a cement mixing box 41, a discharging component arranged at the lower part of the cement mixing box, and a paving slab 42 arranged on the rear side of the discharging component; the road brick laying device It includes a leveling part, a feeding device matched with the leveling part, and a laying part matched with the leveling part. The leveling part includes a leveling platform 51 arranged on the side wall of the cement mixing box, and The road bricks on the feeding device are transported to the conveying part on the whole platform and the guide part arranged on the position above the conveying part. After the road bricks are conveyed to the whole pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com