Automatic coating structure for brake pad

A brake pad, automatic technology, applied in the direction of spraying device, spray booth, etc., can solve the problems that affect the competitiveness and sustainable development of enterprises, production quality and efficiency constraints, lack of capital and technical strength, etc., to achieve simple conveyor belt tensioning body, achieving symmetry, avoiding the effect of downtime risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

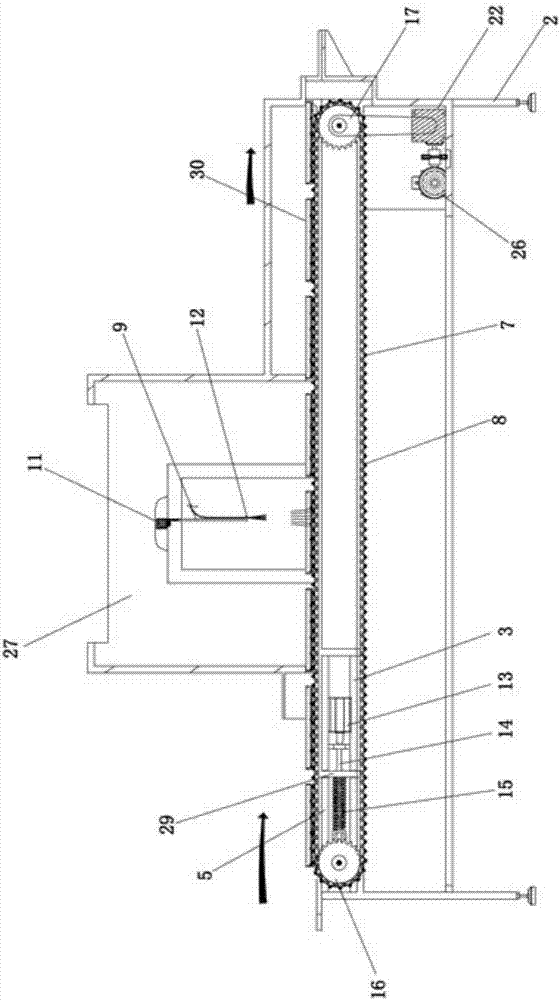

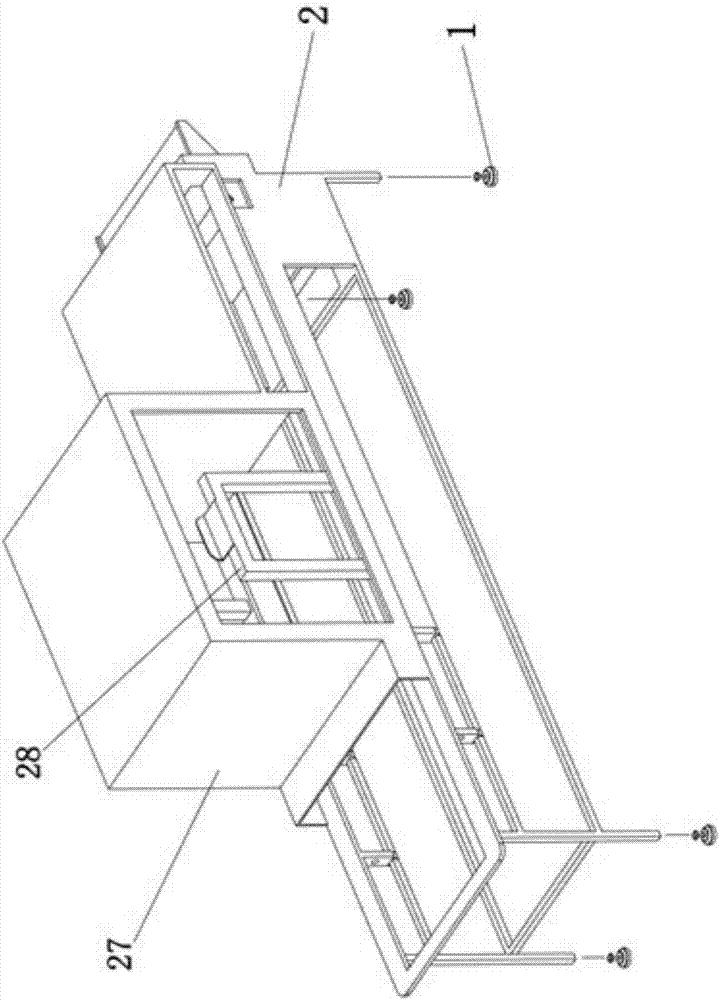

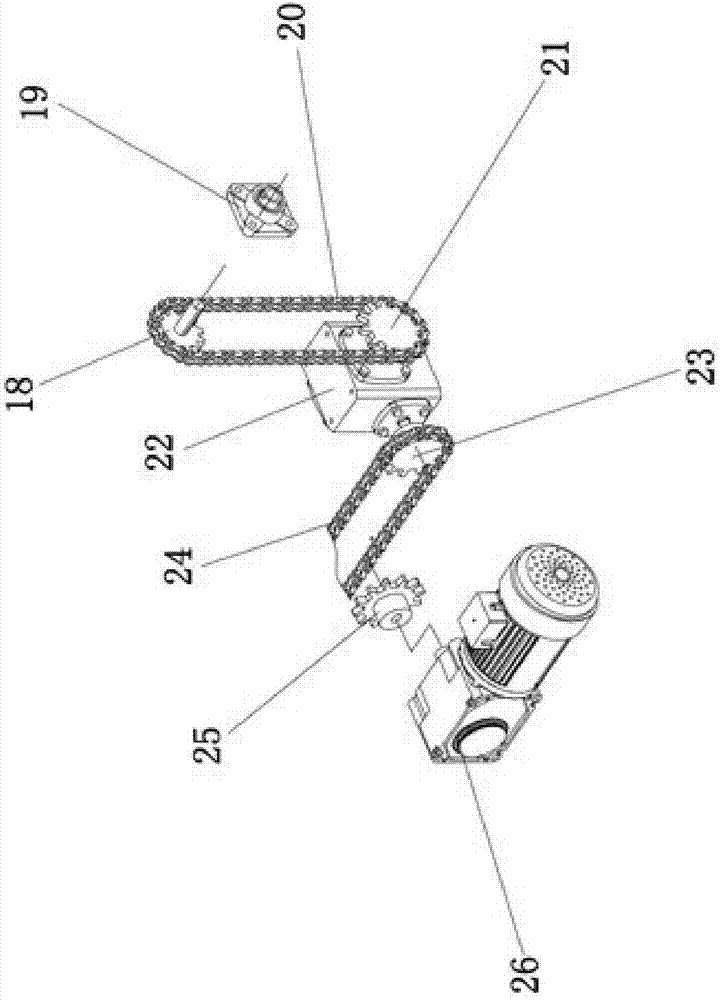

[0017] Such as figure 1 , figure 2 , image 3 As shown, the automatic coating structure for brake pads includes a conveyor belt transmission mechanism, a conveyor belt tensioning mechanism, and a constant speed reciprocating coating mechanism. The conveyor belt transmission mechanism includes a frame 2, a conveyor driven sprocket 16, Conveyor belt driving sprocket 17, speed change gear box 22, gear motor 26, gear motor 26 is located on the frame 2, is provided with gear motor sprocket 25 on the gear motor 26, and speed change gear box 22 is located on the frame 2; The motor sprocket 25 is connected with the first gear box sprocket 23 on the transmission gearbox 22 through the first drive chain 24; 17 is connected with a driving small sprocket 18, and the driving small sprocket 18 is connected with the second gear box sprocket 21 on the transmission gearbox 22 through the second driving chain 20; the conveying driven sprocket 16 is connected to the sliding On the bearing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com