Patents

Literature

44results about How to "Promote interaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

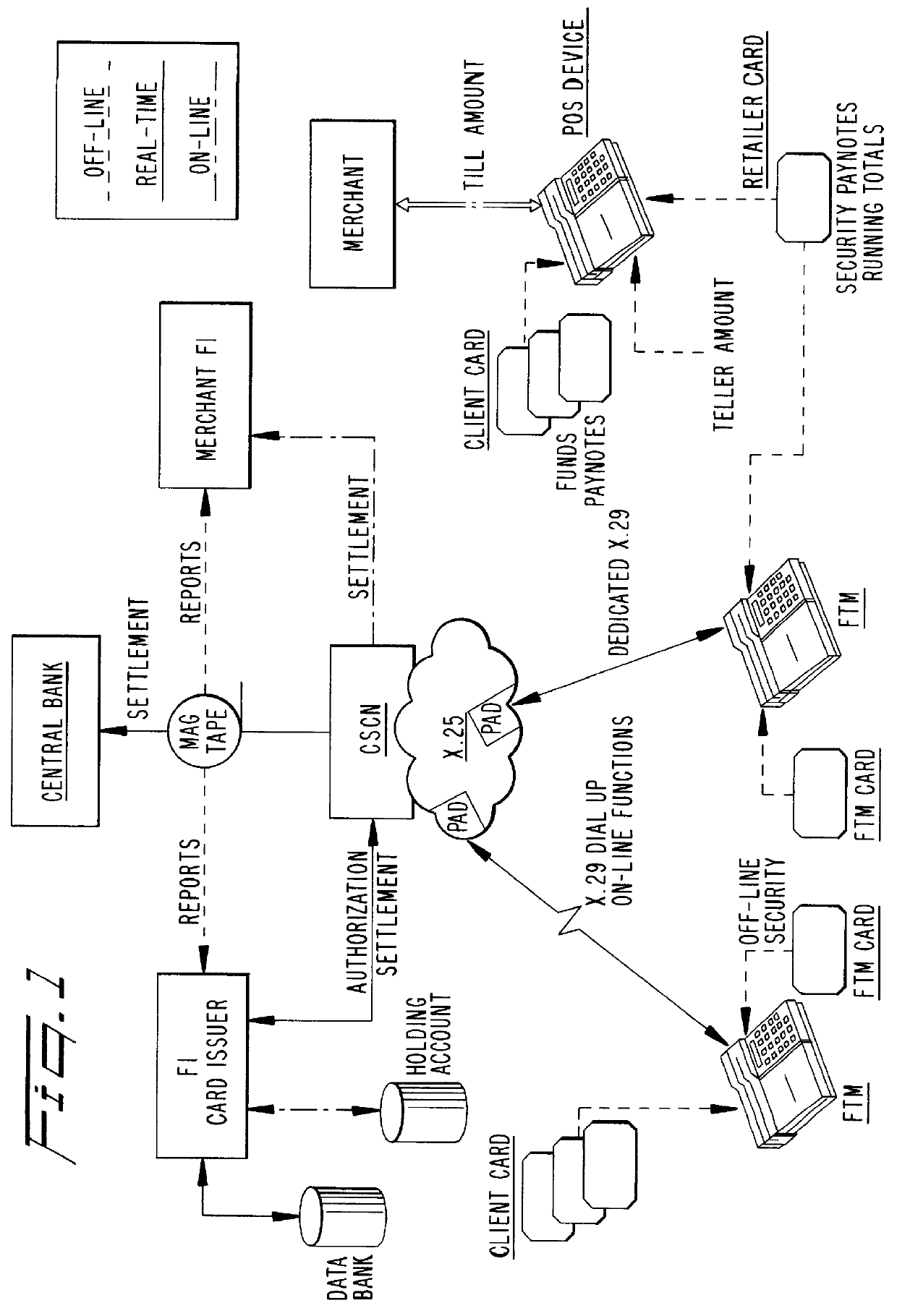

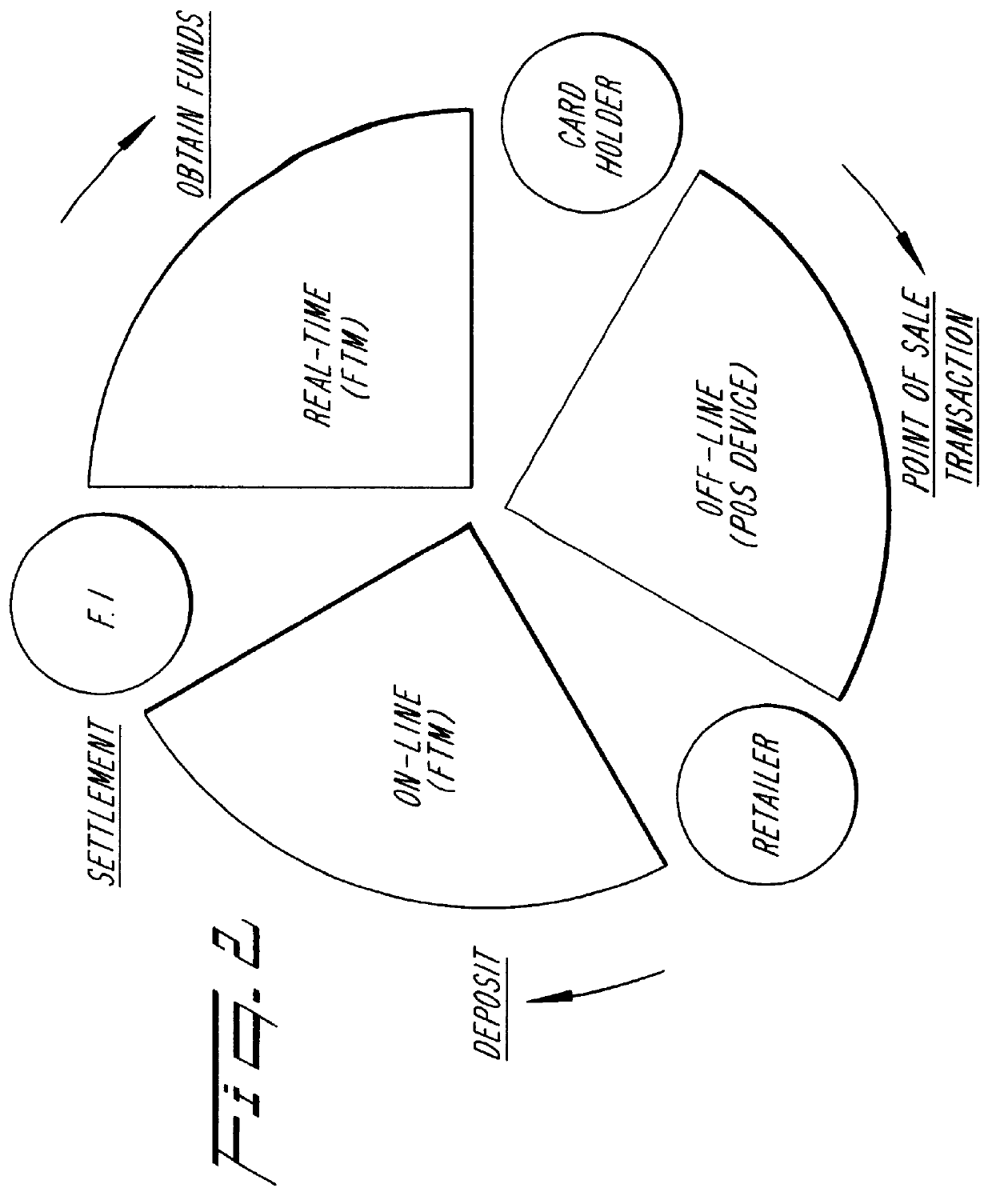

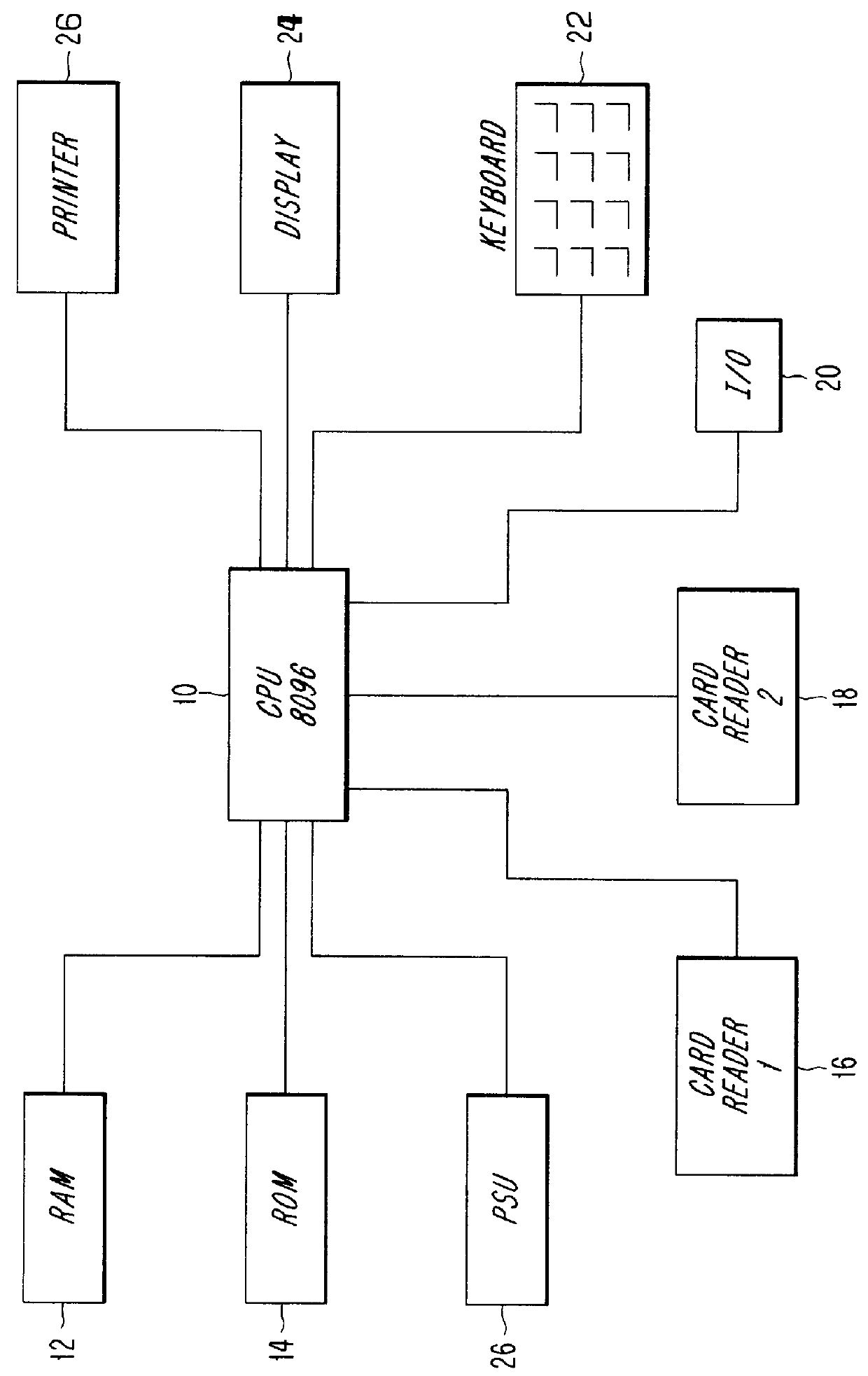

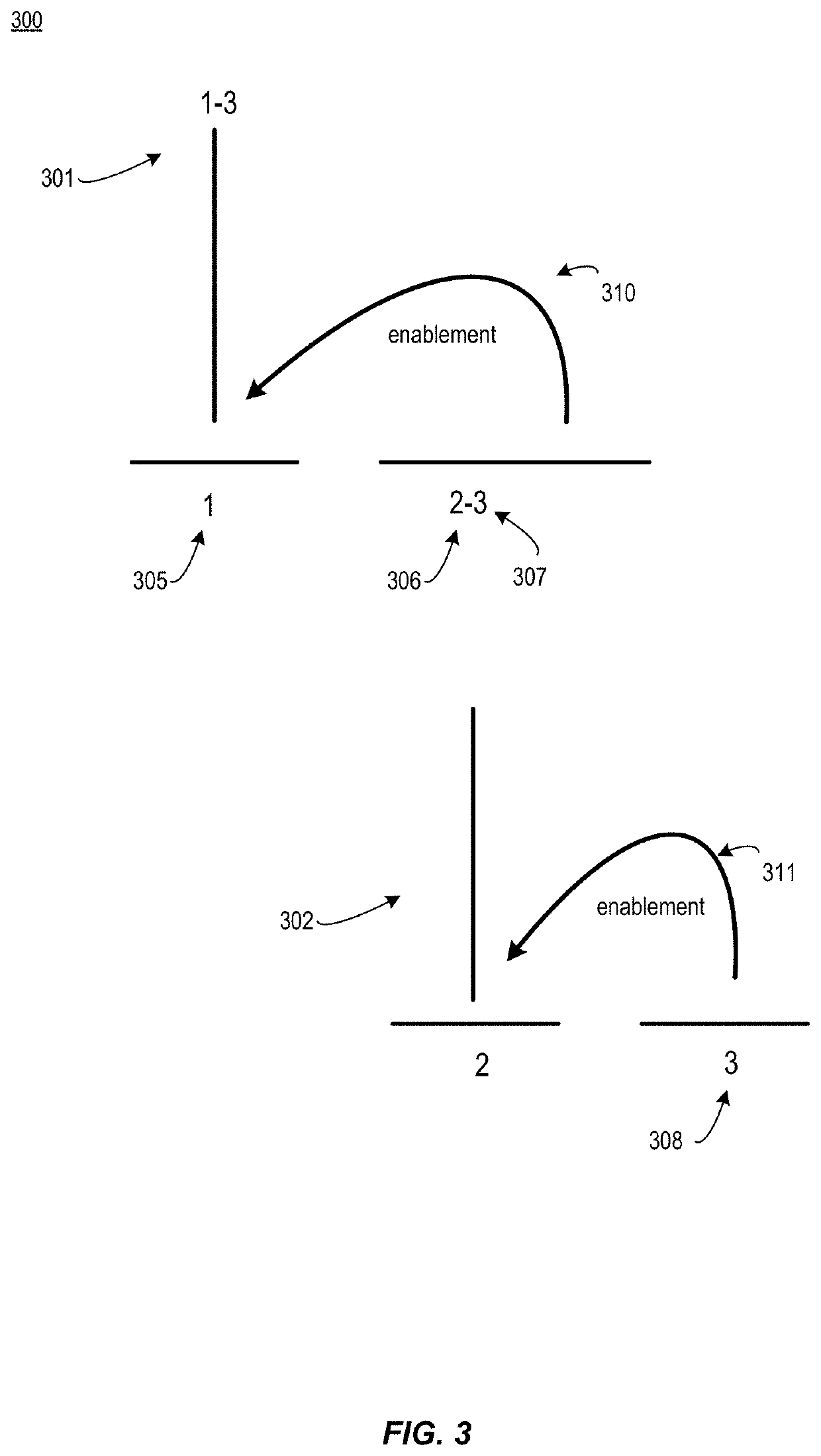

Funds transfer system

InactiveUSRE36788E1Promote interactionEnhanced interactionComplete banking machinesFinanceTransfer systemSmart card

A method of transferring funds includes the steps of linking a first "smart card" to a first financial institution, debiting an account held at the financial institution and recording a corresponding credit value in the first smart card. The first smart card is then linked to a second, similar device, the credit value in the first device is reduced, and a corresponding credit value is recorded in the second device. The second device is then linked to a second financial institution, the credit value in the second device is reduced, and a corresponding credit value is recorded in an account held at the second financial institution. The first and second devices each store at least a portion of a program which is run in a synchronized interactive manner between the first devices. The invention extends to a system for implementing the method.

Owner:NET1 HLDG S A R L

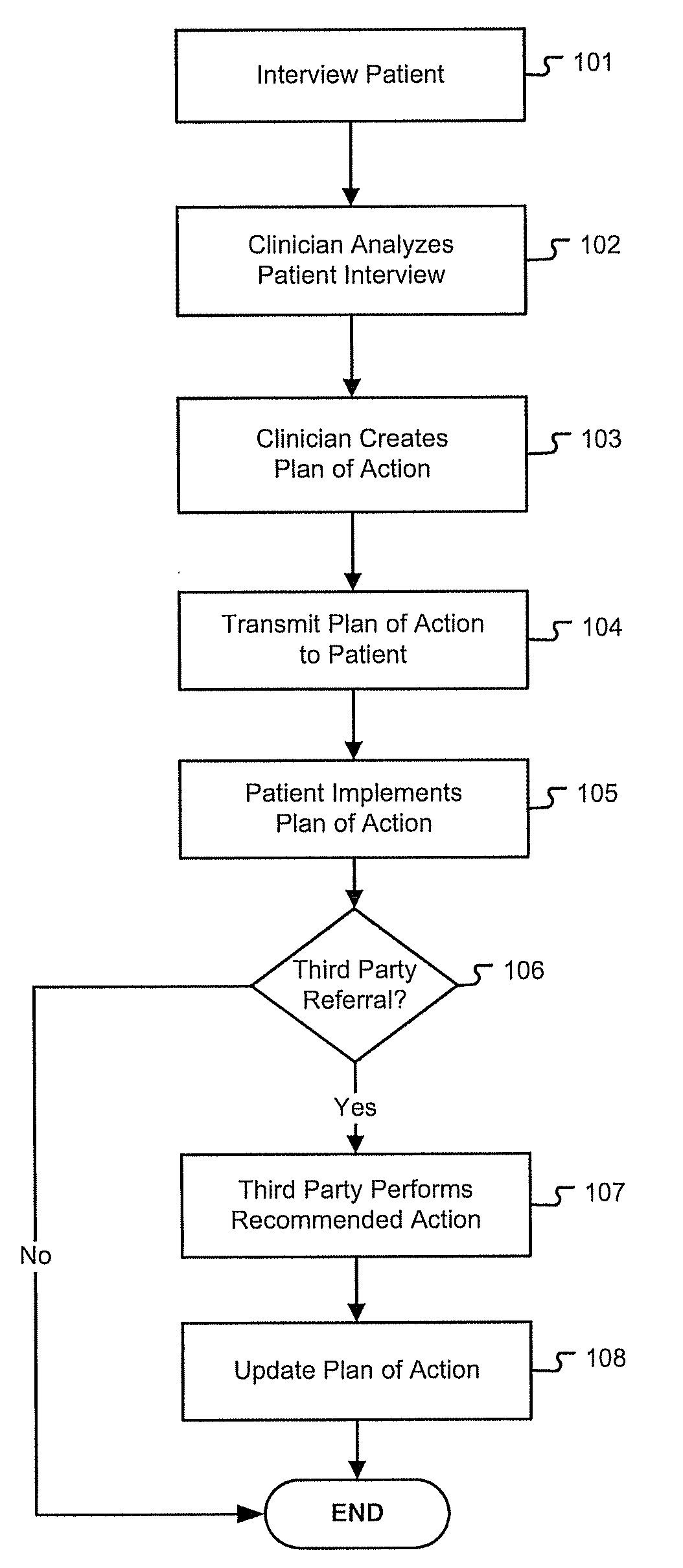

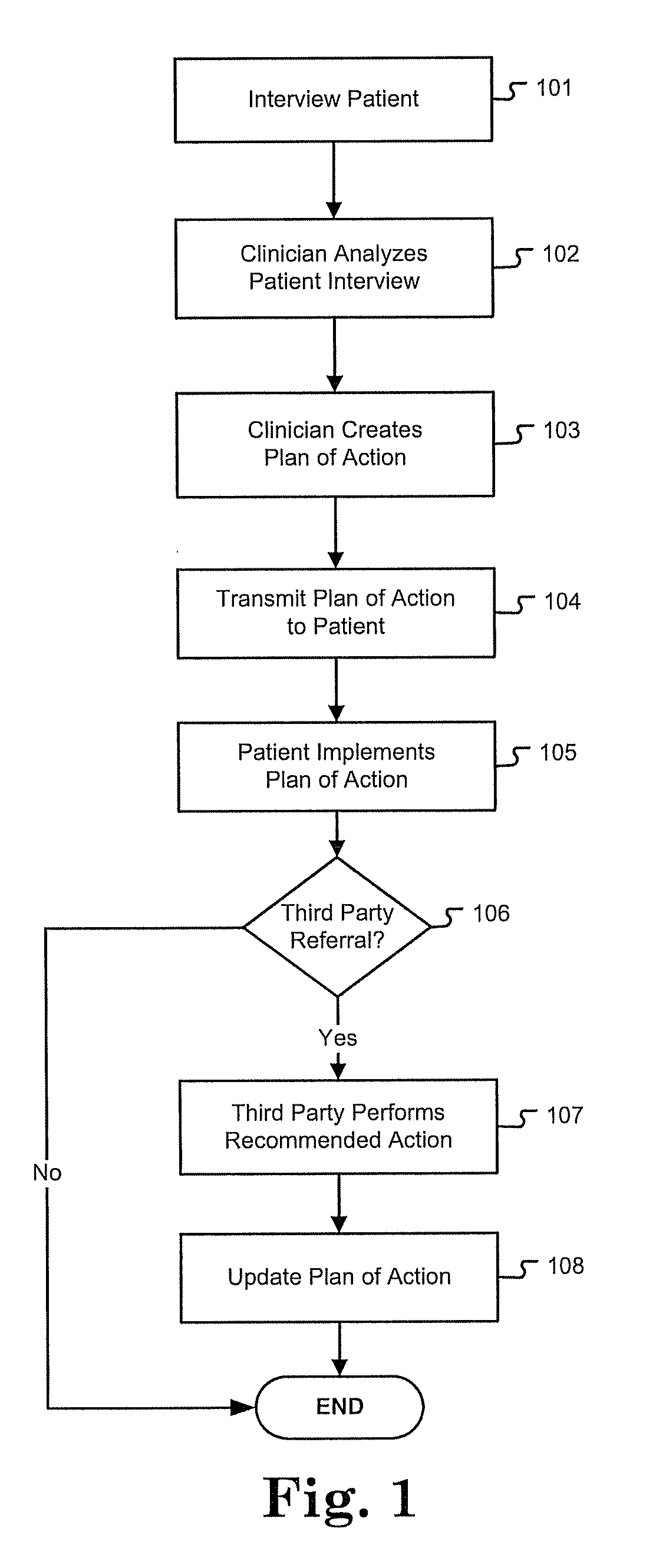

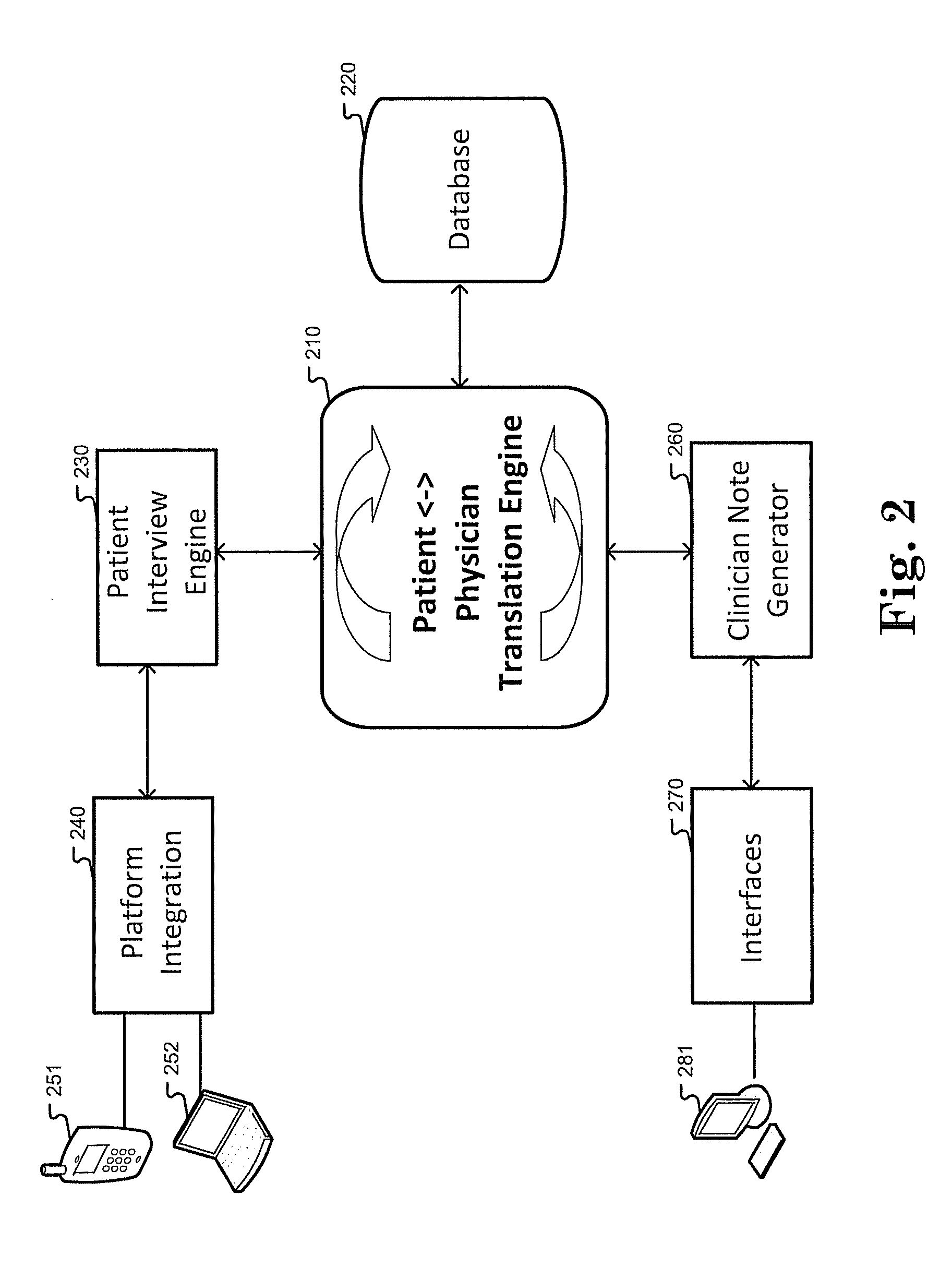

Method and system for digital healthcare platform

InactiveUS20100250271A1Enhanced information flow and healthcare servicePromote interactionTherapiesResourcesPatient informationProgram planning

The presently disclosed digital healthcare platform provides patients and healthcare providers with a precise and focused treatment pathway to address healthcare issues. One embodiment enables a patient-initiated e-Visit to address a healthcare issue with an issue-focused adaptive interview. The results of this adaptive interview are forwarded to a skilled clinician for review, who then provides an assessment and a plan of action for the issue. The plan of action may include specific instructions, a prescription, or a referral to a third party medical provider for testing, consultation, or treatment. Another embodiment provides an identification “ticket” to the patient to coordinate care obtained at third parties. The ticket can be presented by the patient to a third party medical provider (such as with a barcode displayed on a mobile device) to identify the patient and enable the third party medical provider to access patient information from the digital healthcare platform.

