Symmetrically-arranged full-bridge power module

A power module and symmetrical technology, which is applied in the field of power semiconductor devices, can solve the problems of switching oscillation and high turn-off voltage, and achieve the effect of reducing switching oscillation, reducing parasitic inductance, and achieving symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

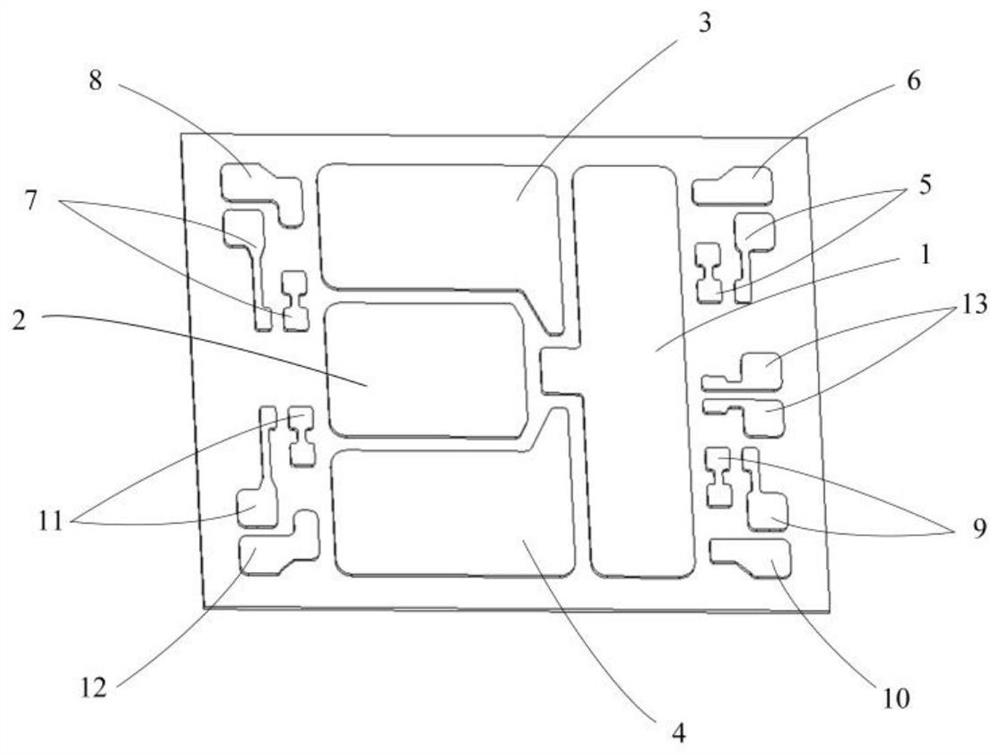

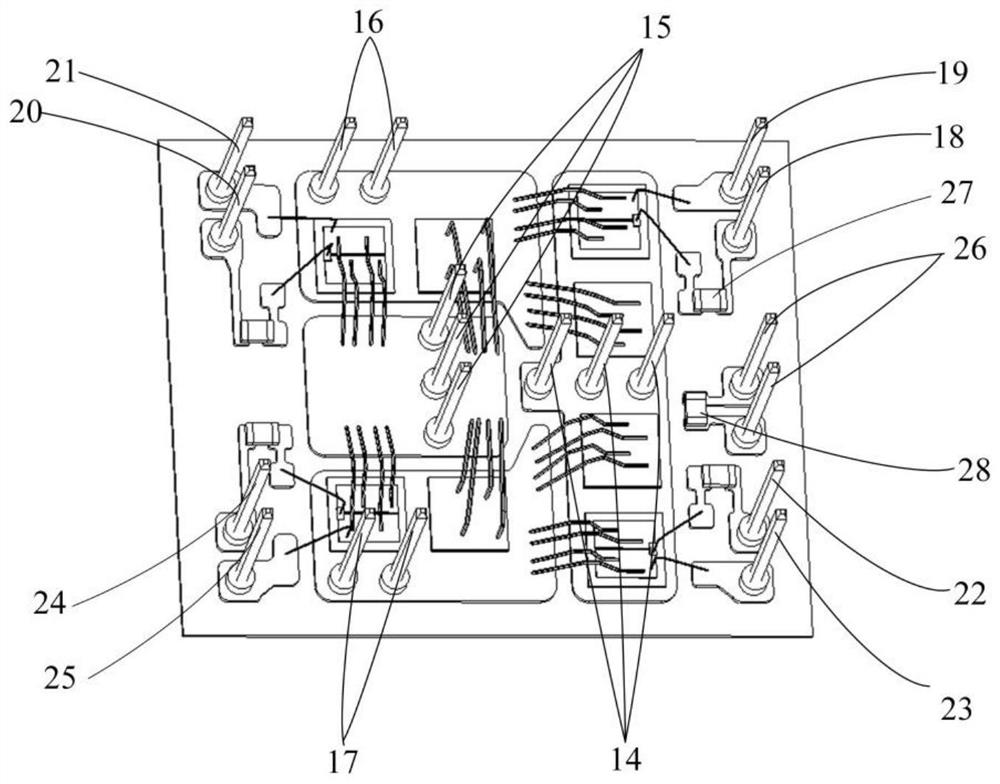

[0034] A full-bridge power module with a symmetrical layout. The full-bridge power module includes insulating substrates, power chips (including switch tube chips and diode chips), terminals and other parts; the insulating substrate is divided into upper surface metal layer, middle insulating layer and The metal layer on the lower surface and the metal layer on the upper surface include: positive electrode metal layer, negative electrode metal layer, first AC electrode metal layer, second AC electrode metal layer and each copper layer for driving signal connection; first AC electrode metal layer, The negative electrode metal layer and the second AC electrode metal layer are arranged laterally in sequence, and all three are adjacent to the positive electrode metal layer; the positive electrode