Water-mist fire extinguishing additive, and preparation method and application thereof

A technology of fine water mist and additives, applied to fire prevention equipment, etc., can solve the problems of single agent composition and insignificant increase in fire extinguishing efficiency, and achieve the effects of reducing oxygen concentration, shortening fire extinguishing time, and improving fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

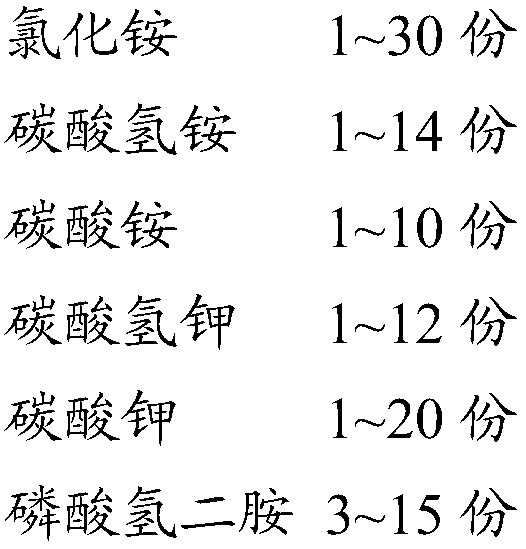

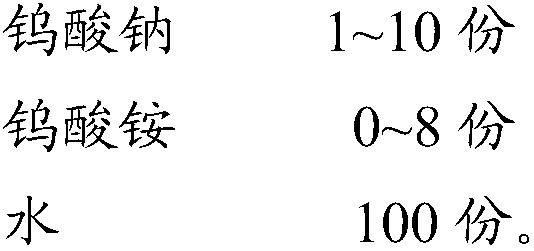

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method for the above-mentioned fine water mist fire extinguishing additive, comprising the following steps:

[0025] Ammonium chloride, ammonium bicarbonate, ammonium carbonate, potassium bicarbonate, potassium carbonate, diammonium hydrogen phosphate, sodium tungstate, ammonium tungstate and water are mixed according to the stated parts by weight to obtain a fine water mist fire extinguishing additive.

[0026] In the present invention, there is no special limitation on the order of adding the components, and the order of addition known to those skilled in the art can be selected.

[0027] The present invention has no special limitation on the mixing method, and the mixing method well-known to those skilled in the art can be selected so that each component can be uniformly dissolved in water.

[0028] The present invention also provides the application of the above-mentioned fine water mist fire extinguishing additive i...

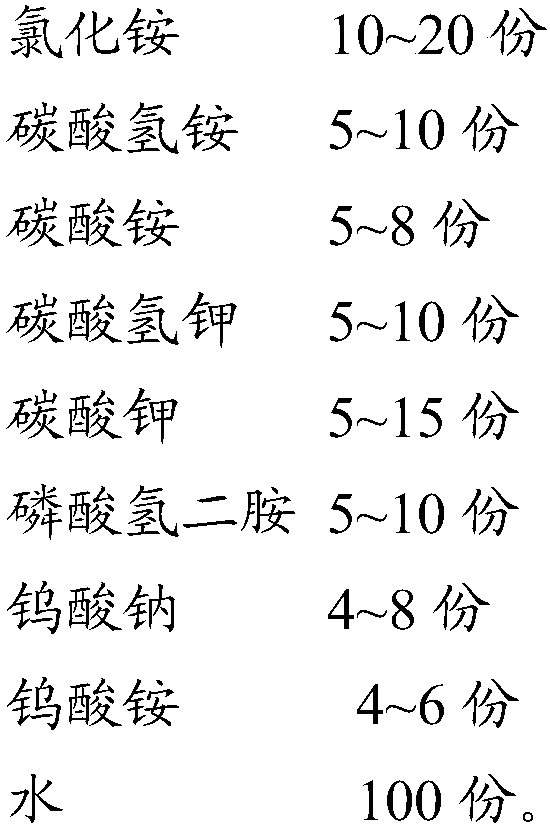

Embodiment 1

[0032] Add 10 parts of ammonium chloride, 2 parts of sodium bicarbonate, 3 parts of sodium carbonate, 1 part of potassium bicarbonate, 5 parts of potassium carbonate, 8 parts of ammonium dihydrogen phosphate, and 6 parts of sodium tungstate to 100 parts of water, and stir until it dissolves Water mist fire extinguishing additive, the additive is mixed with water to obtain a fine water mist fire extinguishing agent, the volume fraction of the additive in the water mist fire extinguishing agent is 6%, and the fine water mist fire extinguishing agent is injected into the mobile fine water mist fire extinguishing equipment, extinguishing 34B And in the 55B oil pan fire experiment, the time was reduced from 1 minute to less than 30 seconds.

Embodiment 2

[0034] Add 8 parts of ammonium chloride, 1 part of sodium bicarbonate, 1 part of sodium carbonate, 4 parts of potassium bicarbonate, 8 parts of potassium carbonate, 10 parts of ammonium dihydrogen phosphate, 1 part of sodium tungstate, and 3 parts of ammonium tungstate to 100 parts of water Stir evenly until the fine water mist fire extinguishing additive is dissolved, mix the additive and water at a volume ratio of 1:1 to obtain a fine water mist fire extinguishing agent, add it to a 2 kg portable water-based fire extinguisher, and extinguish the 34B oil pan fire experiment. The time is about 20s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com