Owner:ZIPNOSIS

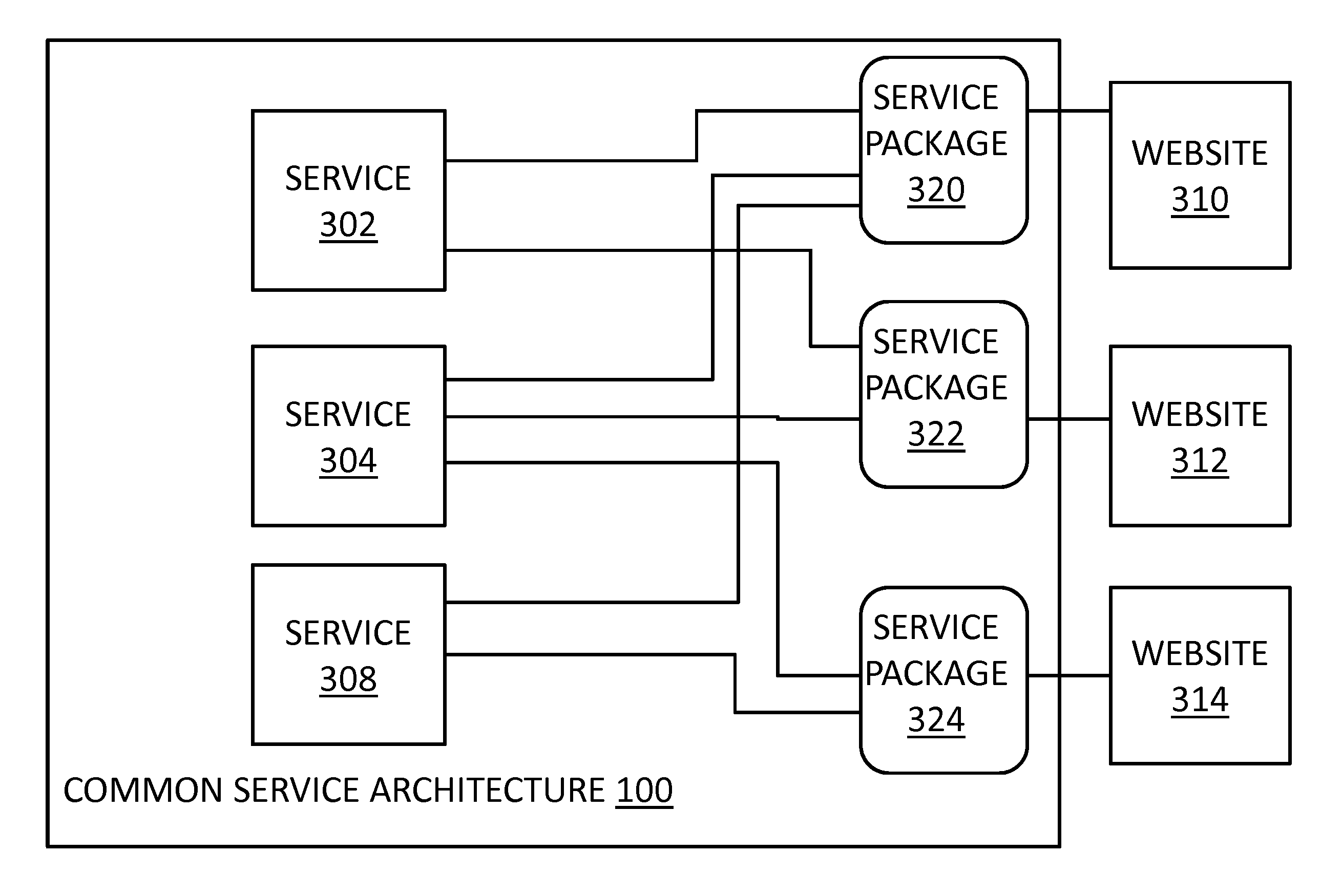

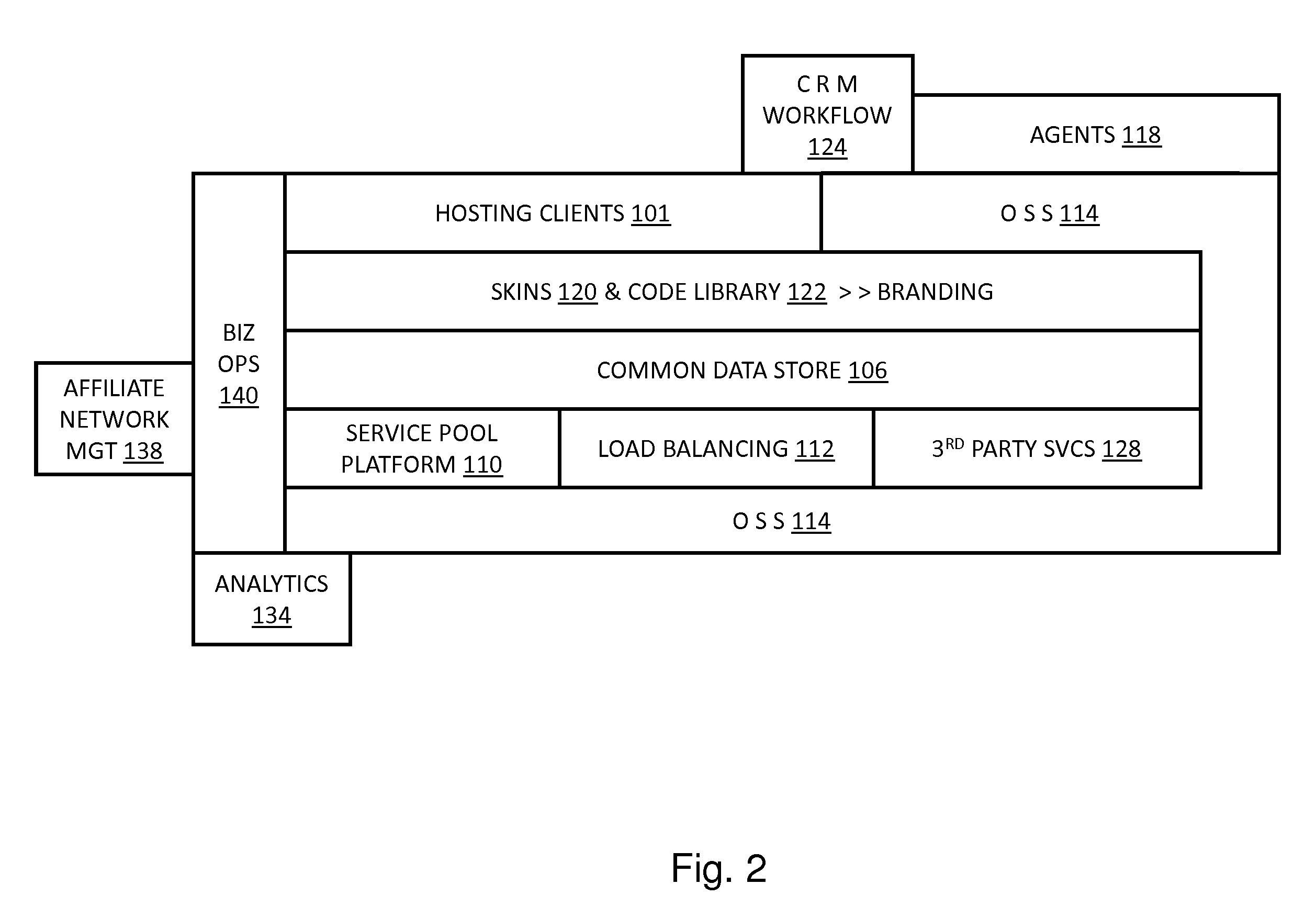

Common services web hosting architecture with multiple branding

InactiveUS20110178890A1Promote interactionFacilitate accessResourcesData switching networksService provisionSchema for Object-Oriented XML

A website hosting service provides a plurality of services, from a common service architecture, to each of a plurality of unaffiliated websites, each of the plurality of services being adapted to contribute to a distinct package of services for at least a plurality of unaffiliated websites, wherein the web hosting service is marketed through a plurality of marketing websites, at least a plurality of the marketing websites describing different market specific offerings for the packages of services.

Owner:ENDURANCE INTERNATIONAL GROUP

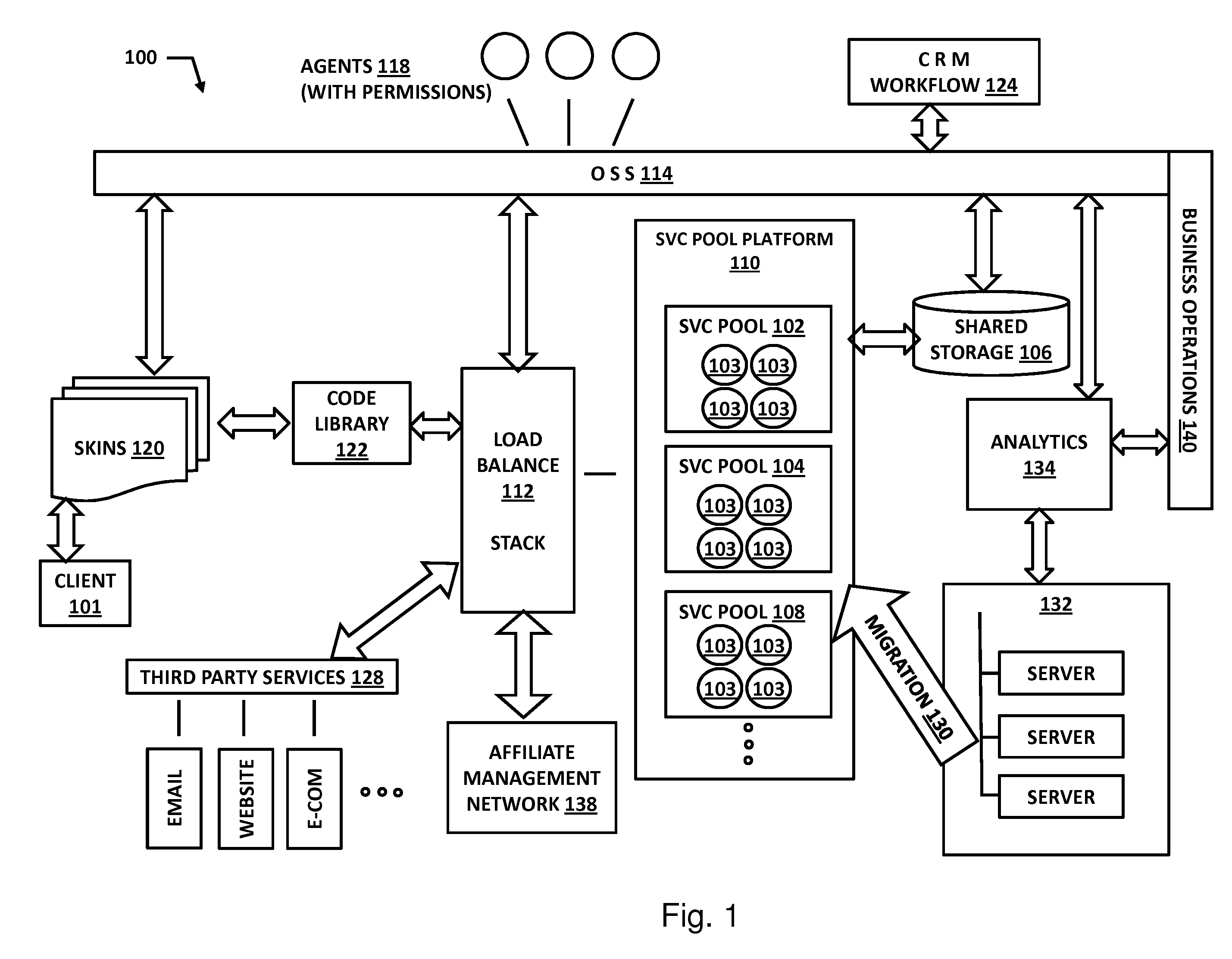

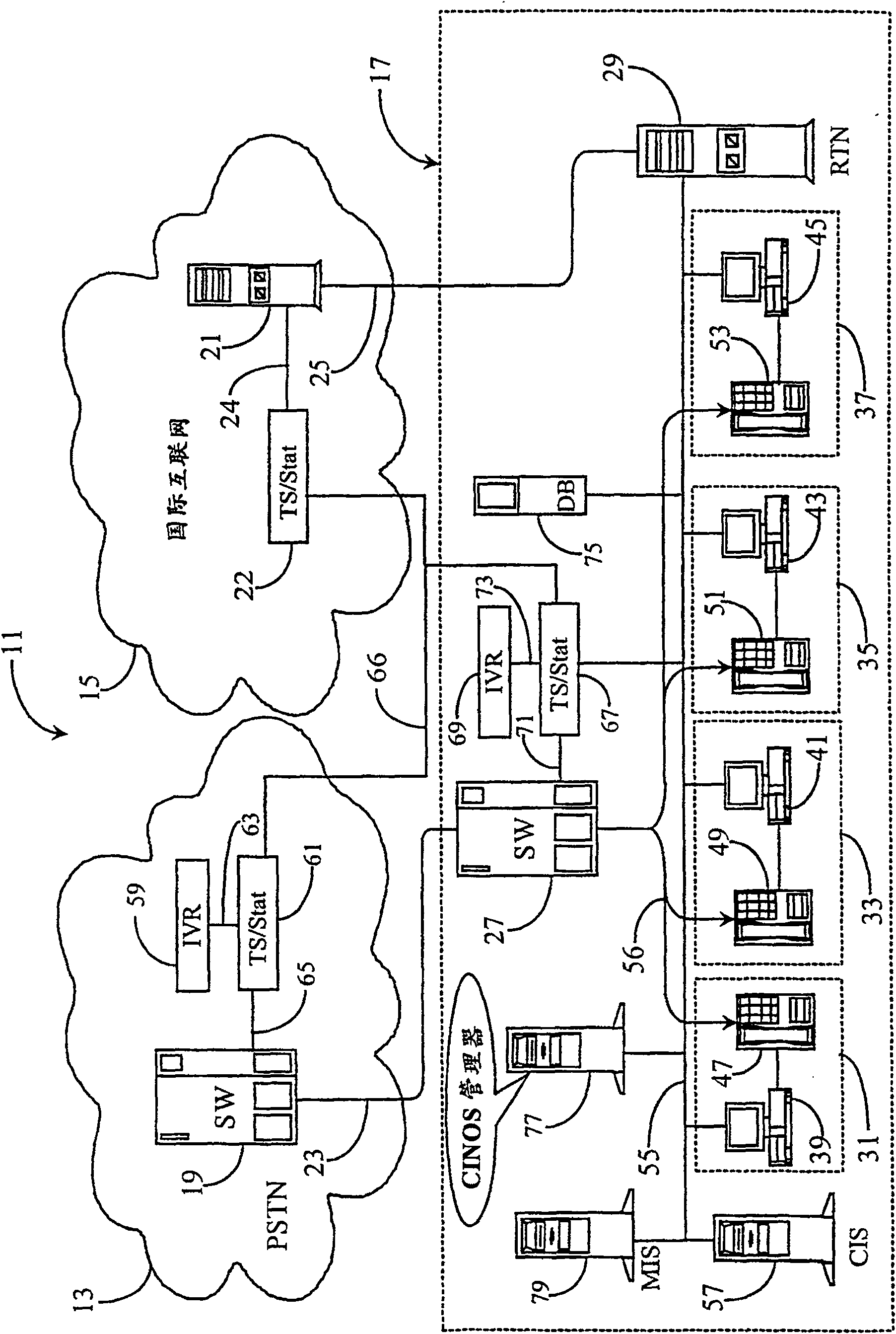

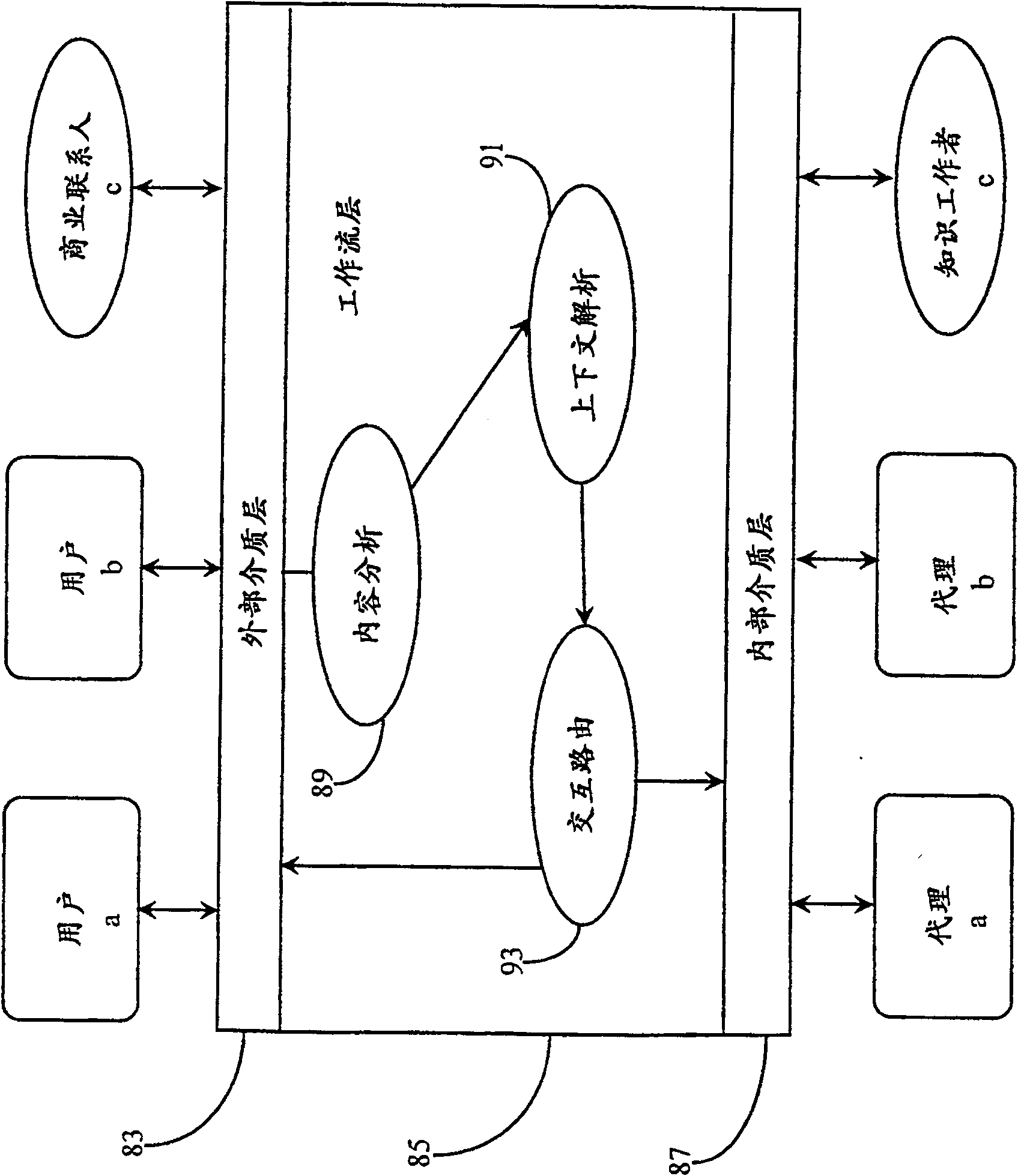

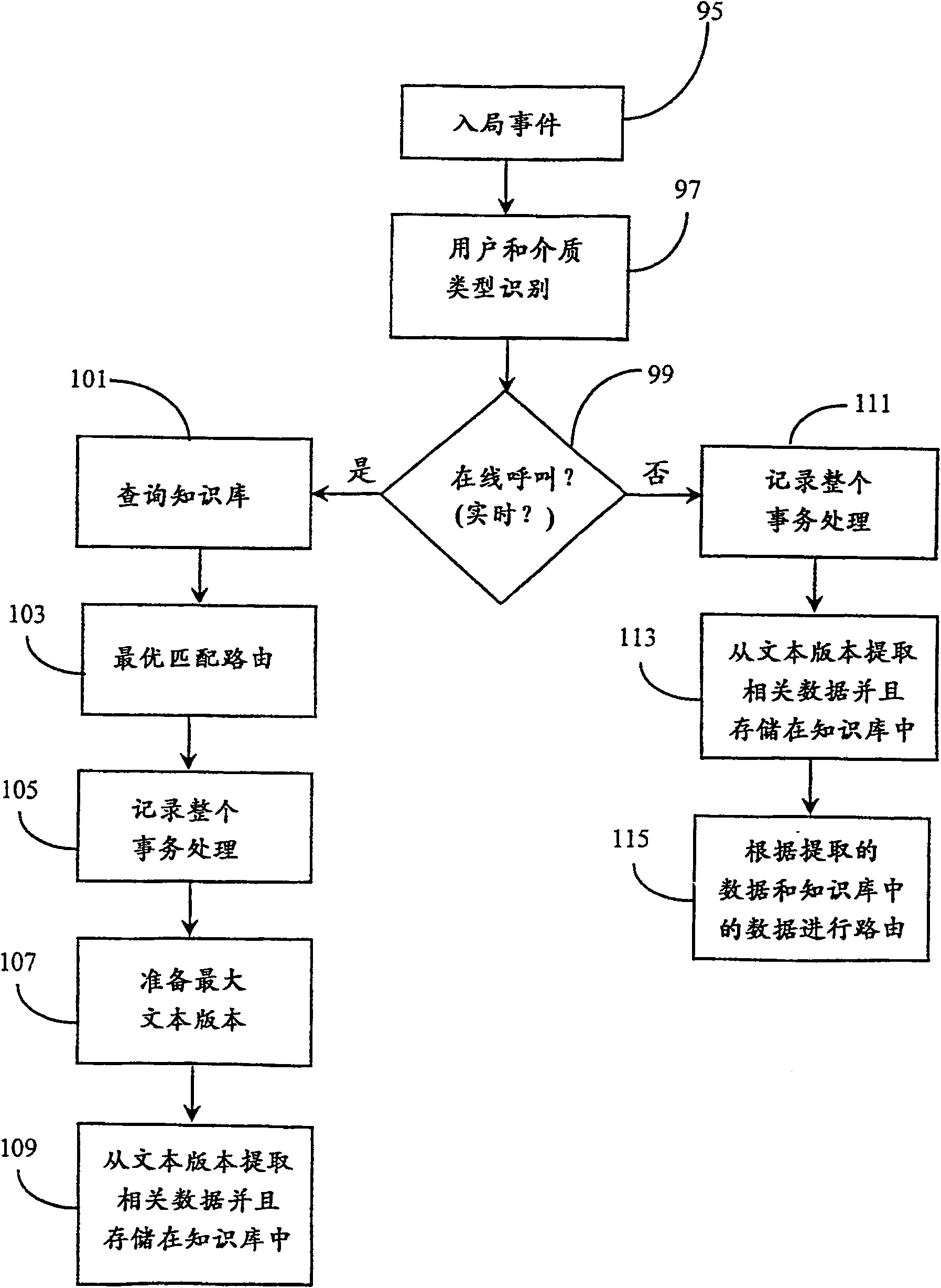

Method for managing interaction between partner for processing transaction

InactiveCN100547568CPromote interactionSpecial service for subscribersMultiprogramming arrangementsNetwork operating systemWorkflow

A multimedia call center includes facility for storing copies of transactions associated with the call center in a data repository, relating the transactions according to specific criteria, and an interactive interface for a user to access the files from a graphic string of identifiers representing the files, and to play the files, thereby reviewing the actual transactions. In a preferred embodiment text versions of non-text events may be prepared and related to the non-text stored files in a manner that the related text files may also be selected and reviewed by use of the same interactive interface. By data extraction applied to the text files, the text files and the non-text files associated with some text files may be related to one another by relational criteria, and other informational files may also be related to the stored event files.