metal layer and the negative electrode metal layer are respectively symmetrical about the central axis, and the first AC electrode metal layer and the second AC electrode metal layer The l...

Embodiment 2

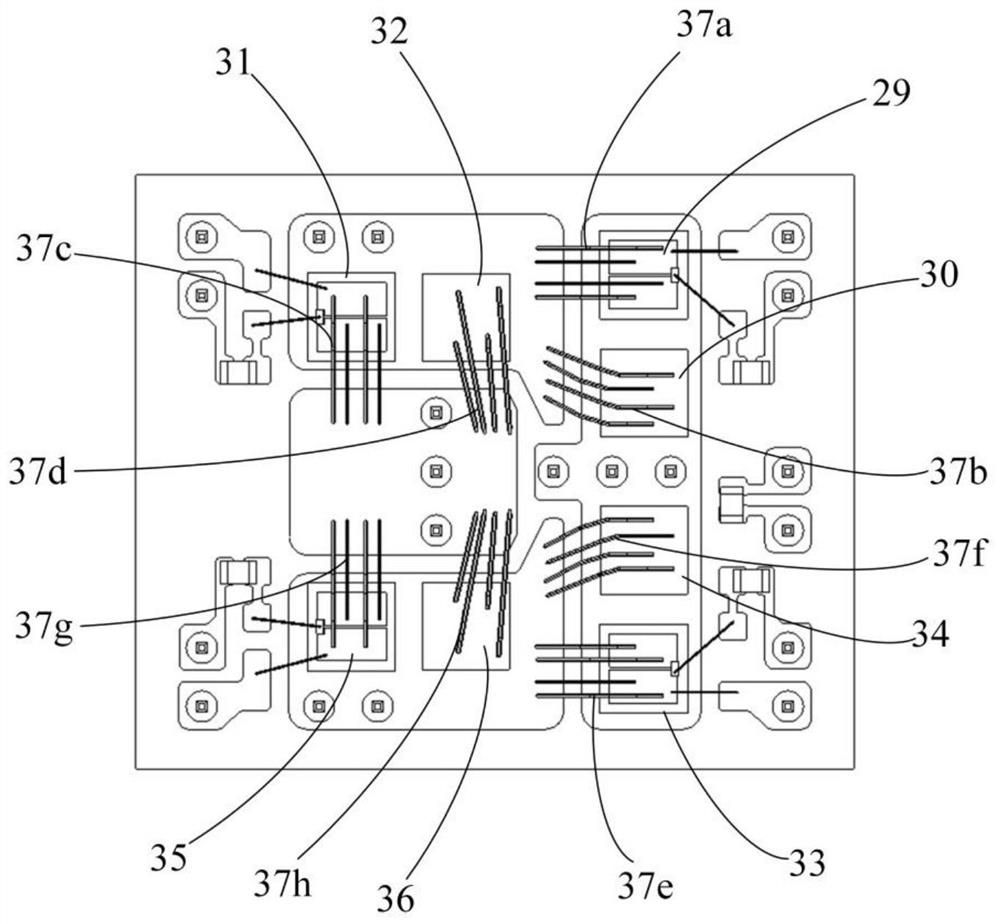

[0060] The power module of the above-mentioned embodiment 1 can realize the topology of the full-bridge rectifier circuit after removing the switching tube chip and keeping only the diode chip; similarly, the working conditions and service life of the diode chips on the four bridge arms can be kept consistent.

[0061] like Image 6 and Figure 7 Shown is a full-bridge rectifier module applying this full-bridge module layout. Similarly, as another example of the present invention, the number of parallel diode chips of each bridge arm is 1; the insulating substrate adopts a direct copper-clad ceramic board (DBC), the corresponding metal layers are copper layers, and the intermediate layer adopts aluminum nitride Ceramic; features pin terminals.

[0062] Image 6 It is a schematic diagram of the internal structure of a full-bridge rectifier module with a symmetrical layout. The arrangement of the copper layer on the upper surface of the insulating substrate is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com