Owner:GENESYS TELECOMMUNICATIONS LABORATORIES INC

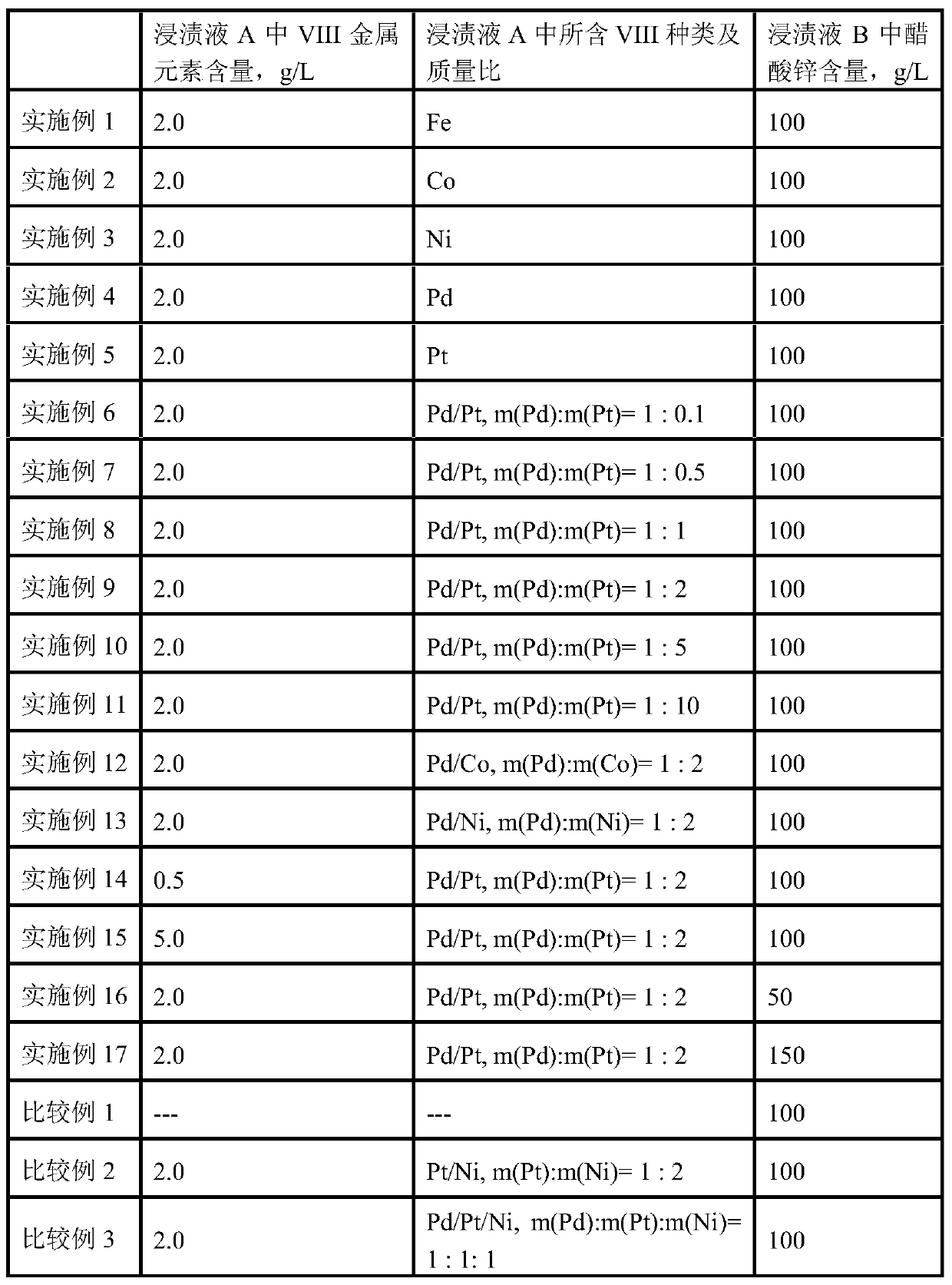

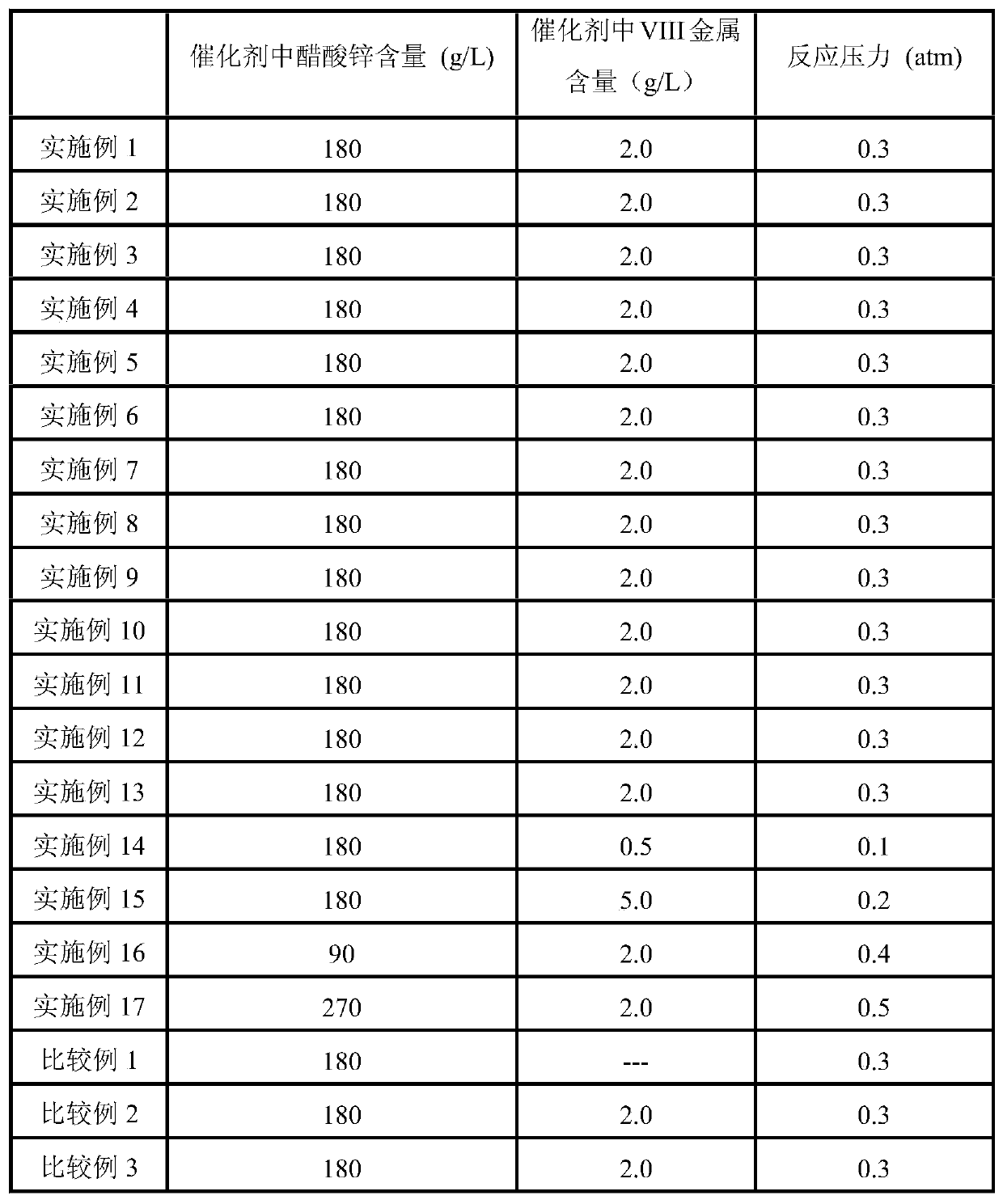

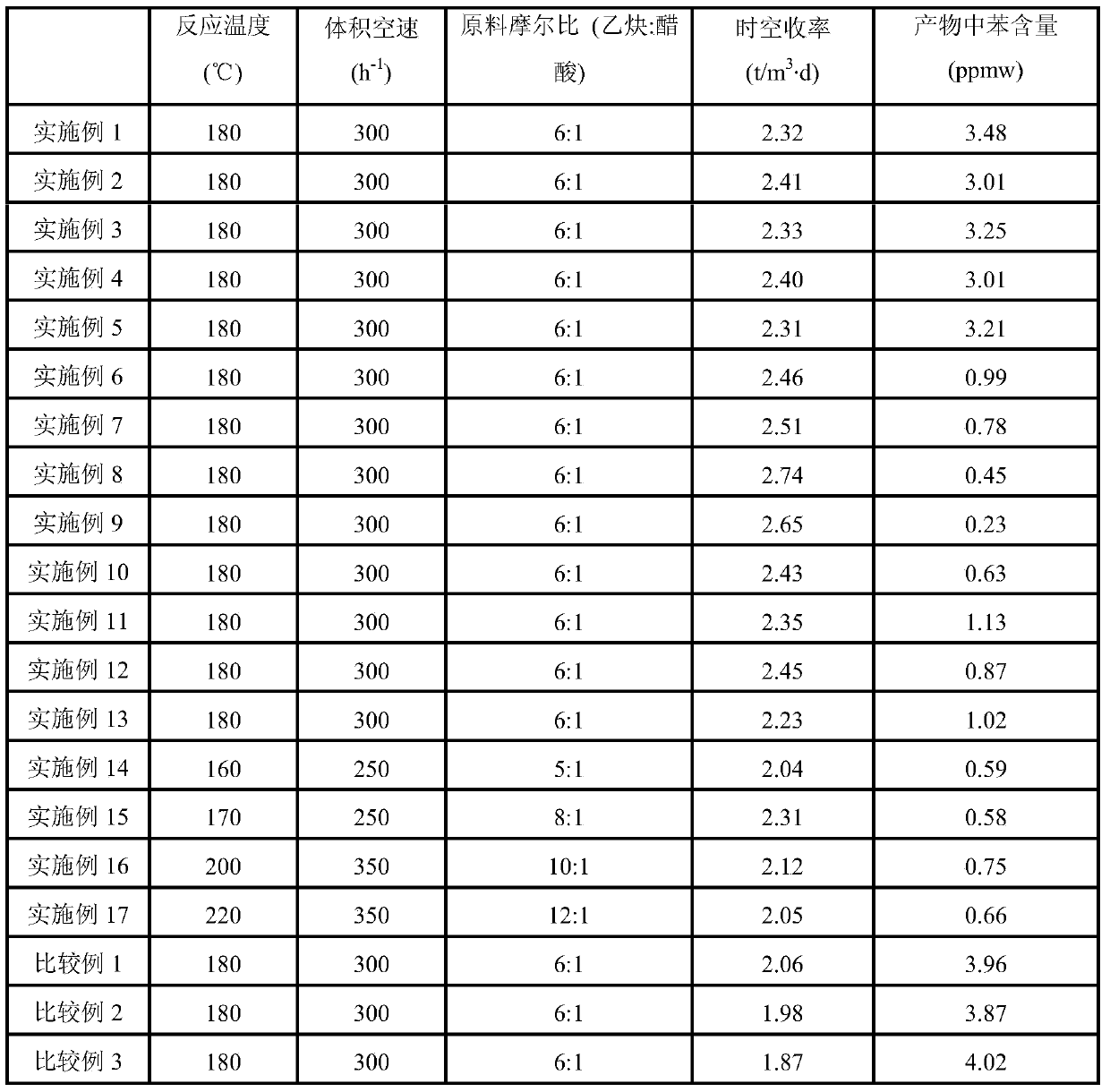

Acetylene process vinyl acetate catalyst

ActiveCN105498778APromote interactionHigh selectivityOrganic compound preparationCarboxylic acid esters preparationZinc Acetate DihydrateChemistry

The invention relates to a catalyst for acetylene process vinyl acetate synthesis and a preparation method thereof, and mainly solves the problem of high content of byproduct benzene in a vinyl acetate product in the prior art. According to a technical scheme, the catalyst for acetylene process vinyl acetate synthesis comprises an active component and a carrier, the active component is zinc acetate, and the carrier is activated carbon modified by VIII group metals. The catalyst well solves the problem, and can be used in the industrial production of acetylene process vinyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN106179462APromote interactionImprove performanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveEngineering

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst is a bulk phase hydrocracking catalyst and comprises hydrogenation active metal components W and Ni, alumina, silicon oxide and molecular sieve, wherein a ratio of the weight content of the surface phase active metal component WO3 to the weight content of the bulk phase active metal component WO3 is 1.2:1-6.0:1, and a ratio of the weight content of the surface phase active metal component NiO to the weight content of the bulk phase active metal component NiO is 1.2:1-5.0:1. The catalyst is especially suitable for a single-stage hydrocracking technology, and has the advantages of high liquid yield and good product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfuration type hydrocracking catalyst and preparation method thereof

ActiveCN106179467APromote interactionImprove performanceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSulfidation

The invention discloses a sulfuration type hydrocracking catalyst and a preparation method thereof. The catalyst is a bulk phase hydrocracking catalyst and comprises sulfides of hydrogenation active metal components W and Ni, aluminum oxide, silicon oxide and molecular sieves, wherein ratio of the weight content of the sulfide of a surface phase active metal component W (by WS2 ) to that of the sulfide of a body phase active metal component W is (2.0 to 1) to (7.0 to 1), and the ratio of the weight content of the sulfide of a surface phase active metal component Ni (by NiS ) to that of the sulfide of a body phase active metal component Ni is (1.5 to 1) to (5.5 to 1). The catalyst is particularly suitable for being used in single-segment hydrocracking technological processes, and has the advantages of being high in liquid yield, good in product quality and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

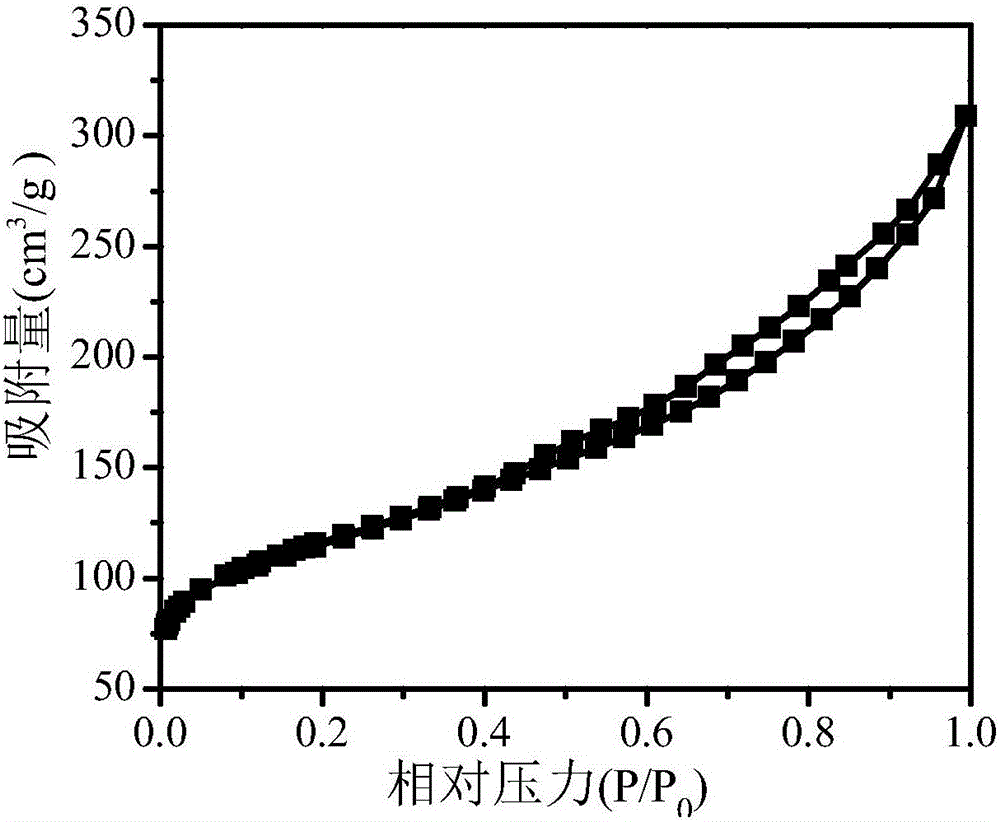

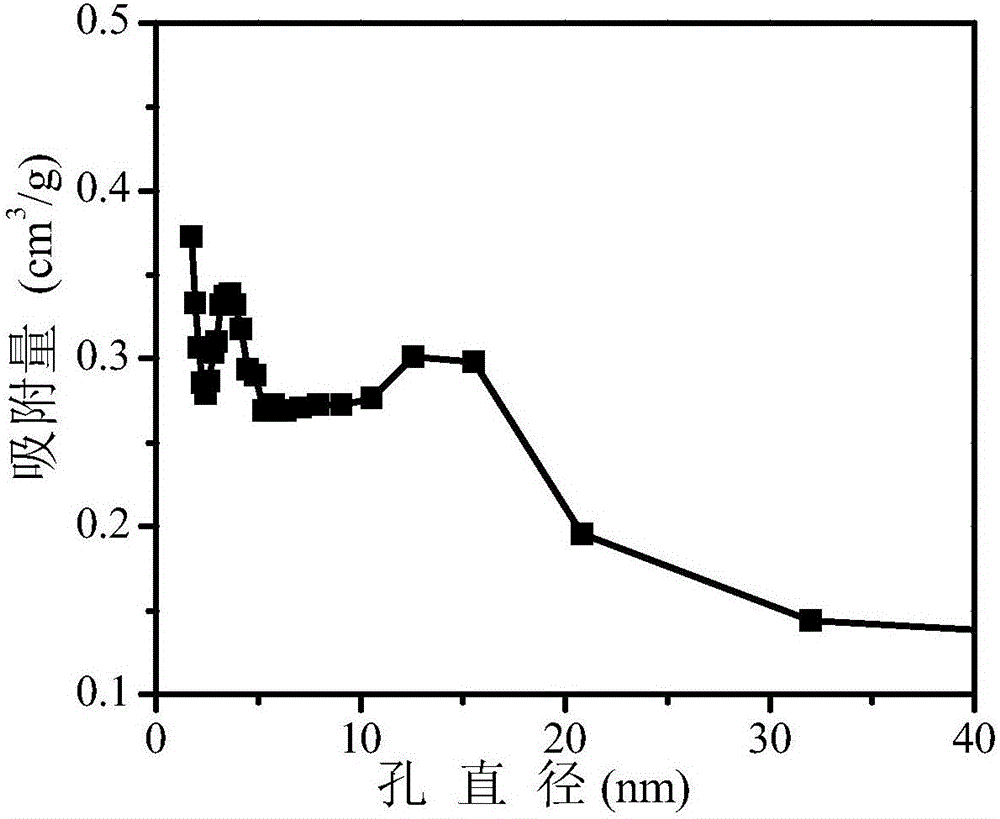

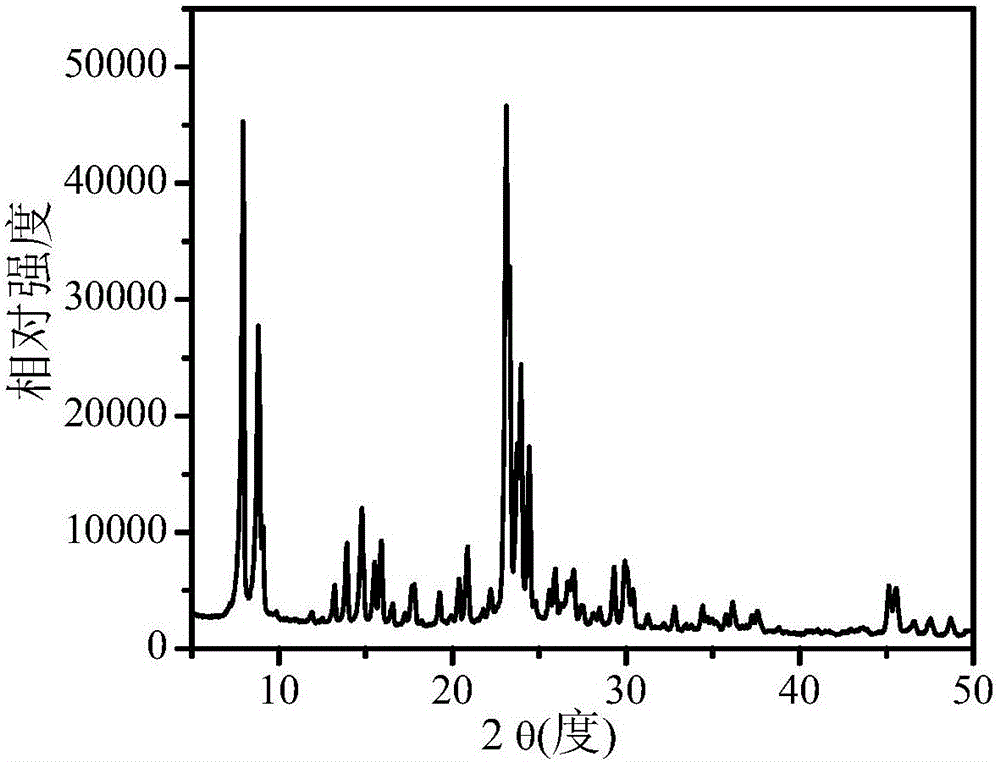

Synthesis of porous ZSM-5 zeolite and gamma-Al2O3 composite material and preparation of hydrodesulfurization catalyst

ActiveCN106391097AAvoid reunionPromote interactionMolecular sieve catalystsHydrocarbon oils refiningChemistryActive phase

The invention discloses synthesis of a porous ZSM-5 zeolite and gamma-Al2O3 composite material and preparation of a hydrodesulfurization catalyst and relates to the technical field of composite materials and the field of hydrodesulfurization catalysts. The composite material is roasted for 3-8 h at the temperature of 450-600 DEG C, and has the following properties that the content of porous ZSM-5 zeolite is 5-95 wt.%, the content of gamma-Al2O3 is 5-95 wt.%, the specific surface area is 400-600 m<2>.g1, the mesopore volume is 0.40-0.85 cm<3>.g1, and the micropore volume is 0.06-0.15 cm<3>. g1. The composite material has multiple stages of porous structures, good hydrothermal stability, high mechanical strength and weak interaction with loaded metal species, changes the existence state of the metal species and promotes reducing and vulcanizing of the metal species, multiple layers of high-activity molybdenum sulfide or tungsten sulfide active phases are easily formed on the composite material, and the hydrodesulfurization performance of the metal sulfide catalyst is improved.

Owner:CHANGZHOU UNIV

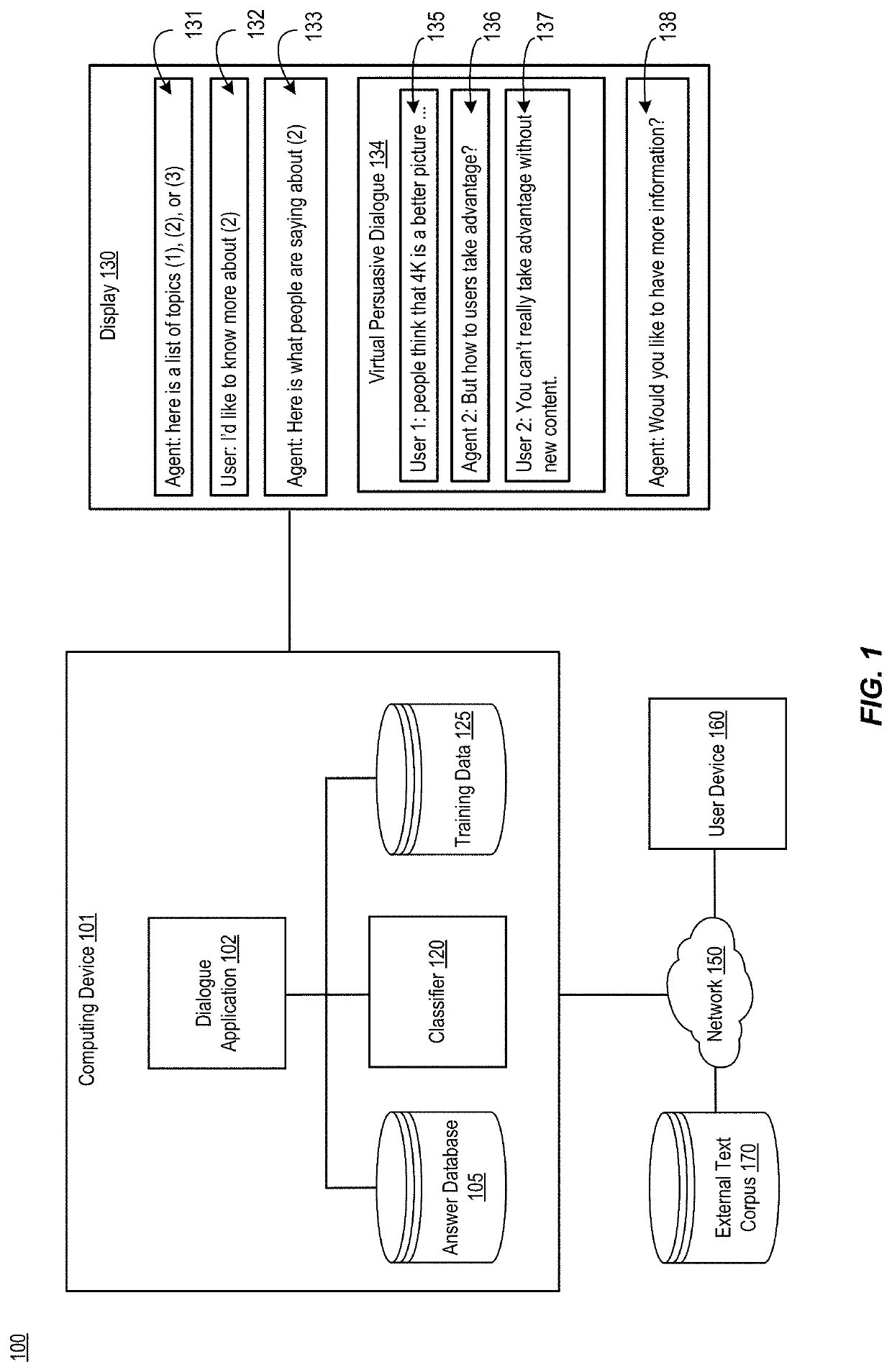

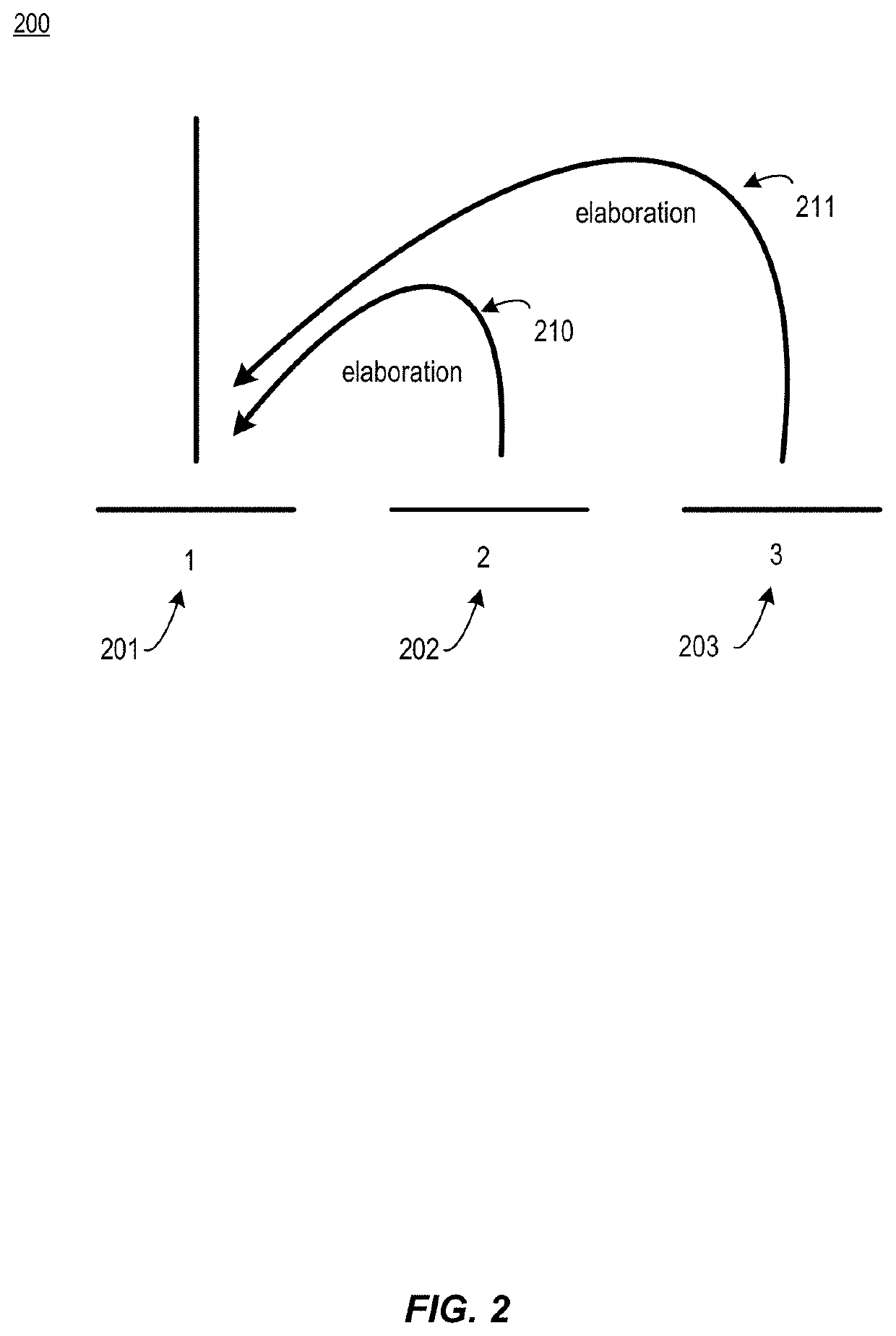

Using communicative discourse trees to create a virtual persuasive dialogue

ActiveUS20200286463A1Promote interactionSpecial data processing applicationsSpeech synthesisData scienceUtterance

Techniques are disclosed for generating a virtual persuasive dialogue. In an example, a dialogue application receives a selection of a topic from a user device. The application identifies document results that are associated with the topic. Using communicative discourse trees, the application identifies document results that include argumentation, transforms these document results into a dialogue form, and presents the results to a user device as a virtual persuasive dialogue.

Owner:ORACLE INT CORP

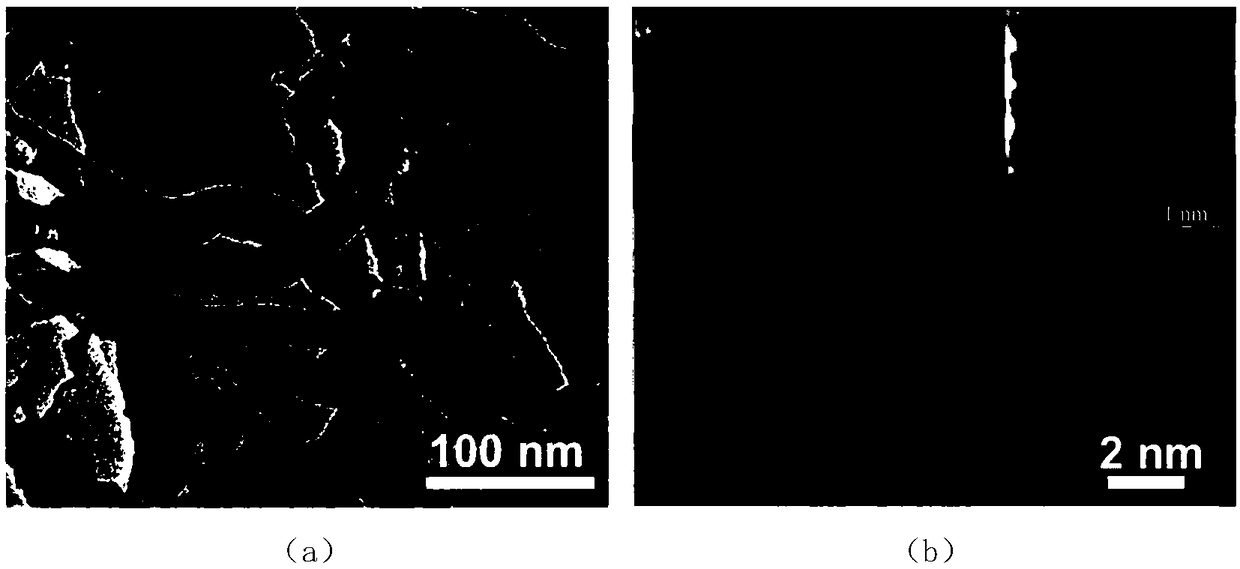

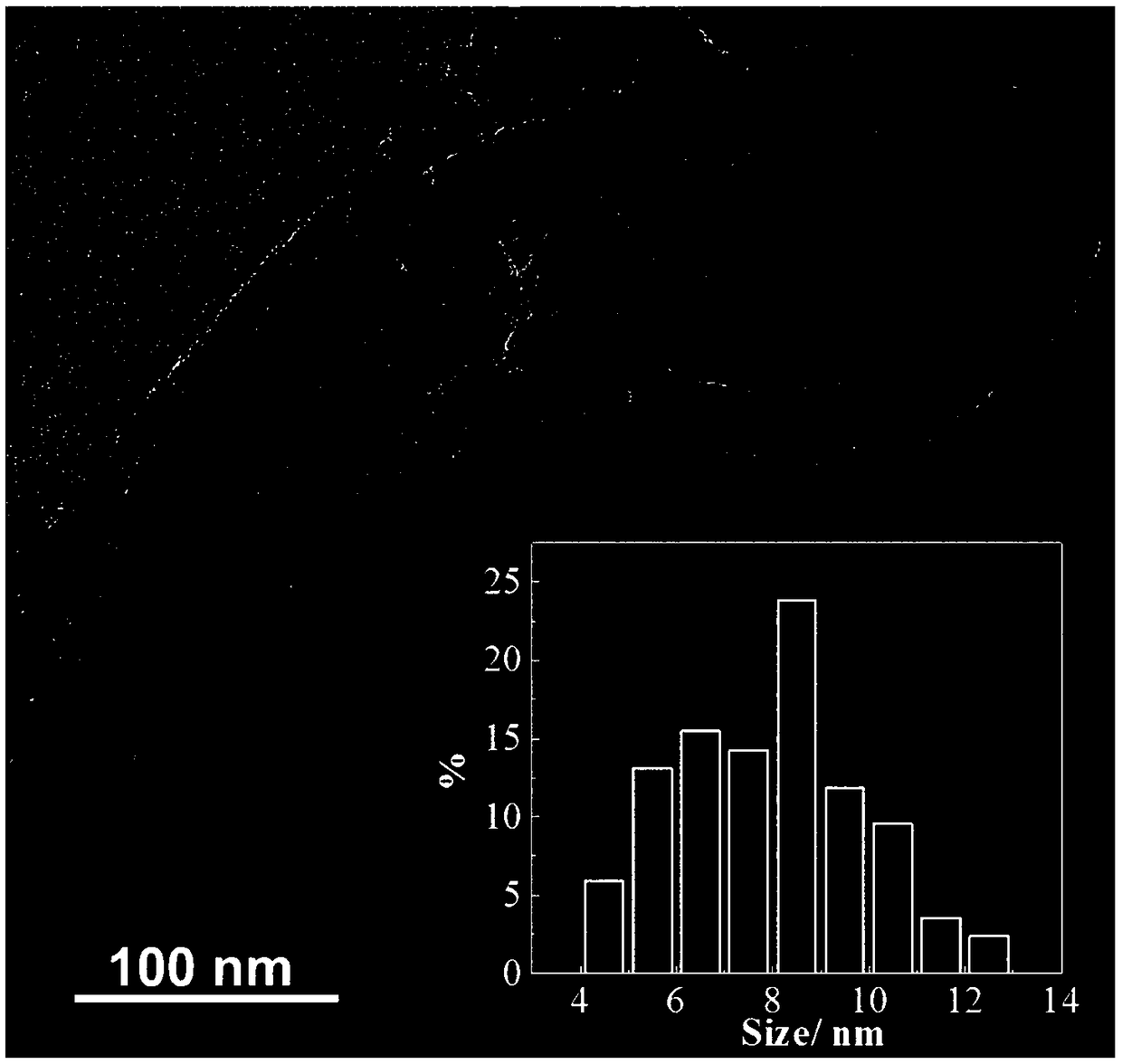

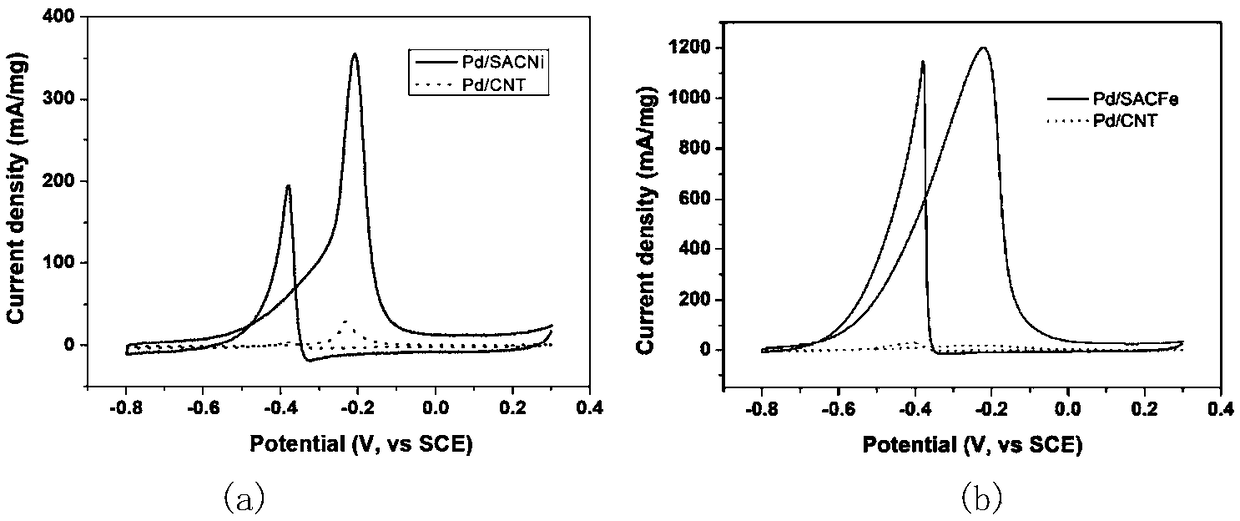

A highly active electrocatalyst for polymer electrolyte membrane fuel cell and a preparation method thereof

InactiveCN109148905APromote interactionImprove stabilityMaterial nanotechnologyCell electrodesChemistryCarbon nanotube

The invention discloses a high-activity electrocatalyst for polymer electrolyte membrane fuel cell and a preparation method thereof. The catalyst comprises a transition metal element monoatomically dispersed carbon nanotube material as a carrier and an active noble metal component supported on the carrier. The preparation method of the catalyst is as follows: A transition metal organometallic saltand dicyandiamide are ground and mixed, heat treatment in an inert atmosphere, A transition metal monoatomic dispersed carbon nanotube is obtained, the carbon nanotube carrier is dispersed in ethylene glycol, salts or acids containing noble metal elements are added into the carbon nanotube carrier, the noble metal catalyst supported on the transition metal monoatomic dispersed carbon nanotube isobtained after the transition metal monoatomic dispersed carbon nanotube carrier is uniformly dispersed by ultrasonic wave, ascorbic acid is added as an assisting reducing agent, and the transition metal monoatomic dispersed carbon nanotube is reduced by stirring. The catalyst of the invention exhibits superior electrocatalytic activity for small molecular alcohol species and oxygen reduction, andis a polymer electrolyte membrane fuel cell electrocatalytic material with wide application prospect.

Owner:北京海得利兹新技术有限公司

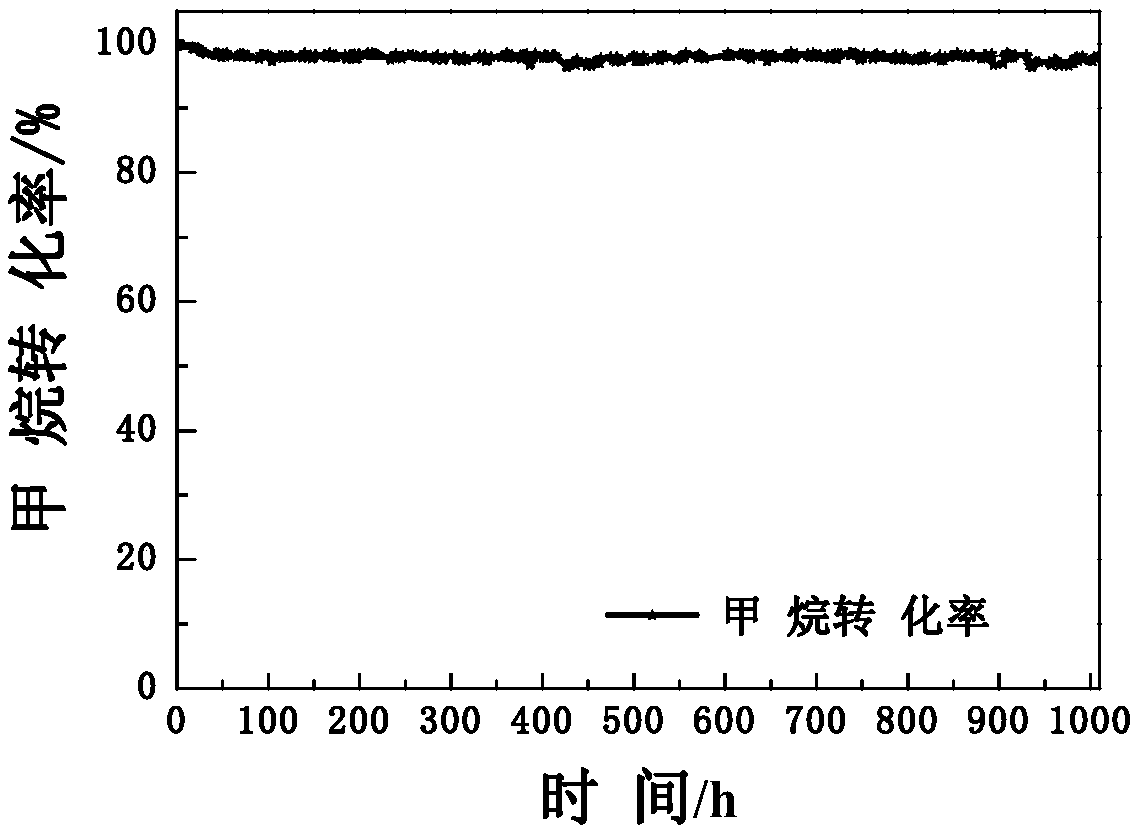

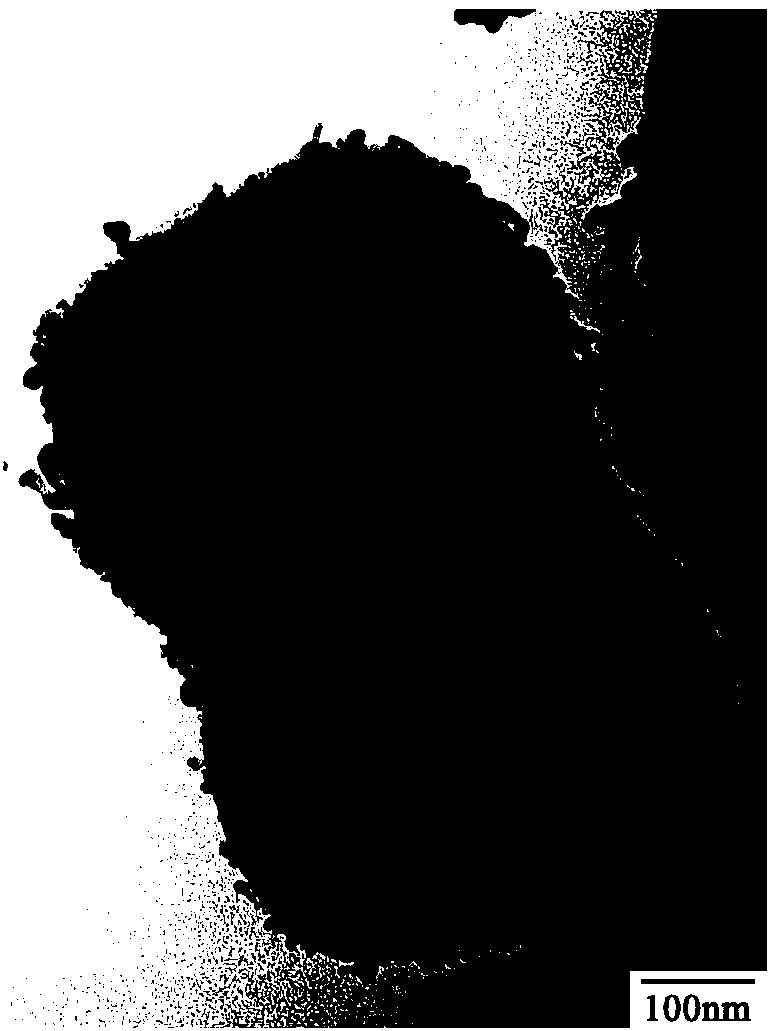

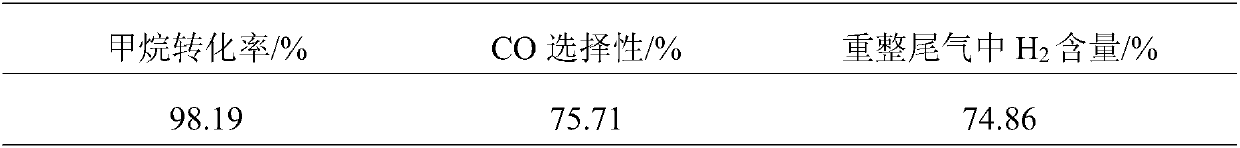

Preparation and application of catalyst with molecular sieve as carrier for hydrogen production by methane vapor reforming

InactiveCN107597171AGood stabilityPromote interactionHydrogenMolecular sieve catalystsMolecular sieveHydrothermal synthesis

The invention belongs to the technical field of catalyzation, and particularly relates to the preparation and application of a catalyst with molecular sieve as a carrier for hydrogen production by methane vapor reforming. The catalyst consists of an active component, an additive and the carrier; one or two metal oxide of iron, cobalt and nickel is chosen as the active component, one or two metal oxide of zirconium and cerium is chosen as the additive, and a nanoscale pure-silica molecular sieve prepared by a hydrothermal synthesis method is chosen as the carrier. The catalyst with the molecular sieve as the carrier for hydrogen production by methane vapor reforming provided by the invention has high activity and good stability on reaction for hydrogen production by catalytic reforming of methane vapor under high temperature, moreover, a catalyst preparation method is simple, and the catalyst can be industrially mass-produced.

Owner:DALIAN UNIVERSITY

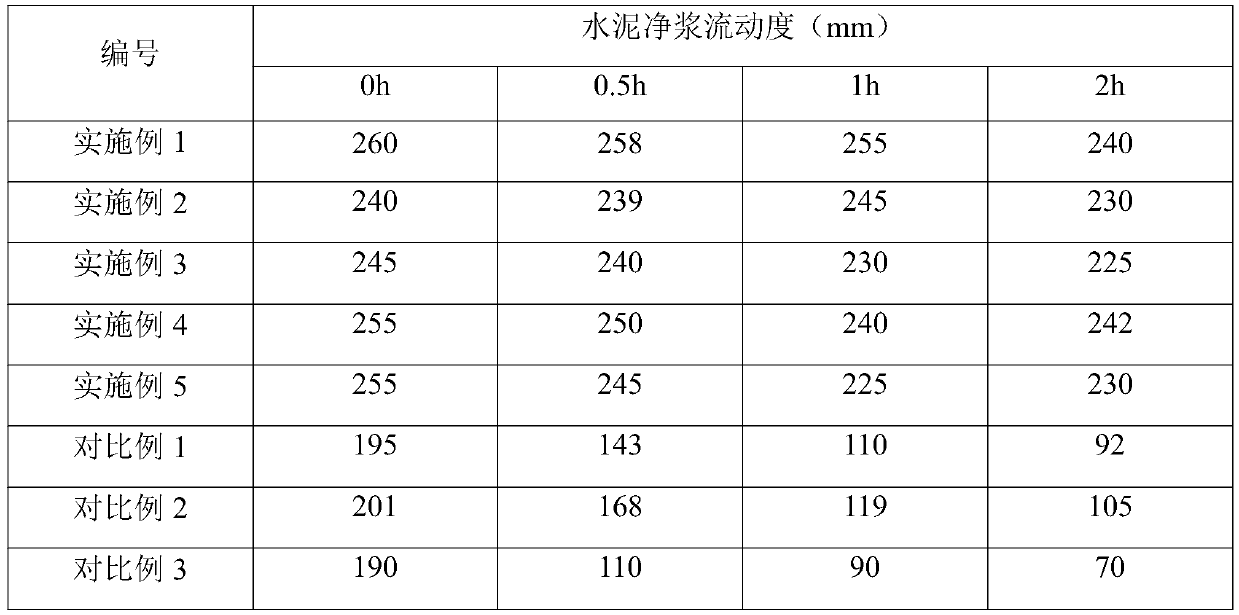

Polycarboxylate water reducer composition for self-compaction high-workability concrete

The invention discloses a polycarboxylate water reducer composition for self-compaction high-workability concrete. The polycarboxylate water reducer composition is composed of the following components: allyl alcohol polyoxyethylene ether, an unsaturated acid, functional monomers, an oxidizing agent, a reducing agent and a chain transfer agent, wherein the unsaturated acid consists of citric acid,acetic anhydride, acrylic acid and methacrylic acid according to a mass ratio of (1-3):(1-2):(2-3):(5-10), and the functional monomers are nano-diatomaceous earth and sulfonated melamine formaldehyderesin. According to the invention, the water reducer is synthesized by the allyl alcohol polyoxyethylene ether and the unsaturated acid, so that mixing performance of concrete can be improved, meanwhile, steel bars can be prevented from rusting, and the service life of the concrete is prolonged. Mutual reactions between cementing materials can be promoted through the functional monomers, and workability of the concrete is enhanced.

Owner:武汉优城科技有限公司

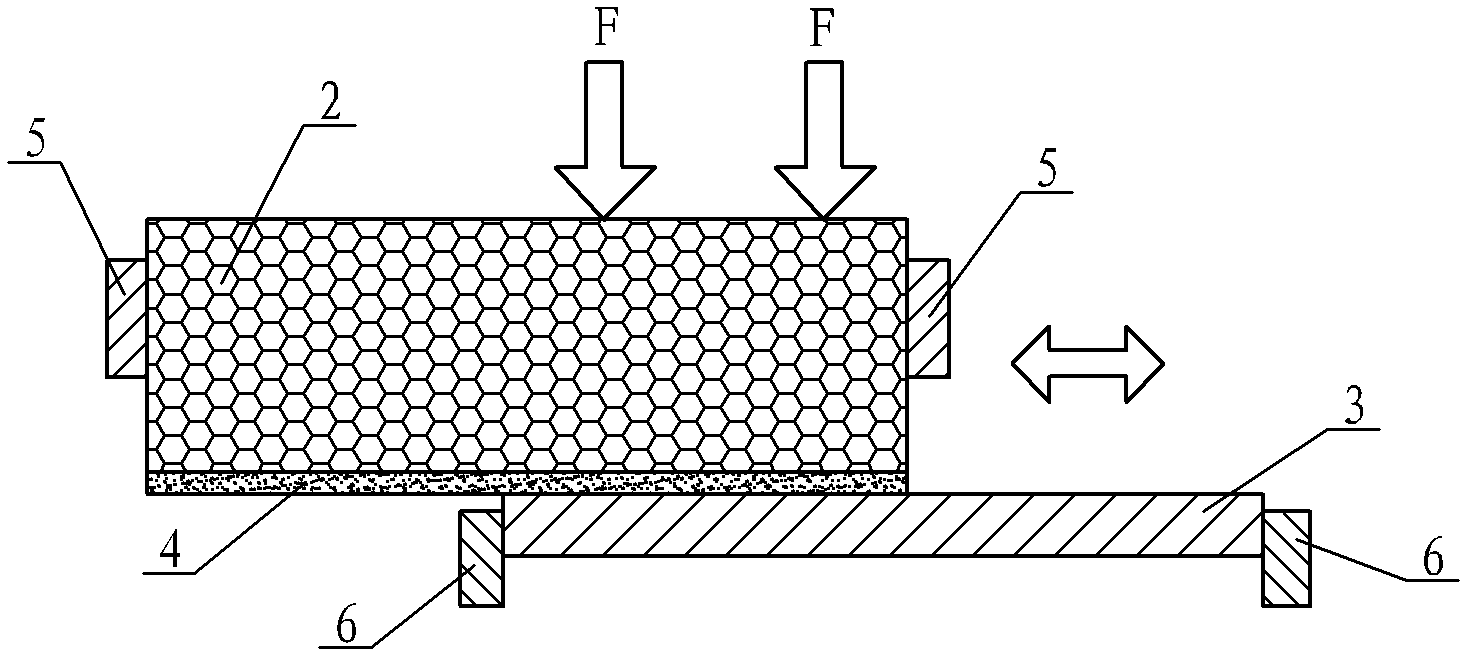

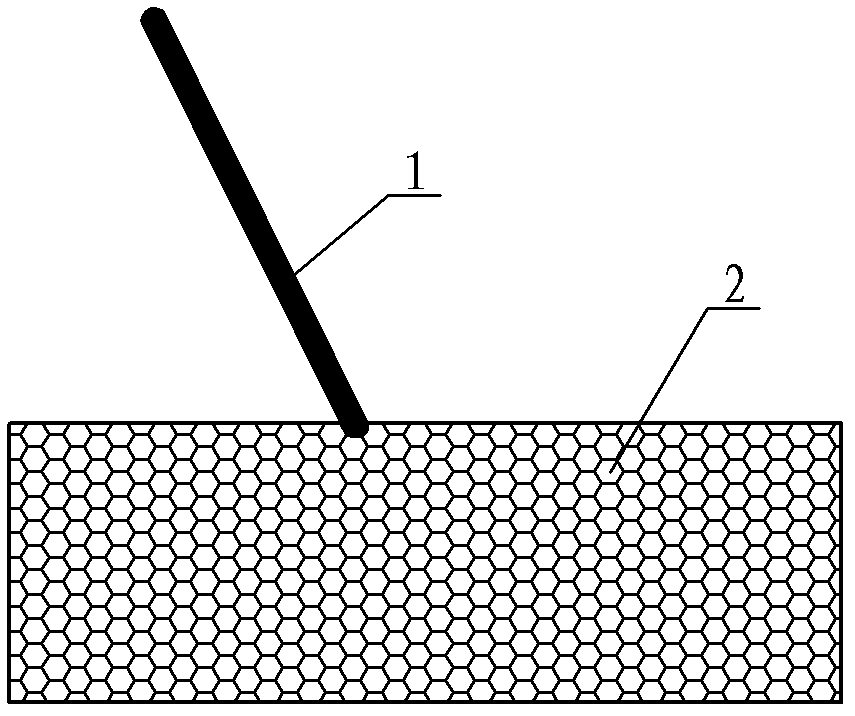

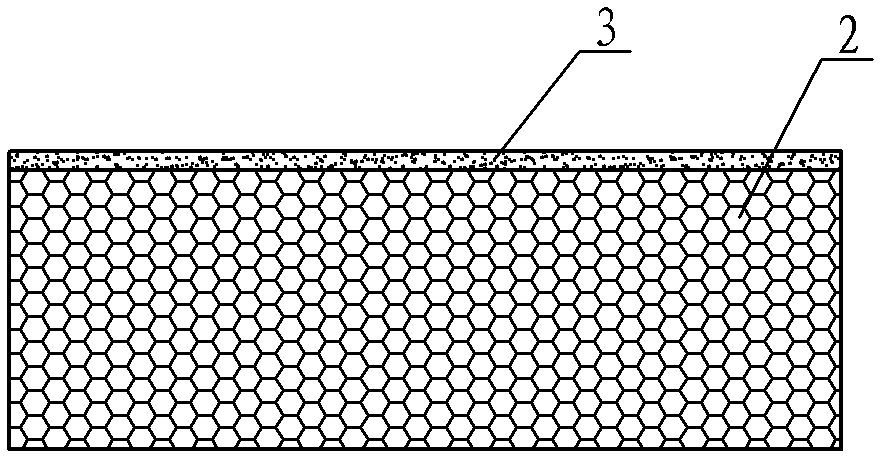

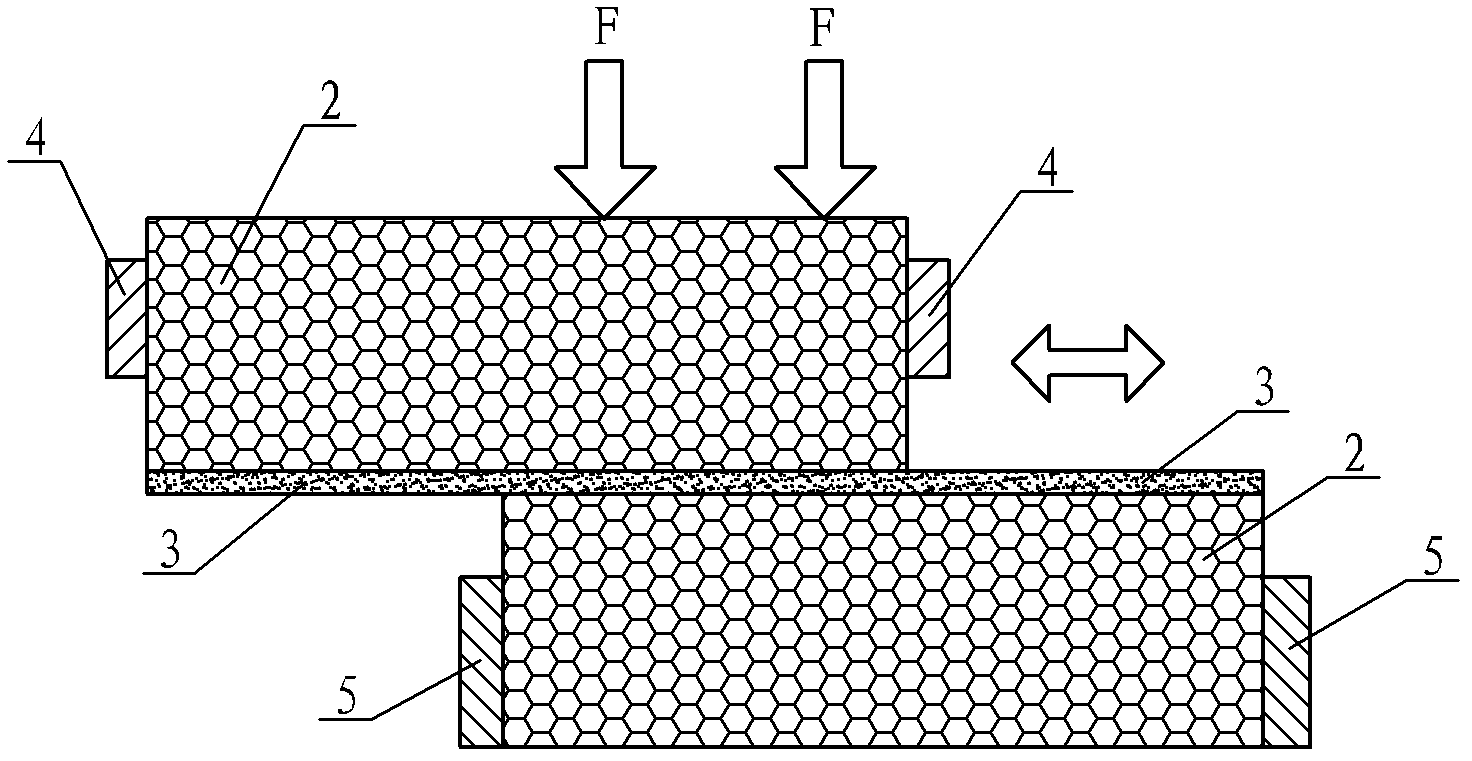

Method for brazing foamed aluminum plate and aluminum plate by removing interfacial oxide films through bubble wall friction

InactiveCN102581415APromote wettingEasy to spreadSoldering apparatusWelding/soldering/cutting articlesInterfacial oxideUltimate tensile strength

A method for brazing a foamed aluminum plate and an aluminum plate by removing interfacial oxide films through bubble wall friction relates to a welding method in the field of brazing, and solves the problem that an existing foamed aluminum plate and an existing aluminum plate are low in joint strength as the existing foamed aluminum plate and the existing aluminum plate are directly brazed, brazing filler metal is non-wetted and oxide films are difficult to remove. The method includes the steps: firstly, cleaning and drying the foamed aluminum plate and the compact aluminum plate; secondly, heating the foamed aluminum plate, sliding rod-like brazing filler metal on a surface to be welded of the foamed aluminum plate in a reciprocating manner, and coating the brazing filler metal on the surface of the foamed aluminum plate to be welded; thirdly, butting end surfaces to be welded of the foamed aluminum plate and the compact aluminum plate, and heating butt joint surfaces to melt the brazing filler metal on the butt joint surfaces; fourthly, sliding the foamed aluminum plate on an interface to be welded in a reciprocating manner for 5-15 times, and exerting pressure in a direction perpendicular to the surface to be welded; and fifthly, stopping sliding friction, exerting pressure again, cooling the plates after heat preservation, and connecting brazing interfaces of the foamed aluminum plate and the compact aluminum plate. The method is used for welding the foamed aluminum plate and the aluminum plate.

Owner:HARBIN INST OF TECH

Method for removing oxidation film and brazing foamed aluminum through self-friction of foam walls

InactiveCN102601475AGive full play to the advantages of light weightPromote fragmentationSoldering apparatusNon wettingMolten state

The invention discloses a method for removing an oxidation film and brazing foamed aluminum through self-friction of foam walls, which relates to a welding method in the brazing field and solves the problem that the joint strength is reduced as brazing filler metal is non-wetting and the oxidation film is removed difficultly in the brazing process of the foamed aluminum. The method for removing the oxidation film and brazing the foamed aluminum comprises the following steps that: 1. two foamed aluminum plates are heated, and the rodlike brazing filler metal can slide on to-be-welded surfaces of the two foamed aluminum plates in a reciprocating way respectively, so that the brazing filler metal can be coated on the to-be-welded surfaces; 2. the end surfaces of the two foamed aluminum plates, which are coated with the brazing filler metal, are butted, and the brazing filler metal on the contact surfaces of the two foamed aluminum plates can be in a molten state after heating; 3. the foamed aluminum plates clamped by slidable fixtures can slide at the to-be-welded interfaces in a reciprocating way, and the pressure is exerted in the direction vertical to the welding surfaces at the same time; and 4. the sliding of the foamed aluminum plates can be stopped, the to-be-welded surfaces of the two foamed aluminum plates are aligned with each other and are pressurized again, heat preservation is carried out on the to-be-welded surfaces of the two foamed aluminum plates for 1-3 minutes, and then the to-be-welded surfaces of the two foamed aluminum plates can be cooled naturally to the room temperature, so as to realize a metallurgical-bonding brazing interface between the two foamed aluminum plates. The method for removing the oxidation film and brazing the foamed aluminum can be used for welding the foamed aluminum.

Owner:HARBIN INST OF TECH

Preparation method of compound containing mulberry anthocyan

The invention discloses a preparation method of a compound containing mulberry anthocyan. The preparation method comprises the following steps of mixing partly-acylate konjac glucomannan with the mulberry anthocyan in a certain proportion to obtain a mulberry anthocyan compound product, wherein in the mulberry anthocyan compound product, the weight ratio of the partly-acylate konjac glucomannan tothe mulberry anthocyan is (20 to 1) to (400 to 1). According to the preparation method of the compound containing mulberry anthocyan, fade of the mulberry anthocyan caused by being too hot is effectively restrained, and the stability of the mulberry anthocyan is greatly improved; and color of the compound containing mulberry anthocyan is enriched and increased, and the preparation method has excellent application value. The preparation method is simple and convenient, easy to operate, safe, and environmental-friendly, and realization of industrial enlarged application is facilitated.

Owner:SHANGHAI JIAO TONG UNIV

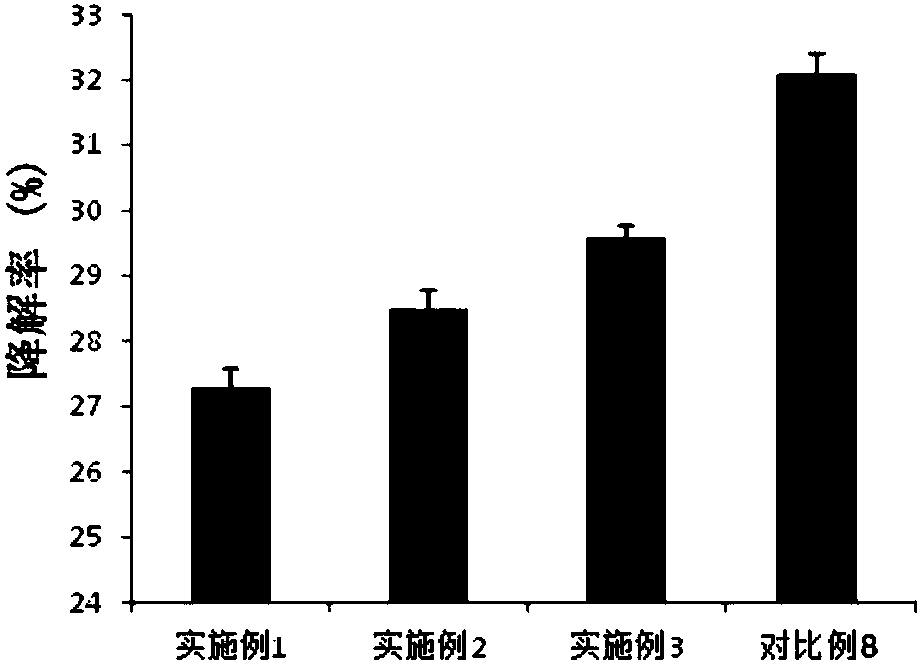

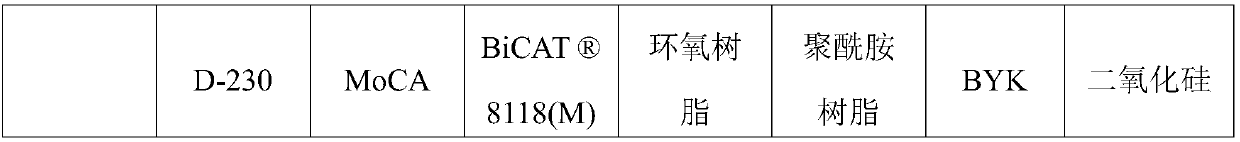

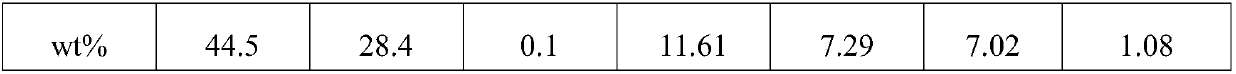

Preparation method of anti-corrosive polyurea elastomer coating

InactiveCN107936802AImprove uniformityHigh reactivityAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerDiluent

The invention relates to the technical field of polyurea coatings, and in particular relates to an anti-corrosive polyurea elastomer coating and a preparation method thereof. The anti-corrosive polyurea elastomer coating comprises a component A and a component B. The preparation method comprises the following steps: (1) carrying out vacuum dehydrating treatment on polyether glycol, carrying out reaction on dehydrated polyether glycol, diisocyanate and a diluent in an inert gas atmosphere for 2-4h at 40-95 DEG C, and cooling and discharging the mixture to obtain the component A; and (2) separately carrying out dehydration at a reduced pressure on terminal amino polyether and an amine chain extender in a reaction kettle, then adding a composite enhancing material and a catalyst, stirring themixture for 1-2h at 40-60 DEG C, carrying out ultrasonic treatment for 5-15min, and cooling and discharging the mixture to obtain the component B. By means of ultrasonic treatment, the uniformity andreacting activity of the components can be improved to promote interaction among the components, and the crosslinking degree of the composite enhancing material and the polyurea elastomer coating isimproved, so that the binding strength of the polyurea elastomer coating is improved.

Owner:长沙盾甲新材料科技有限公司

Preparation method of low-acid-value anti-degradation polyvinyl butyral

The invention discloses a preparation method of low-acid-value anti-degradation polyvinyl butyral. The preparation method comprises the following steps: using polyvinyl alcohol with an alcoholysis degree of 97.0-98.0% as a raw material, dissolving the polyvinyl alcohol by using dimethyl sulfone (DMSO), carrying out a reaction with butyraldehyde at a high temperature under the catalysis of an inorganic acid, distilling out the DMSO when the temperature is reduced to a proper temperature, carrying out diluting with deionized water until the concentration of the residual DMSO in the kettle is notmore than 10%, then adding absolute ethyl alcohol, continuing carrying out reflux for 0.5-1.5 hours, then distilling out all the ethyl alcohol, remaining the residues into a granulator, carrying outextrusion moulding, and placing the obtained material in a vacuum drying oven to obtain the product. The low-acid-value anti-degradation polyvinyl butyral provided by the invention has good transparency, acetalization degree, weather resistance, water resistance and corrosion resistance, simultaneously has good stripping performance and low acid value, and can accelerate improve the compatibilitywith other organic solvents such as acetone, toluene, benzene and the like. The product has stable quality, is not easy to degrade, and is suitable for industrial production of workshops.

Owner:营口天元高分子树脂有限公司

Storage method capable of quickening white liquor aging

InactiveCN107557258AEasy to storePlay a role in filtration and purificationAlcoholic beverage preparationPressure riseVacuum pumping

The invention discloses a storage method capable of quickening white liquor aging. The storage method is characterized by comprising the following steps: (1) filtering, distilling white liquor for a second time until alcoholic strength is greater than 52 degrees, and adding active carbon into liquor to perform ultrasonic oscillation; (2) performing low-temperature ionization, pouring filtered white liquor into a sealed ionization slot to perform low-temperature ionization; (3) performing negative-oxygen treatment, pouring ionized white liquor into the sealed tank, using a guide tube for introducing negative oxygen ions into the white liquor to aerate, and performing pressure-rising treatment; (4) performing variable-temperature storage, filling white liquor subjected to negative-oxygen treatment into a wine jar, and sealing the wine jar, separately regulating the temperatures of two storage rooms to 1-3 DEG C and 26-29 DEG C, and separately storing the sealed white liquor in a low-temperature room and a high-temperature room alliteratively; and (3) performing pool storage, i.e., using sticky mud to coat the wine jar until the wine jar is completely covered, repeatedly coating by 2-3 times, performing low-temperature drying, using a vacuum bag to downwards fill liquor from an upper jar hole, sealing, performing vacuum-pumping, and putting the wine jar into the bottom of a waterpool to perform pool storage.

Owner:ANHUI WANGJIABA WINE

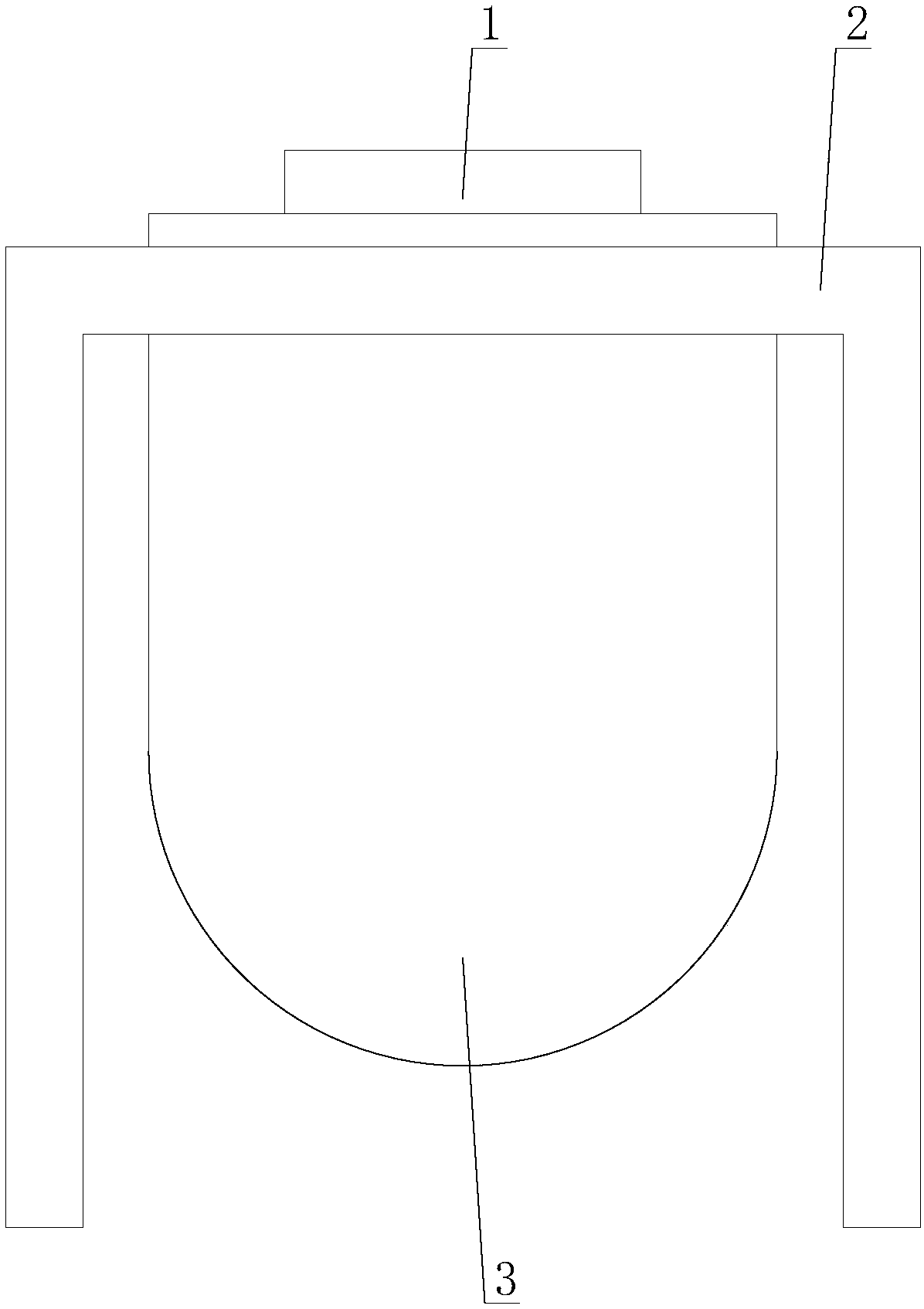

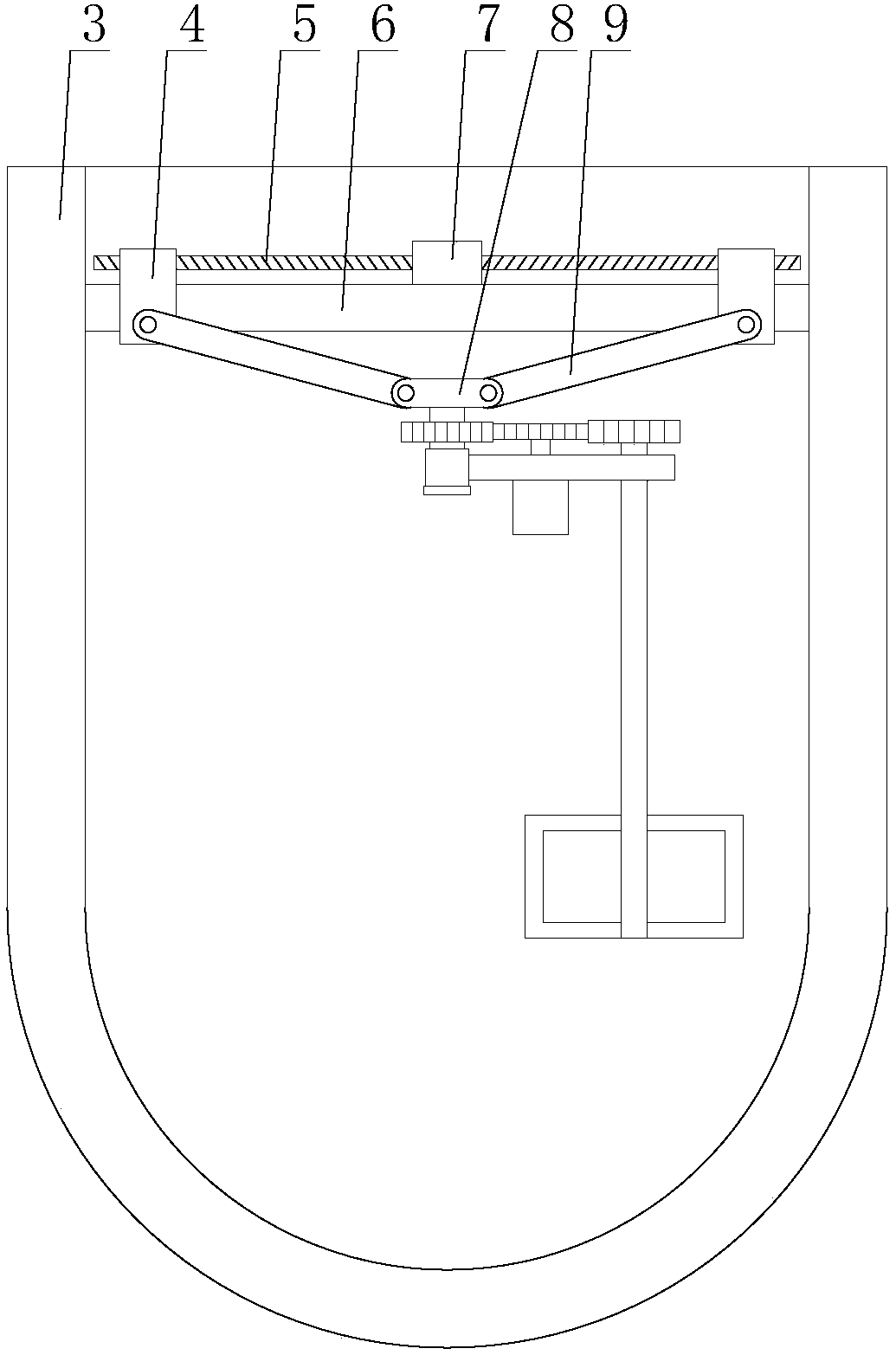

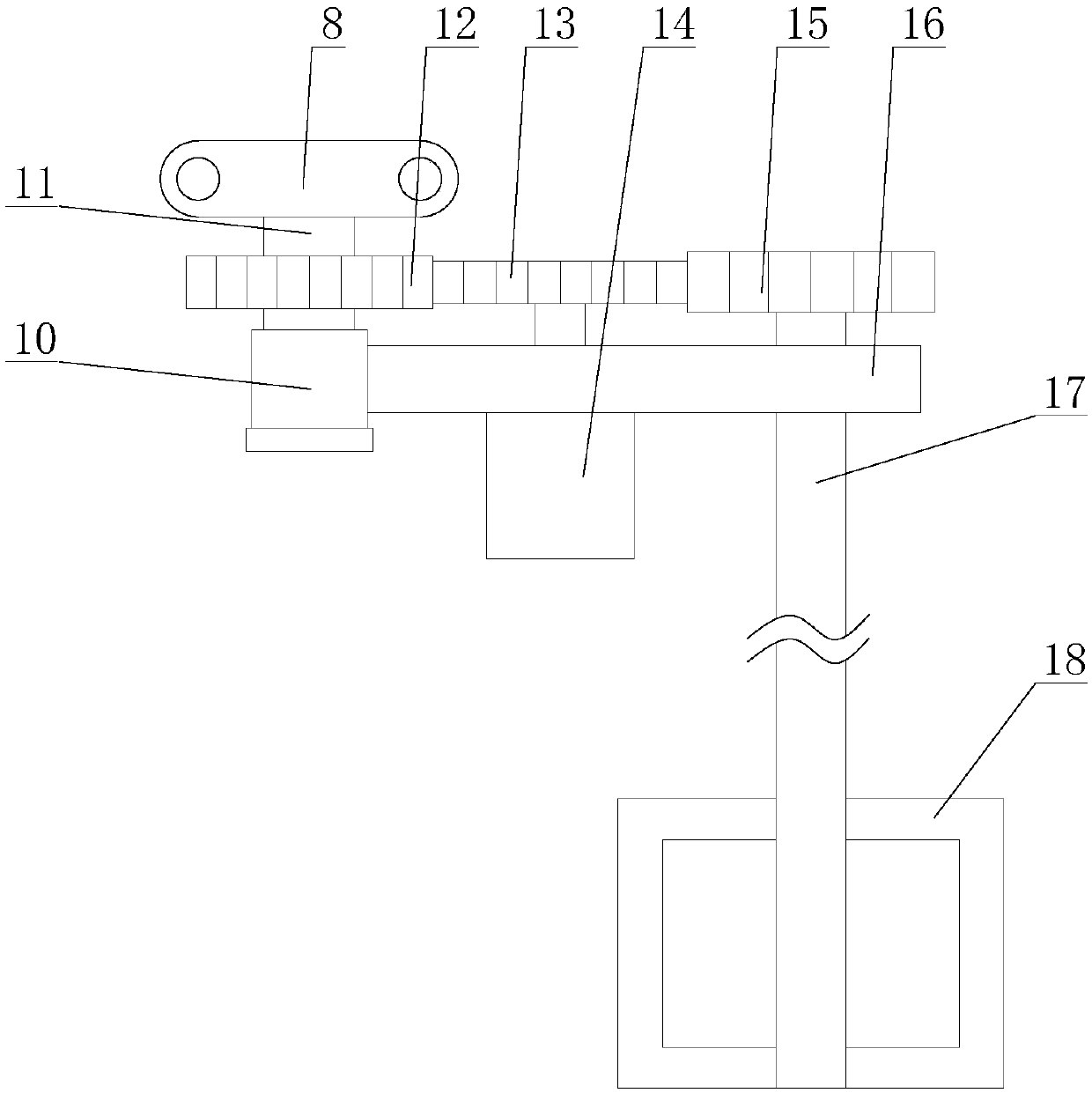

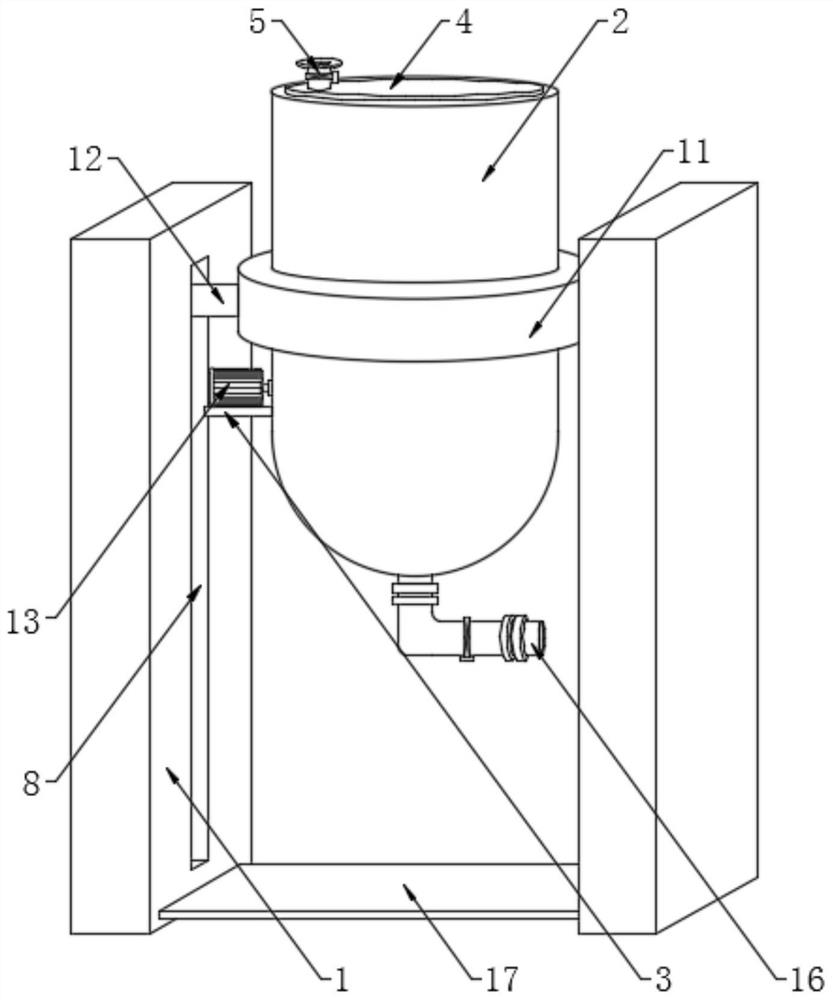

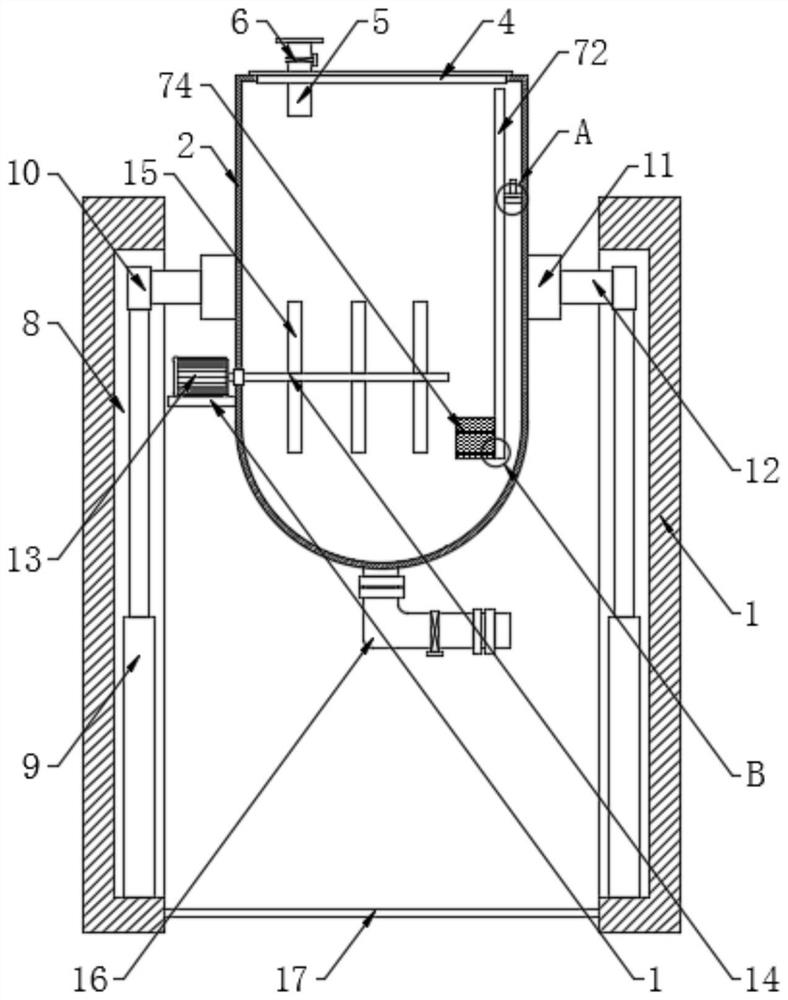

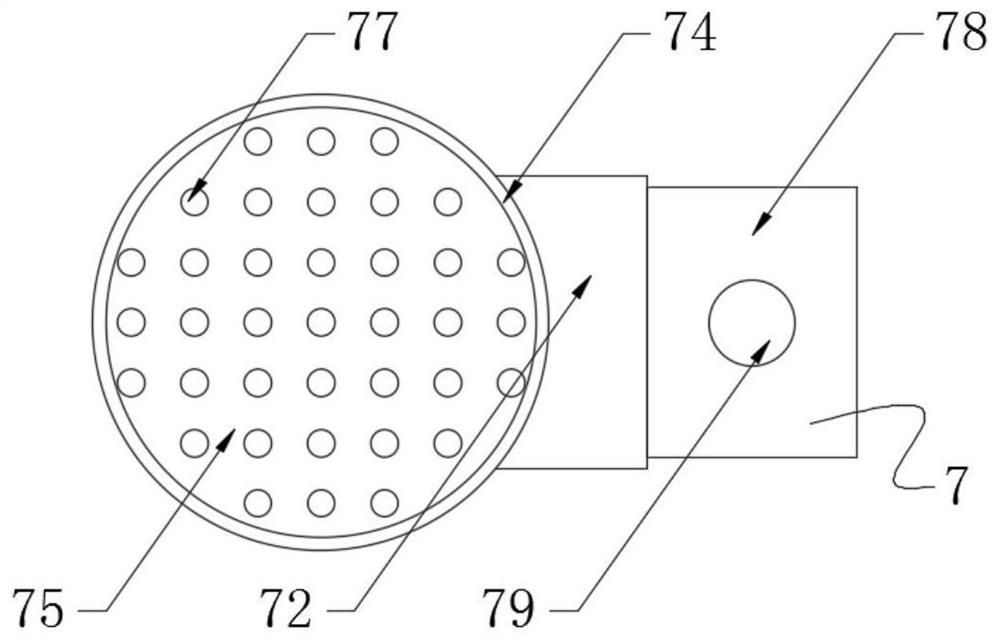

Efficient graphene production equipment on basis of internet of things

InactiveCN107827099AKeep the temperature constantExpand the mixing rangeGrapheneThe InternetEngineering

The invention relates to efficient graphene production equipment on the basis of an internet of things. The efficient graphene production equipment comprises a sealing cover, a support frame, a reaction kettle, a stirring mechanism and a temperature regulating mechanism. The stirring mechanism comprises a driving assembly, a stirring assembly, a first support rod, a second transmission rod, two first transmission rods and two first movable blocks, and the temperature regulating mechanism comprises a water pipe, a water tank, a rack, a movable assembly, a water outlet, a hot water opening, a cold water opening, a water pump and a sealing block. The efficient graphene production equipment on the basis of the internet of things has the advantages that stirring paddles can be driven by the stirring mechanism to ascend and descend, can rotate and can simultaneously move in the reaction kettle, the stirring ranges of the stirring paddles can be extended, accordingly, sufficient reaction canbe carried out on raw materials in the reaction kettle, and the output of the efficient graphene production equipment can be increased; the temperature of the reaction kettle can be regulated by the temperature regulating mechanism to rise and drop and further can keep constant by the temperature regulating mechanism, accordingly, the reaction can be promoted, and the quality of finished productsproduced by the efficient graphene production equipment can be improved.

Owner:深圳市中科智诚科技有限公司

Plant fiber firework outer cylinder and production method thereof

The invention discloses a plant fiber firework outer cylinder and a production method thereof. The plant fiber firework outer cylinder is produced from the following raw materials in parts by weight:60-65 parts of straw, 12-18 parts of reinforcing powder, 8-12 parts of corn starch, 6-10 parts of PVA, 0.2-0.4 part of a cross-linking agent, 0.3-0.7 part of a moisture proof agent, 0.8-1.2 parts of arelease agent and 1.5-2 parts of a toughener. According to the plant fiber firework outer cylinder, the plant straw is used as a raw material so that the usage amount of paper can be indirectly reduced, and environmental pollution in a papermaking process is correspondingly reduced; meanwhile, novel application of the plant straw is provided, pollution caused by plant straw combustion is avoided,and the incomes of farmers are improved; and the plant fiber firework outer cylinder can be naturally degraded, and products obtained after the plant fiber firework outer cylinder is degraded can improve the soil fertility and optimize soil, and can be recovered and used for producing firework outer cylinders again or used as fuel.

Owner:湖南省妙音花炮集团有限公司

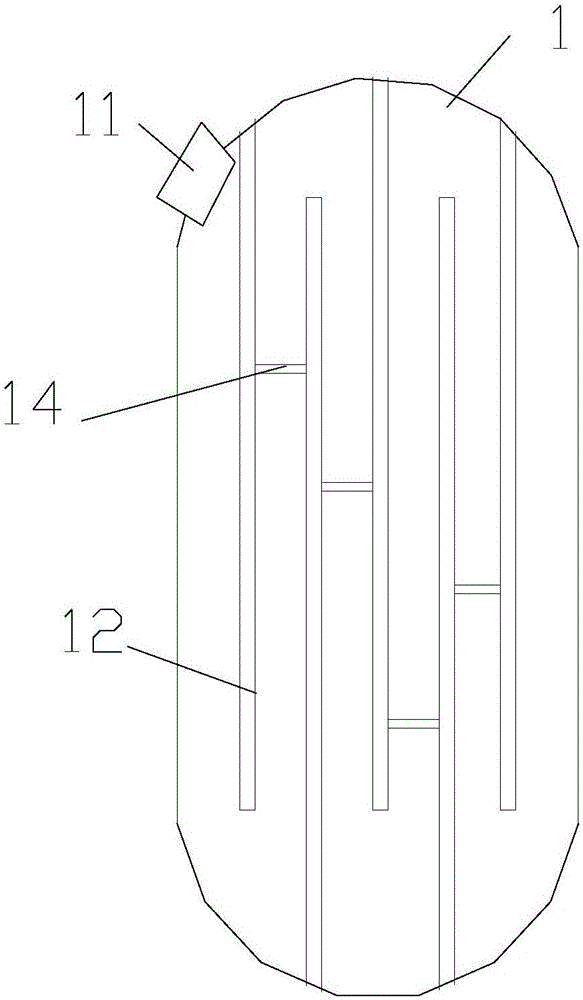

Catalytic distillation device for preparing methanol, and use method thereof

PendingCN113952758ASolve take outSolve the problem of very inconvenient replacementOrganic compound preparationChemical industryPtru catalystCatalytic distillation

The invention discloses a catalytic distillation device for preparing methanol, and a use method thereof. A storage mechanism comprises a supporting plate and a vertical plate, a vertical rod is fixedly connected to the top of the supporting plate, a column is fixedly connected to one side of the vertical plate, a containing groove is formed in the top of the column, and a first through hole part is formed in the outer surface of the column. The invention relates to the technical field of methanol preparation. According to the catalytic distillation device for preparing methanol, and the use method thereof, under the cooperative use of the supporting plate, the vertical plate, the vertical rod, the column , the containing groove, the first through hole part, a second through hole part, a first connecting plate and a limiting hole, a catalyst is intensively placed in the containing groove, and when a sealing cover is opened, the catalyst can be taken out and replaced only by taking out the vertical plate, so the device is convenient to use, and solves the problem that when the catalyst is used in an existing catalytic distillation device, the catalyst is generally and directly placed in the catalytic distillation device, so that the subsequent catalyst is very inconvenient to take out and replace.

Owner:老河口瑞祥化工有限公司

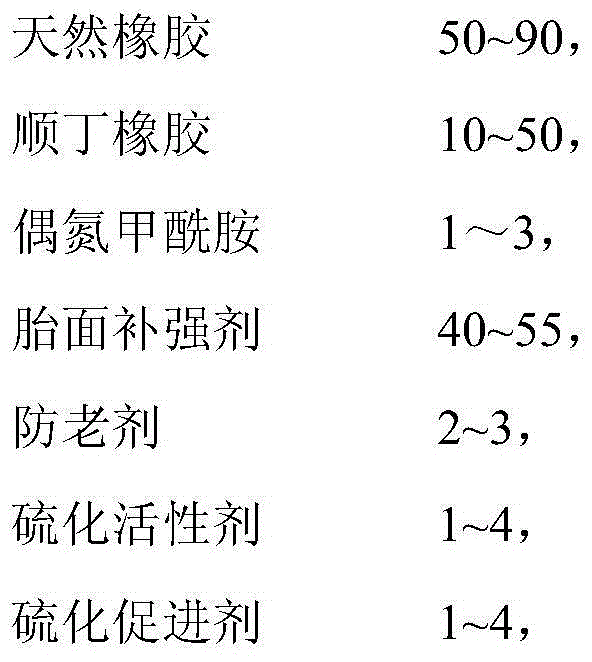

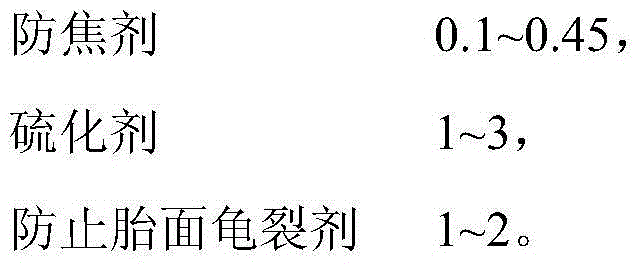

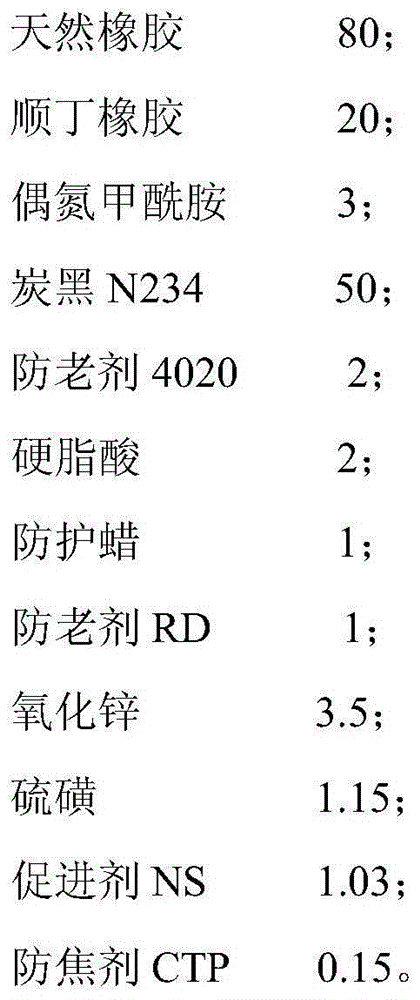

Improved tread rubber material and preparation method thereof

ActiveCN104650402APromote interactionImprove wear resistanceSpecial tyresCarbon blackAzodicarbonamide

The invention provides an improved tread rubber material. The improved tread rubber material is prepared from the following raw materials in parts by weight: 50-90 parts of natural rubber, 10-50 parts of butadiene rubber, 1-3 parts of azodicarbonamide, 40-55 parts of tread reinforcing agent, 2-3 parts of anti-aging agent, 1-4 parts of vulcanizing activator, 1-4 parts of vulcanization accelerator, 0.1-0.45 parts of scorch retarder, 1-3 parts of vulcanizing agent and 1-2 parts of tread fracturing preventing agent. The invention further provides a preparation method of the improved tread rubber material. The method provided by the invention is a new method for improving tread rubber wearing resistance and reducing heat; by virtue of added azodicarbonamide, the interaction between rubber and carbon black can be improved, and the tread rubber has better wearing resistance and lower compression heat generation; meanwhile, the preparation method of the tread is simple in process and easy for industrialization.

Owner:SHANGHAI TIRE & RUBBER TIRE RES INST +1

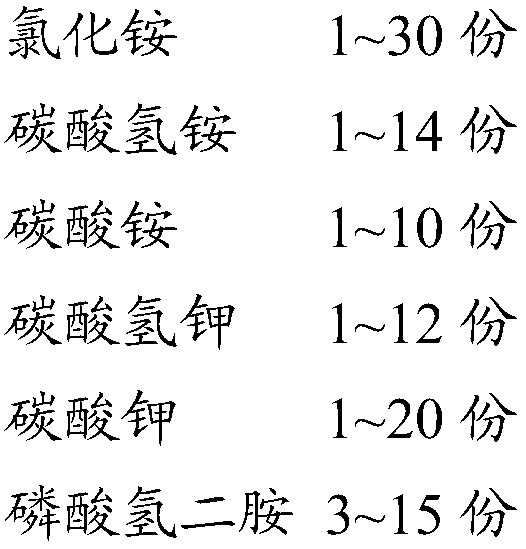

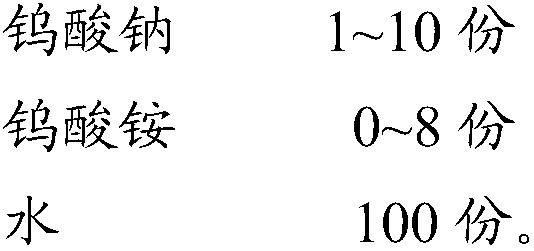

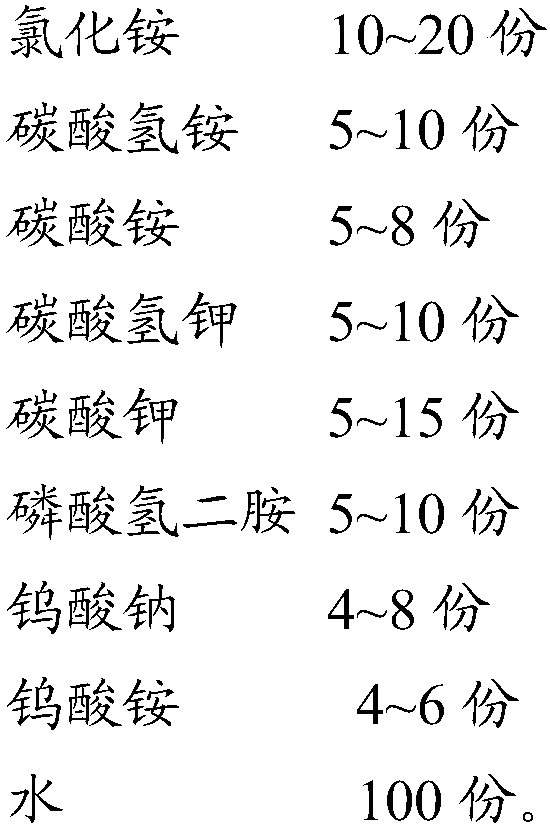

Water-mist fire extinguishing additive, and preparation method and application thereof

The invention provides a water-mist fire extinguishing additive, and belongs to the technical field of firefighting. Multiple inorganic salts are adopted, mutual replacement reaction degrees are controlled through limitation on addition proportions of the inorganic salts, release of inertia gases, such as ammonia gases and carbon dioxide, of drugs in a fire scene is promoted, and the oxygen concentration of the fire scene is sufficiently reduced to achieve physical smothering and fire-extinguishing effect. Element substances such as sodium, chlorine and potassium in the additive generate freeradicals for resisting flames in the fire scene, and accordingly, chemical fire-extinguishing effect is achieved. Inorganic salt covering layers can form on the surfaces of solid substances through phosphates, and the obvious fire-extinguishing effect on type-A fire hazards of solids can be achieved. Tungstate is added as a catalyst to promote mutual reactions among additives. The fire extinguishing additive is applied to a water-mist fire extinguishing system, and can remarkably improve fire extinguishing efficiency and shorten fire extinguishing time.

Owner:应急管理部四川消防研究所

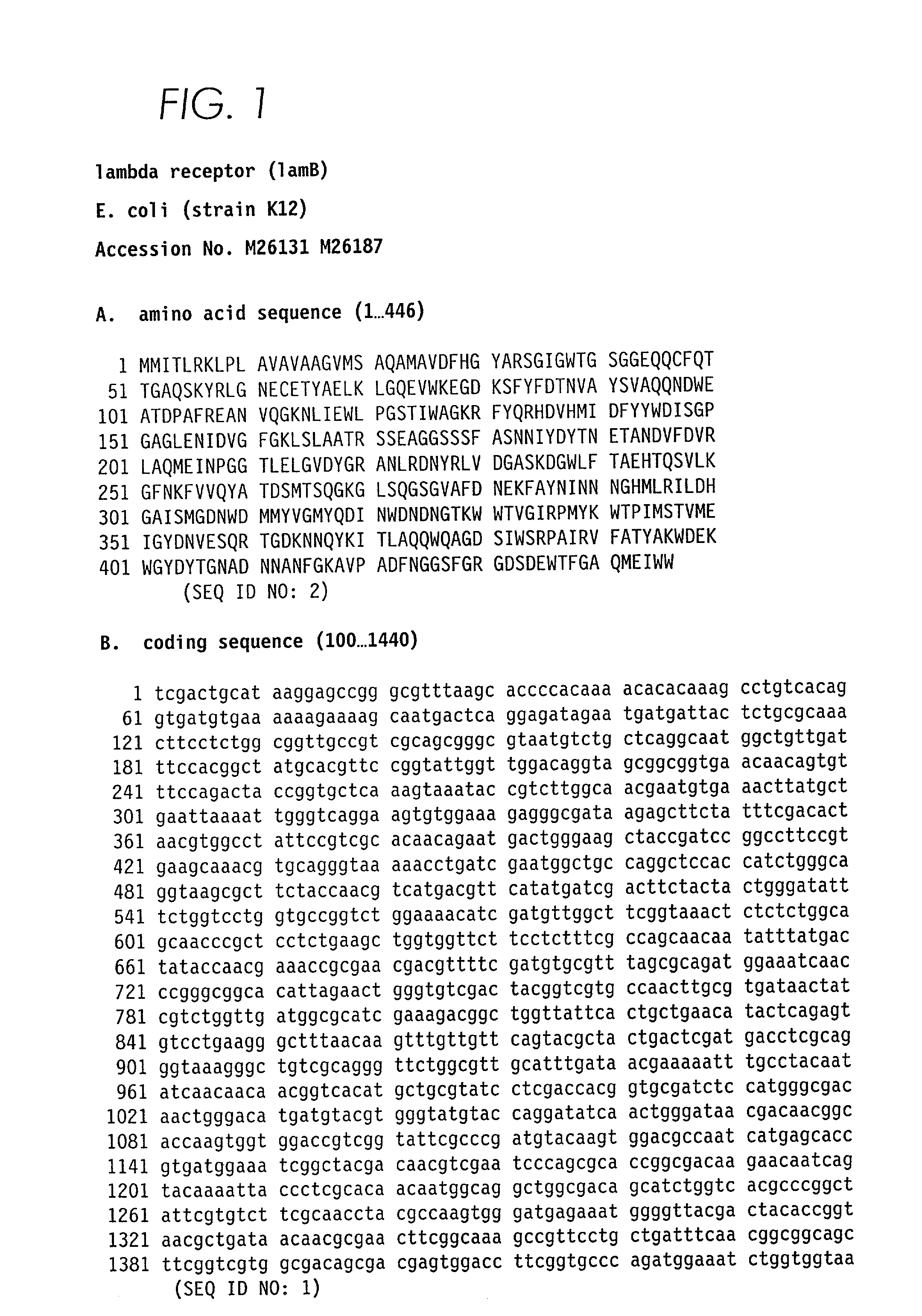

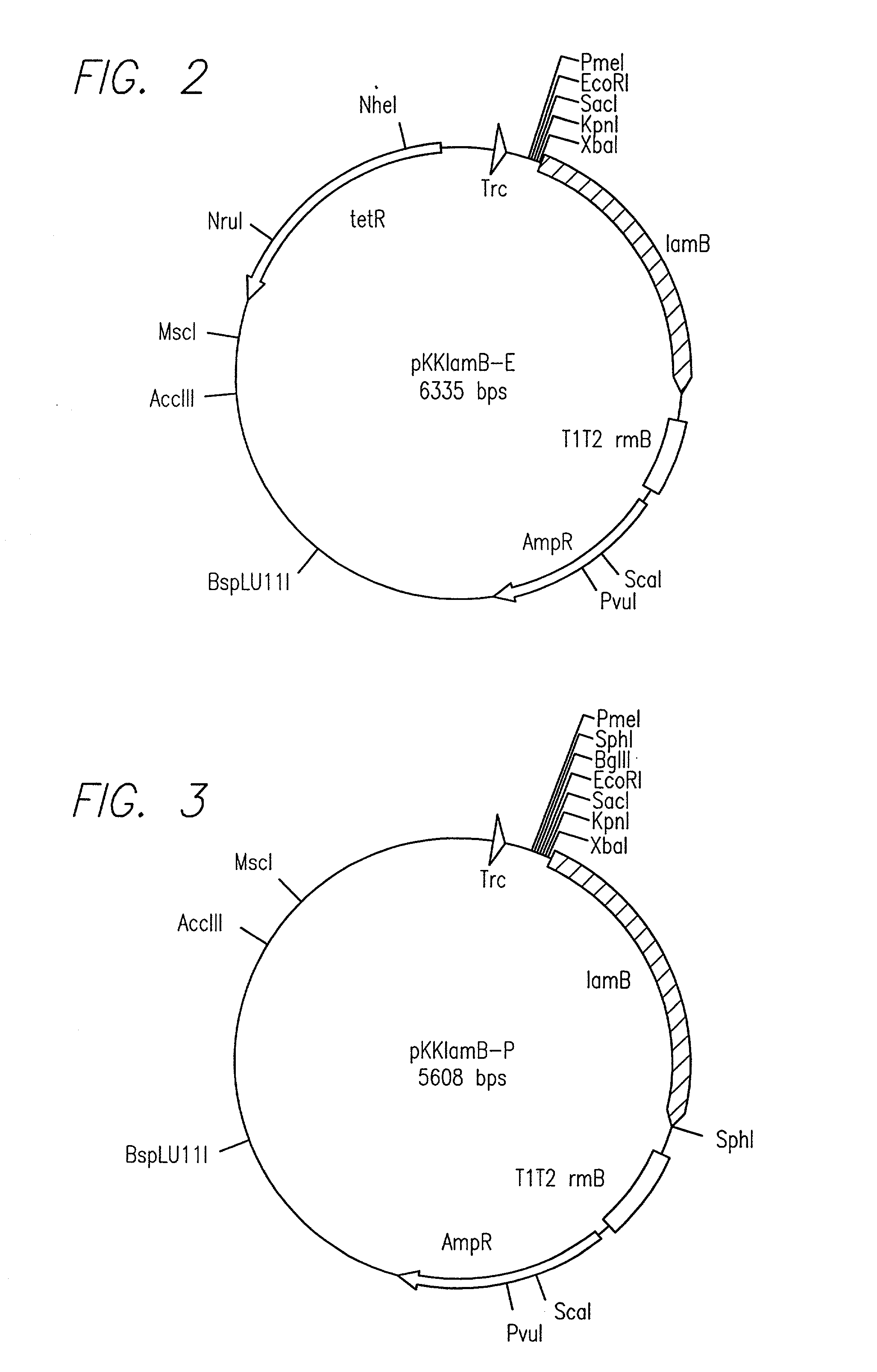

Screening system to identify polynucleotides encoding cleavable N-terminal signal sequences

InactiveUS20030096223A1Facilitate identificationPromote interactionAntibody mimetics/scaffoldsMicrobiological testing/measurementENCODENucleotide

Owner:STRATAGENE INC US

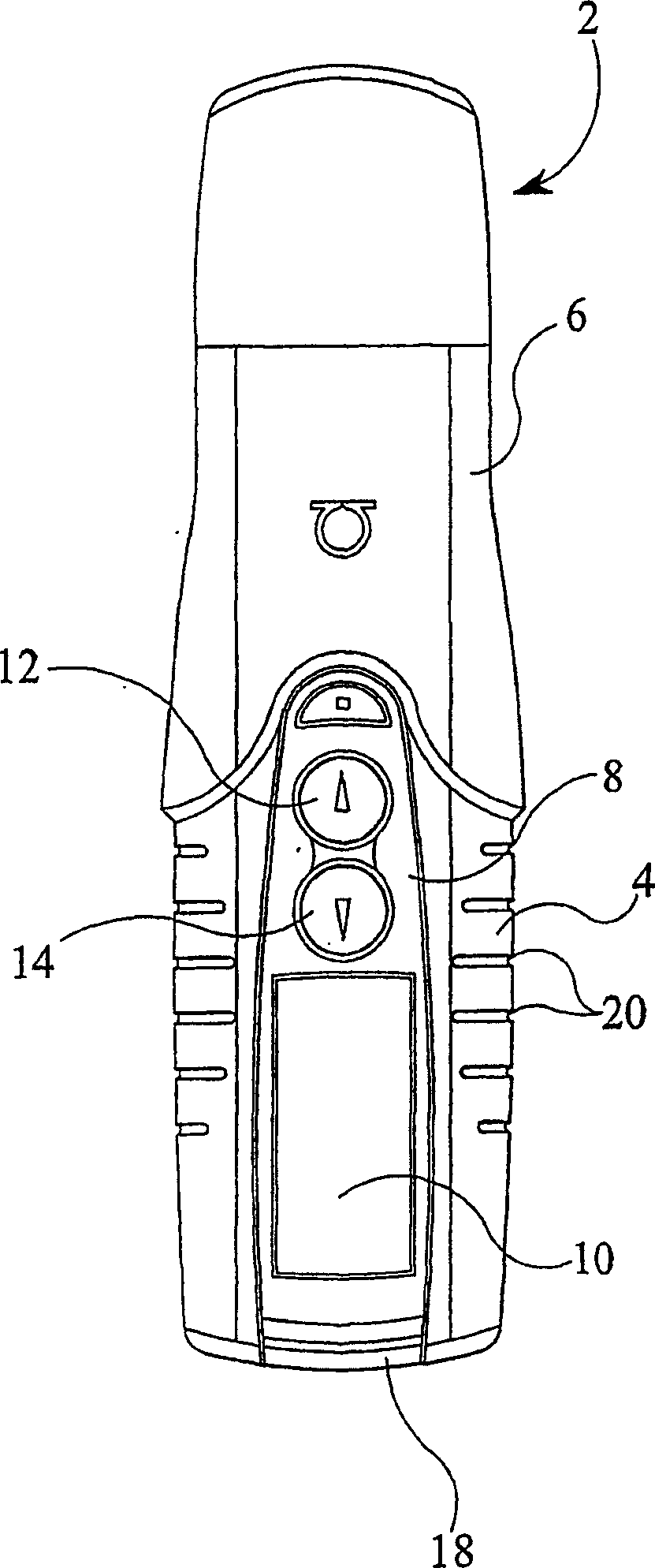

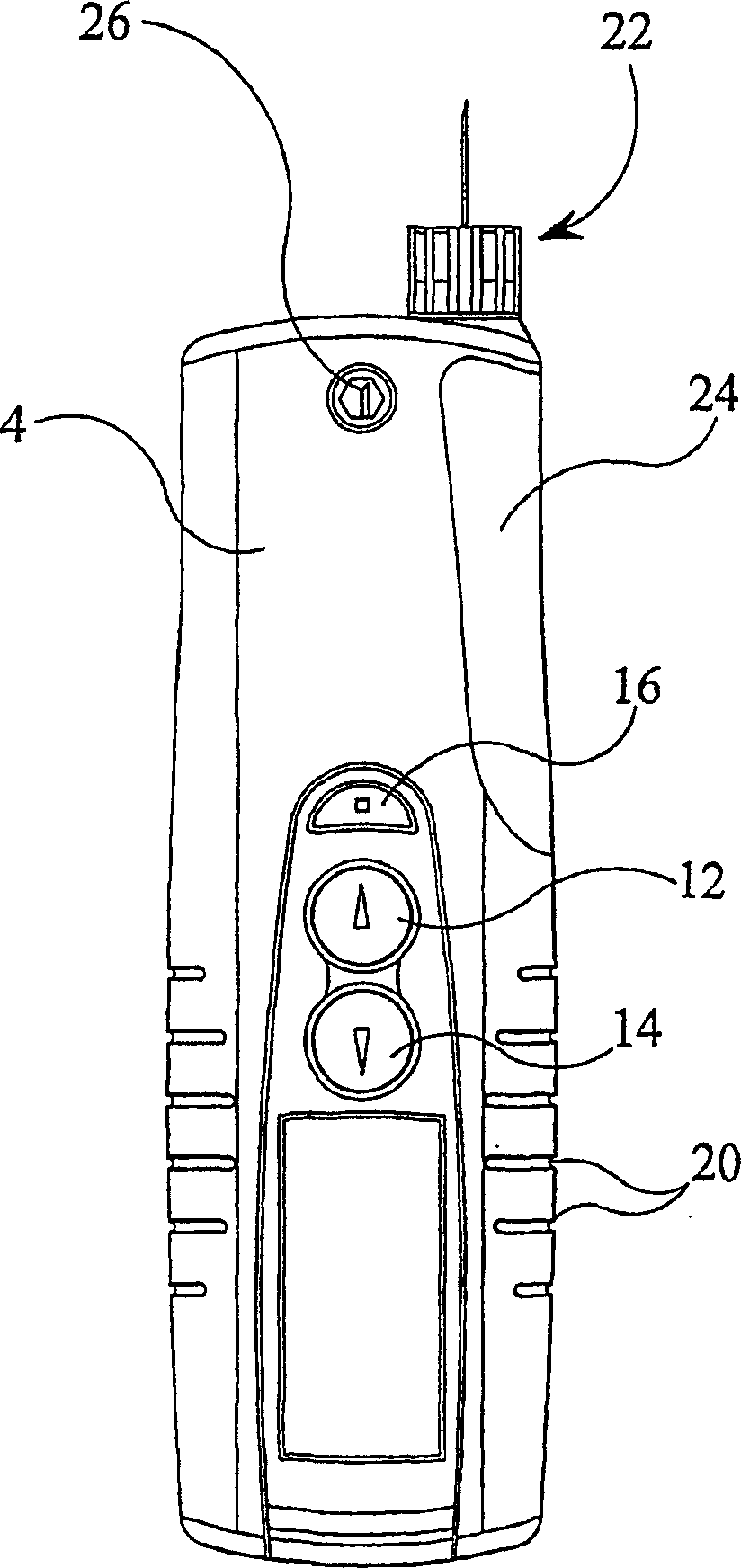

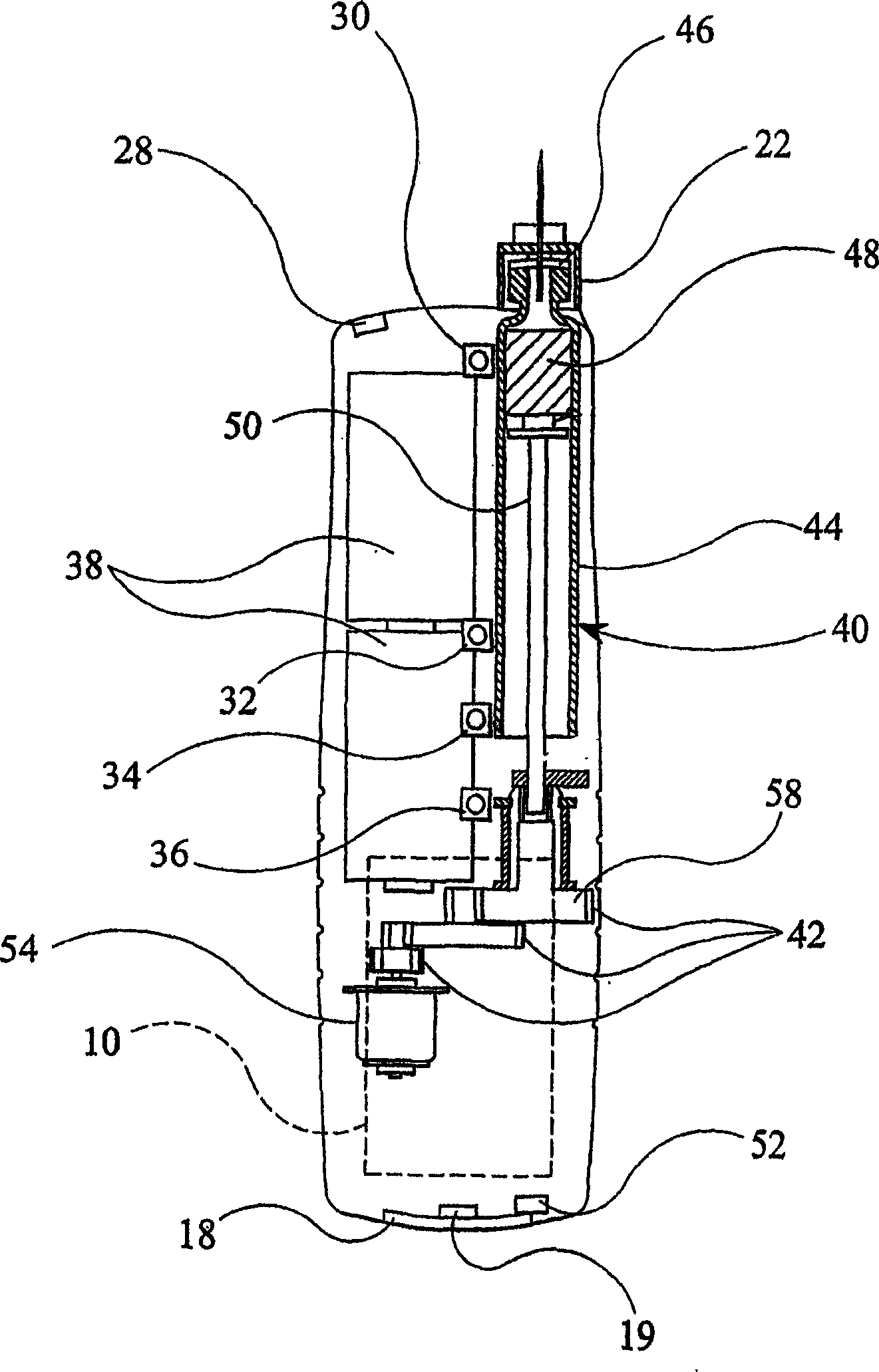

Drive mechanism for injection device

InactiveCN1248746CImprove conveniencePromote interactionAmpoule syringesOther blood circulation devicesPistonElectronic control unit

An injection device having a drive mechanism 42 to expel selectively a dose of medicament from a medicament cartridge 40 through a needle unit 22 is disclosed. The injection device further comprises an electronic control unit to control the drive mechanism 42, and a dispense button 18 to generate a dispense button signal to the electronic control unit indicative of the dose to be expelled in which an arm button 16 causes a first arm button signal to be sent to the electronic control unit to permit the dose to be expelled.

Owner:SANOFI AVENTIS DEUTSCHLAND GMBH

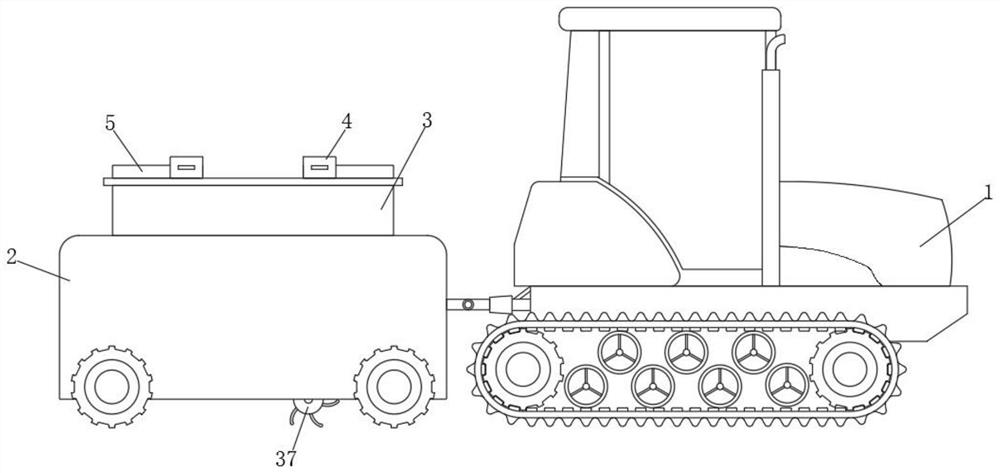

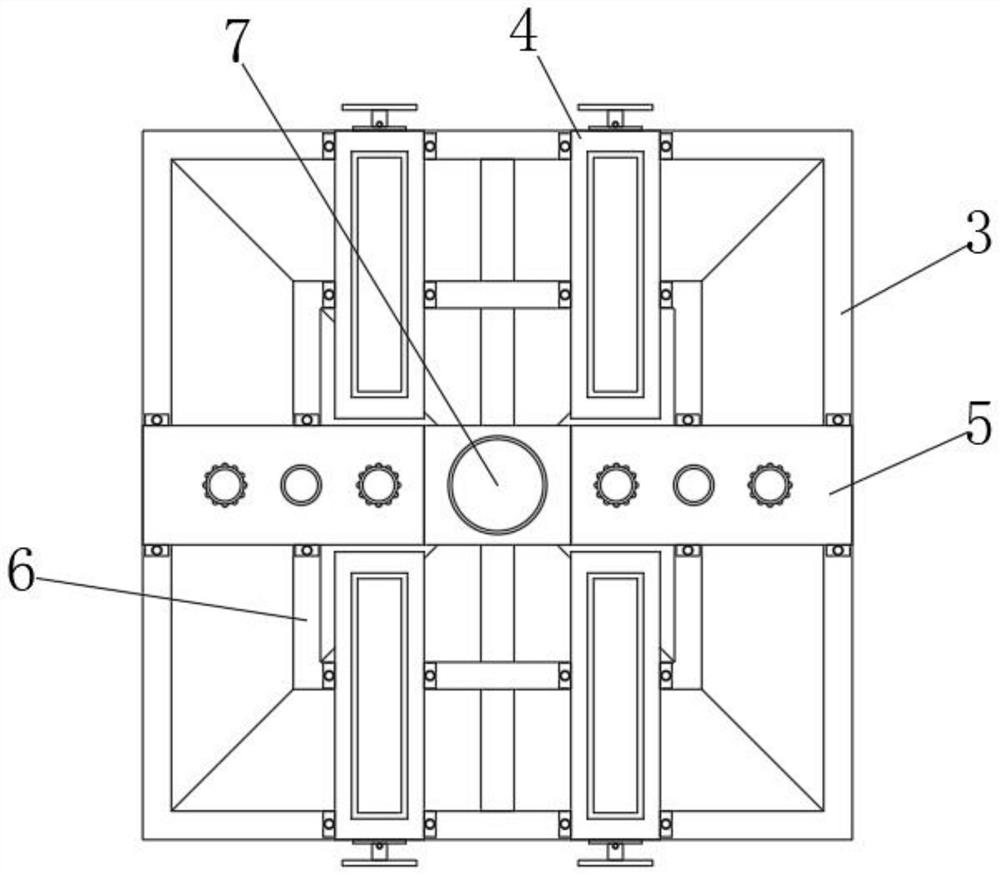

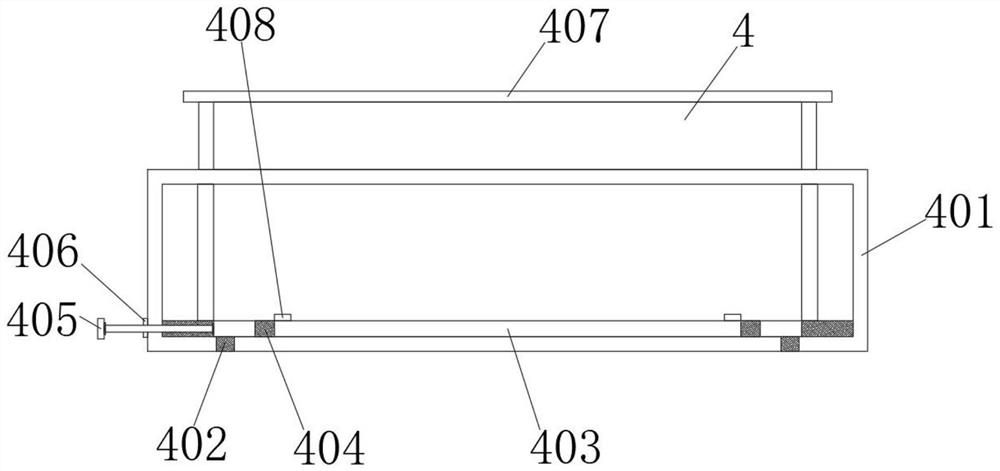

Remediation agent preparation device for soil remediation

ActiveCN114260309AFacilitate mixed reactionsPromote interactionContaminated soil reclamationGrain treatmentsSoil remediationEngineering

The invention discloses a preparation device of a remediation agent for soil remediation, and relates to the technical field of soil remediation, the preparation device comprises a trailer, a box body, a first material separation groove and a second material separation groove, the box body is installed at one end of the trailer, the first material separation groove is installed at the top of the box body, and the second material separation groove is installed in the first material separation groove; the solid quantitative dosing mechanism and the liquid quantitative dosing mechanism are mounted on the first material separation groove and the second material separation groove, so that a worker can conveniently mix and prepare a medicament on to-be-remediated soil in time, the prepared medicament can timely exert the efficacy, meanwhile, the worker can conveniently mix and react a solid medicament and a liquid medicament, and the remediation efficiency is improved. And the first material separation groove and the second material separation groove form two relatively independent reaction grooves, so that mutual reaction between the agents is facilitated, and the situation that part of reactants in the agents influence each other due to the fact that the agents are added into the reaction grooves at a time, and the pesticide effect of the soil remediation agent is reduced is avoided.

Owner:张友超

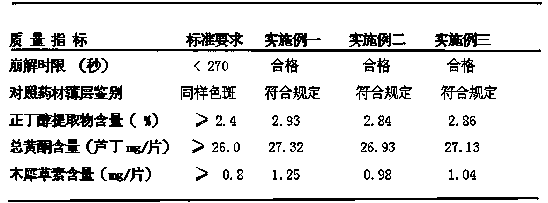

Preparation method of Tibetan medicine unique effervescent tablet

ActiveCN104107213BHigh extraction rateAvoid direct contactPharmaceutical delivery mechanismPlant ingredientsLamiophlomis rotataEffervescent tablet

A preparation method of a preparation method of a Tibetan medicine Lamiophlomis rotata effervescent tablet belongs to the field of Chinese patent medicinal preparations. The method comprises the following steps: 1, preparing a Lamiophlomis rotata extract; 2, preparing an alkali source wrappage; 3, carrying out dry granulation; 4, tabletting; 5, examining; and 6, packaging. The effective components of the above medicinal material are extracted by adopting an ultrasonic extraction process, so energy saving, time saving and high extraction rate of the effective components are realized; an alkali source indispensable in the preparation is wrapped by PVP (polyvinylpyrrolidone) in advance, so the direct contact of an acid with an alkali in the preparation is avoided, the stability is increased, and it is in favor of solving a sticking problem during tabletting; and the contact time of the extract with the acid, the alkali, water and heat is maximally reduced, so the acceleration of interaction of the extract in the above prescription with the acid source and the alkali source is avoided, the material fluidity is improved, and the production period is shortened.

Owner:JIANGXI POZIN PHARMA

Gas reaction kettle

InactiveCN106492720AEasy to cleanGood compatibilityFlow mixersTransportation and packagingProduct gas

Owner:DONGZHI TIANFU CHEM

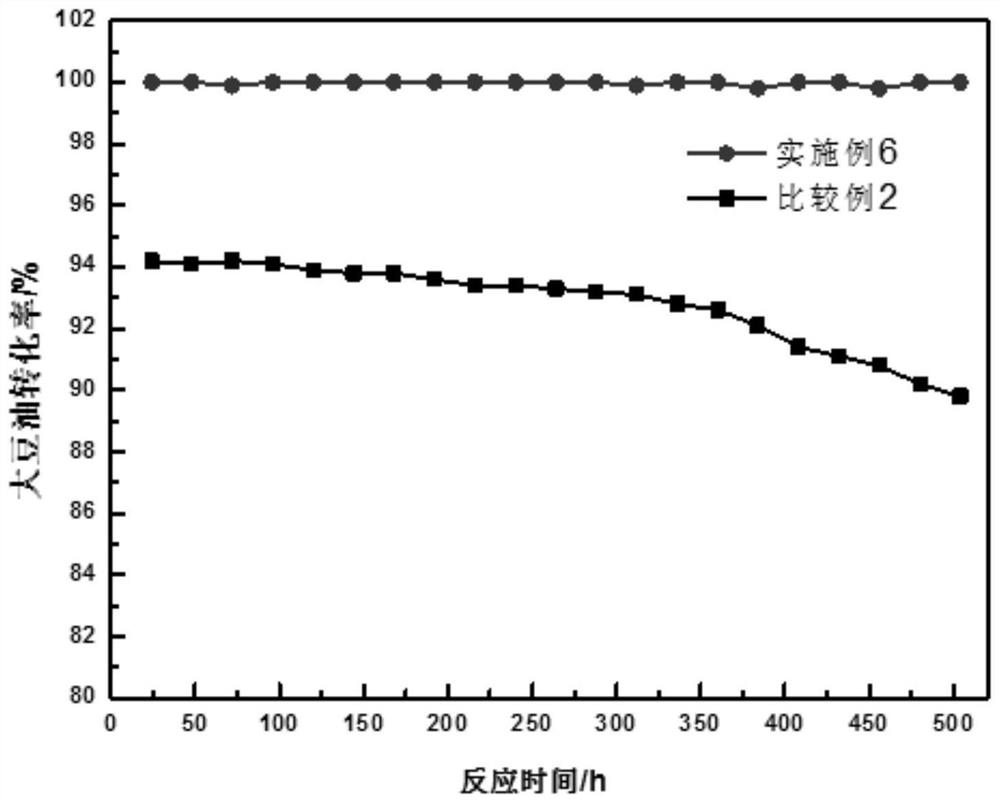

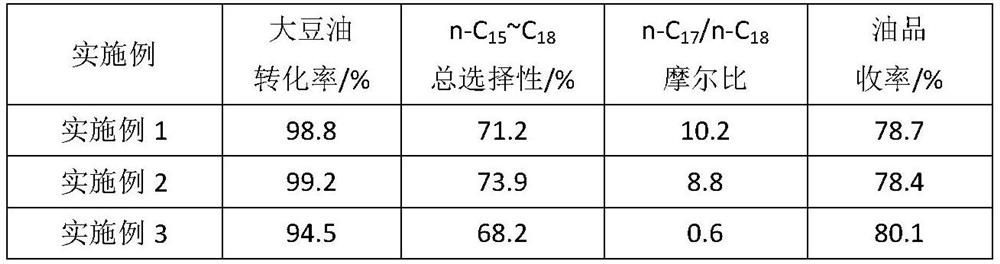

Hydrodeoxygenation catalyst for biological oil and fat as well as preparation and application of hydrodeoxygenation catalyst

PendingCN114522697AImprove stabilityPromote interactionLiquid hydrocarbon mixture productionBio-feedstockBiolipidTrickle-bed reactor

The invention discloses a catalyst for preparing alkane through catalytic hydrodeoxygenation of biolipid and application of the catalyst, and belongs to the new technical field of biological energy. Comprising the following steps: (1) soaking gamma-Al2O3 in a Ni-containing soluble metal salt solution, and then drying and roasting to generate a nickel aluminate spinel structure on the surface of Al2O3; (2) dipping Al2O3 with a nickel aluminate spinel structure on the surface as a carrier in a soluble metal salt solution of a rare earth element, and then drying and roasting; and (3) dipping soluble metal salt of Ni, Mo or / and W, drying and roasting to obtain the supported metal catalyst. The catalyst is used for carrying out hydrodeoxygenation reaction on a trickle bed reactor by taking biolipid as a raw material, the conversion rate can reach 100%, and the oil product yield can reach 82%. The catalyst provided by the invention has stable surface properties. In addition, the catalyst can replace a sulfurized catalyst for a traditional hydrodeoxygenation reaction, so that the harm of sulfides to the environment is avoided, and the catalyst is suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

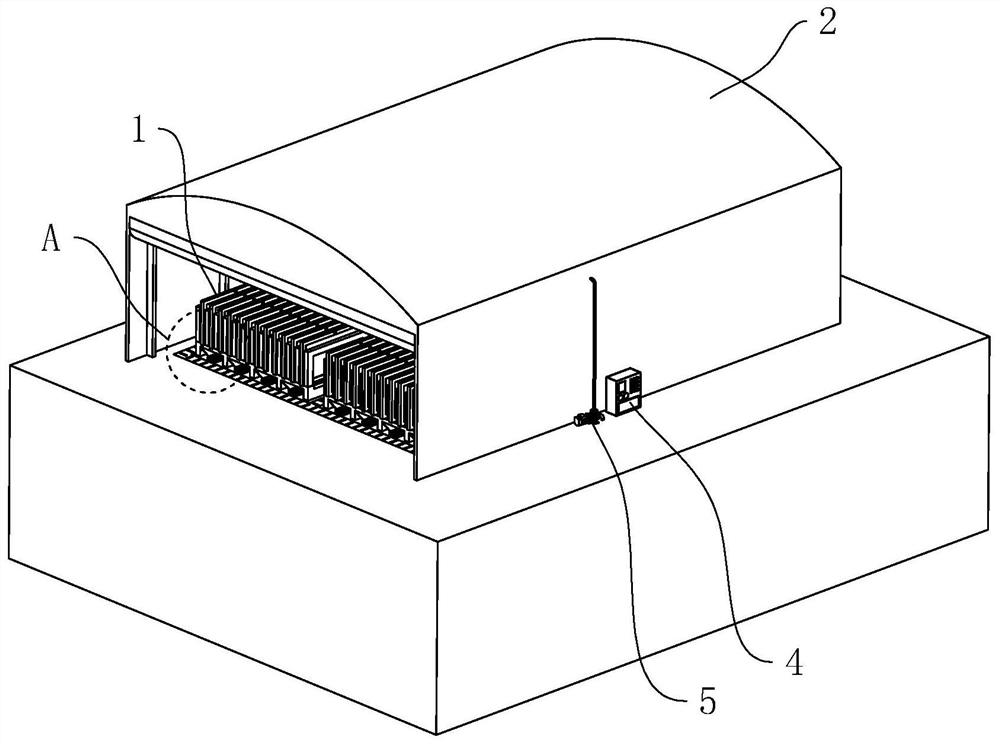

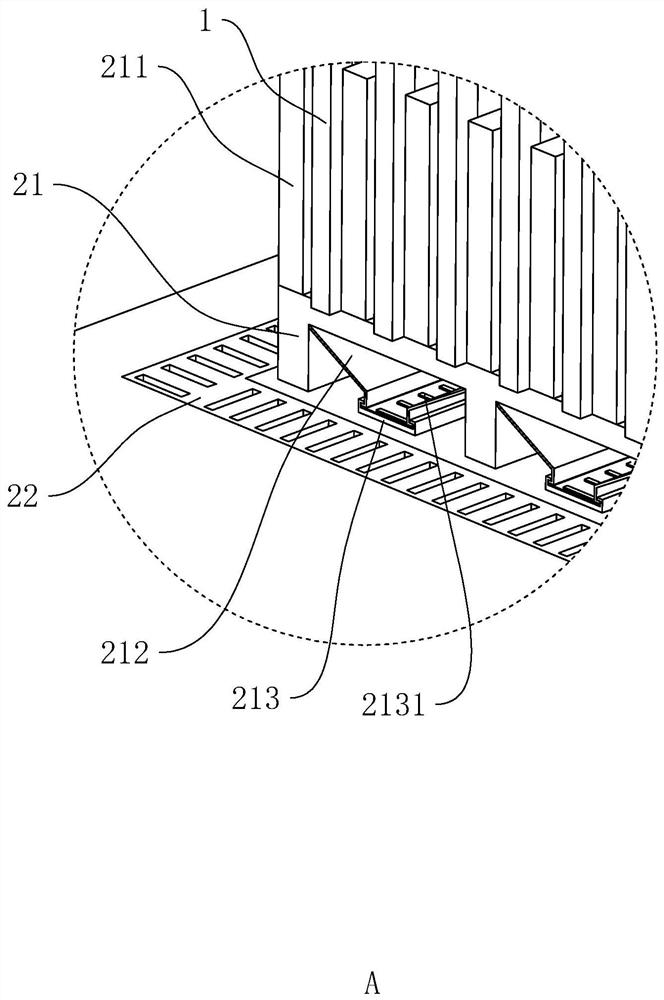

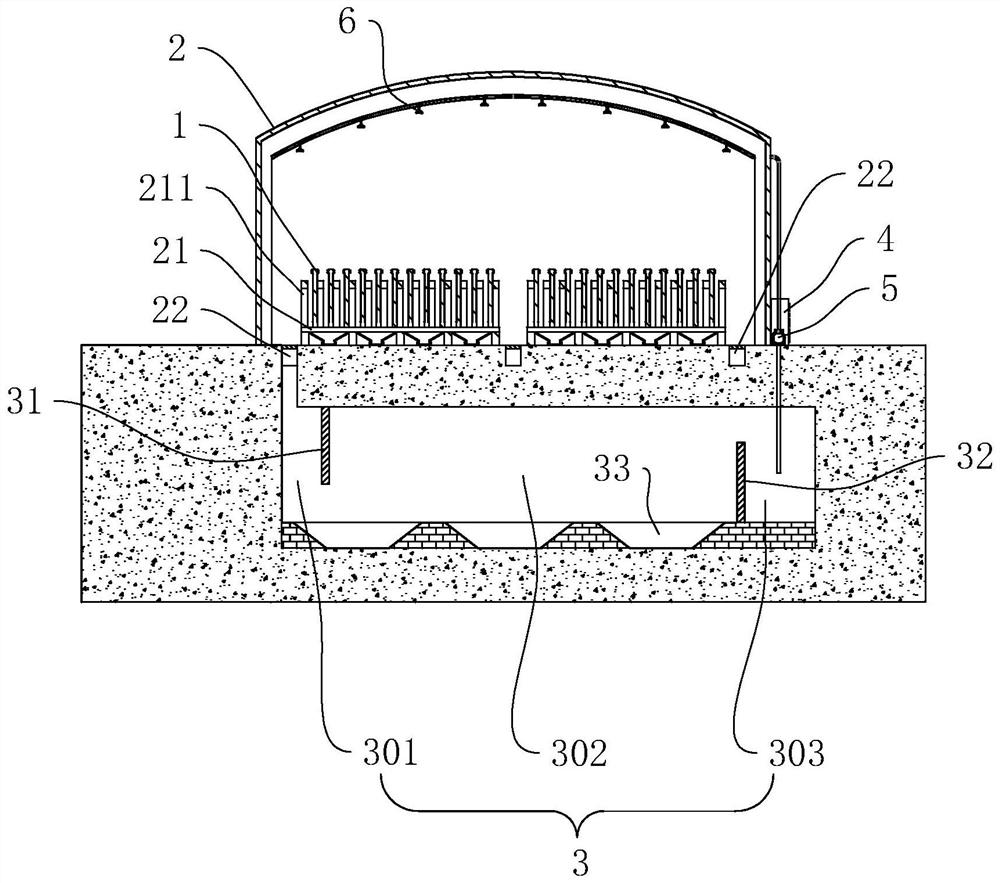

Cement civil air defense door circulating water automatic maintenance device and cement civil air defense door manufacturing method

InactiveCN113306014AImprove wettabilityImprove adhesionAuxillary shaping apparatusArchitectural engineeringWater resources

The invention relates to a cement civil air defense door circulating water automatic maintenance device and a cement civil air defense door manufacturing method, and belongs to the field of civil air defense door production. The cement civil air defense door circulating water automatic maintenance device comprises a maintenance shed, a placement seat is arranged in the maintenance shed, multiple sets of guardrails are arranged on the placement seat at intervals, a water treatment pond is arranged below the maintenance shed, a drainage channel communicated with the water treatment pond is arranged at the side edge of the placement seat, and spray heads are installed at the top in the maintenance shed; the spray heads are connected with the water treatment pond through water pipes and water suction pumps, and a controller is arranged outside the maintenance shed and electrically connected with the water suction pumps; maintenance water is stored in the water treatment pond and comprises the following raw material components in parts by weight of water, polyacrylamide, fatty alcohol-polyoxyethylene ether, sodium dodecyl benzene sulfonate and glyceryl triacetate; and according to the cement civil air defense door manufacturing method, a cement civil air defense door is maintained through the cement civil air defense door circulating water automatic maintenance device. The cement civil air defense door circulating water automatic maintenance device has the effect of improving the cement civil air defense door maintenance effect, and water resources are saved.

Owner:广州市羊城地下工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com